Electronic lock

A technology of electronic locks and lock housings, which is applied in the field of electronic locks, can solve the problems of easy-wearing transmission parts, over-turning knobs, dislocation and dislocation of transmission parts, etc., and achieve low wear rate of transmission parts, precise transmission process and few transmission parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, the inside of the door is an electronic lock that opens to the right.

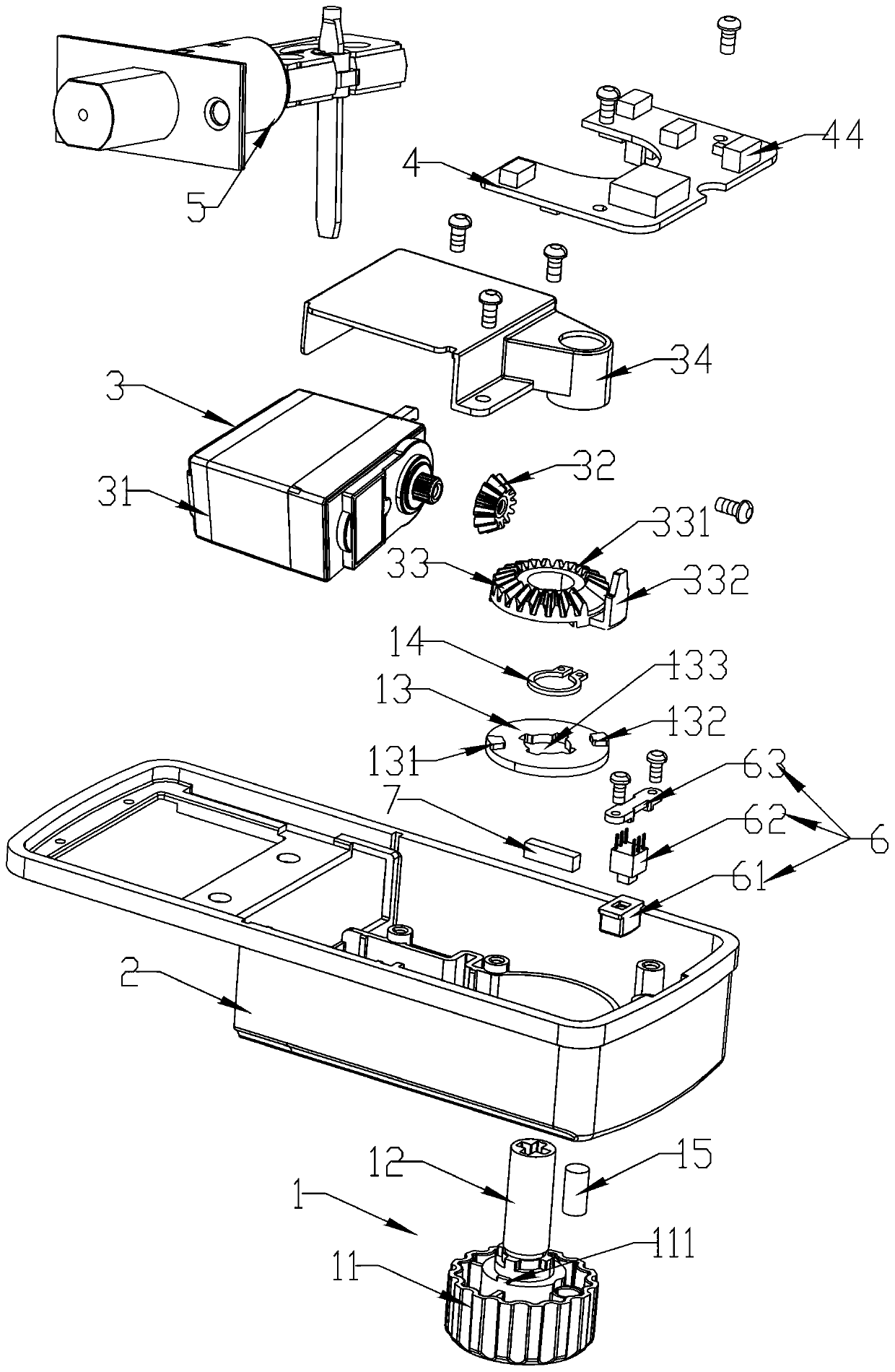

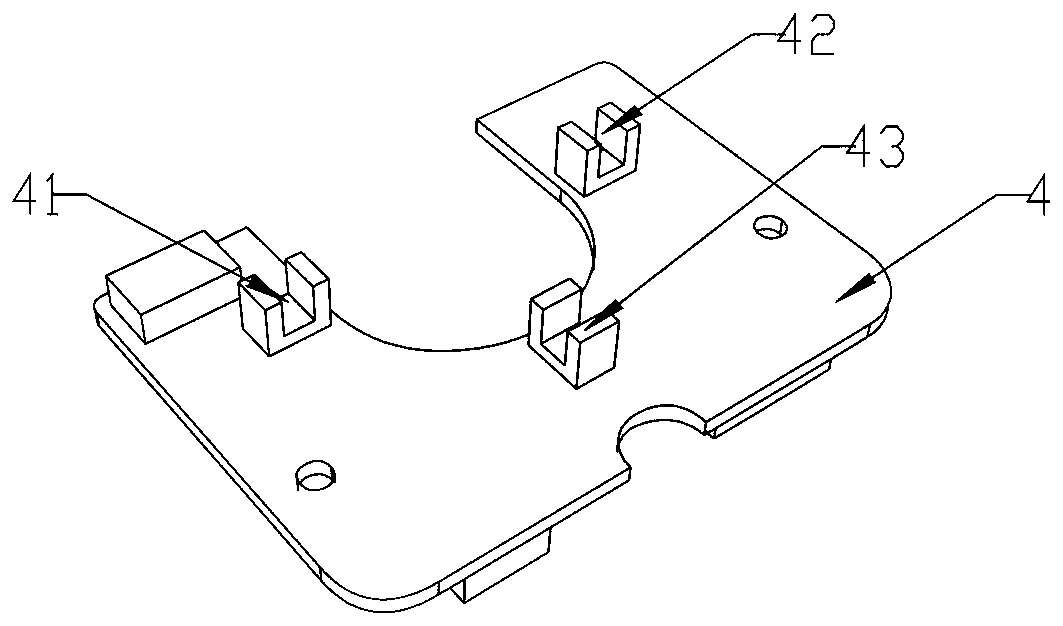

[0035] Such as figure 1 , an electronic lock, comprising: a knob mechanism 1, a lock case 2, a transmission mechanism 3, a control board 4, and a bolt mechanism 5.

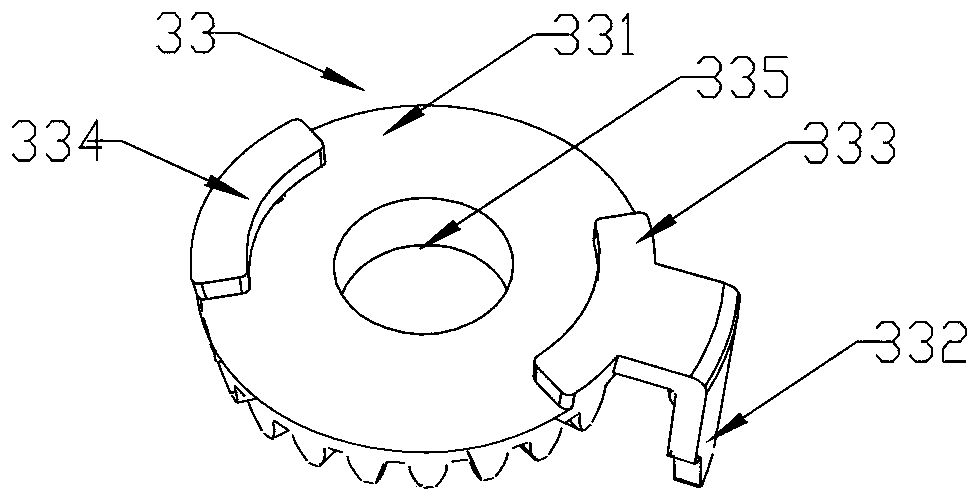

[0036] Such as figure 1 with 4 , the knob mechanism 1 includes a knob 11 , a knob shaft 12 , and a knob linkage 13 . The knob 1 is located on the outside of the lock case 2 . The knob shaft 12 is connected to the inner side of the knob 11, and the knob 11 vertically extends into the anti-lock shaft hole 21 on the lock housing 2 and extends into the inner side of the lock housing 2; It can drive the extension or retraction of the dead bolt mechanism 5. The knob linkage 13 is provided with a linkage through hole 133, and the linkage through hole 133 is sleeved on the knob shaft 12 and compressed by the circlip 14; the knob linkage 13 can rotate synchronously with the knob shaft 12 . The knob linkage 13 is provid...

Embodiment 2

[0048] Such as Figure 10-13 , the present embodiment is the action process of opening the electronic lock from the left. The difference between this embodiment and Embodiment 1 is that there is no need to replace any parts, only need to adjust the control program of the main control panel 4, and adjust the relative relationship between the knob linkage 13 and the driven gear plate 33 in the initial state (normally open state). location, such as Figure 10 (c). Its locking, unlocking, and control principles are consistent with Embodiment 1.

[0049] Such as Figure 11 , the knob 11 is turned 90° clockwise to realize locking; the locking of the knob does not drive the rotation of the transmission mechanism 3 .

[0050] Such as Figure 12 , the driven gear plate 33 rotates 90° clockwise to realize unlocking; the rotation of the speed change transmission mechanism 3 will drive the knob 11 to rotate synchronously;

[0051] Such as Figure 13 , the driven gear plate 33 rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com