Apparatus and method for calibration of laser triangulation system

A laser triangulation and calibration device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to adjust the mechanical position, unsatisfactory geometric relationship, mechanical error of the adjustment device, etc., and achieve easy calibration accuracy and adaptability The effect of strong flexibility and improved calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

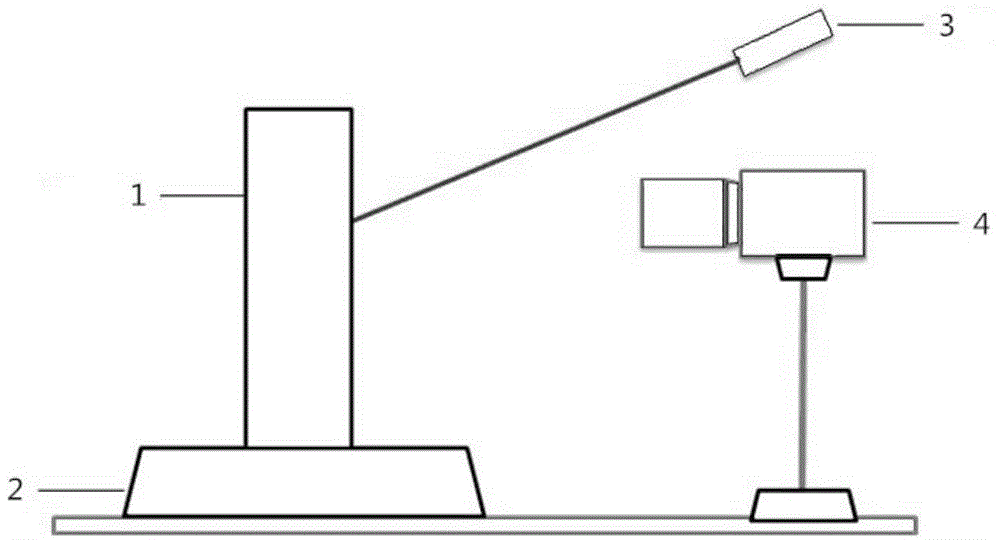

[0045] figure 1 Shown is a schematic structural diagram of the calibration device of this embodiment. A calibration device for a laser triangulation measurement system, comprising a turntable 2, a thimble ( figure 1 not shown in ) and the calibration cylinder 1; the calibration cylinder 1 is fixedly placed above the turntable 2, and the thimble presses against the upper surface of the calibration cylinder 1. also, figure 1 The accompanying laser 3 and camera 4 are also shown in .

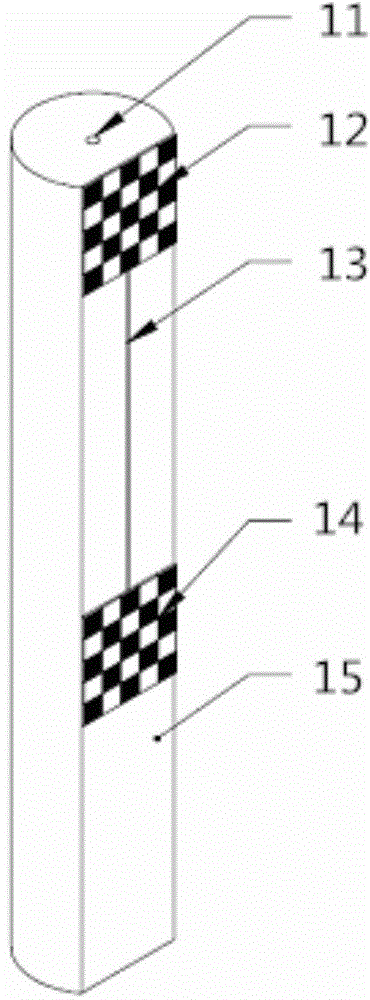

[0046] figure 2 Shown is a detailed structural drawing of the calibration cylinder 1 . The illustrations are respectively the small hole 11, the upper checkerboard calibration plate 12, the slit 13, the lower chec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com