A composite thin film pMUTs and a preparation method thereof

A combined and thin-film technology, which is applied to the coupling of optical waveguides, the manufacture of microstructure devices, and microstructure devices composed of deformable elements, etc., to achieve the effects of enhanced mutual coupling, wide ultrasonic receiving bandwidth, and improved ultrasonic transmission power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is described in detail below in conjunction with accompanying drawing:

[0054] The invention proposes a combined thin-film pMUTs and a preparation method thereof, in order to improve the feasibility, reliability and consistency of unit structure and performance of the pMUTs chip preparation process while increasing the pMUTs transmission power and ultrasonic receiving bandwidth.

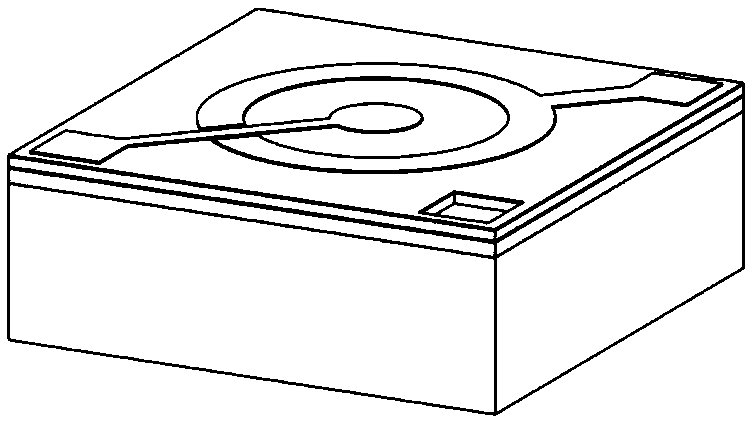

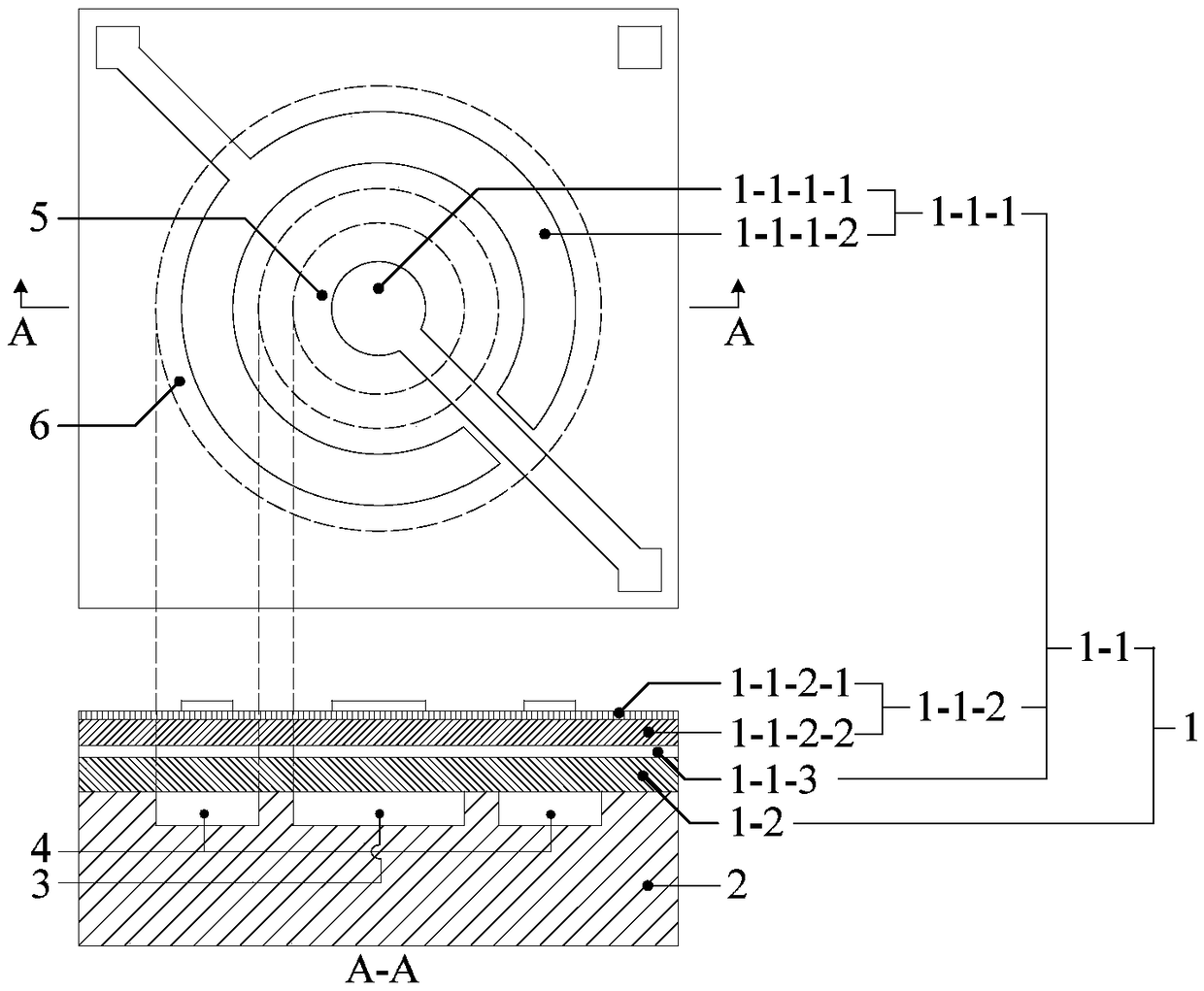

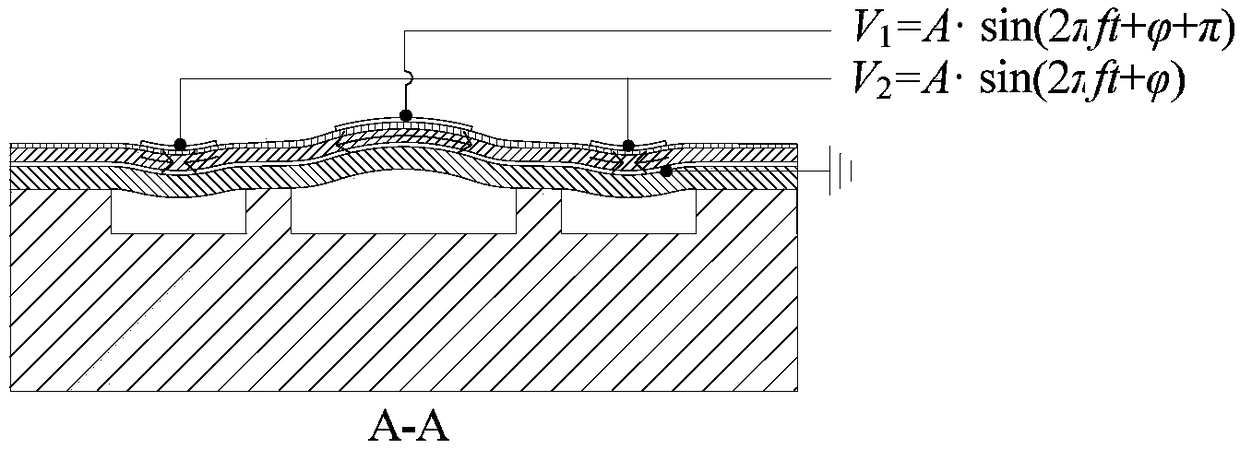

[0055] Such as figure 1 , figure 2 with image 3 As shown, a combined thin film pMUTs of the present invention is composed of a multilayer composite thin film 1 and a base structure 2 from top to bottom.

[0056] The multi-layer composite film 1 is composed of a piezoelectric driving layer structure 1-1 and a non-driving layer structure 1-2. The piezoelectric driving layer structure 1-1 is composed of a top electrode 1-1-1, a dielectric layer 1-1-2, and a bottom electrode 1-1-3 from top to bottom in the thickness direction.

[0057] The dielectric layer 1-1-2 is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com