High-efficiency energy-saving hoist gear change device for vessel

A high-efficiency, energy-saving, speed-changing device technology, applied in hoisting devices, transmission devices, transmission device parts, etc., can solve problems such as easy breakage of undercuts, complex processing technology, and influence on overall strength, and achieve good transmission stability, Reduced size and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

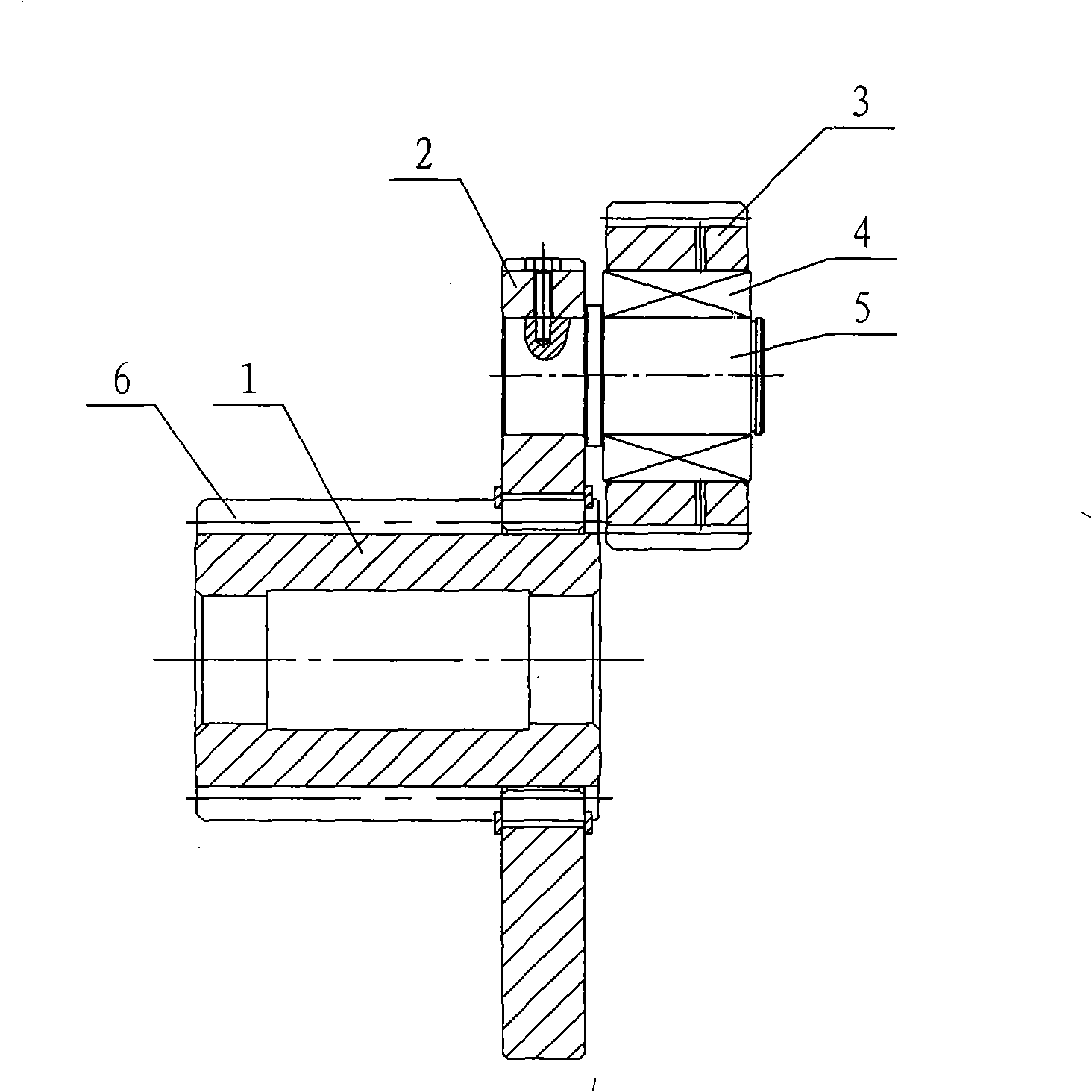

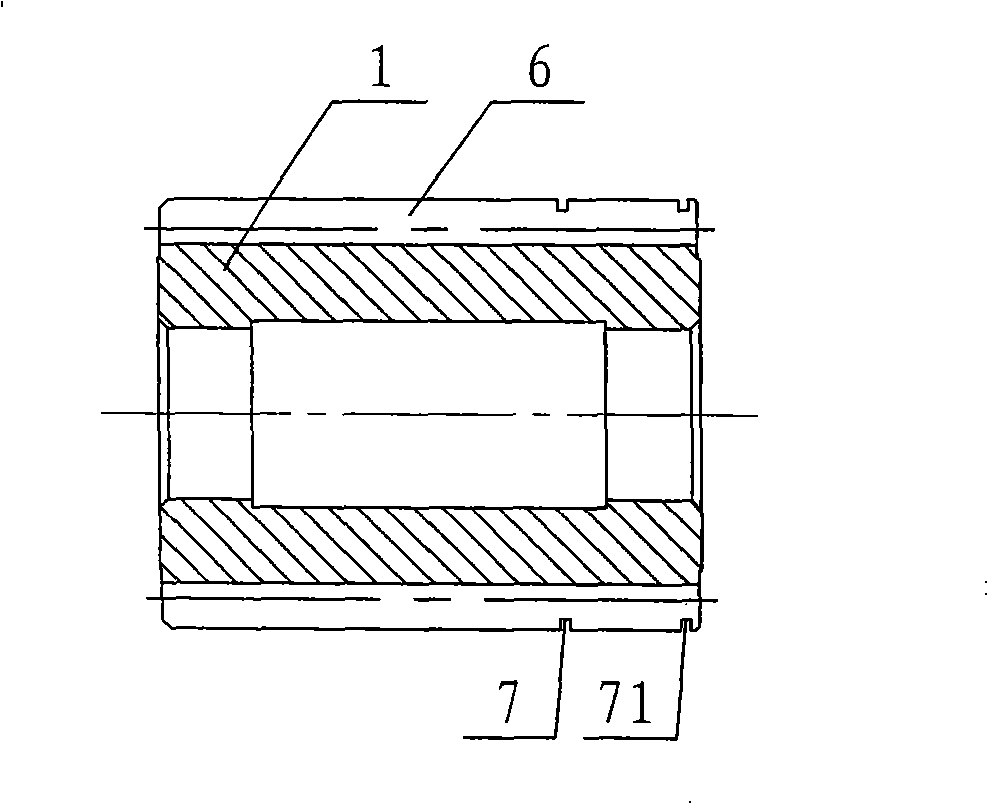

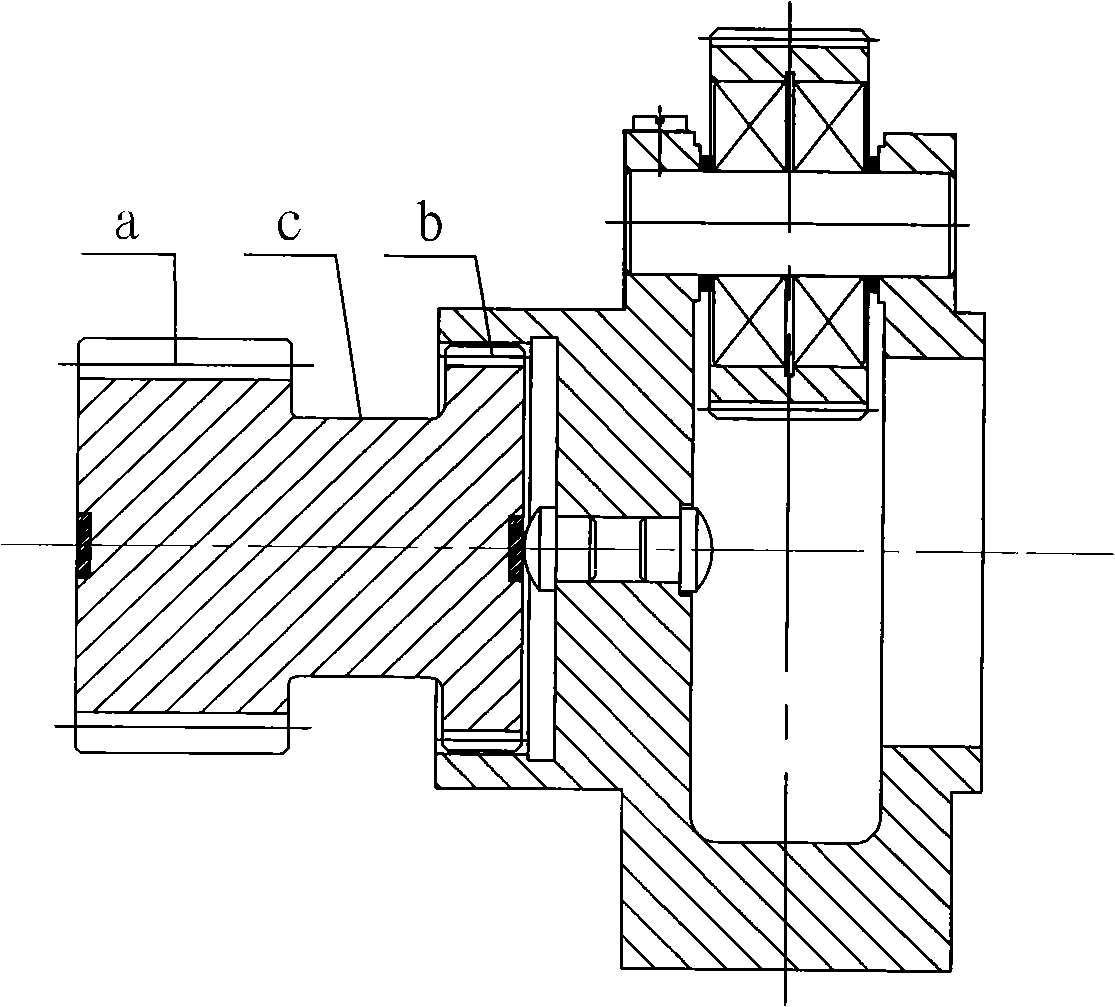

[0012] exist figure 1 , 2 , 5, a high-efficiency energy-saving winch speed change device for marine use, the winch is driven by a motor, transmitted to the reel through the speed change device, and then pulled by a steel cable to achieve the purpose of lifting objects. During the transmission process of the speed change device, the central shaft 8 drives the planetary gear 3 to run, and the planetary gear drives the planetary carrier 2 through the bearing 4 and the planetary shaft 5. The planetary carrier 2 and the sun gear 1 form a coupling, which is repeatedly transmitted through different gears, so that To achieve the speed change effect. In the structure of the speed change device, the tooth part a and the tooth part b of the traditional sun gear are combined into one, and the shape of a long tooth part 6 of the sun gear 1 of this device is changed, and the relief groove and the double tooth part are omitted processing; two spaced snap ring grooves 7, 71 are processed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com