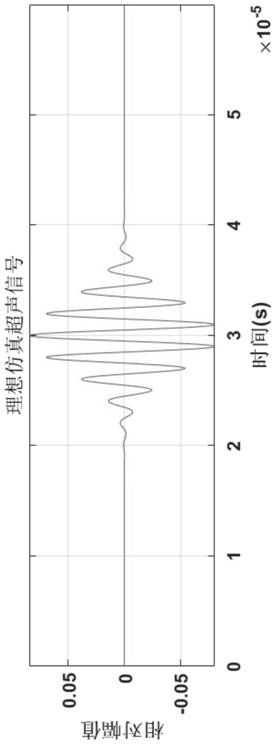

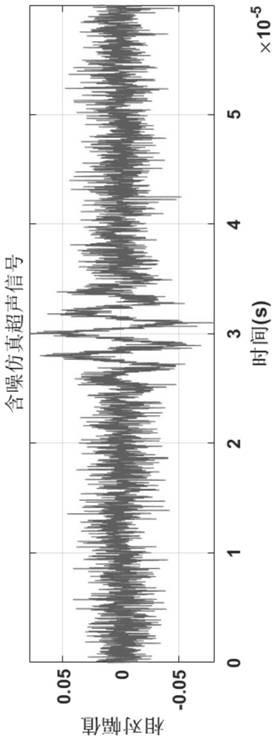

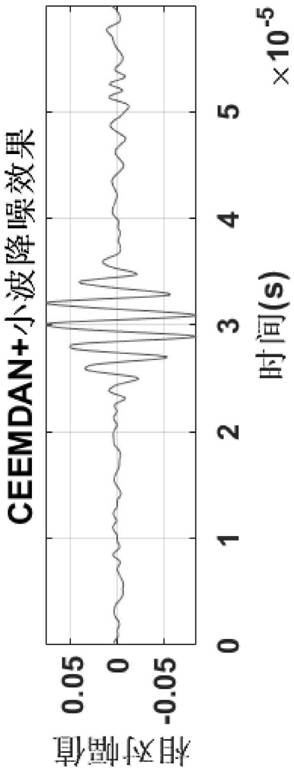

Ultrasonic detection sensor and signal processing method thereof

A sensor signal, ultrasonic detection technology, applied in the processing of the detected response signal, the measurement of ultrasonic/sonic/infrasonic waves, the use of sonic/ultrasonic/infrasonic waves to analyze solids, etc. It can solve the problem of low signal-to-noise ratio and resolution, and difficult surface coupling , Ultrasonic copper plate material attenuation rate and other problems, to achieve the effect of improving signal-to-noise ratio and resolution, improving receiving sensitivity, and overcoming device burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0057] Example. A sensor for ultrasonic detection, constituted as Figures 1 to 5 As shown, it includes a sensor housing 1, a piezoelectric unit 5 and auxiliary components located in the sensor housing 1; the piezoelectric unit 5 includes a receiving piezoelectric wafer 7 and a transmitting piezoelectric wafer 8 located below the receiving piezoelectric wafer 7 ; The transmitting piezoelectric chip 8 and the receiving piezoelectric chip 7 are axially connected in series; the area of the piezoelectric unit 5 is 3mm×3mm.

[0058] The auxiliary components include two lead wire connectors 2 arranged at the top of the sensor housing 1, a wedge 6 arranged at the bottom of the sensor housing 1, two lead wires 3 and a damper arranged inside the sensor housing 1 above the piezoelectric unit 5. Block 4. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com