Loop-forming mechanism of few-guide-bar yarn-pressing warp knitting machine

A technology of knitting mechanism and warp knitting machine, which is applied in warp knitting, textiles, papermaking, knitting, etc. It can solve the problems that cannot meet the development trend of pattern diversification, unreliable pressing action, and insufficient patterns. , to achieve the effect of rich fabric patterns, satisfying pattern diversification, and reliable yarn pressing action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

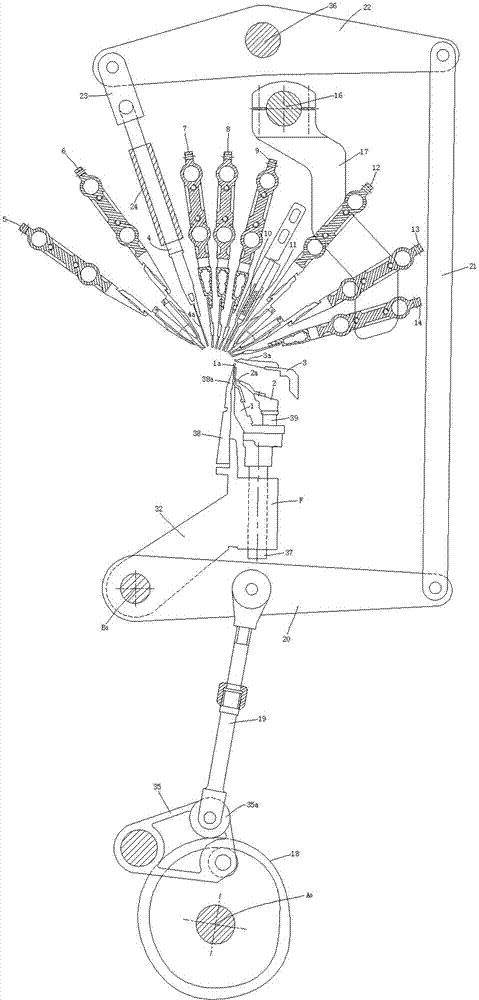

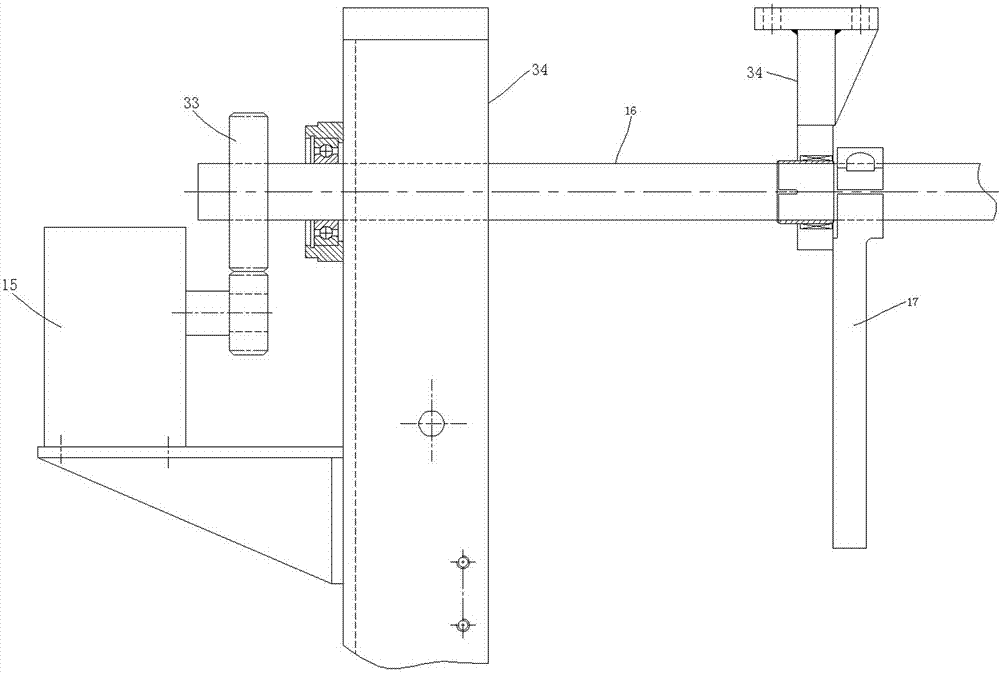

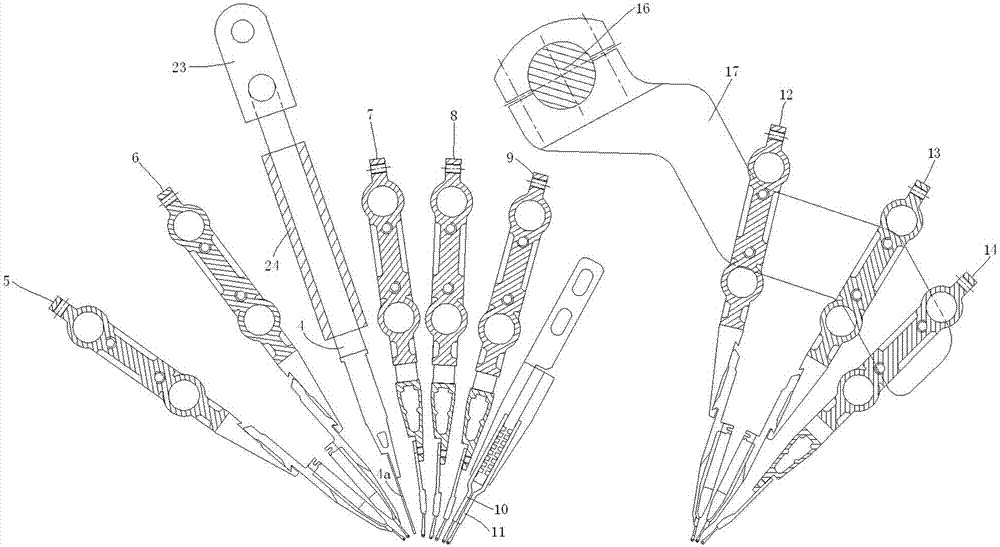

[0021] see Figure 1 to Figure 5 The shown knitting mechanism of a kind of less-comb pressing yarn warp knitting machine includes the grooved needle 1a fixedly installed on the grooved needle bed 1, the needle core 2a fixedly installed on the needle core bed 2, and the needle core 2a fixedly installed on the settling bed 3 The sinker 3a on the top, the yarn pressing plate 4a fixedly installed on the lower end of the yarn pressing plate mounting seat 4, the up and down movement mechanism of the slotted needle, the swinging mechanism of the slotted needle, and the combing bar mechanism with several combing bars; The kinematic mechanism can adopt a conventional planar link mechanism, which is not shown in the figure; the grooved needle swing mechanism preferably adopts Figure 5 The plane link mechanism shown; when working, the grooved needle bed 1 and the grooved needles 1a on it are driven by the grooved needle up and down movement mechanism to move up and down in a straight li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com