Method for precisely measuring inner diameter of multi-direction shaft hole based on laser triangulation method

A technology of laser triangulation and precision measurement, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of difficult online detection, long measurement time, high rotation accuracy requirements, etc., and achieve high automatic online measurement and fast speed , The effect of shortening the time required for measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

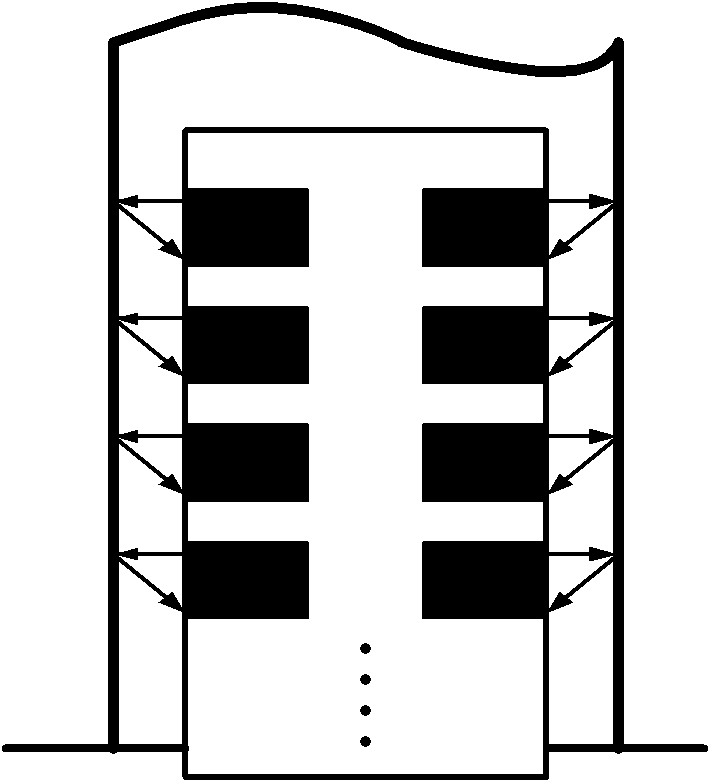

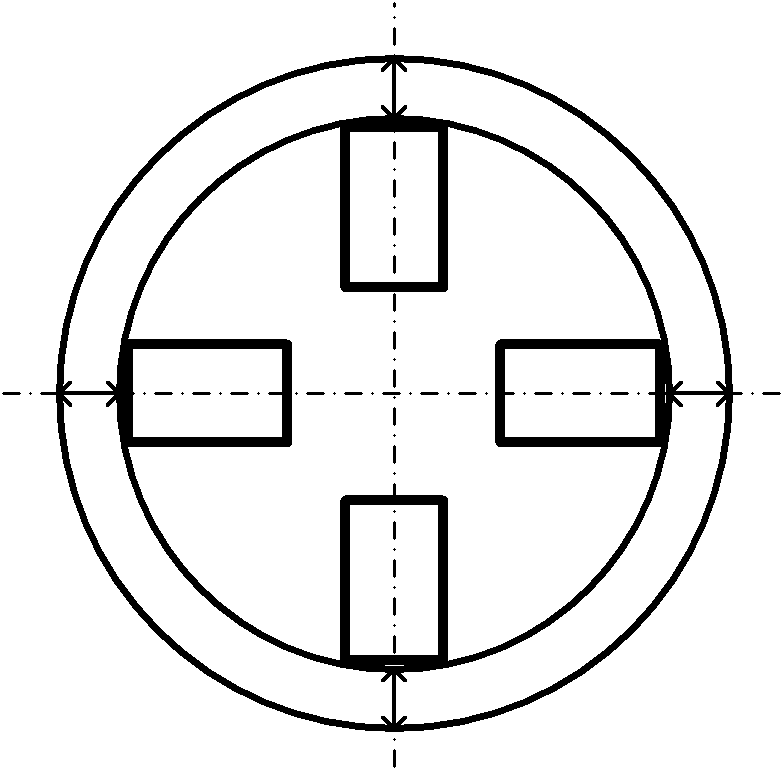

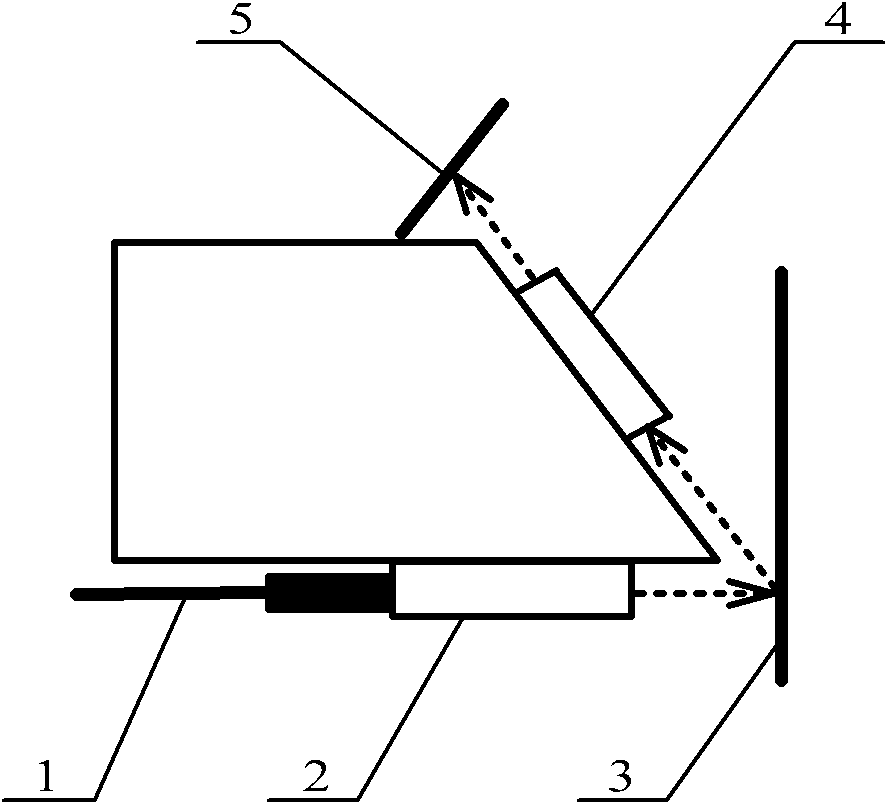

[0015] See Figure 1 ~ Figure 3 , the present invention is based on a laser triangulation method for precise measurement of the inner diameter of a multi-directional shaft hole, 1) pre-calibrate the measuring head, and establish the relationship between the output electrical signal of the measurement unit and the actual surface displacement of the measured shaft hole; 2) pre-calibrate the same The triangulation method of the four probes on the circumference of the section measures the origin position; 3) Deepen the measuring rod into a certain position inside the measured shaft hole, such as figure 1 As shown, turn on the laser, such as image 3 As shown, the laser is transmitted to the inside of the probe through the pigtail 1, collimated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com