Tray unstacking/stacking machine

A pallet and stacker technology, applied in the direction of unstacking of objects, conveyors, stacking of objects, etc., can solve the problems of inconvenient maintenance, large structure, complex transmission, etc., achieve simple structure, simple and compact structure, save transmission The effect of the piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

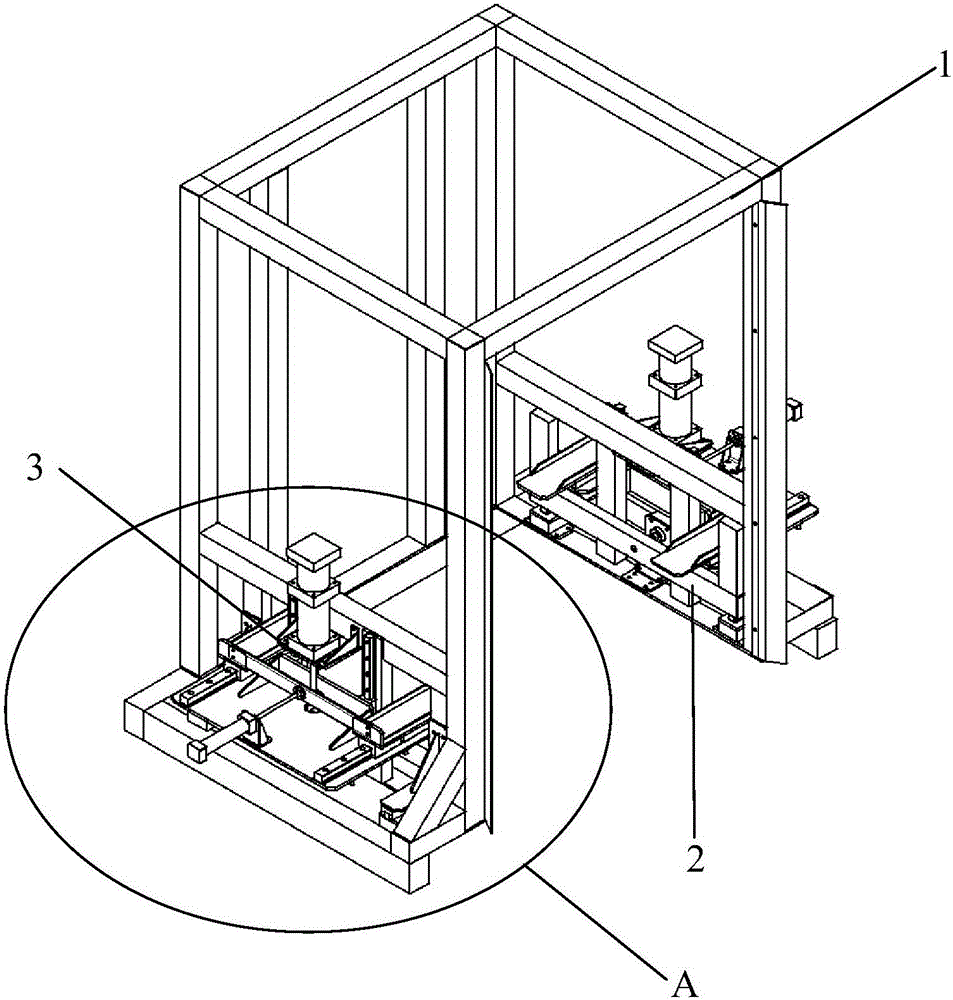

[0023] Such as figure 1 with 2 Shown, be the pallet destacking stacker of the present embodiment;

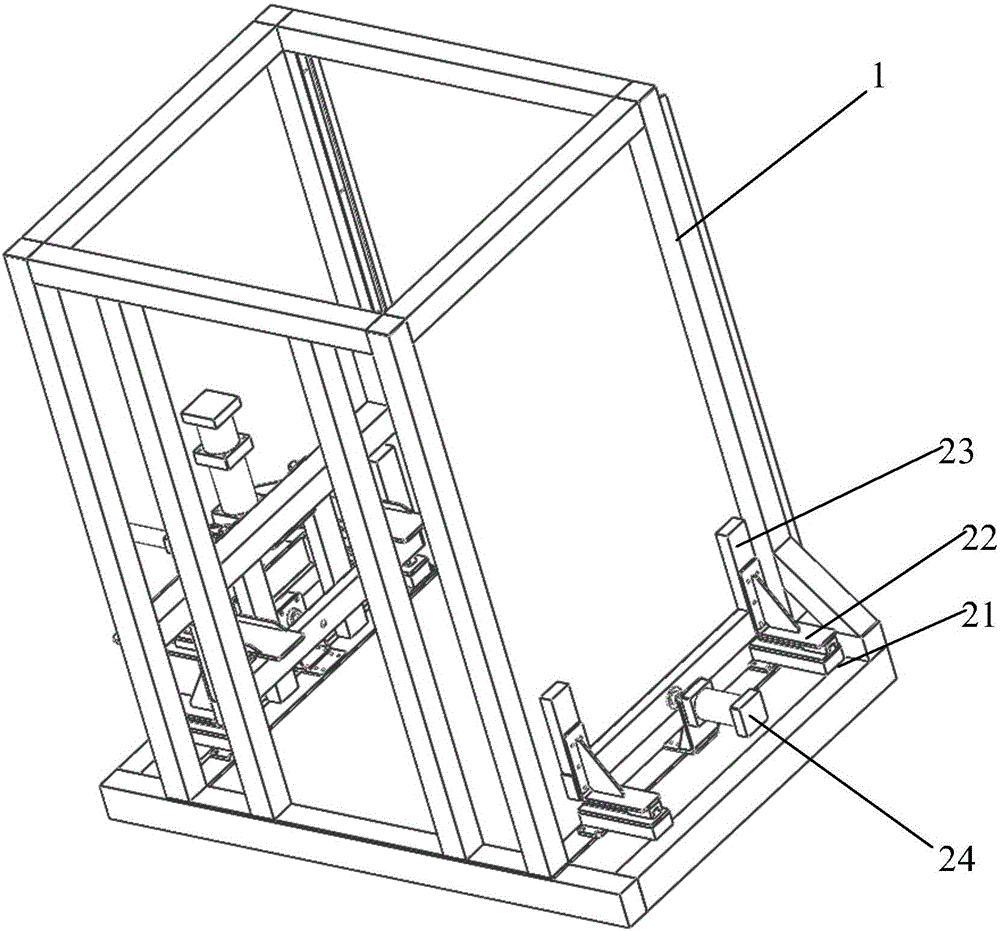

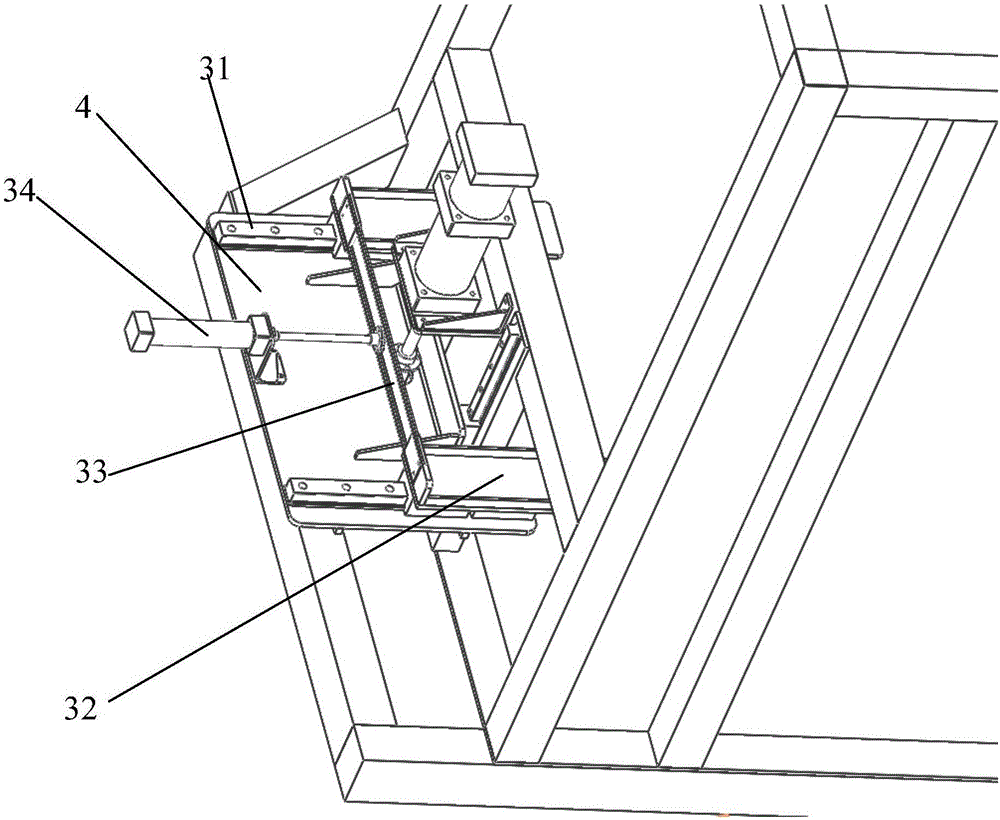

[0024] A pallet depalletizing and palletizing machine, comprising a "door"-shaped rigid support 1, two pneumatic clapping mechanisms 2 and two pallet fork mechanisms 3; figure 1 with 2 As shown, the rigid support 1 in the shape of a "door" is placed on the ground, and the interior of the rigid support is a fixed-point space for the pallet; There is a pneumatic slapping mechanism 2 for sorting the trays, and the two pneumatic slapping mechanisms 2 are symmetrically arranged; above the two pneumatic slapping mechanisms, a hanging plate 4 is provided to hold the tray and can drive the tray to slide vertically up and down The pallet fork mechanism3.

[0025] Such as figure 2 As shown, the bottom of the left side of the rigid support 1 and the bottom of the rear side protrude outward and are respectively provided with an open steel beam 11 for installing a pneumatic clapping me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com