Tool for detecting mould outline curvature radius

A technology of contour curvature and detection tools, which is applied in the field of iron and steel casting, can solve the problems of excessive shape and position tolerances, difficult alignment of measurement benchmarks and process benchmarks, etc., and achieve the effects of compact structure, wide application range and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

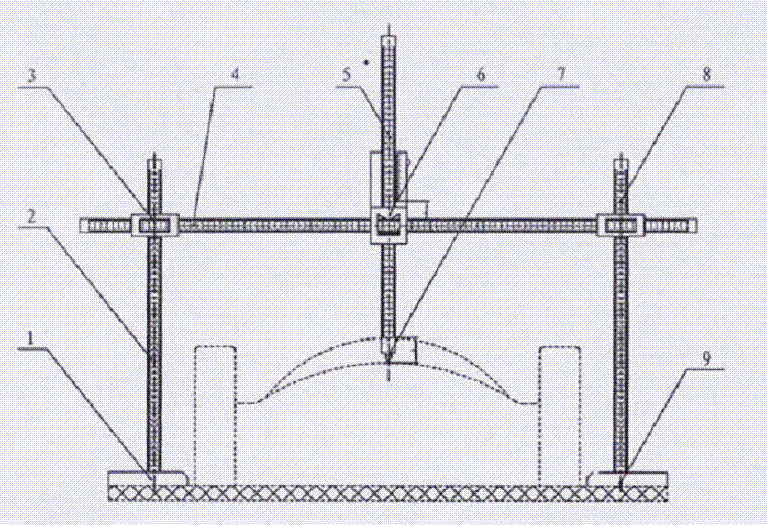

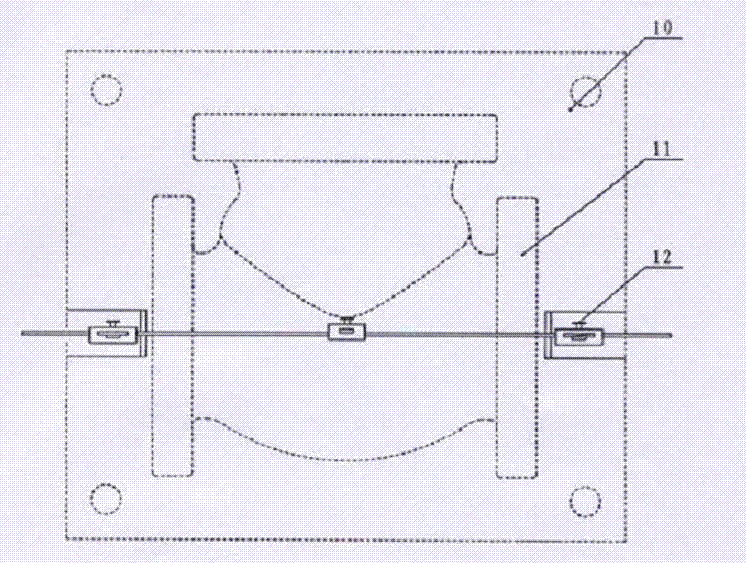

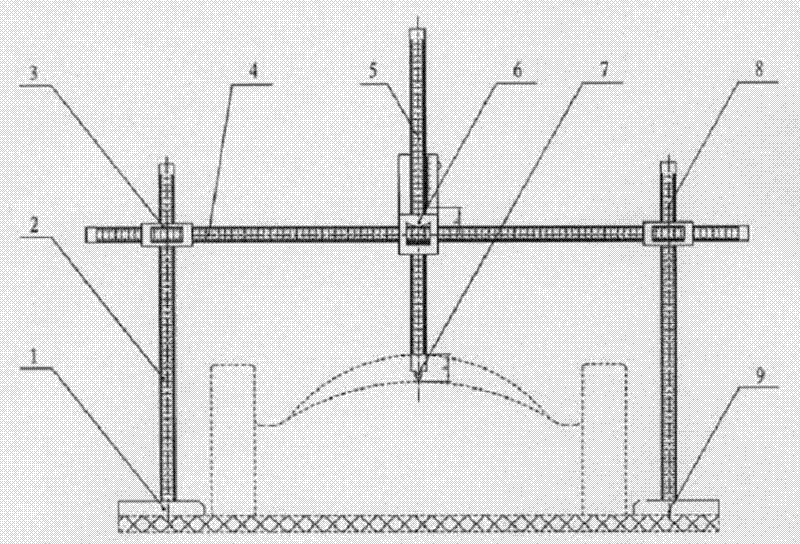

[0007] The present invention demonstrates the implementation mode through its working principle. When using the detection tool, use the reference line on the left and right supports to align with the position line of the profile section, and fix it on the template with 502 glue for easy removal. , the right connecting pair 3, after sliding and adjusting the horizontal ruler 4 to the set left vertical ruler 2 and the right vertical ruler 8 at the same height, the 0 line on the horizontal ruler 4 is located in the middle of the left vertical ruler 2 and the right vertical ruler 8 with fastening Lock the screw, and slide to adjust the center line of the ruler 5 to coincide with the 0 line of the ruler 4, so that the distance from the lower end point of the ruler to the 0 line of the ruler is equal to the distance from the center line of the ruler to the 0 line of the vernier of the ruler. The lower end point touches the contour surface of pattern 11, read the sum Y0 of the integer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com