Piezoelectric ultrasonic transducer and manufacturing method thereof

A piezoelectric ultrasonic and transducer technology, applied in the field of ultrasonic sensors, can solve the problems of low output impedance, large influence of parasitic capacitance, and high driving voltage, and achieve increased sound pressure output, large dynamic range, and increased effective area area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

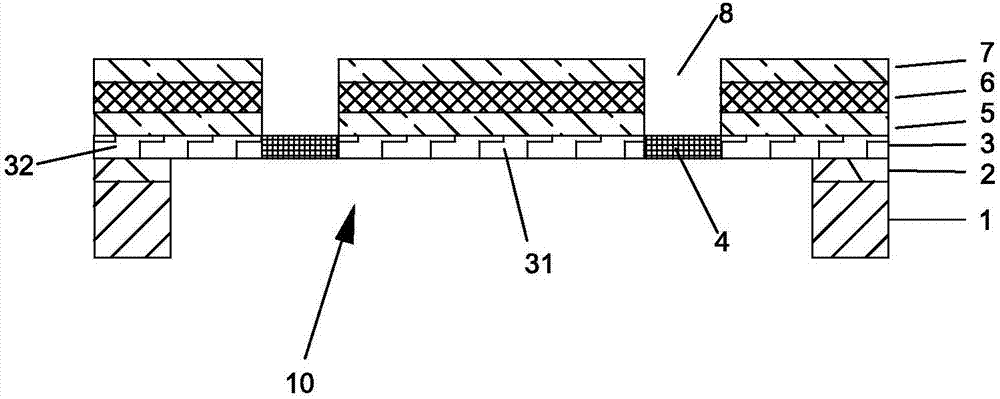

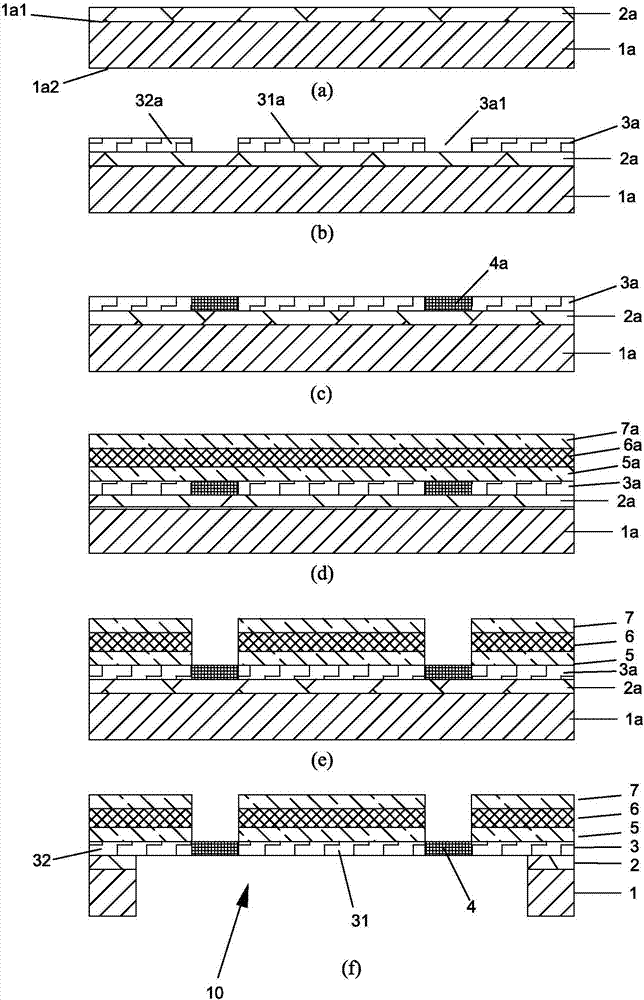

[0026] Such as figure 1 As shown, the piezoelectric ultrasonic transducer of this embodiment includes a substrate 1, a diaphragm 3 fixed on the substrate 1, and a first electrode 5 sequentially deposited on the diaphragm from the substrate 1 to the direction of the diaphragm 3 , piezoelectric film 6 and second electrode 7 . A cavity 10 is arranged at the center of the substrate 1 , and the diaphragm 3 covers the cavity 10 .

[0027] The diaphragm 3 includes a first diaphragm 31 located in the center and a second diaphragm 32 located outside the first diaphragm, the first diaphragm 31 and the second diaphragm 32 are spaced apart and passed through an elastic structural layer 4 connected, the elastic structure layer 4 is a hollow ring structure. The piezoelectric ultrasonic transducer is also provided with a through hole 8 through the second electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com