A method for selecting and matching mechanical parts based on geometrical tolerance and dimensional tolerance is disclosed

A dimensional tolerance and geometric tolerance technology, which is applied in the field of mechanical parts selection based on geometric and dimensional tolerances, can solve the problems of complex dimensional chains, many quality requirements, and the difficulty of intelligent algorithms to coordinate the optimization of multiple quality requirements at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention is described in further detail below in conjunction with accompanying drawing:

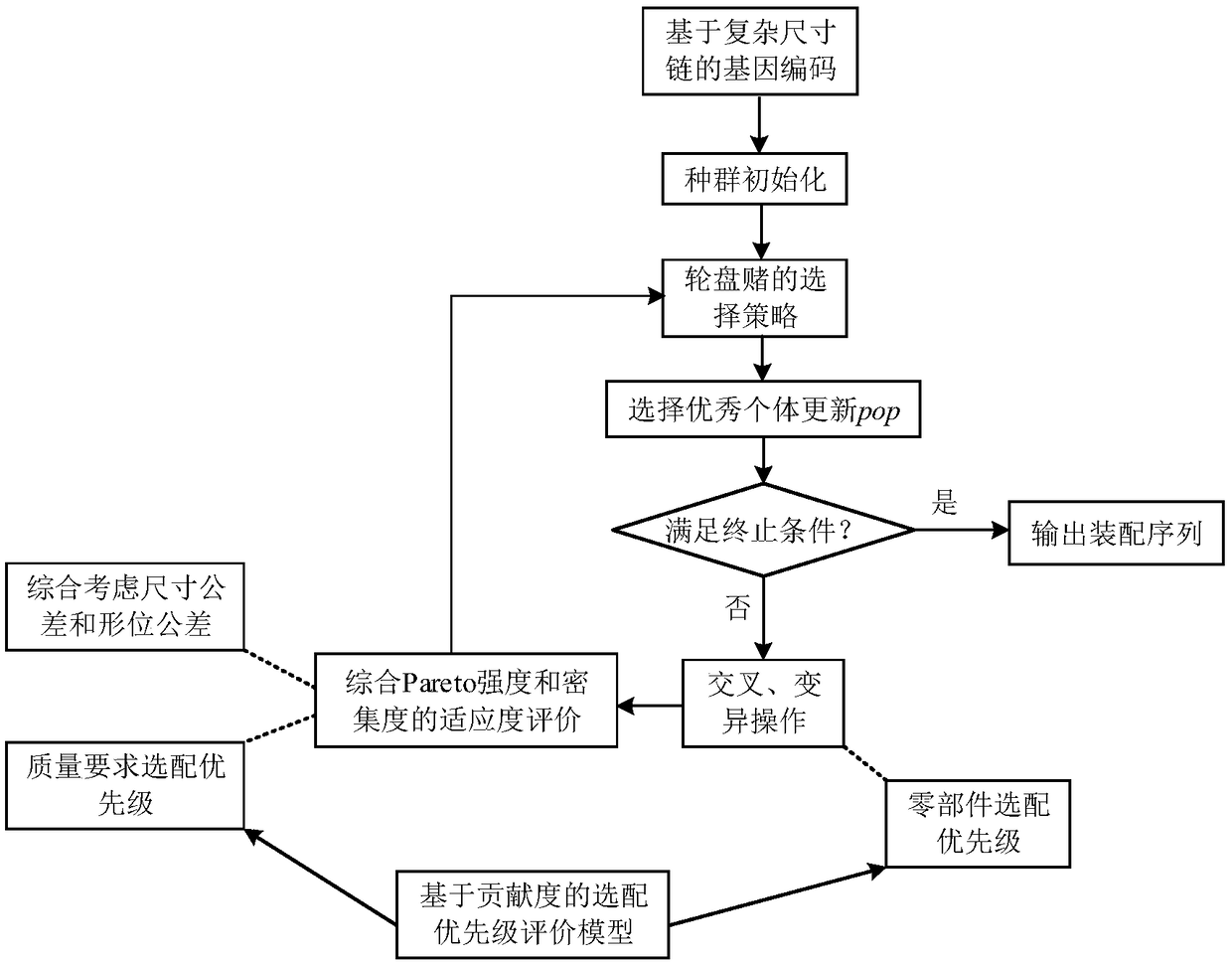

[0079] Such as figure 1 As shown, a matching method of mechanical parts based on geometric tolerance and dimensional tolerance includes the following steps:

[0080] Step 1), establish a multi-objective optimization matching model

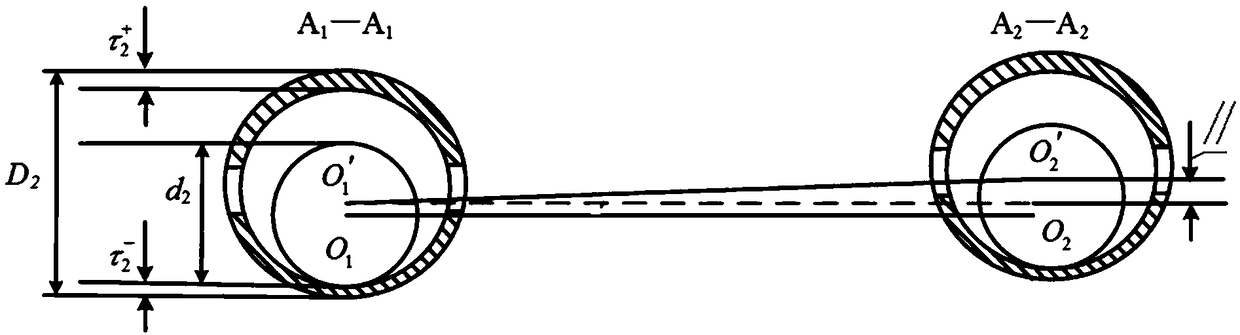

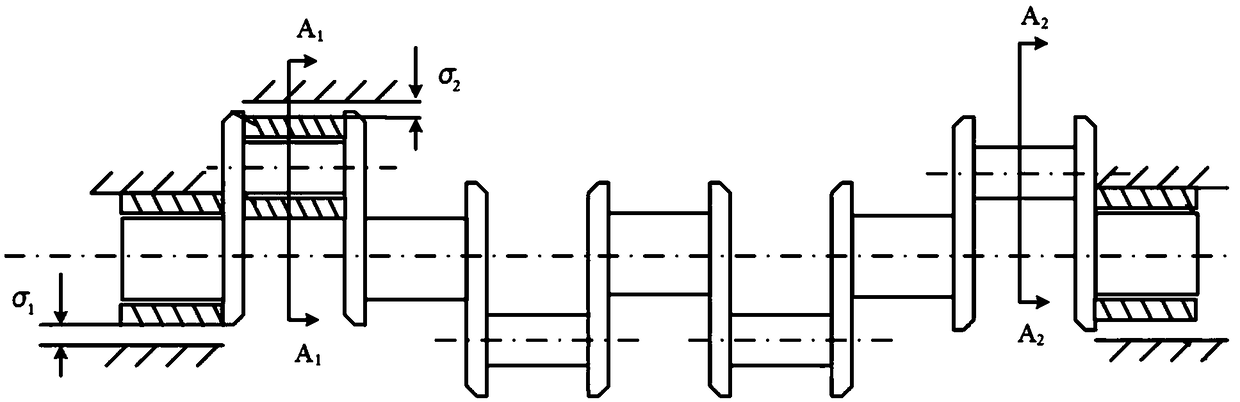

[0081] According to the effective characterization form of the measured value of the geometrical tolerance, the comprehensive geometrical tolerance and dimensional tolerance are used as the optimization target, and the assembly success rate and assembly accuracy are used as the evaluation indicators of the quality requirements, and the complex mechanical product combination of the geometrical tolerance and the dimensional tolerance is established. Target optimization matching model;

[0082] Specifically, the assembly sequence of parts is represented by mathematical methods, and the assembly scheme matrix X based on parts layering is esta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com