Patents

Literature

41results about How to "Small shape and position tolerance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

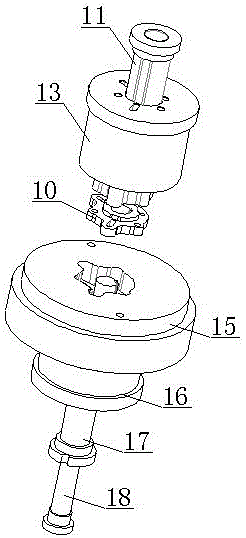

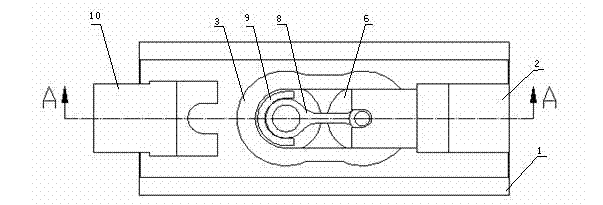

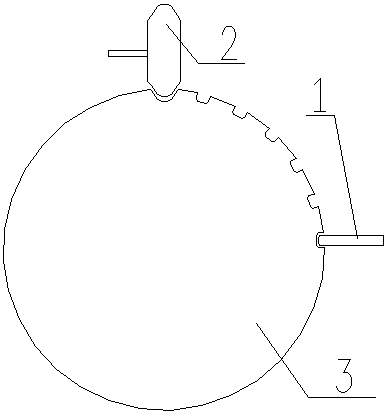

Electro-hydraulic servo valve

InactiveCN104454729AImprove the ability to withstand external pressureGuarantee job stabilityServomotor componentsValve members for absorbing fluid energyFluid controlElectro hydraulic

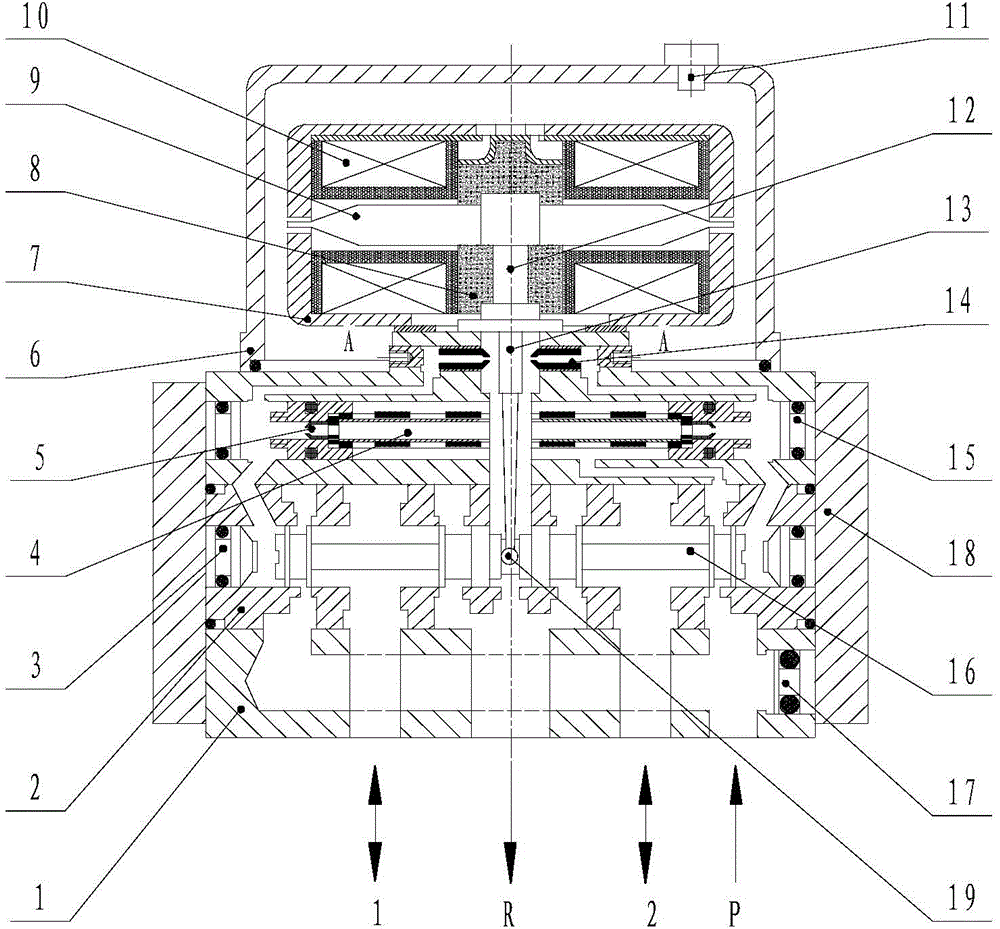

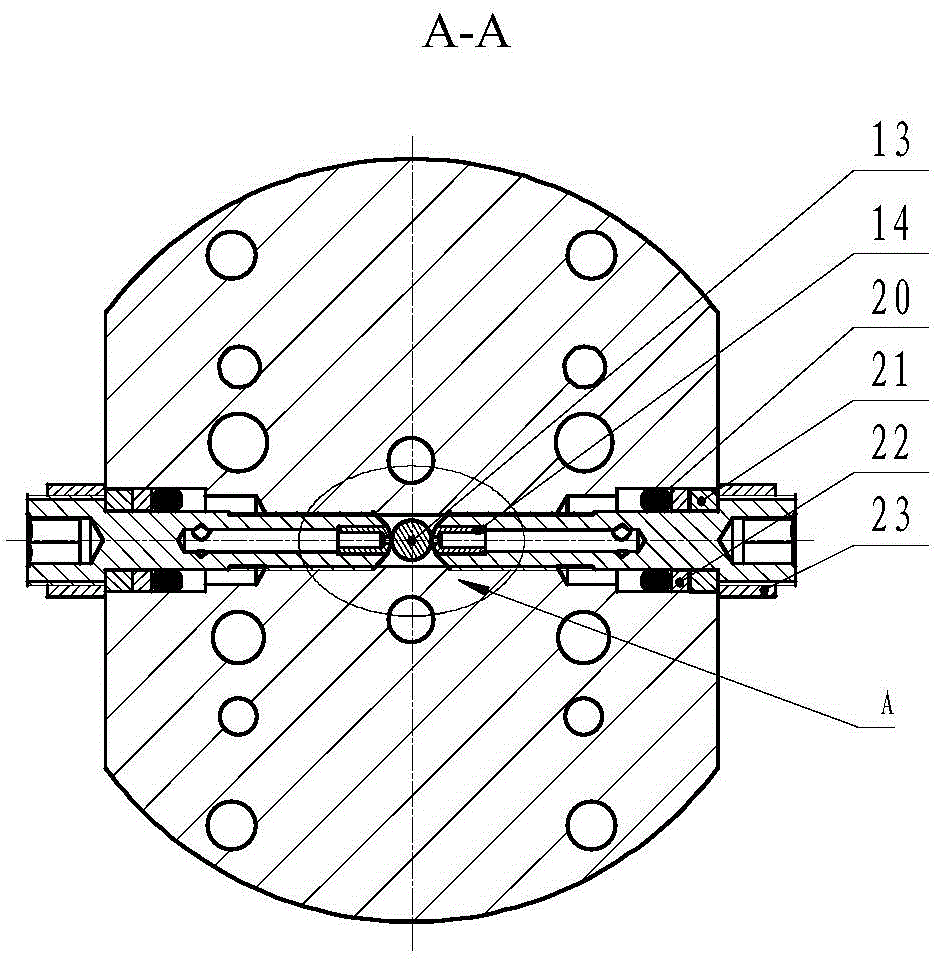

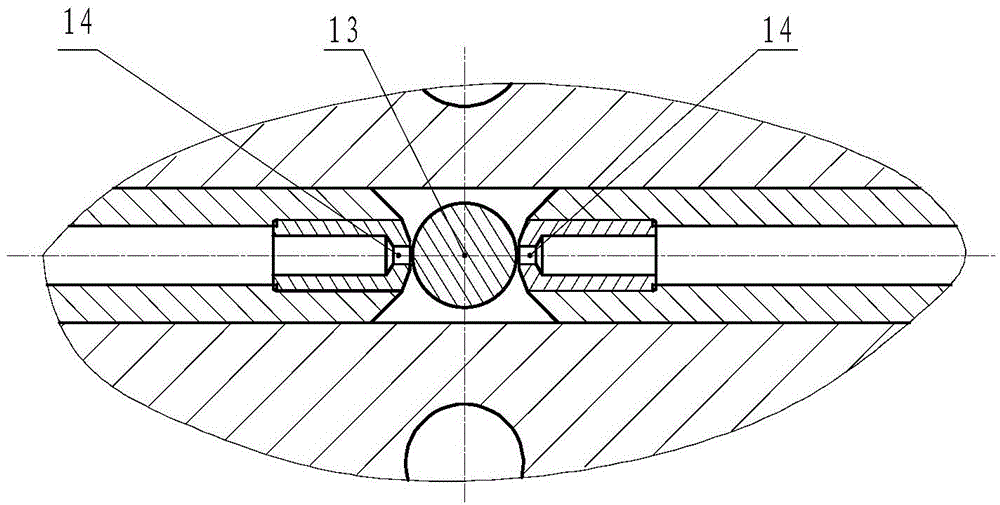

The invention relates to a fluid control device, in particular to a novel electro-hydraulic servo valve. The novel electro-hydraulic servo valve comprises a shell (1), a valve element (7), a valve sleeve (2), a fixed throttling hole (5), a spraying nozzle (14), a coil (10), an armature (9), a spring pipe (12), a baffle (13), a feedback rod (19), permanent magnetic steel (8) and a pressure equalizing oil filter (11). The electro-hydraulic servo valve is characterized in that external pressure increased along with increase of submerged depth is used for equalizing pressure on the inner side and the outer side of the spring pipe (12) through the pressure equalizing oil filter (11), and the requirement for the structural strength of a cover body (6) and the spring pipe (12) is lowered. A changeable throttling device composed of the baffle (13) and the spraying nozzle (14) can increase the working stability of the electro-hydraulic servo valve and can also guarantee the driving capacity of the electro-hydraulic servo valve in deep-sea high-pressure high-viscosity fluid. The baffle (13) and the feedback rod (19) are integrally designed, and feedback moment is directly fed back to the baffle. The baffle (13) is a cylindrical baffle, and the machining difficulty of parts is lowered.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

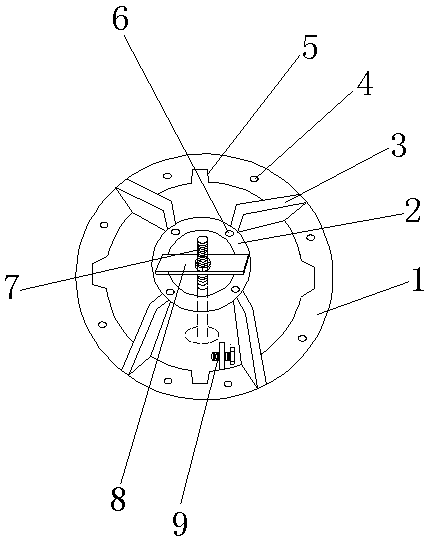

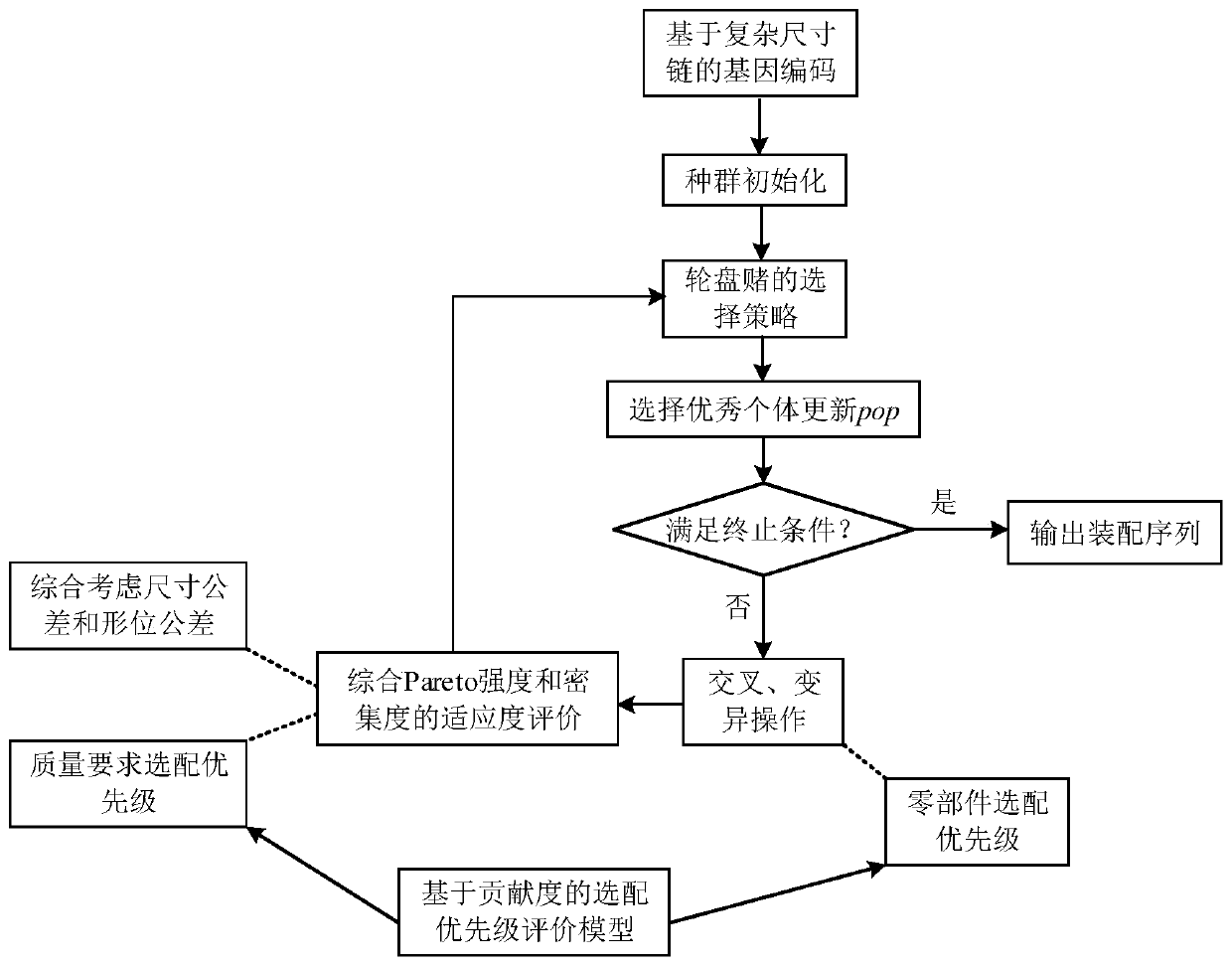

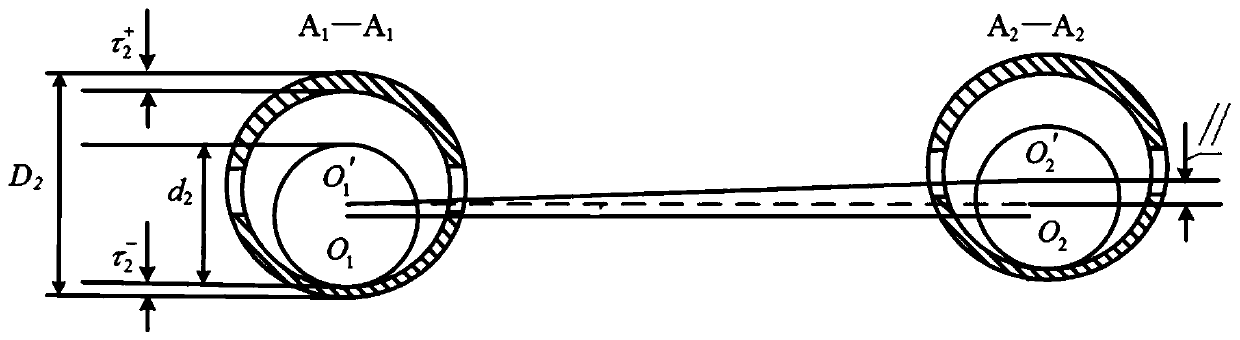

A method for selecting and matching mechanical parts based on geometrical tolerance and dimensional tolerance is disclosed

ActiveCN109271653AImprove convergence speedOptional implementationGeometric CADSpecial data processing applicationsPosition toleranceMachine parts

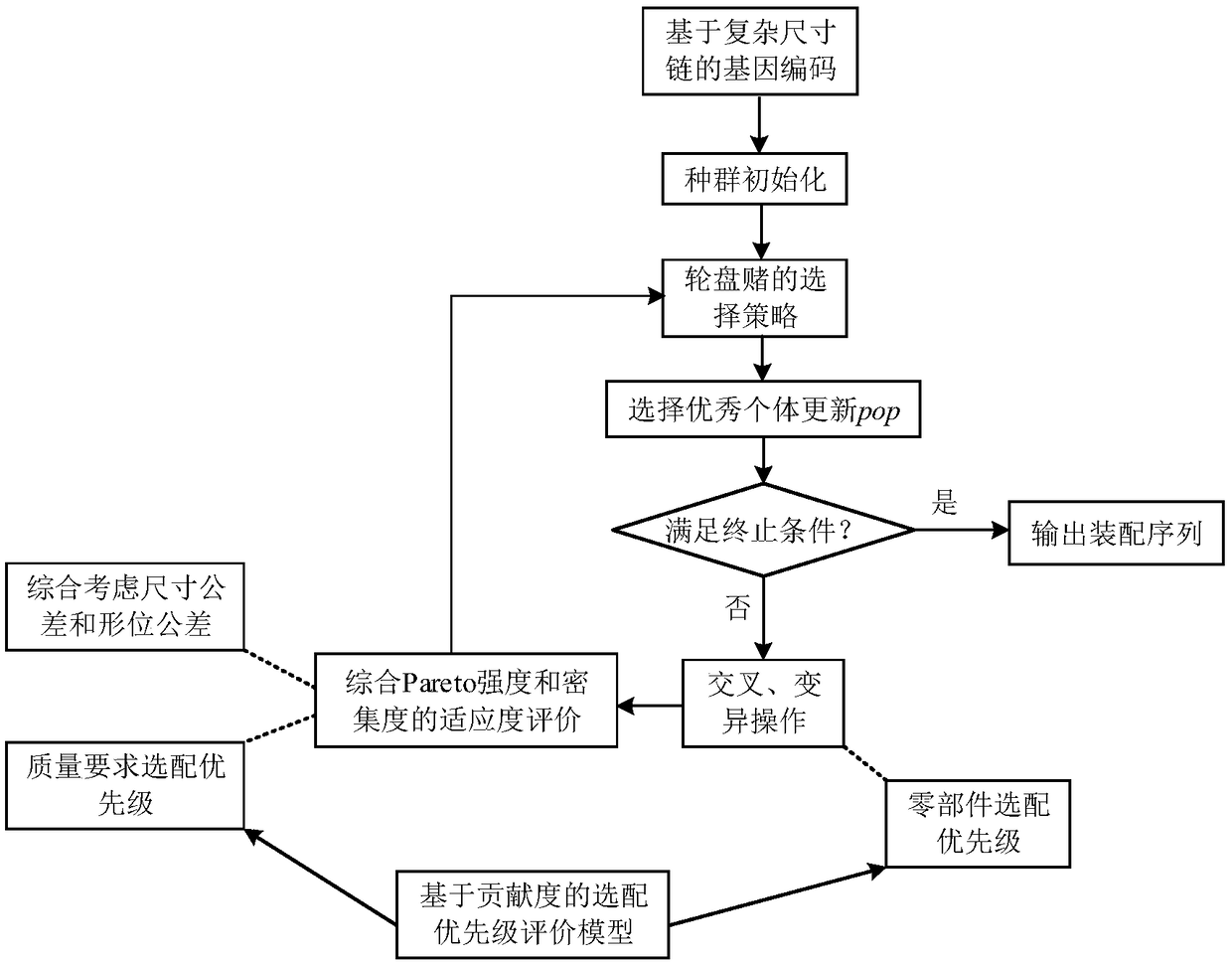

The invention discloses a method for selecting and matching complex mechanical products based on genetic algorithm, which comprehensively considers shape and position tolerance and dimension tolerance, through the coding method of complex dimension chain, the assembly problems of complex mechanical products are mapped into mathematical models, assembly accuracy and assembly success rate are used as the evaluation indexes of quality requirements, a comprehensive optimization model of selection and matching under the multi-quality requirements is established, by using the effective characterization form of the measured values of geometrical tolerances in the selection, the optimization model of geometrical tolerances and dimensional tolerances is established, Based on Pareto intensity and density as fitness evaluation criteria of genetic algorithm, the algorithm is improved by introducing the priority of parts and the priority of quality requirement. The method not only realizes the selection and matching of complex mechanical products, improves the success rate of assembly, ensures the assembly accuracy, ensures the dimensional tolerance assembly accuracy, but also effectively reduces the shape and position tolerances of products, and the genetic algorithm with the priority of selection and matching has a better convergence speed.

Owner:XI AN JIAOTONG UNIV

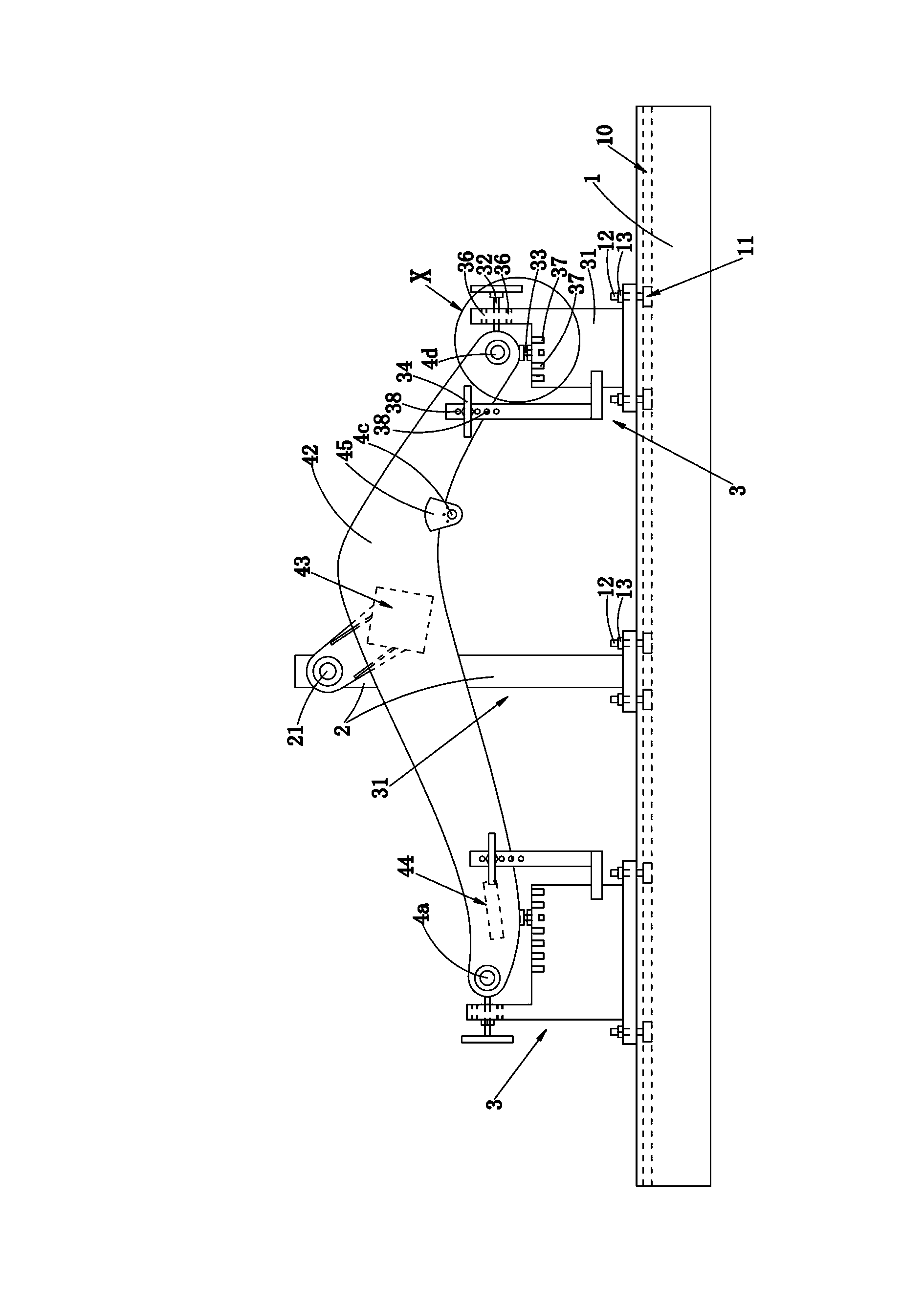

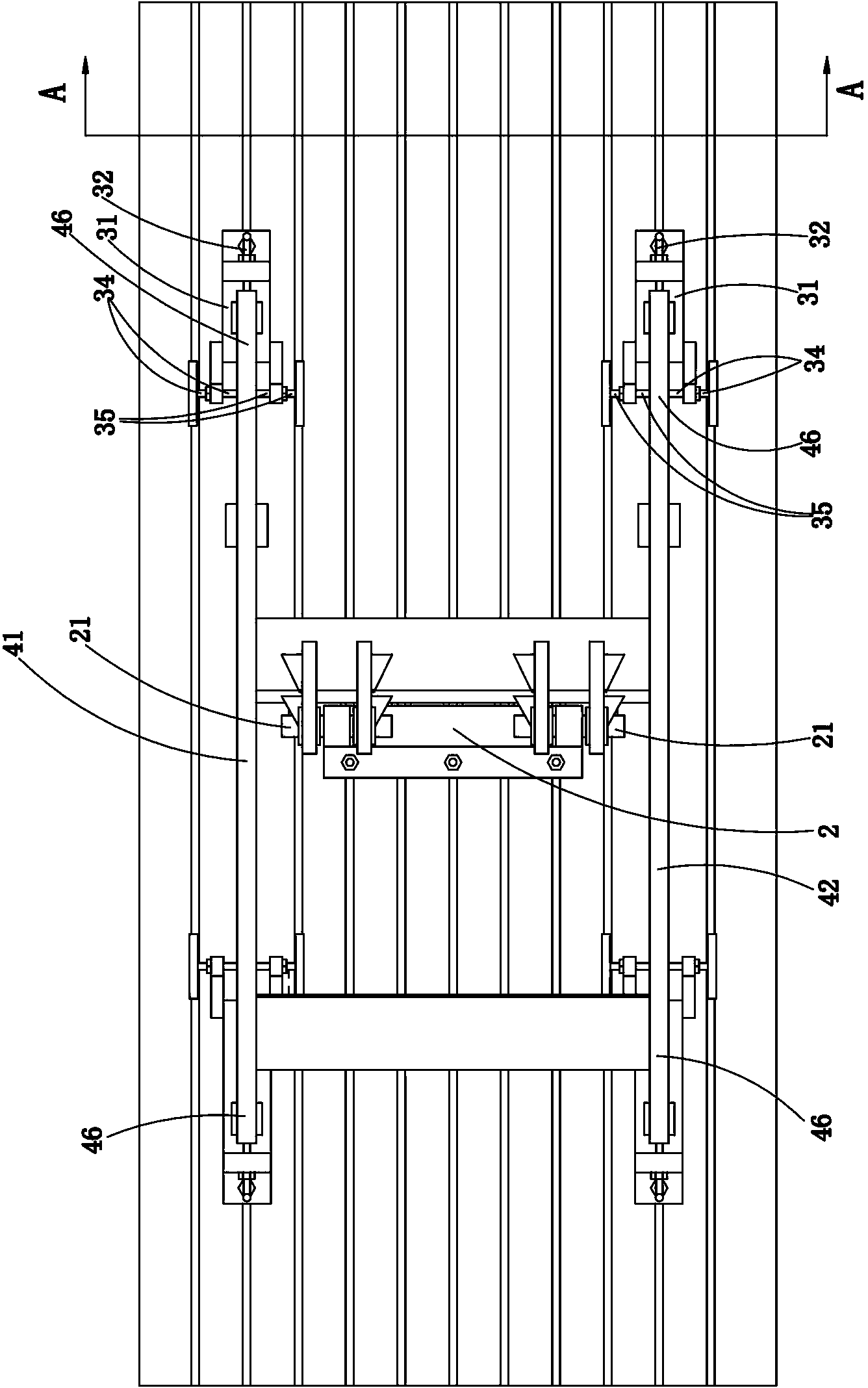

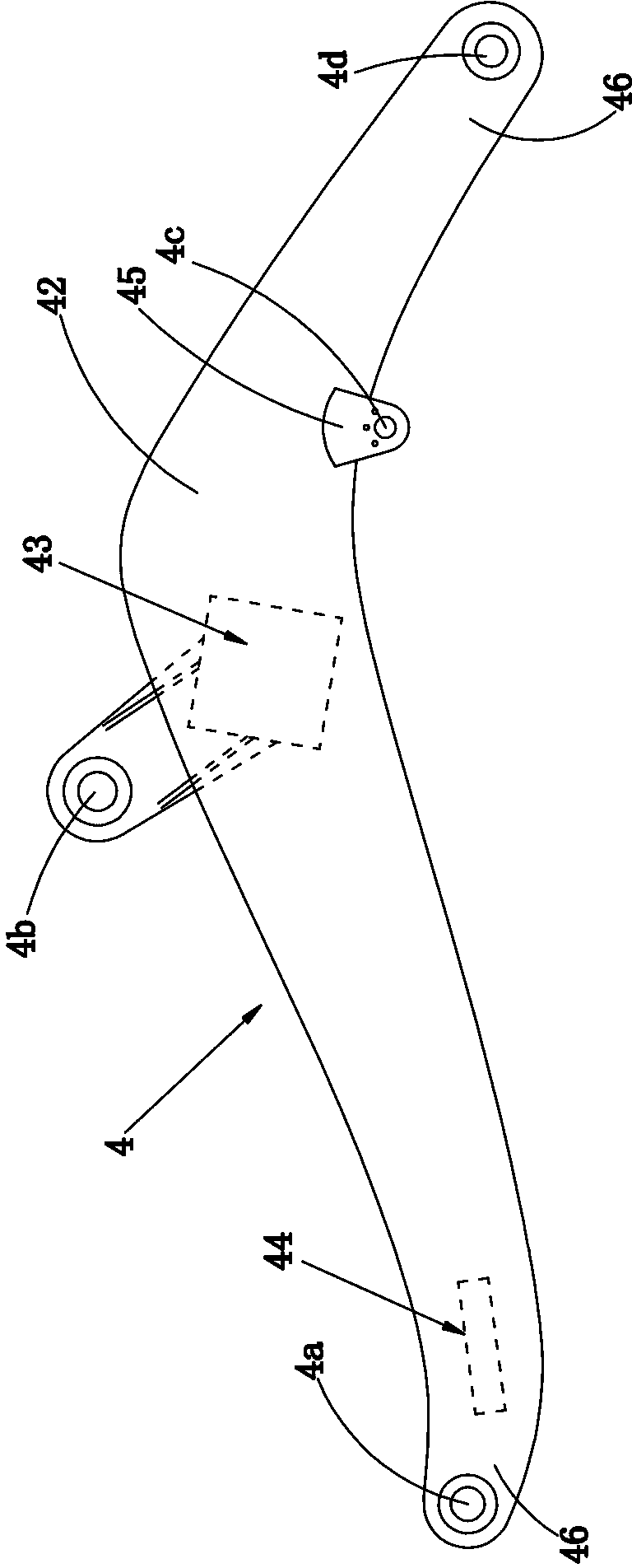

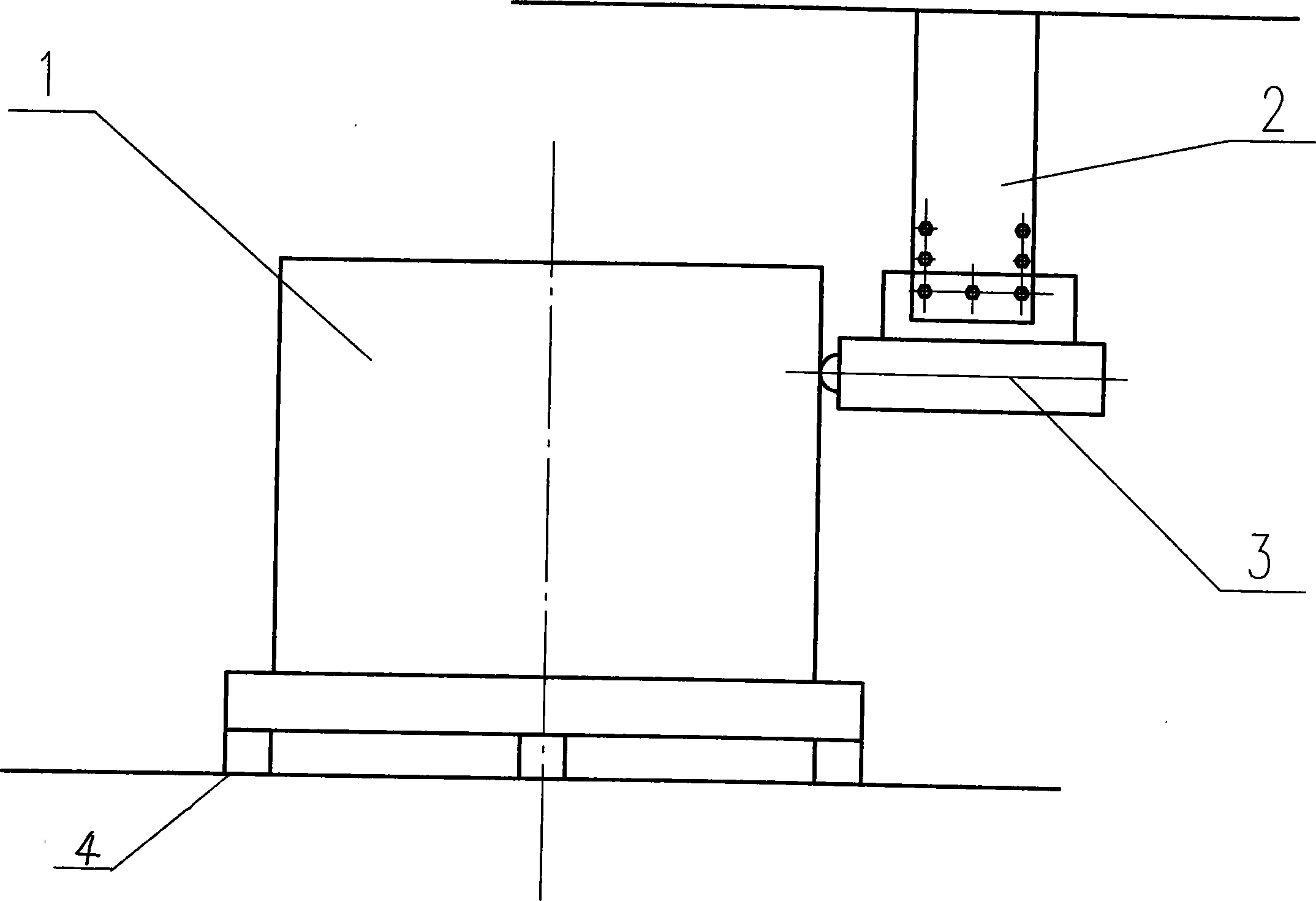

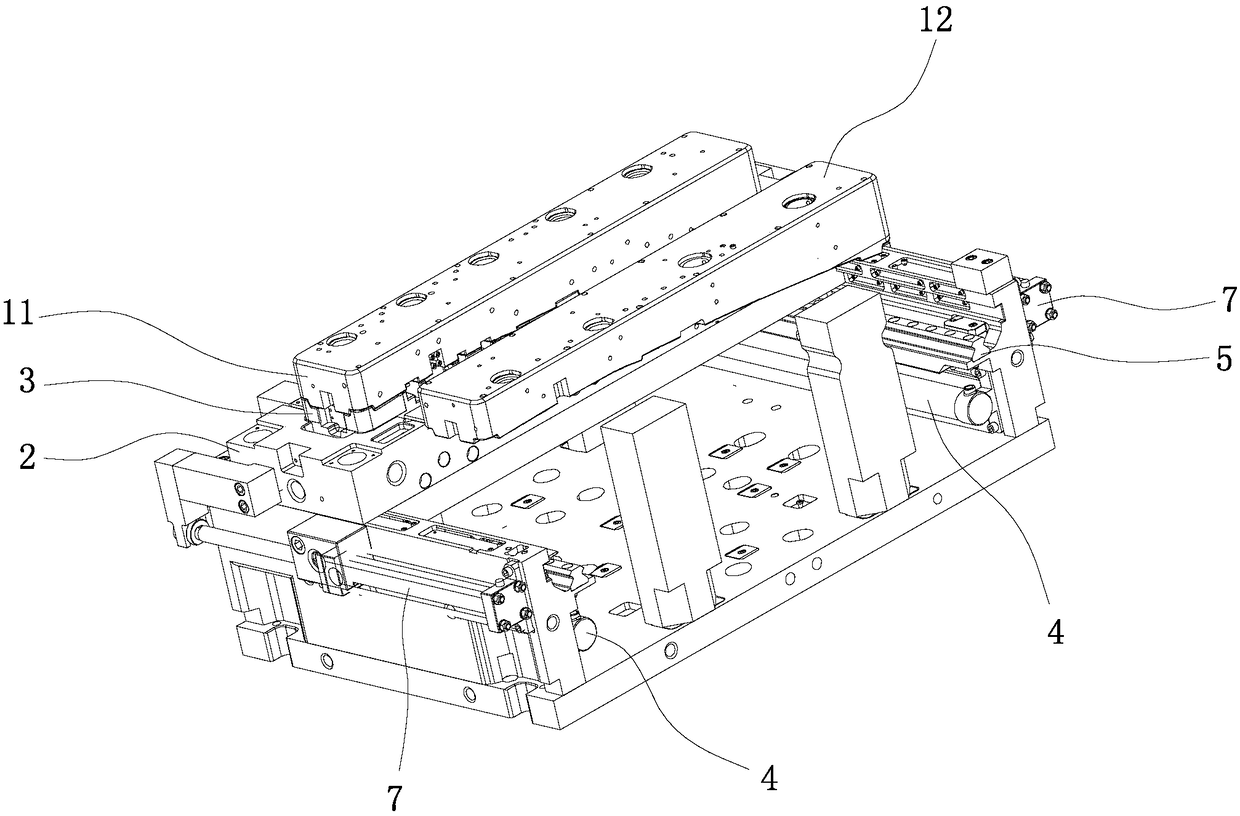

Production process of movable arm of forklift loader/loading machine and fine processing fixing tooling of movable arm

ActiveCN103464985ASimple structureNo wearPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention relates to a production process of a movable arm of a forklift loader / loading machine and a fine processing fixing tooling of the movable arm. The fixing tooling comprises a base, a main support frame and four fixing mechanisms, wherein the main support frame and the four fixing mechanisms are assembled on the base, a rocker arm connecting hole of the movable arm is assembled in the top of the main support frame through a pin haft, and the four fixing mechanisms are respectively used for fixing the four arm ends of the movable arm. According to the production process, the formed movable arm is obtained after the materials are manufactured through the work procedures of numerical control cutting, point welding, full welding, correction, coarse and fine processing and the like. The technical scheme provided by the invention is adopted for preparing the movable arm, the coaxiality of corresponding holes in the movable arm is effectively improved, the form and location tolerance of the movable arm is small, the rejection rate is effectively reduced, the product quality is also perfectly ensured, the problem that the form and location tolerance correction dimension precision cannot be ensured due to the welding deformation quantity of the original process is avoided, the dependence on experienced workers with special skills in the production and service processes is also reduced, the production efficiency is effectively improved, and the production cost is reduced.

Owner:QUANZHOU WEISHENG MECHINE DEV

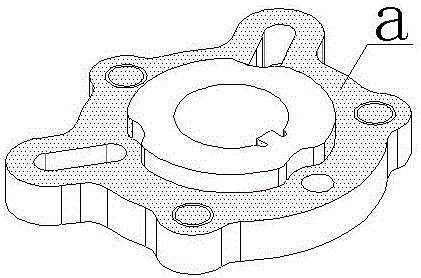

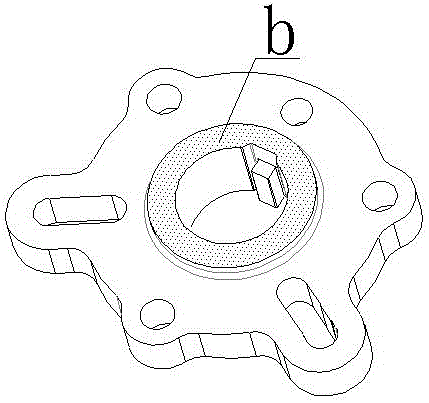

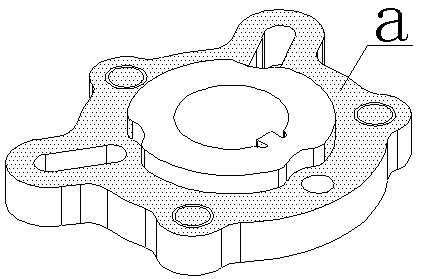

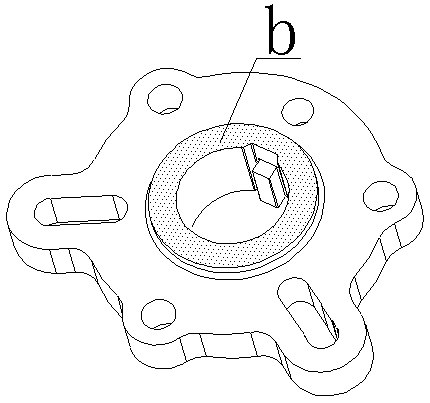

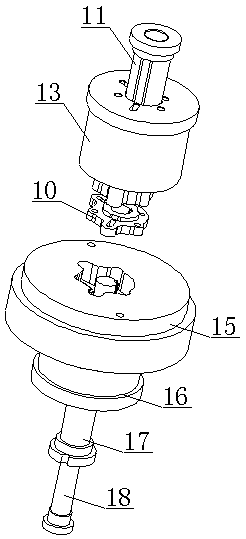

Camshaft toothed wheel hub for automobile engine and powder metallurgical preparation method for camshaft toothed wheel hub

ActiveCN106041094AReduce the amount of processingImprove shift outputTransportation and packagingMetal-working apparatusCamMachining

The invention discloses a camshaft toothed wheel hub for an automobile engine and a powder metallurgical preparation method for the camshaft toothed wheel hub. The method comprises the following steps: S101, preparing materials; S102, pressing and forming; S103, sintering blank; S104, refining and processing; S105, performing steam treatment; and S106, detecting and packaging. The method is linked up orderly, is fewer in processes, and has a material utilization rate higher than 95%. The camshaft toothed wheel hub obtained by the method is less in machining amount, is high in output per shift and is good in consistency, so that the product manufacturing cost is reduced by 50% when various performance requirements of the camshaft toothed wheel hub are met.

Owner:马鞍山市华东粉末冶金厂

Bearing alloy surface high-frequency impact processing method

The HF impact machining process for the surface of alloy bearing includes: fixing the HF impact head in the cutter holder of a vertical lathe and the bearing workpiece on the rotary table of the vertical lathe; and starting the HF impact head to impact the inner and outer surfaces of bearing bush in the frequency of 20-30 KHz and impact amplitude of 30-50 microns. The present invention has the advantages of capacity of decreasing the number of fine machining equipment, short technological process, high machining precision and long service life.

Owner:DALIAN METALLURGICAL BEARING

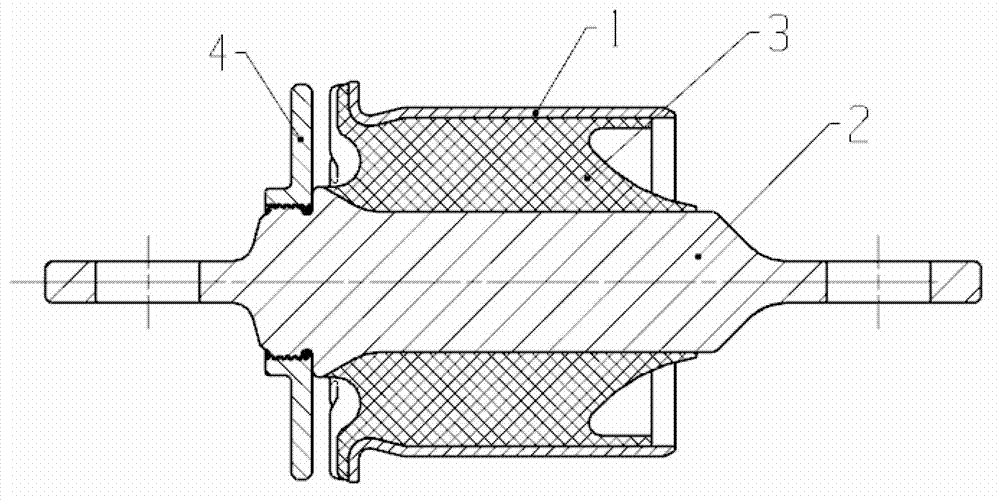

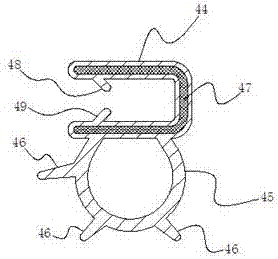

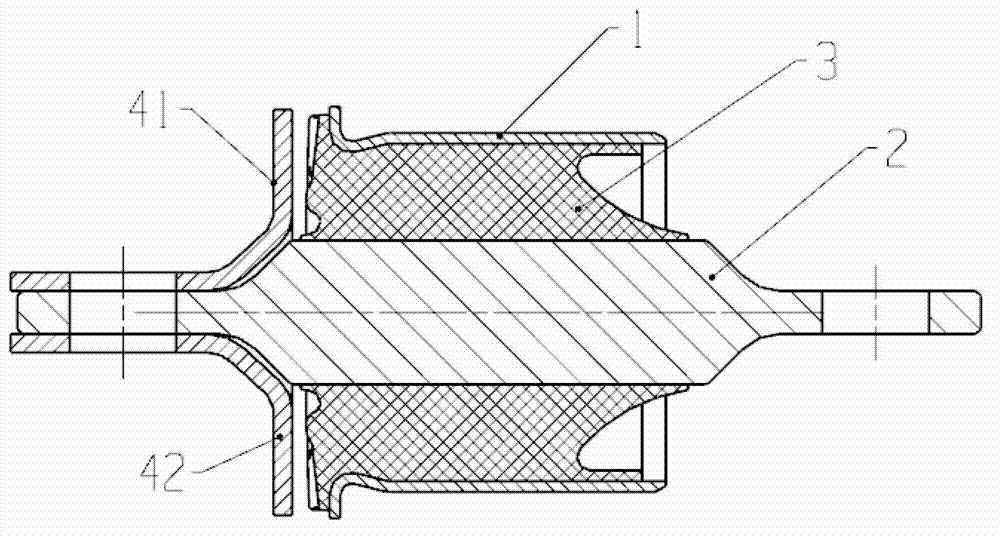

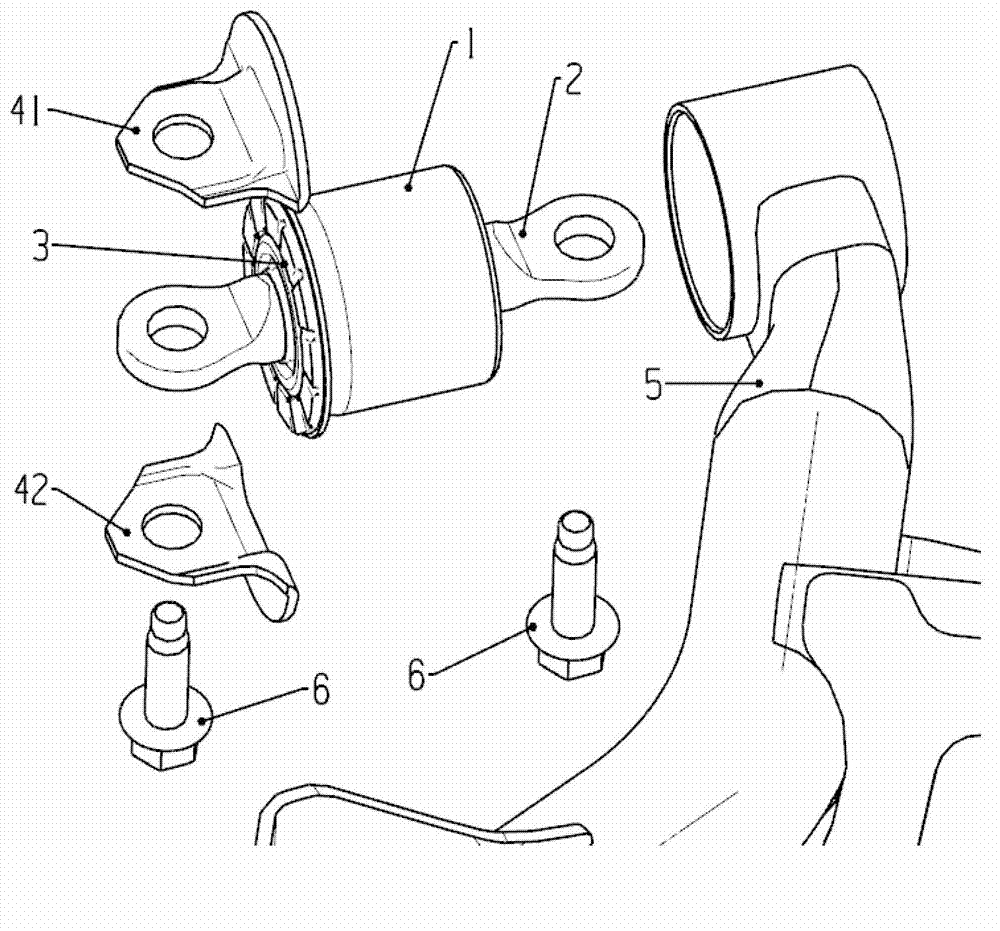

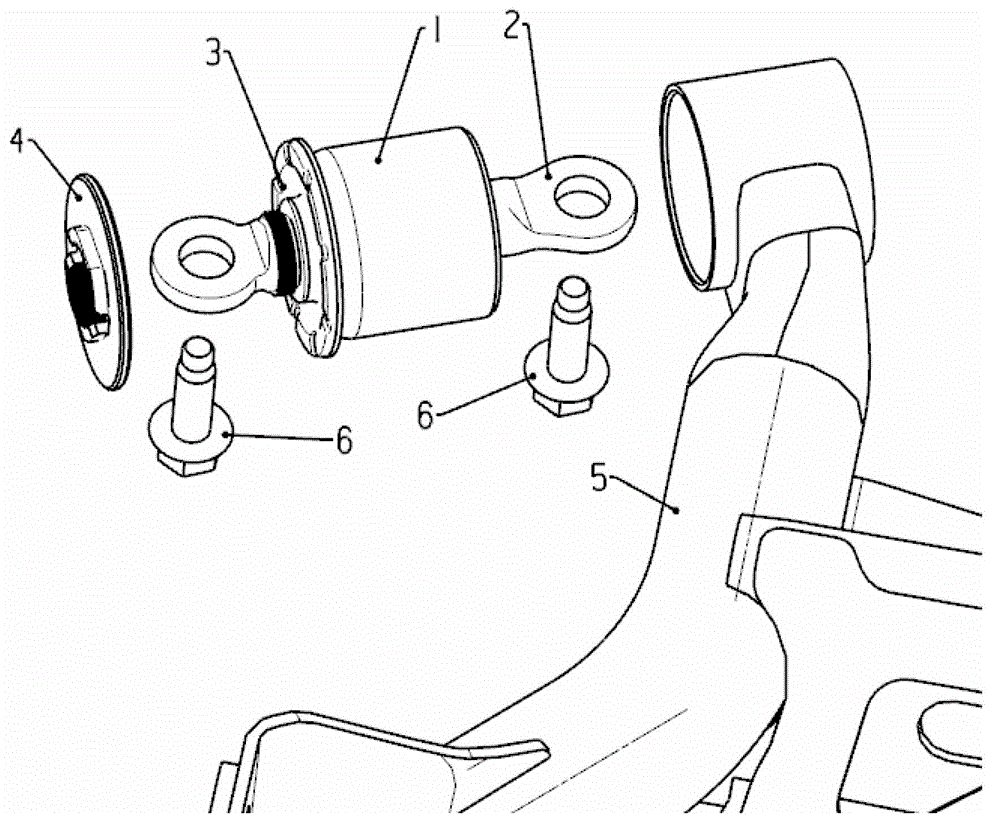

Torsion beam bush component and production and mounting method thereof

InactiveCN102865323AImprove performanceImprove reliabilityRubber-like material springsRubber materialInterference fit

A torsion beam bush component comprises a tubular bush assembly with mounting support lugs and a limit ring at one end of the tubular bush assembly. The tubular bush assembly comprises an outer bush, an integrated axial inner bush and an integrated part integrally vulcanized by rubber materials. The integrated part is filled into an axial annular space between the outer bush and the integrated axial inner bush. The integrated axial inner bush is an integrated part comprising an inner bush and the supports lugs at two ends. The limit ring is flange plate with a threaded inner hole. During use, the tubular bush assembly is pressed to a torsion beam through interference fit, and the limit ring is integrally connected with the integrated axial inner bush mounted on the torsion beam in a threaded manner. A torsion beam suspension using the torsion beam bush component has improved assembling precision, overall performance and reliability. In addition, the torsion beam bush component is convenient to machine and mount and low in cost.

Owner:柳州孔辉汽车科技有限公司

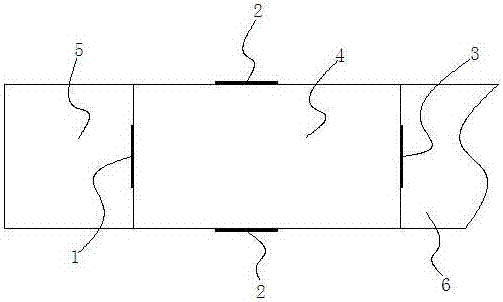

Manufacturing method of rapid power concentrated rail motor coach motor car carbon fiber locomotive door

ActiveCN107187066AReduce weightSmall shape and position toleranceDoor arrangementDomestic articlesWork in processEngineering

The invention discloses a manufacturing method of a rapid power concentrated rail motor coach motor car carbon fiber locomotive door. According to the manufacturing method, an outer panel, an inner panel and a door body framework are manufactured through carbon fiber materials in a die pressing integrated molding manner and are then pasted together. Pasting includes the steps that (1) the position between the outer panel and the door body framework is smeared with epoxy resin adhesive; (2) the outer panel and the door body framework are clamped together and are then sent to an oven to be backed, and therefore the outer panel and the door body framework are completely pasted; (3) an acoustic insulating material is taken out from the oven to be placed into the door body framework; (4) the position between the inner panel and the door body framework is smeared with epoxy resin adhesive; (5) the outer panel, the inner panel and the door body framework are clamped together to form a locomotive door semi-finished product, and then the locomotive door semi-finished product is sent to the oven to be baked; and (6) after baking is completed, the locomotive door semi-finished product is taken out from the oven and is subject to follow-up machining treatment, and a finished product is formed. According to the manufacturing method, the light design requirement is met, and the manufacturing accuracy is high.

Owner:TIANYI IND HUNAN RAILWAY PROFESSIONAL TECH COLLEGE

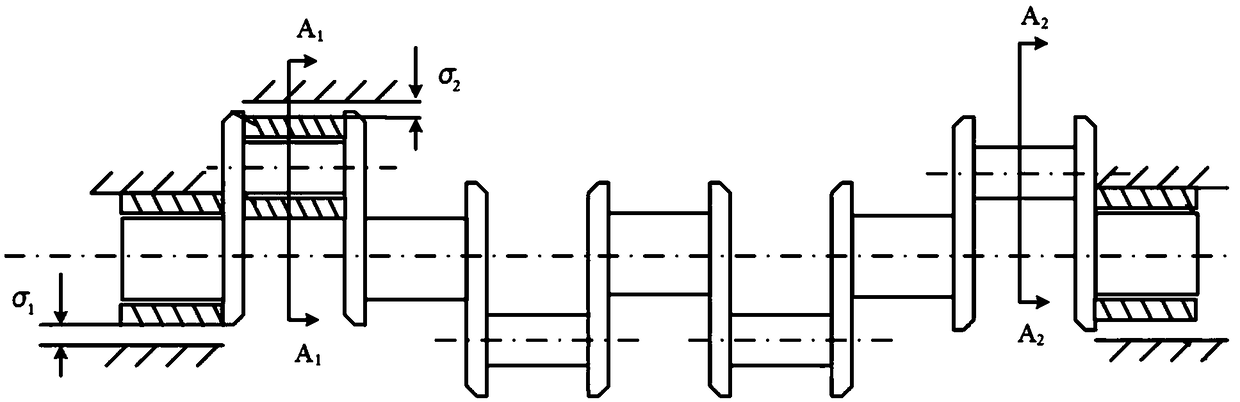

Processing method of power senary shunting rotary frame of large-scale vertical mill reducer

The invention discloses a processing method of a power senary shunting rotary frame of a large-scale vertical mill reducer. A power senary shunting rotary frame with the porous system and parallel hole system processing accuracy standard of DIN3961 10a27 and the surface roughness of RaO.4 is adopted in the method. The method comprises the processes of rough finishing, heat treatment, multi-procedure semi-finishing, simultation processing, fine finishing and finishing. The method is a novel processing technology of a high precision porous system workpiece, which combines an ordinary machine tool with a precision numerical control machine, combines a traditional technological method with a new technological method, i.e. a computer simulation technology, combines an ordinary technological process with a special technological process, and has the advantages of less geometric tolerance, high processing accuracy, uniform planet hole distribution and low noise after assembly.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Method and mould for manufacturing floor spring rotating shaft head

ActiveCN102225503ABeautiful appearanceReduce manufacturing costExtrusion diesMechanical engineering technologyExtrusion

The invention provides a method and a mould for manufacturing a floor spring rotating shaft head, belonging to the technical field of mechanical engineering. The method solves the problems such as low production efficiency, high cost, weak market competitive power of products and the like in the existing method for manufacturing a rotating shaft. The method for manufacturing the floor spring rotating shaft head includes the steps of blank tooling, cold extrusion, surface treatment, etc. A mould for forming the floor spring rotating shaft head comprises a lower die, an upper die, a pedestal, aradial positioning mechanism and an axial positioning mechanism. A mould for trimming concave shoulder bottom surfaces of the floor spring rotating shaft head comprises a positioning mould and a forming mould, wherein flattening surfaces capable of corresponding to the concave shoulder bottom surfaces in position and structure one by one are arranged on one end of the forming mould, and a placinghole through which a workpiece head can penetrate is also arranged on the forming mould. The floor spring rotating shaft produced by the manufacturing method has the advantages of being low in production cost, beautiful in appearance and strong in market competitive power. The mould for forming the floor spring rotating shaft head has the advantages of being reasonable in design and convenient inuse.

Owner:玉环市江洲机械有限公司

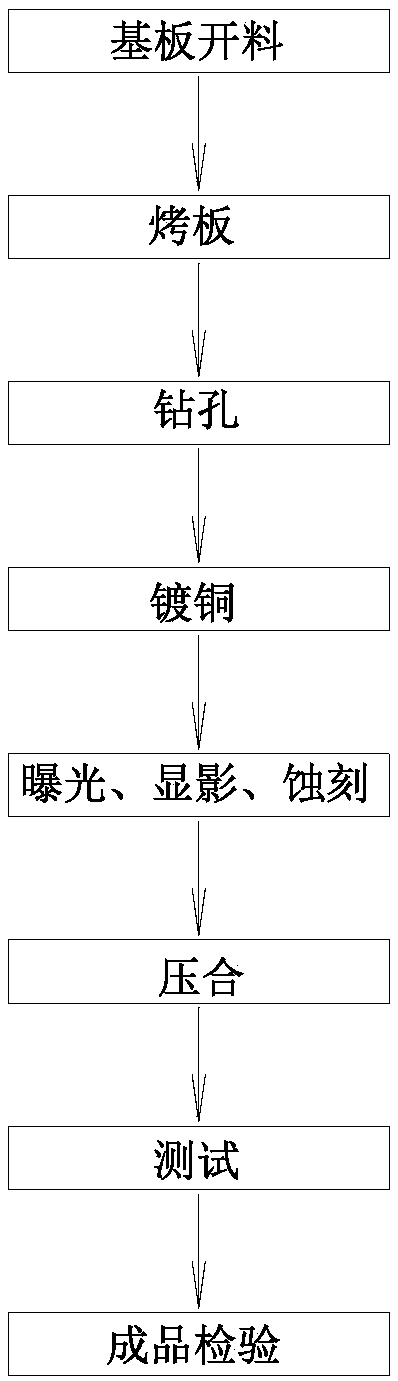

Production process of FPC board

InactiveCN108513461AQuality assuranceGuaranteed efficiencyMultilayer circuit manufactureCooking & bakingCopper plating

The invention discloses a production process of an FPC board. The production process comprises the steps of selecting substrates, stacking 2-13 substrates for baking at 100-140 DEG C for 45-75min; drilling via holes and positioning holes in the substrates and coating the substrates with copper; humidifying and laminating the substrates and a film and then carrying out exposure, development and etching to obtain front and back circuits separately; and carrying out high-temperature lamination on at least two substrates to obtain a circuit board. The stacking density and the substrate baking temperature and time are comprehensively considered, so that the substrate baking quality and the substrate baking efficiency are ensured, and manpower and material resources are saved; the substrates andthe film are tightly fitted when laminated to remove gaps and bubbles, and the film does not locally tilt or deform, so that the exposure accuracy is good, the geometrical tolerance of the circuits in development and etching is minimum, and the circuits are clear and free of corner deficiency.

Owner:珠海智锐科技有限公司

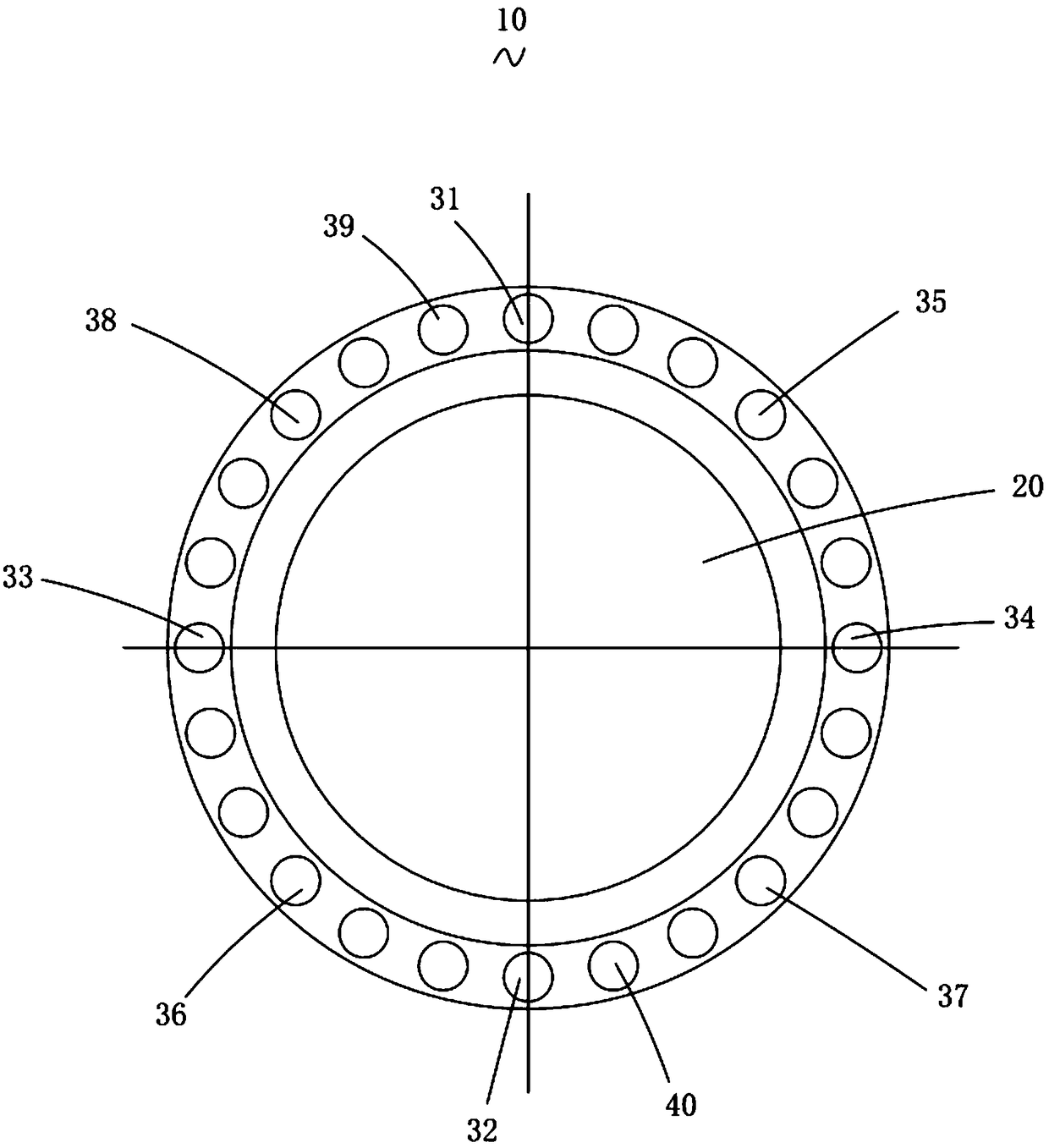

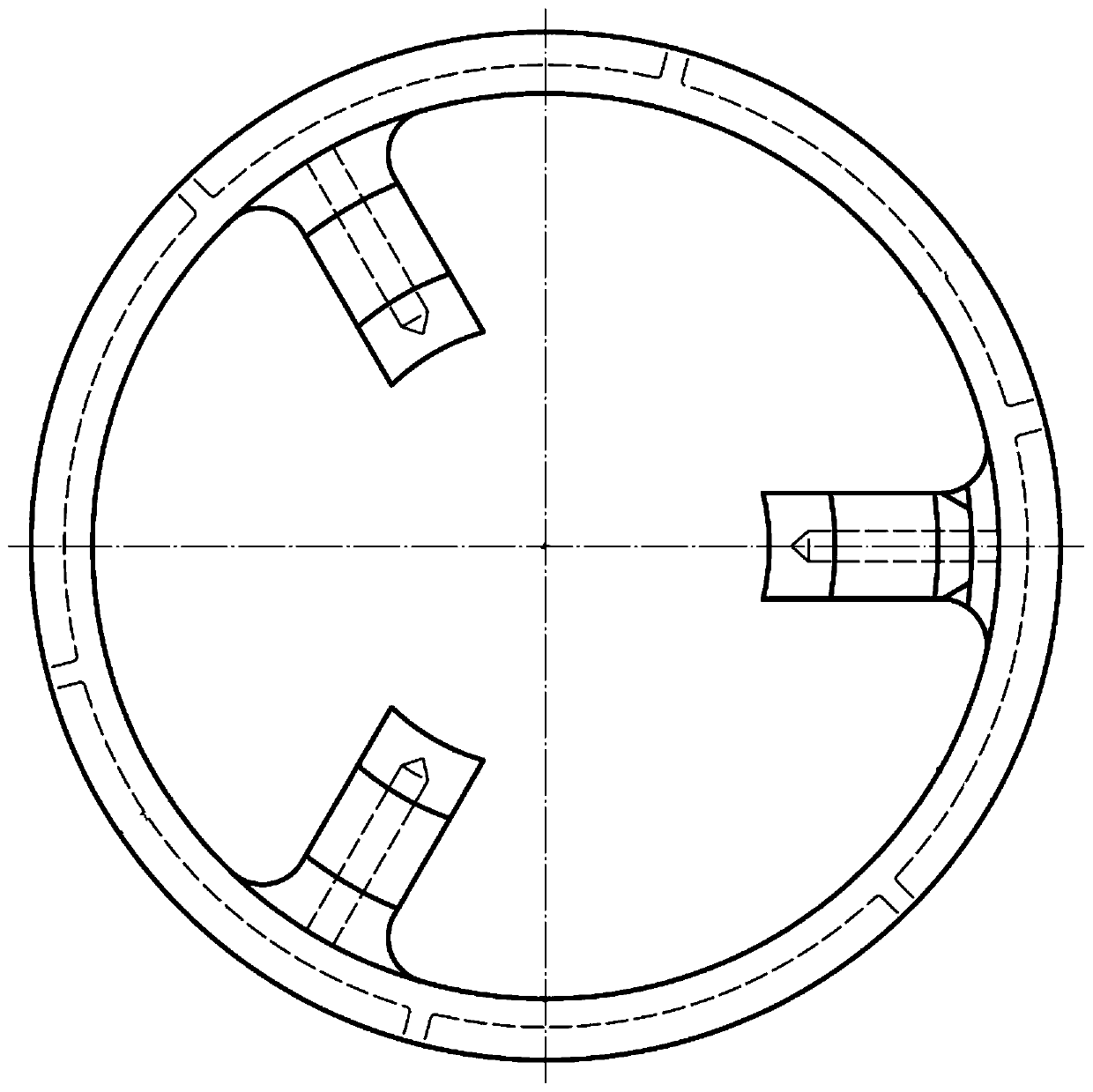

High precision hole system machining method

ActiveCN108161065AConsistent deformationEnsure balanceFeeding apparatusBoring/drilling componentsEngineeringDrill

The invention relates to a high precision hole system machining method, and belongs to the technical field of machining. According to the method, a manner that a drill and a boring cutter are combinedfor machining holes is used for machining a hole system on a workpiece, the drill is used for hole drilling in advance firstly, the hole diameters of the holes drilled in advance are 2 / 3 of the target diameter of a to-be-machined hole, then the boring cutter is used for later machining of the hole system, and meanwhile, an intermittent and jumpy method is used for machining the hole system; and specifically, the first hole system is machined firstly, a second hole located on the same diameter of a center through hole of the workpiece together with the circle center of the first hole is machined, by parity of reasoning, a next hole needing to be machined serves as a hole between two machined adjacent holes, the distances between the hole needing to be machined and the two adjacent holes are equal, the hole system is machined in this way, and therefore the balance of the workpiece in the rotating process can be guaranteed, the form and location tolerance of the overall workpiece hole system is reduced, and the machining accuracy of the workpiece is improved.

Owner:NINGXIA TIANDI BENNIU IND GRP +1

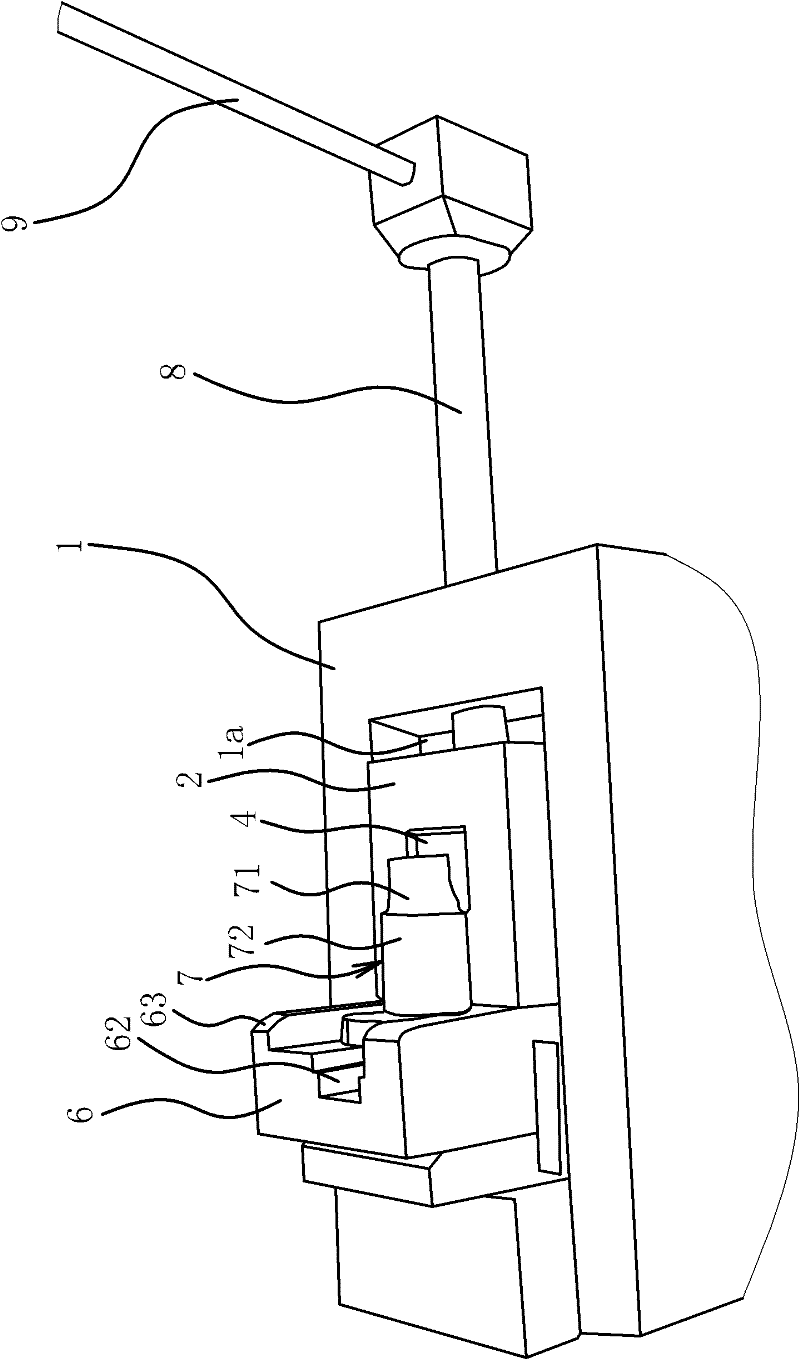

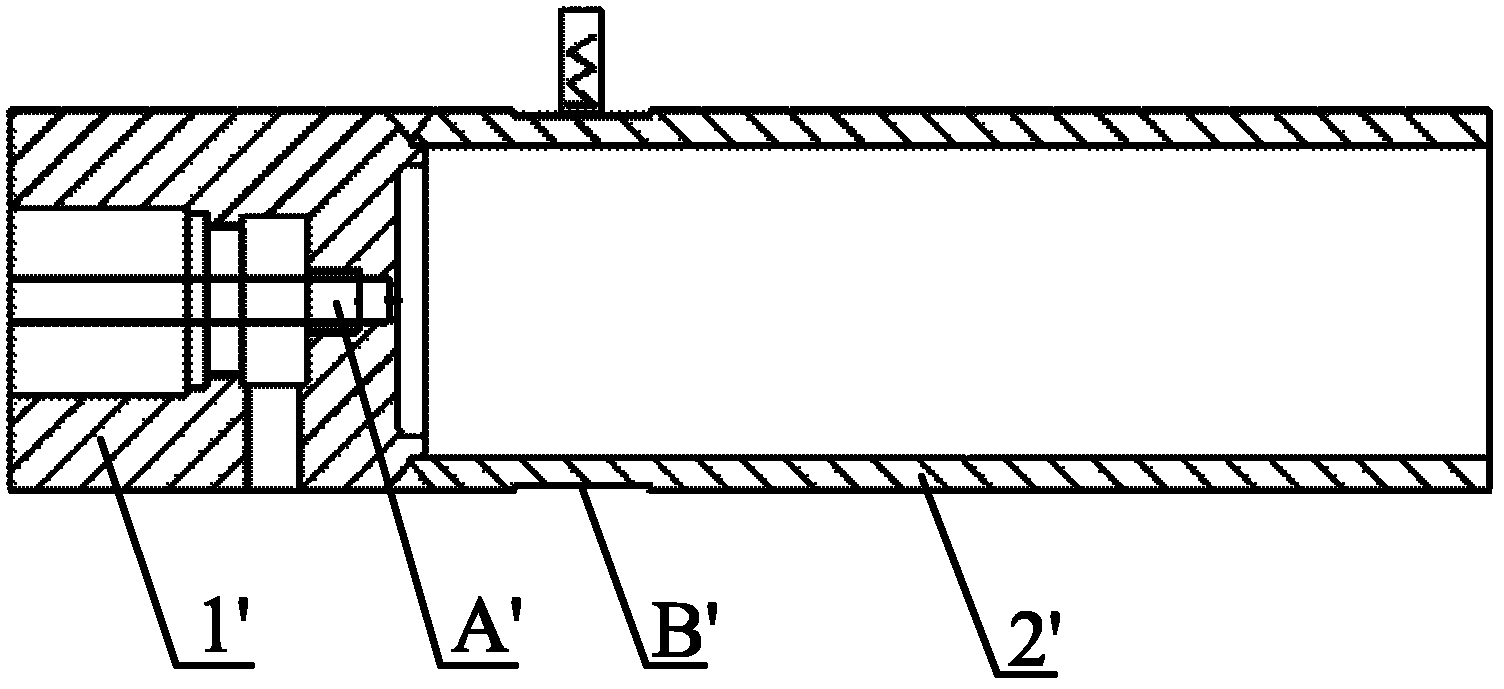

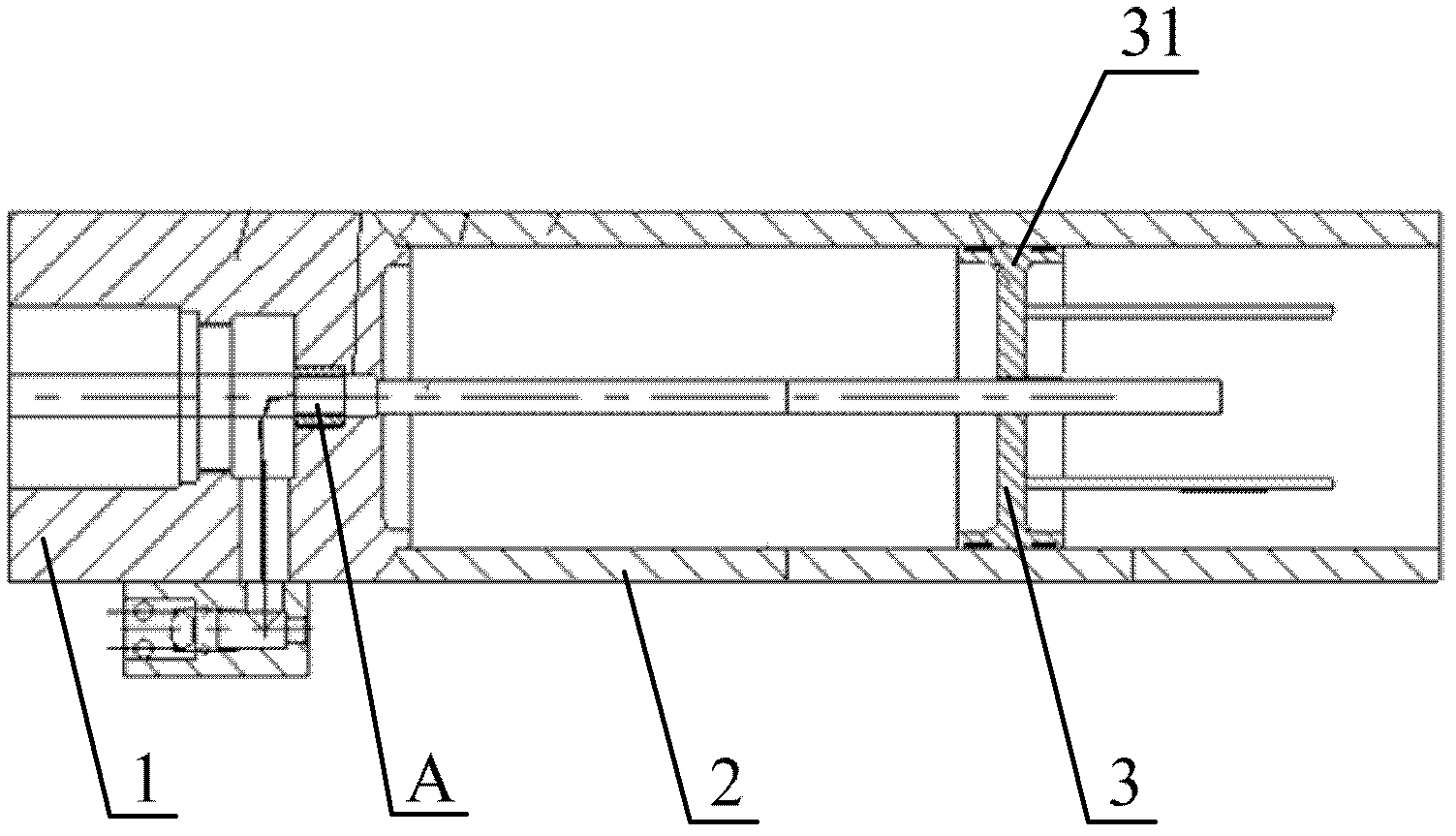

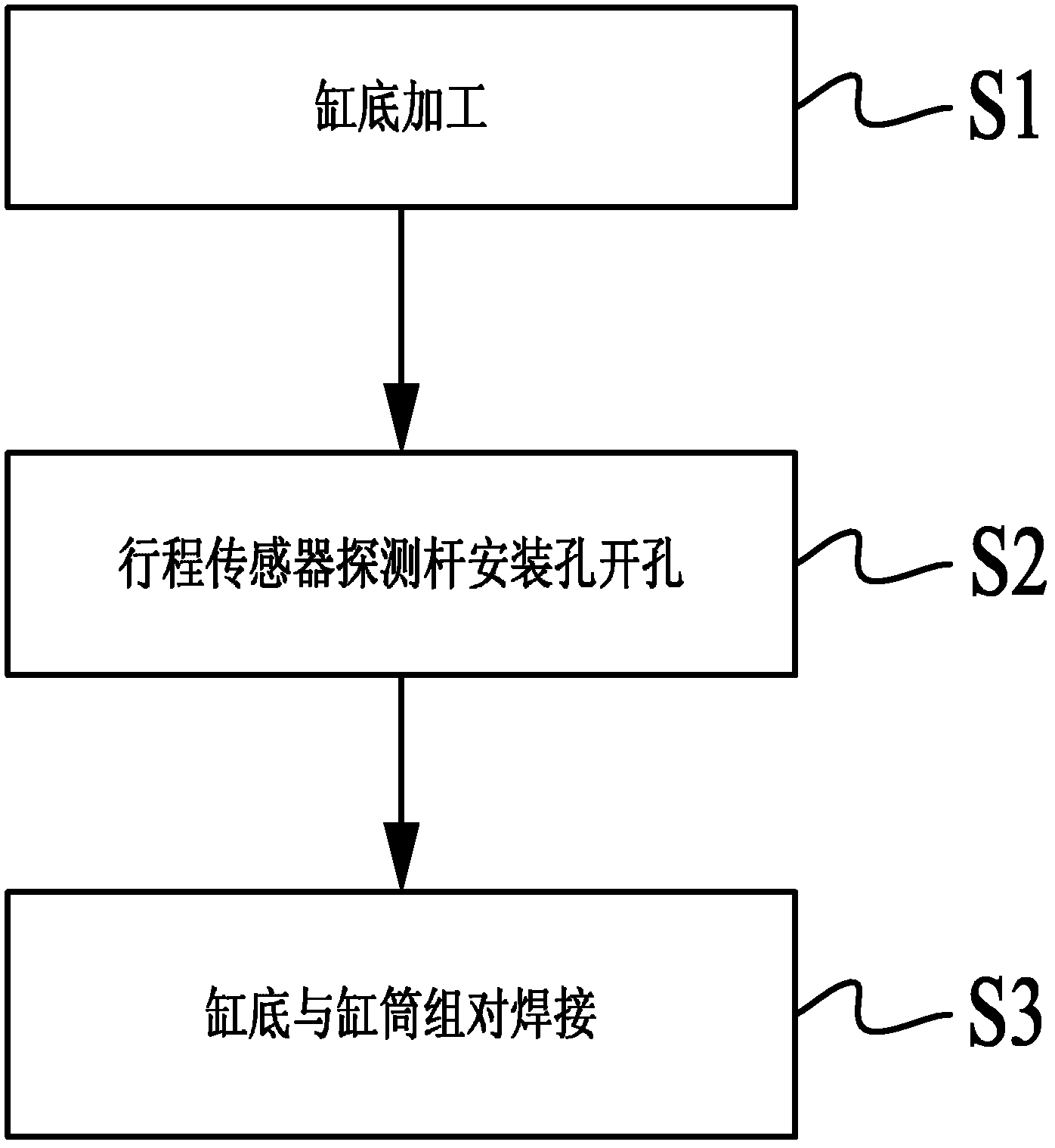

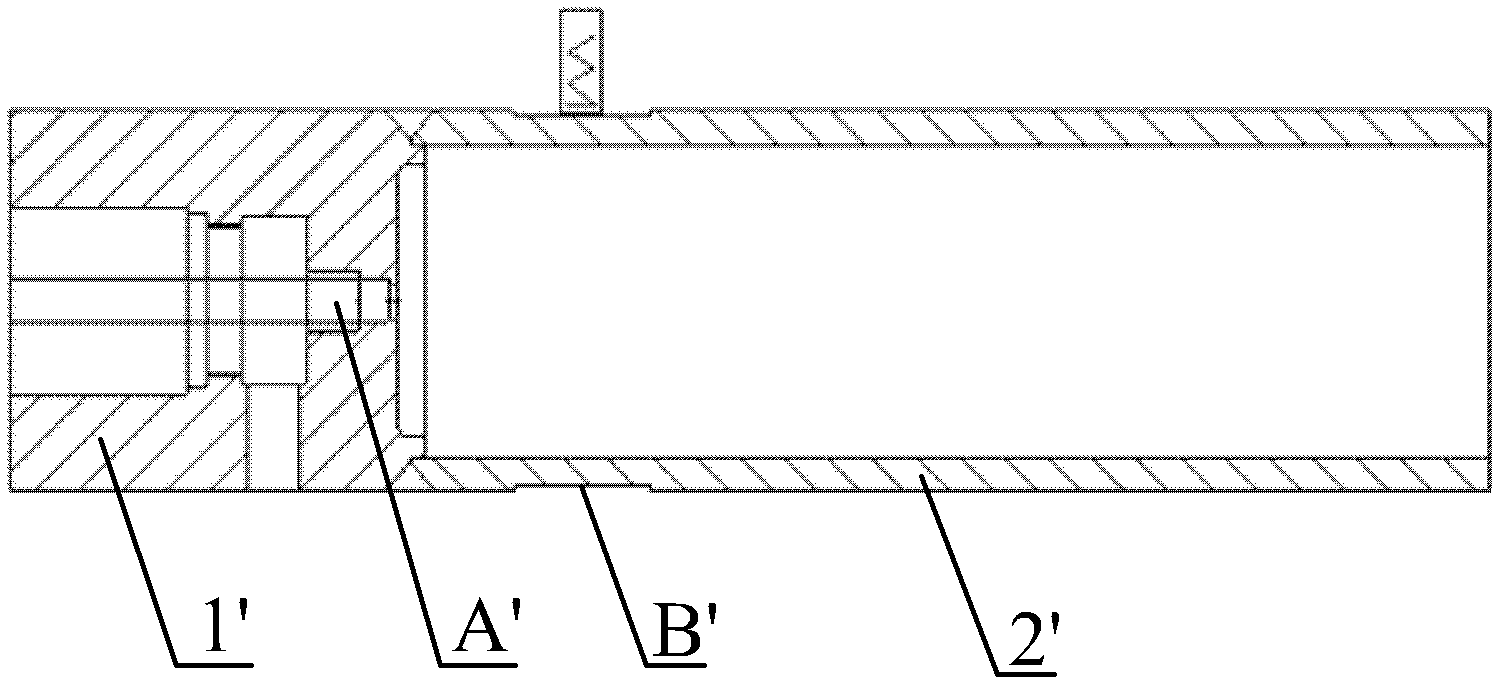

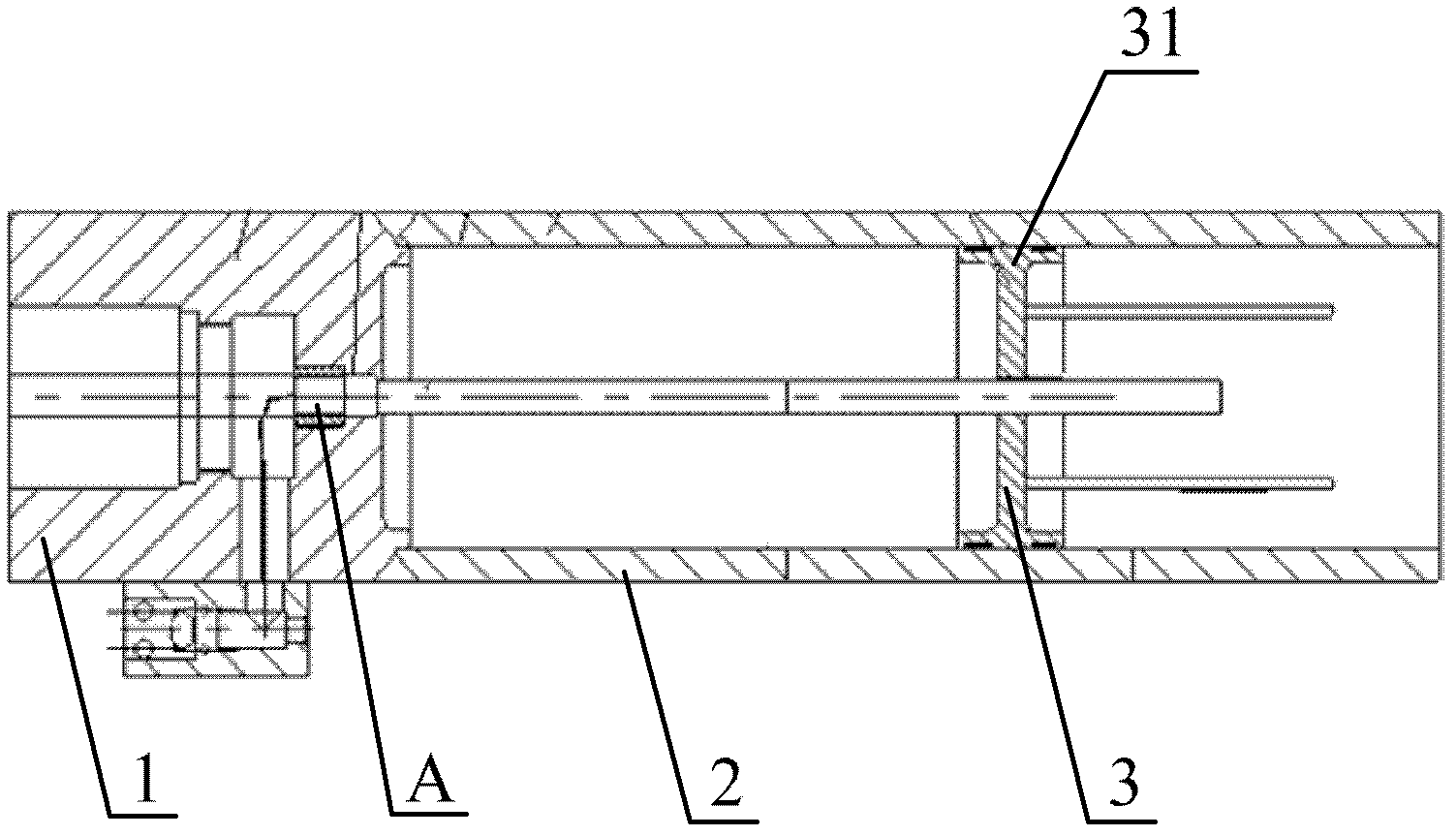

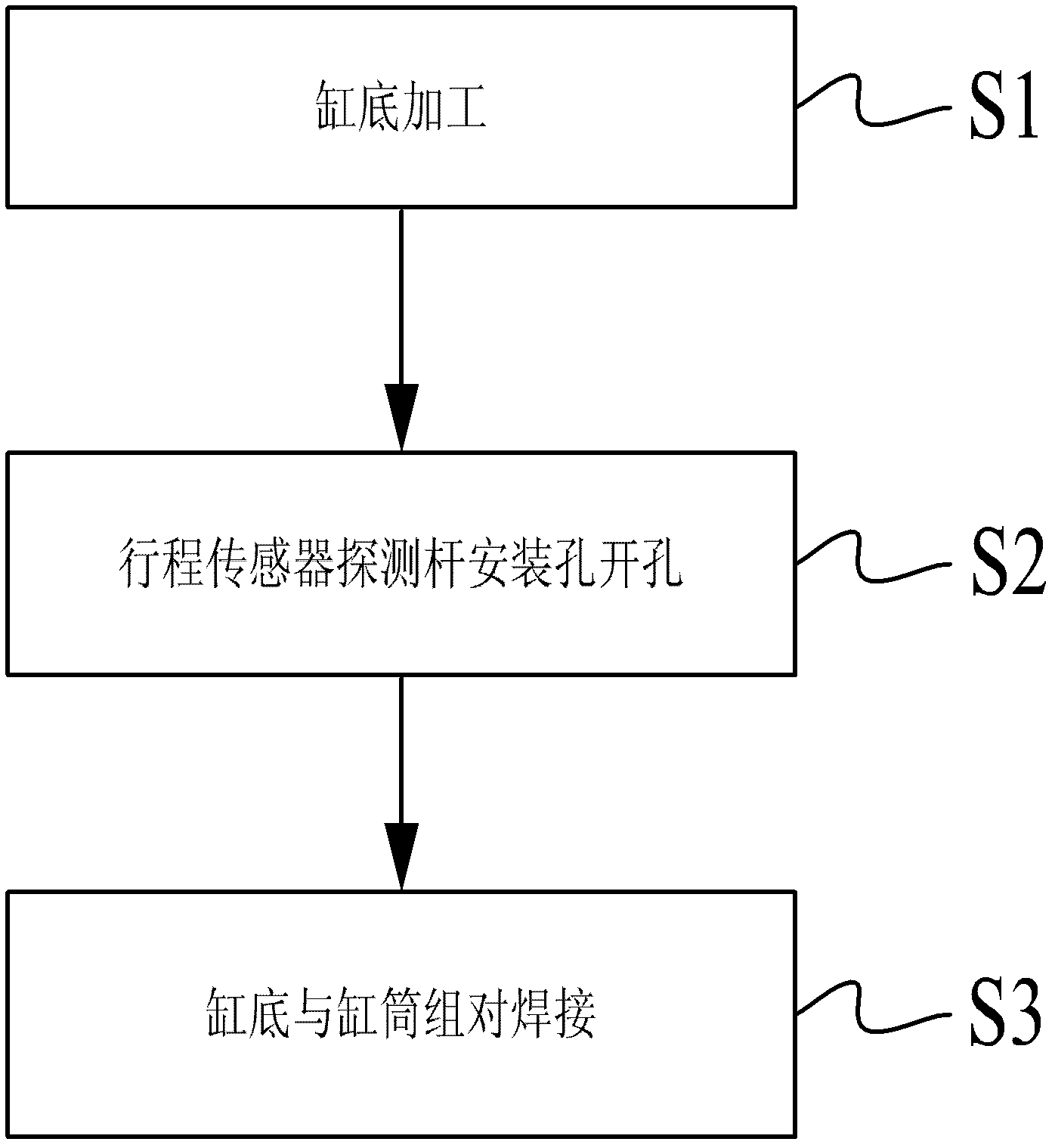

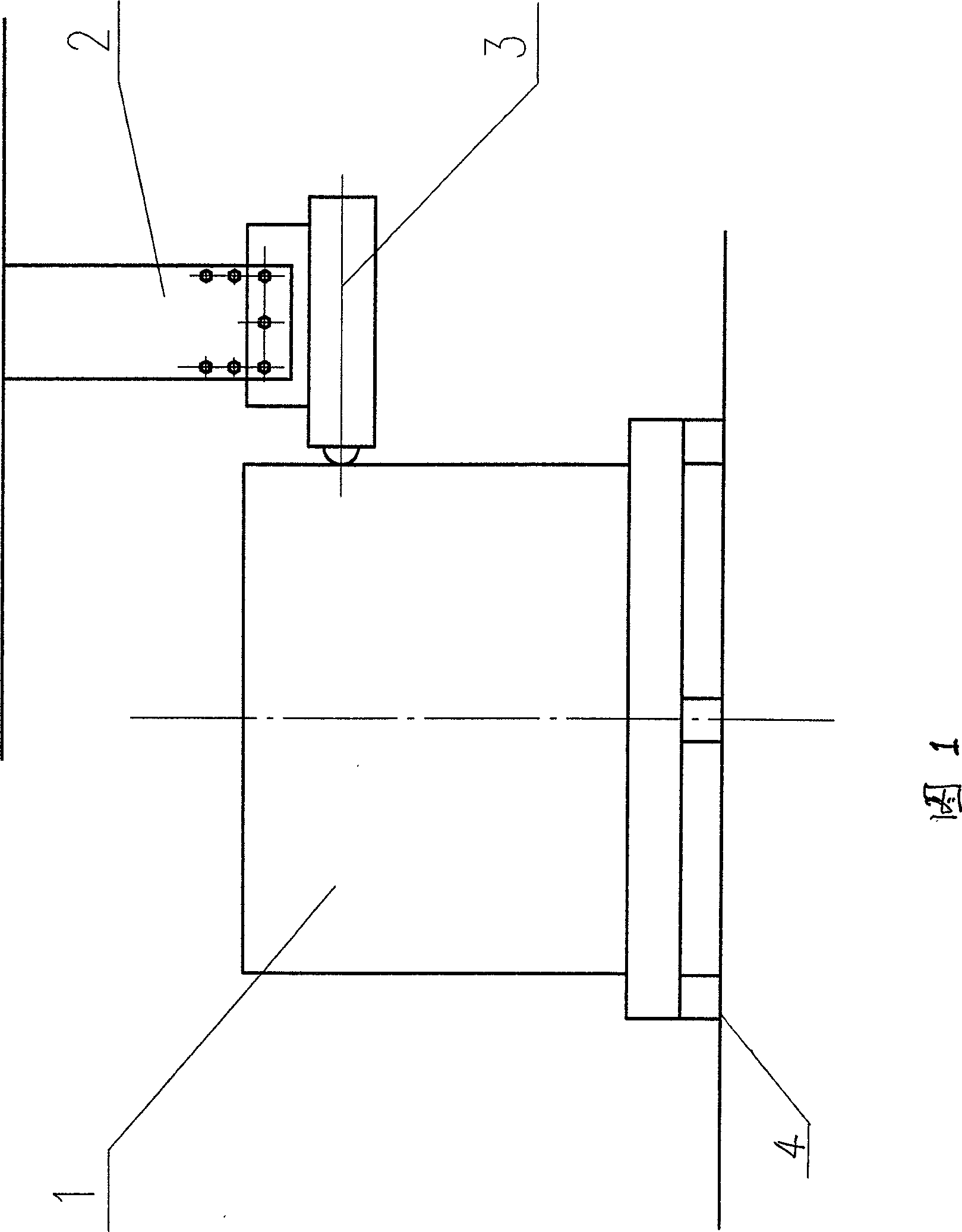

Hole opening method for jack cylinder bottom and auxiliary tool for welding

ActiveCN102489949ASmall sizeSmall shape and position toleranceWelding/cutting auxillary devicesAuxillary welding devicesPosition toleranceButt welding

The invention discloses a hole opening method for a jack cylinder bottom and an auxiliary tool for welding. A stroke sensor detection rod installation hole is processed when the cylinder bottom is processed. When the method is used for opening holes at the cylinder bottom, a required hole opening cutter is short, thereby guaranteeing that the size and the form and position tolerance of the stroke sensor detection rod installation hole are small and improving coaxial accuracy of the stroke sensor detection rod installation hole and a cylinder. The invention further provides an auxiliary tool for welding, which is used for locating butt welding between the cylinder bottom of a jack and a cylinder set. Due to the fact that the stroke sensor detection rod detection rod installation hole is processed firstly, the hole is small in the size and the form and position tolerance. Therefore, when the auxiliary tool for the welding is used for datum transformation, error is little. Thus, coaxial degree between the stroke sensor detection rod installation hole and the cylinder is enabled to be high.

Owner:YANKUANG GRP CO LTD

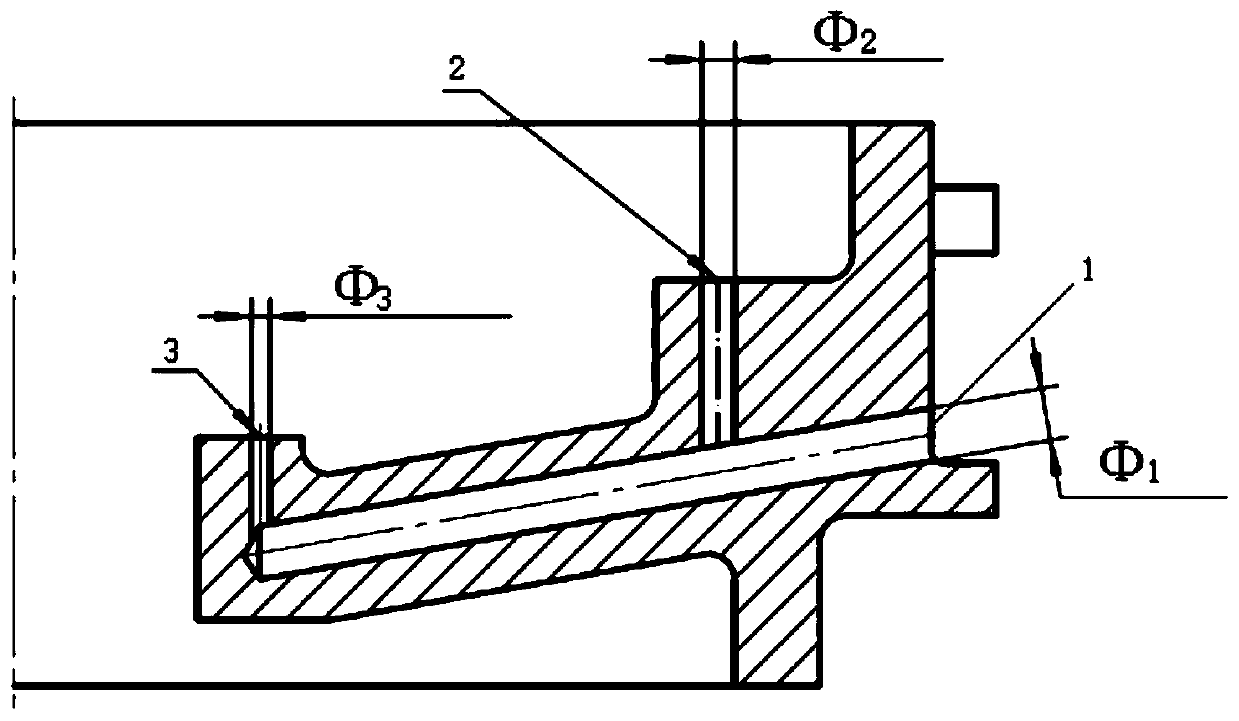

Processing method for improving flow precision of oil injecting ring

The present invention discloses a processing method for improving the flow precision of an oil injecting ring. Drilling and reaming processes are adopted for forming oil injecting holes and oil feeding holes of an oil path, a single-oil-path flow process test is performed, and the diameter phi 1 of one oil feeding hole and the diameters phi 2 and phi 3 of two oil injecting holes, which meet the median flow requirements under the processing precision level of the reaming process are determined; then the oil feeding holes and the oil injecting holes are formed according to the drilling and reaming processes, after all the oil feeding holes and oil injecting holes are formed, the oil path test is performed, a reamer is adopted for polishing the oil injecting holes when the flow test is not qualified, the smaller feeding amount is adopted in polishing, and the whole oil path of the oil injecting holes is completely polished, so that polishing of only the oil path near oil discharging holesof the oil injecting holes is avoided; the better inner hole surface roughness and the smaller geometric tolerance in the oil path are improved, the flow test frequency is greatly reduced, and the problem of part scrapping caused by flow out-of-tolerance is eliminated; and on-time on-demand delivery of the oil injecting ring is ensured.

Owner:AECC AVIATION POWER CO LTD

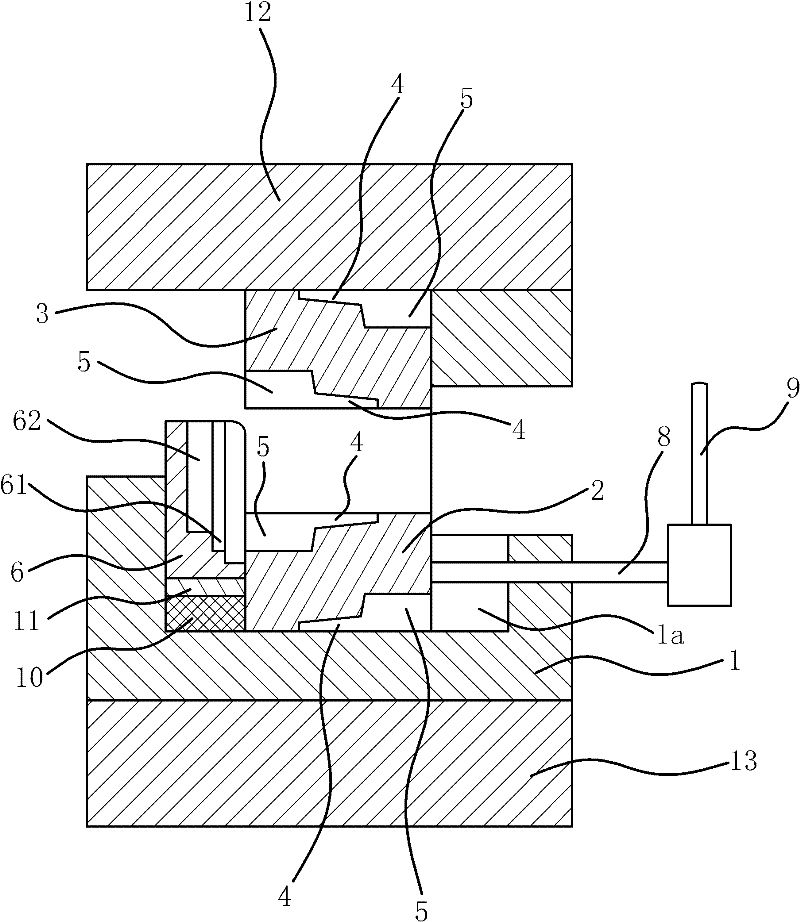

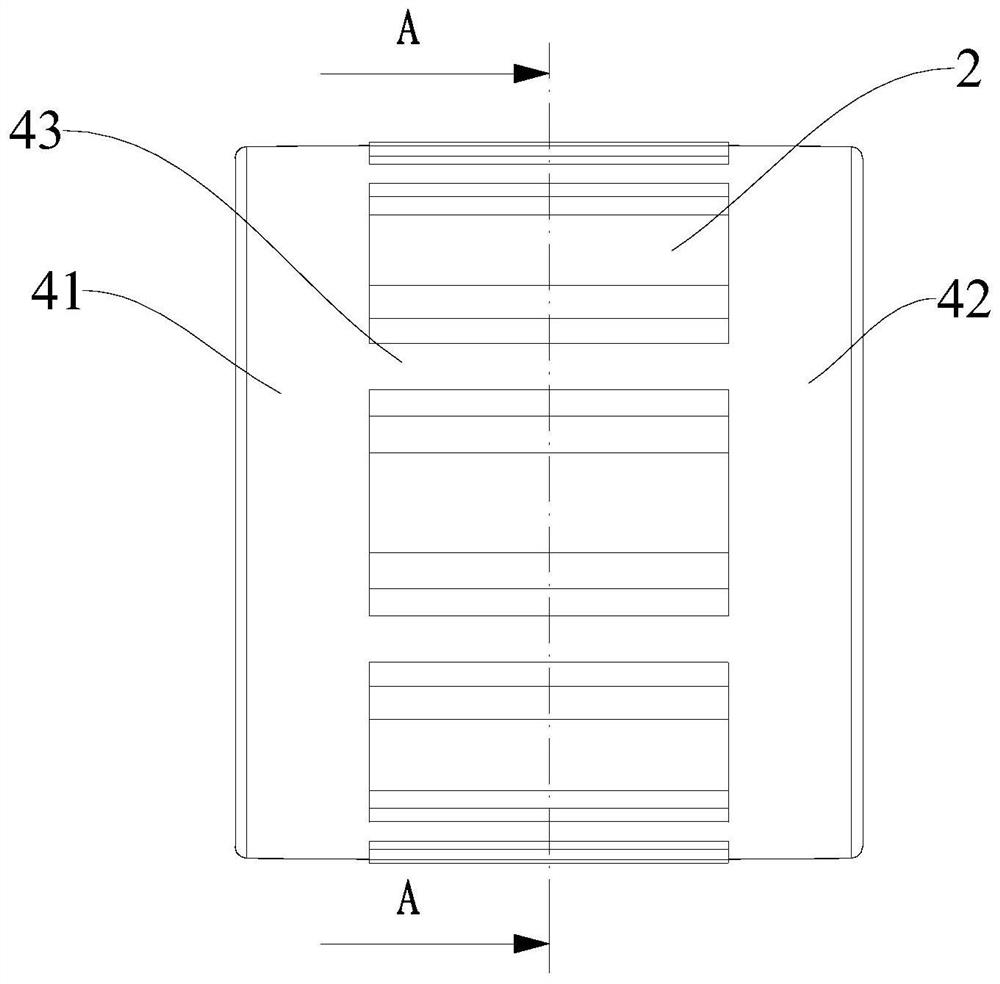

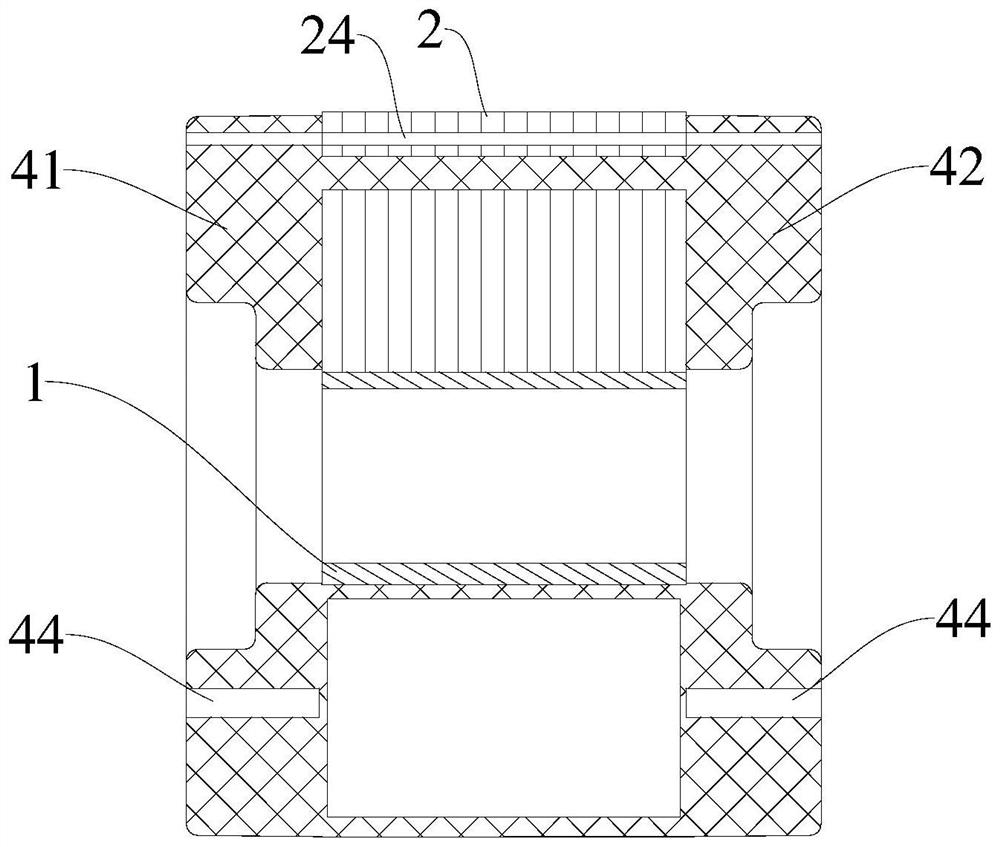

High-precision plastic product forming device

The invention discloses a high-precision plastic product forming device. The high-precision plastic product forming device comprises a support, a movable template, a first front die core and a secondfront die core. The movable template is internally provided with a rear die core. The support is provided with a slide rail used for being in sliding connection with the movable template. The supportor the movable template is connected with a lifting power piece. The movable end of the lifting power piece and the rear die core are both provided with connected first oblique planes. The first oblique planes are gradually heightened in the direction towards the first front die core along the second front die core. The transverse sliding of the movable end of the lifting power piece is used for controlling the rear die core to ascend to be attached to the front die cores and descend to keep away from the front die cores. By means of the oriented transverse sliding of the rear die core along the sliding rail and the oriented vertical sliding of the rear die core along a cavity part of the movable template, the attaching butt joint precision of the rear die core and the front die core is high, dislocation is not prone to occurring, a formed product cannot be crushed and is relatively good in appearance, and the form and location tolerance of the formed product is relatively small; and by means of the characteristics of oblique plane transmission, the power direction is flexibly changed.

Owner:精英模具(珠海)有限公司

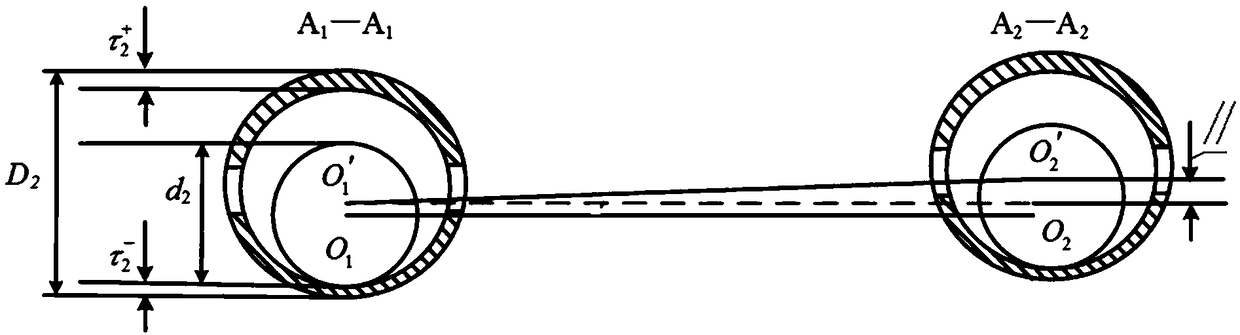

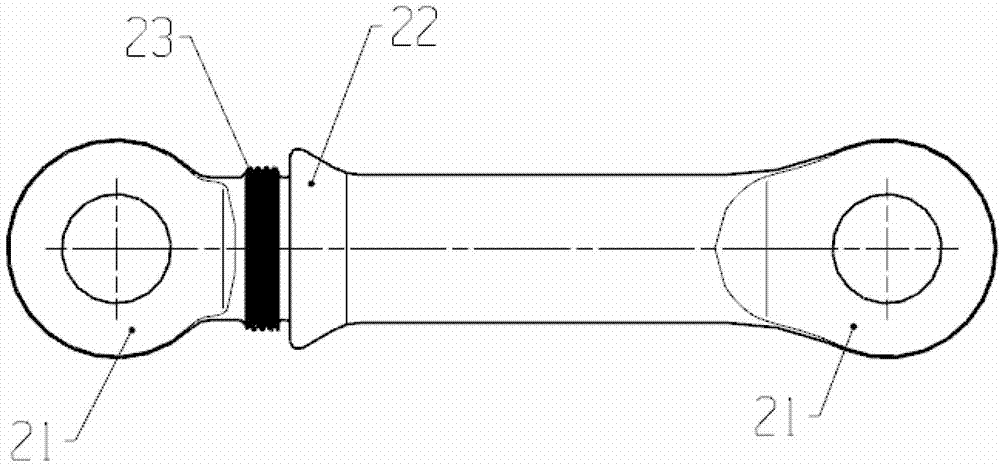

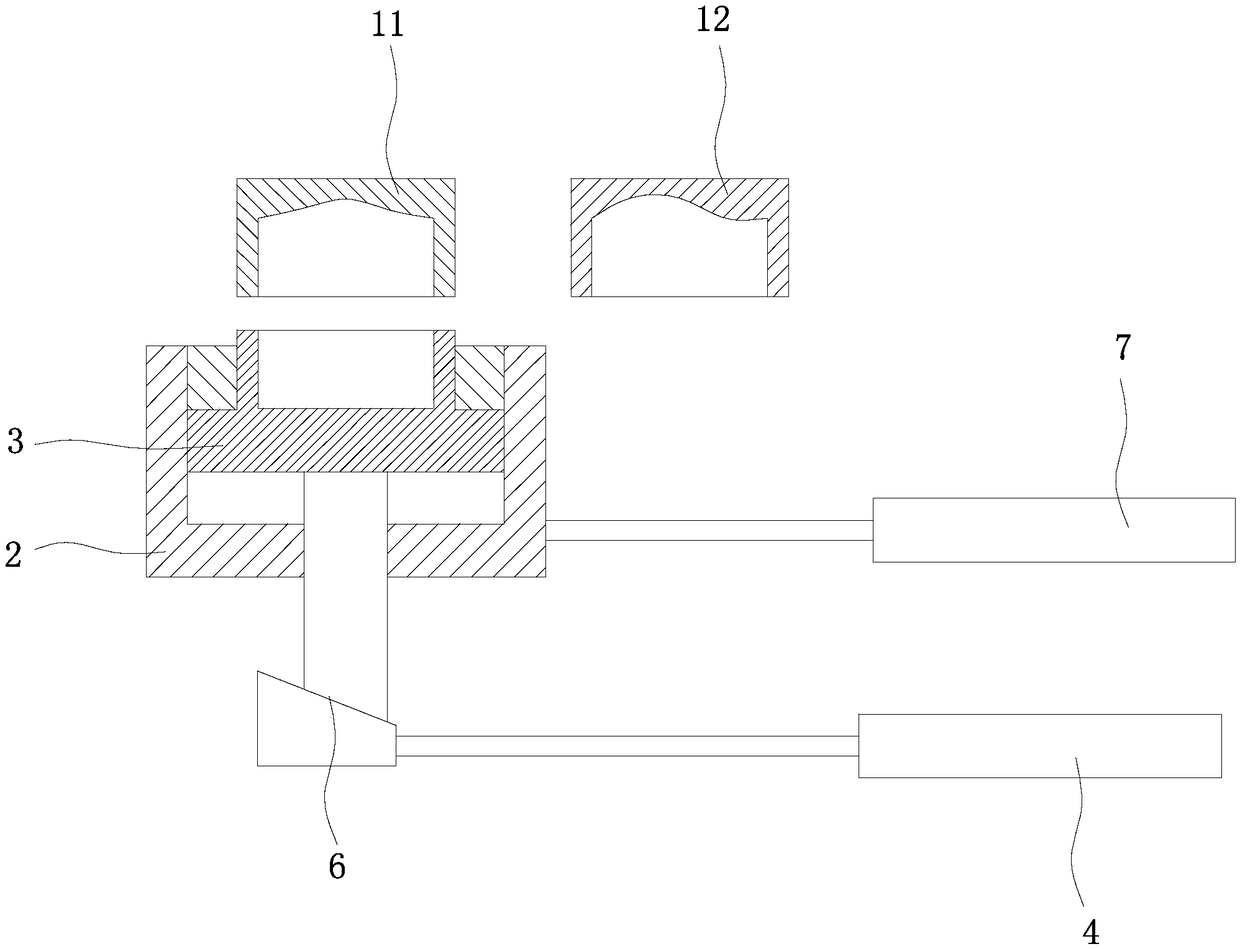

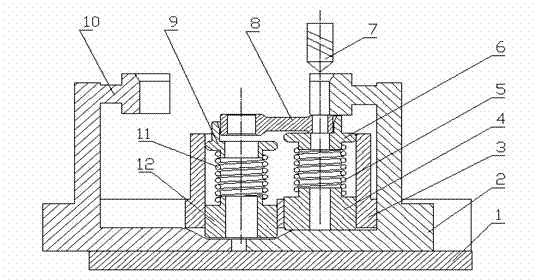

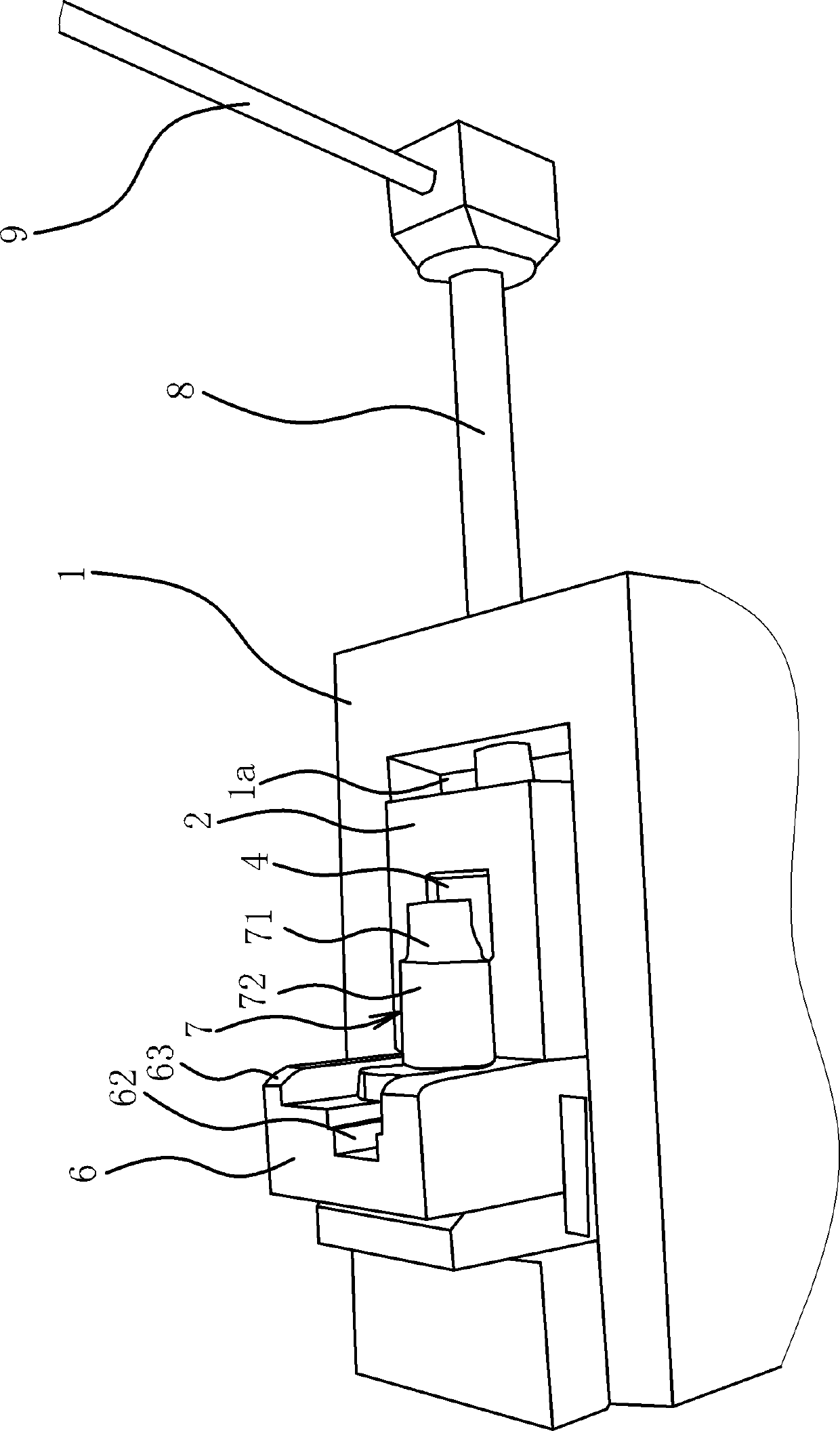

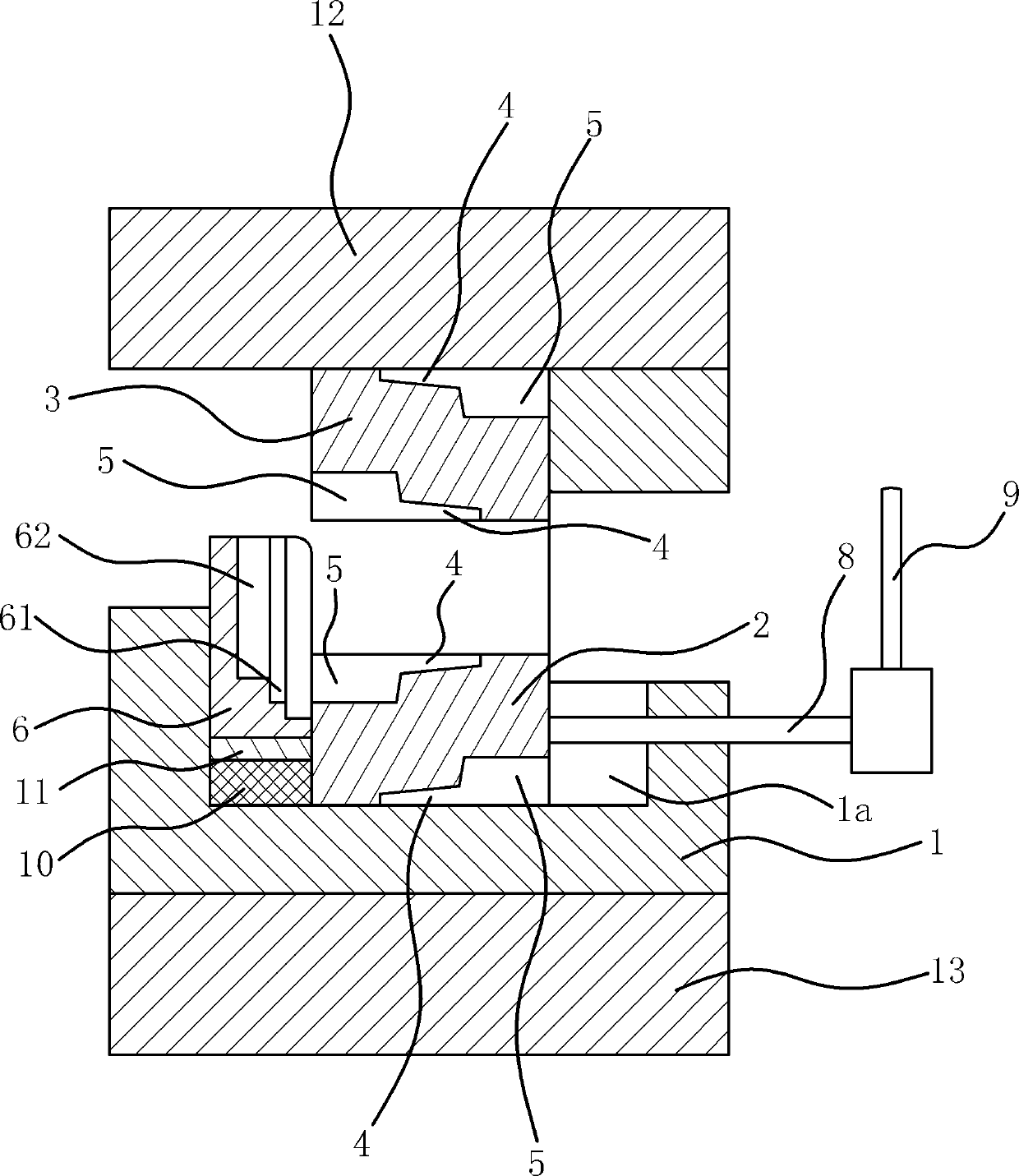

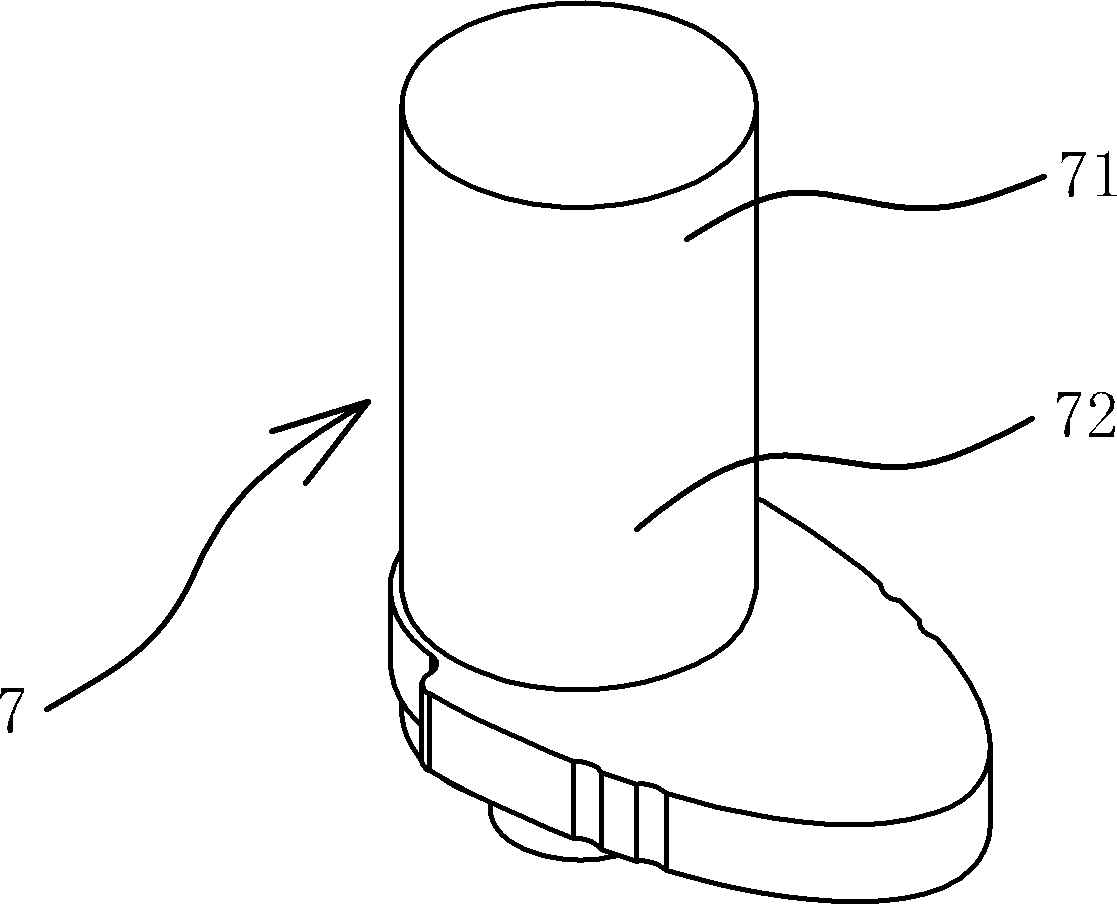

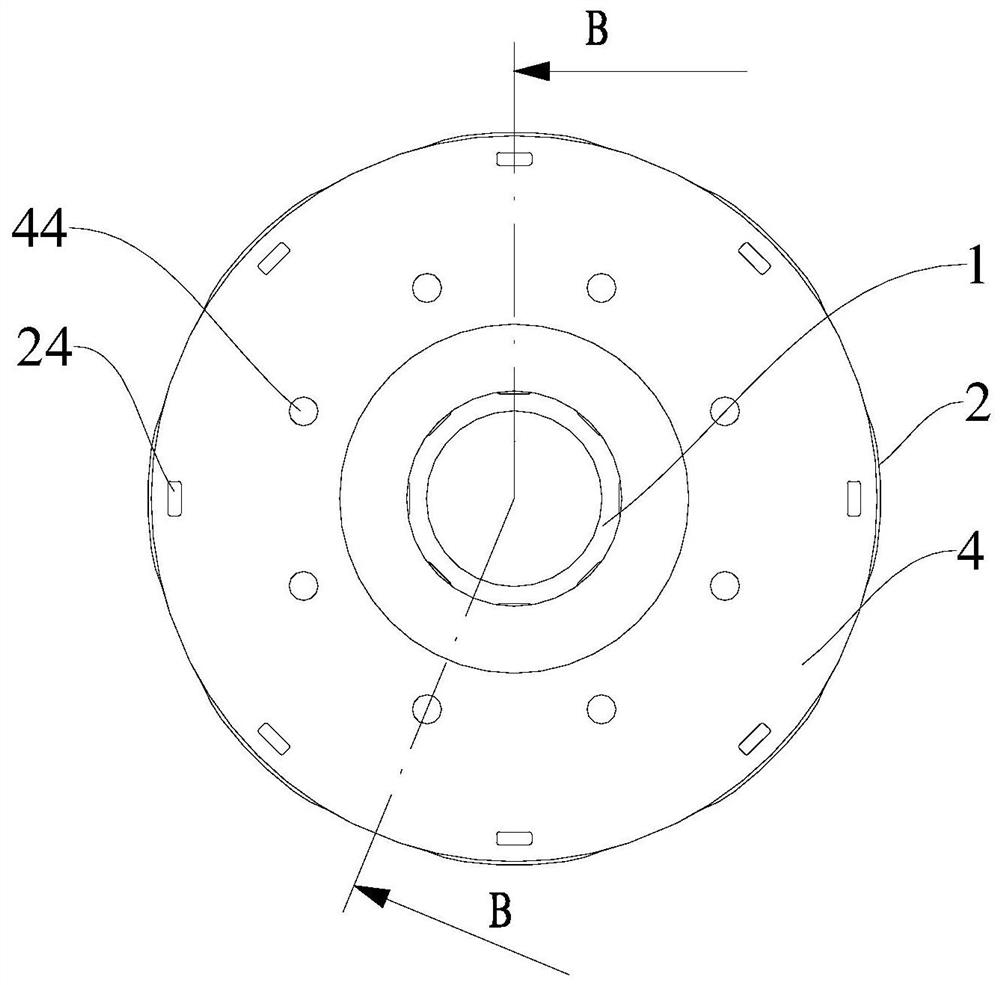

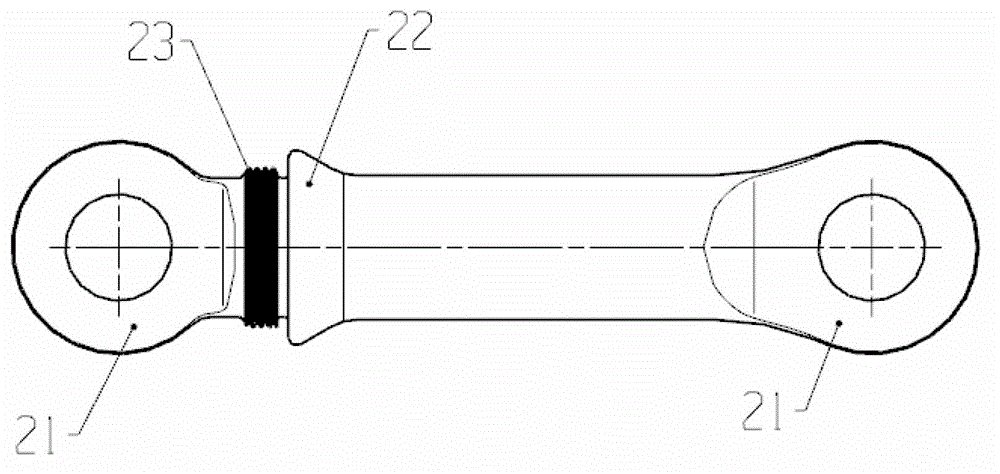

Piston-type refrigerating compressor connecting rod dual-hole honing fixture

ActiveCN103170897AReduce frictionSmall shape and position toleranceHoning toolsHoning machinesPistonManufacturing engineering

The invention discloses a fixture for honing and manufacturing a piston-type refrigerating compressor connecting hole. The fixture or honing and manufacturing the piston-type refrigerating compressor connecting hole comprises a fixture base, a reversing positioning rod, a dual-semispherical floating spacing sleeve, a workpiece positioning component A, a tool and a workpiece positioning component B. By adopting the novel structure scheme, the labor productivity in manufacturing workpieces can be improved; the production cost can be lowered; the product quality can be improved; and resources can be saved, and the efficiency can be improved.

Owner:WUHU ABAUR MECHANICAL & ELECTRICAL

Torsion beam lining component and manufacturing and mounting method thereof

InactiveCN102874064AImprove performanceImprove reliabilityResilient suspensionsRubber materialInterference fit

The invention discloses a torsion beam lining component, which comprises a barrel-shaped body lining assembly with mounting supporting lugs and an upper limiting frame and a lower limiting frame which are positioned at one end of the barrel-shaped body lining assembly with the mounting supporting lugs, wherein the barrel-shaped body lining assembly with the mounting supporting lugs is an integrated part formed by integrally vulcanizing a lining outer sleeve, an integrated shaft-type lining inner sleeve and a rubber material filled in an axial annular space between the lining outer sleeve and the integrated shaft-type lining inner sleeve; the integrated shaft-type lining inner sleeve is an integrated part comprising a lining inner sleeve and the supporting lugs at two ends; and the upper limiting frame and the lower limiting frame are an upper half flange and a lower half flange which are provided with mounting lug plates and have the same shape. In a used state, the barrel-shaped body lining assembly is pressed on a torsion beam in an interference fit manner; and the upper limiting frame and the lower limiting frame are connected with the integrated shaft-type lining inner sleeve arranged on the torsion beam through mounting bolts to form a whole. By using a torsion beam suspension of the torsion beam lining component, the mounting precision is improved, and the performance and the reliability of the whole vehicle are improved; the torsion beam lining component is convenient to manufacture and mount; and the cost is low.

Owner:柳州孔辉汽车科技有限公司

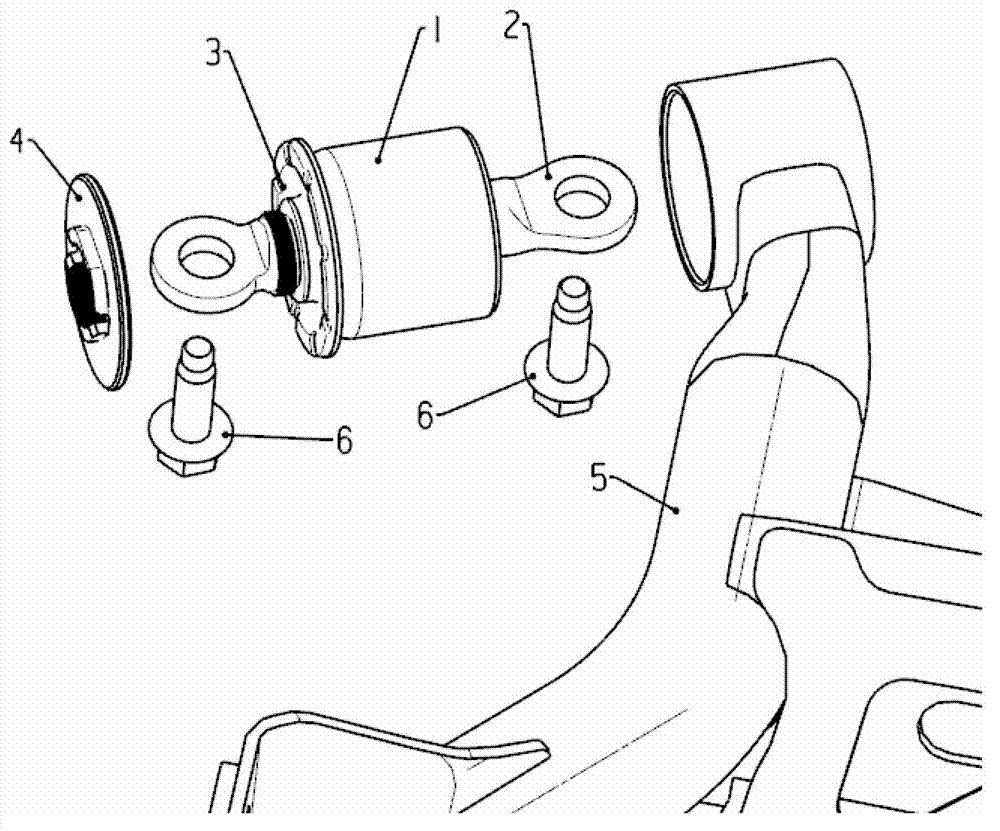

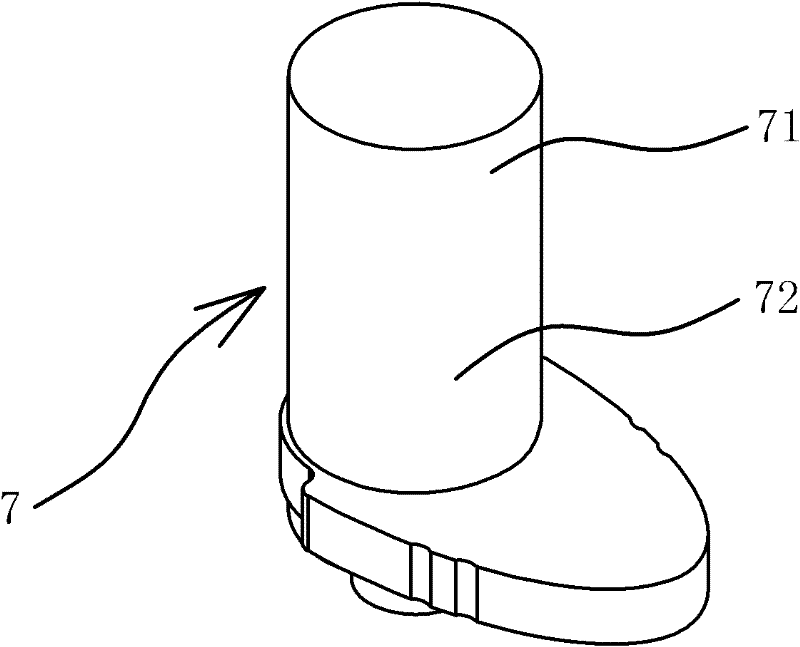

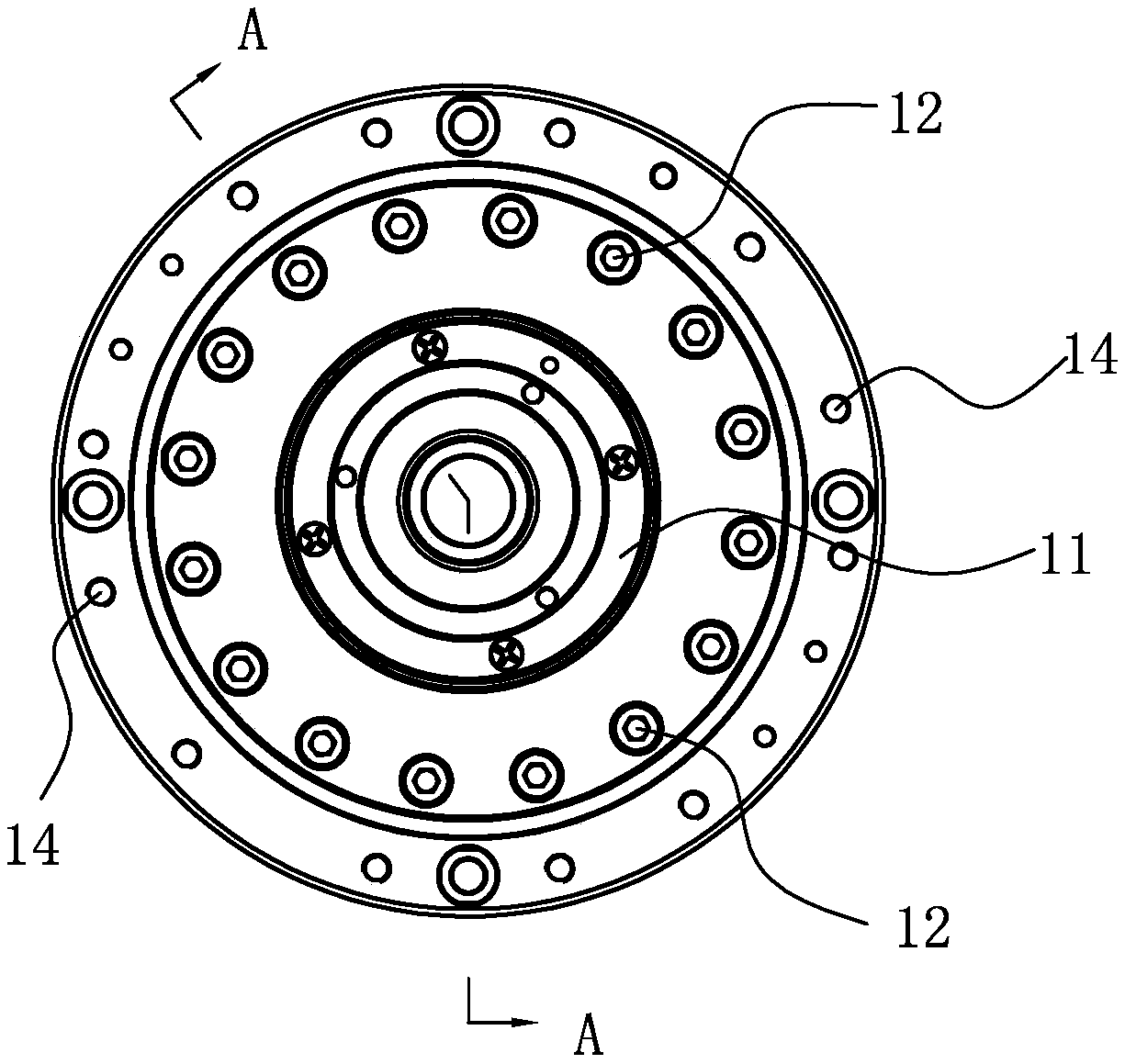

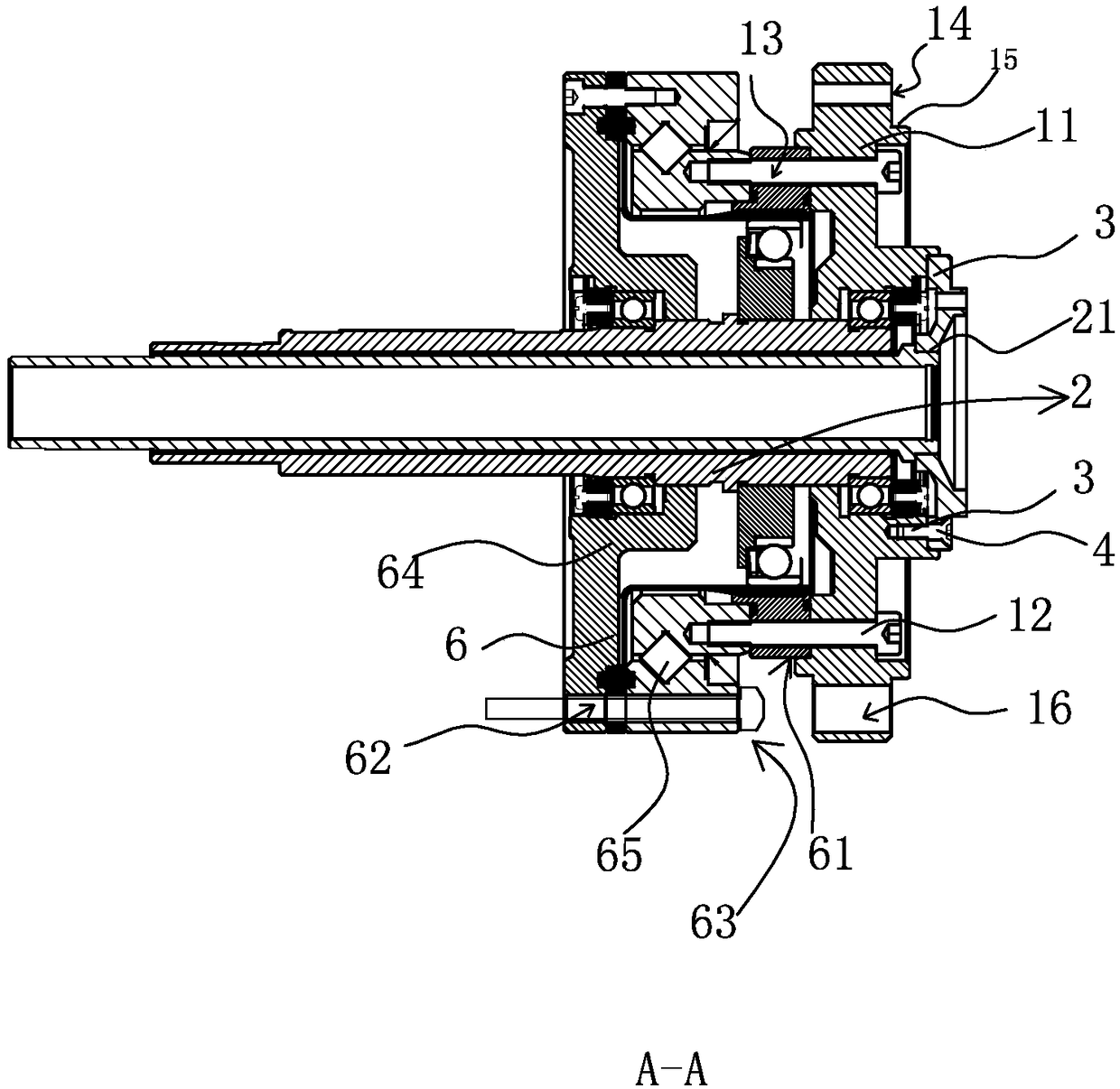

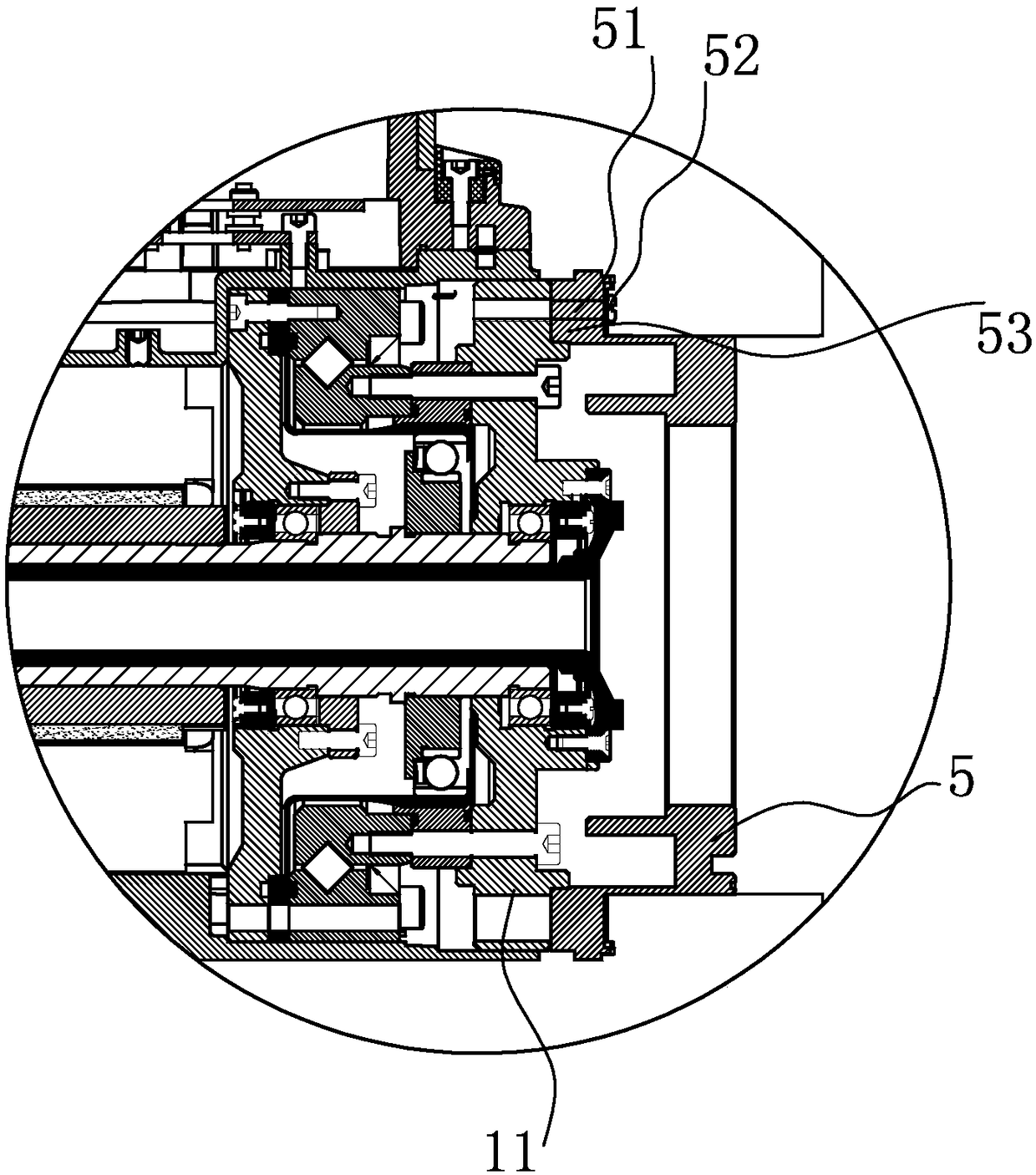

Harmonic reducer capable of being directly connected with a mechanical arm

PendingCN109253227ASmall shape and position toleranceFew accessoriesProgramme-controlled manipulatorGearingReduction driveHarmonic

The invention relates to a harmonic reducer, and belongs to the field of manufacturing of mechanical arms. The harmonic reducer is provided, an output end is connected with joints at high precision, the joints are assembled conveniently, a rear end cap is arranged at the rear end of the harmonic reducer on a first mechanical arm joint, a plurality of rear end cap connecting screw holes which are distributed in the peripheral direction are formed in the rear end cap, and a step is further arranged at an end of the rear end cap; and a second joint fixing hole which corresponds to a connecting screw hole is formed in a second joint, a second joint fixing screw penetrates through the second joint fixing hole and is fixed in a connecting screw hole, and therefore, the rear end cap is connectedwith the second joint. The original traditional speed reducer flange plate connecting method is abandoned, thus, the harmonic reducer mechanism is compact and simple, form and location tolerance is relieved, an effect of improving the product connecting precision is achieved, and the production cost is reduced on the basis of reduction of accessories.

Owner:杨庆华

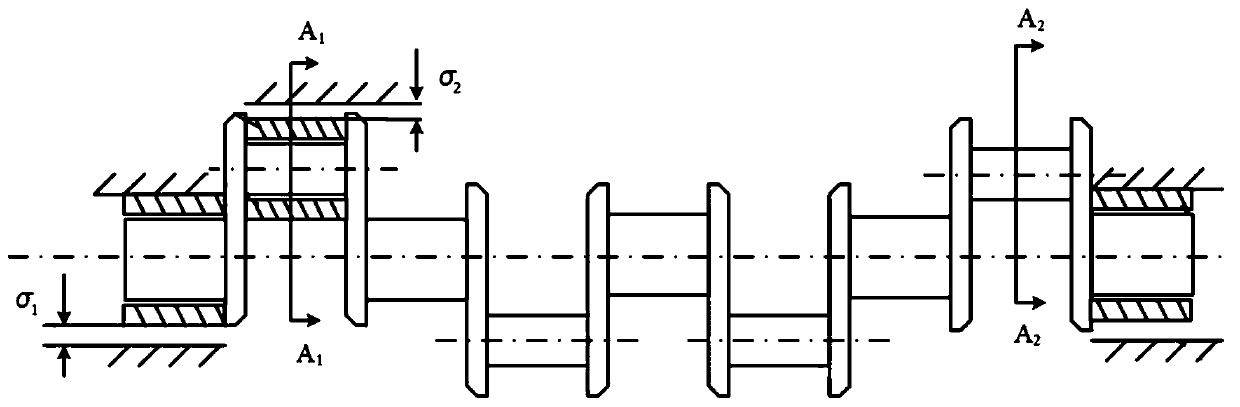

The Method of Machining Roll Involute Splines Using CNC Double-sided Milling Machine

ActiveCN105598511BShorten the timeIncrease productivityMilling equipment detailsNumerical controlEngineering

The invention relates to a spline processing method, in particular to a method adopting a numerical control double-side milling machine for processing a roller involute spline, and belongs to the technical field of machining. The specific processing method is as follows: firstly, a workpiece is clamped on a machine tool and aligned, line drawing is performed to the workpiece according to the spline tooth shape, then the spline is milled by the numerical control double-side milling machine which is provided with two main shafts, and rough milling and semi-fine milling can be performed simultaneously. With the adaption of the spline processing method, the numerical control double-side milling machine is used for processing the spline, two processing steps of rough milling and semi-fine milling can be completed simultaneously by one time clamping, the production efficiency is improved, at the same time, the processing error caused by multiple times of clamping is reduced, and the processing quality of the workpiece is improved.

Owner:邢台轧辊小冷辊有限责任公司

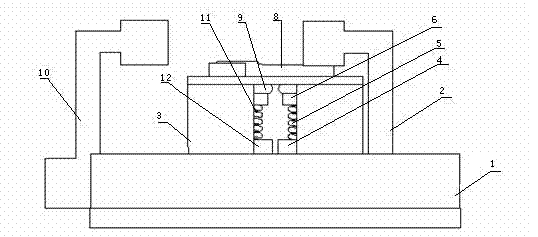

Double-layer punching tool for control valve deck

InactiveCN104028808APrecise positioningSmall shape and position toleranceDrill jigsPunchingStructural engineering

The invention provides a double-layer punching tool for a control valve deck. The double-layer punching tool comprises a bottom layer circular ring, a top layer circular ring, a connecting armature, a bottom layer drill jig, a locating groove, a top layer drill jig, a fixing screw rod, a weight and a locating pile. The bottom layer circular ring is an iron circular ring, the ring surface of the bottom layer circular ring is provided with the bottom layer drill jig, and the locating groove is formed in the ring surface. The top layer circular ring is an iron circular ring and is connected with the bottom layer circular ring through the connecting armature, and the top layer drill jig is arranged on the ring surface of the top layer circular ring. The locating pile is arranged on the bottom layer circular ring. The control valve deck and the tool are connected through the fixing screw rod and pressed and fixed through the weight. The double-layer punching tool is simple in structure, accurate in location and high in practicality, and improves the production efficiency to a great extent.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

A Matching Method of Mechanical Parts Based on Geometric Tolerance and Dimensional Tolerance

ActiveCN109271653BImprove convergence speedOptional implementationGeometric CADDesign optimisation/simulationPosition toleranceAlgorithm

Owner:XI AN JIAOTONG UNIV

Processing method of power senary shunting rotary frame of large-scale vertical mill reducer

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Method and mould for manufacturing floor spring rotating shaft head

ActiveCN102225503BBeautiful appearanceReduce manufacturing costExtrusion diesMechanical engineering technologyEngineering

The invention provides a method and a mould for manufacturing a floor spring rotating shaft head, belonging to the technical field of mechanical engineering. The method solves the problems such as low production efficiency, high cost, weak market competitive power of products and the like in the existing method for manufacturing a rotating shaft. The method for manufacturing the floor spring rotating shaft head includes the steps of blank tooling, cold extrusion, surface treatment, etc. A mould for forming the floor spring rotating shaft head comprises a lower die, an upper die, a pedestal, aradial positioning mechanism and an axial positioning mechanism. A mould for trimming concave shoulder bottom surfaces of the floor spring rotating shaft head comprises a positioning mould and a forming mould, wherein flattening surfaces capable of corresponding to the concave shoulder bottom surfaces in position and structure one by one are arranged on one end of the forming mould, and a placinghole through which a workpiece head can penetrate is also arranged on the forming mould. The floor spring rotating shaft produced by the manufacturing method has the advantages of being low in production cost, beautiful in appearance and strong in market competitive power. The mould for forming the floor spring rotating shaft head has the advantages of being reasonable in design and convenient inuse.

Owner:玉环市江洲机械有限公司

Hole opening method for jack cylinder bottom and auxiliary tool for welding

ActiveCN102489949BSmall sizeSmall shape and position toleranceWelding/cutting auxillary devicesAuxillary welding devicesPosition toleranceButt welding

Owner:YANKUANG GRP CO LTD

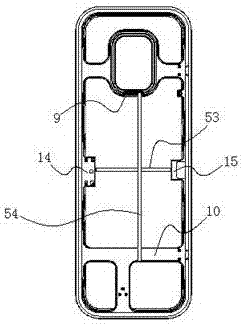

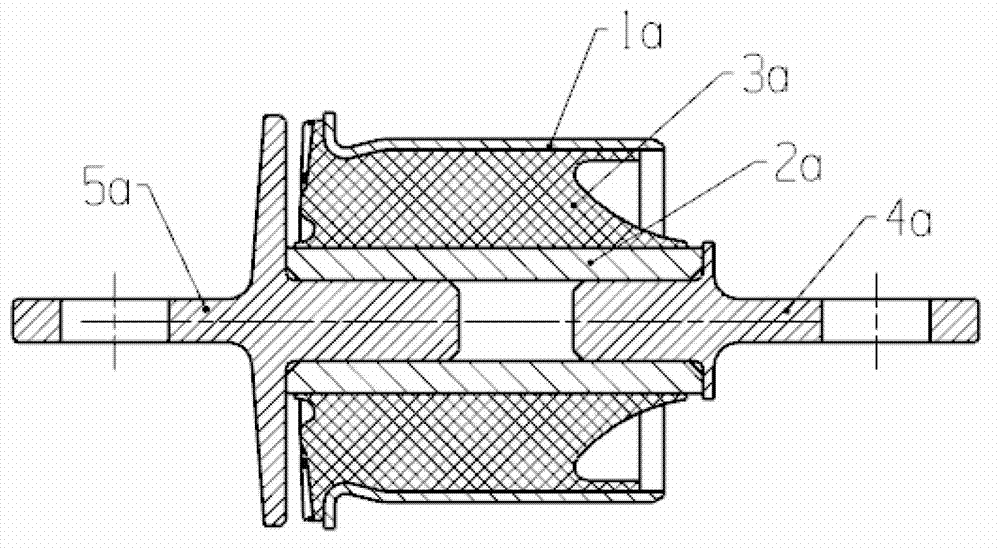

Rotor assembly, motor and household electrical appliance

ActiveCN113054773AImprove structural strengthReduce magnetic flux leakageMagnetic circuit rotating partsElectric machinesElectric machineEngineering

The invention discloses a rotor assembly, a motor and a household electrical appliance, the rotor assembly comprises a shaft sleeve, a plurality of reinforcing bosses, a plurality of rotor cores and a plurality of permanent magnets, the shaft sleeve is made of a non-magnetic material, the plurality of reinforcing bosses are arranged at intervals along the circumferential direction of the shaft sleeve, and the plurality of rotor cores are arranged at intervals in the circumferential direction of the shaft sleeve. The plurality of rotor cores are arranged at intervals in the circumferential direction of the shaft sleeve, a mounting groove is formed between every two adjacent rotor cores, each rotor core comprises a protruding part, the protruding parts are connected with the shaft sleeve, a spacing distance is formed between any two protruding parts, the permanent magnets are arranged in the mounting grooves, and the permanent magnets are arranged in the mounting grooves. The plurality of permanent magnets and the plurality of rotor cores are sequentially and alternately arranged in the circumferential direction of the shaft sleeve. According to the rotor assembly provided by the embodiment of the invention, the magnetic circuit magnetic flux flowing through the rotor iron core and the shaft sleeve is effectively limited, so that the magnetic leakage phenomenon of the end part of the rotor is effectively reduced, the motor power density is improved, and the motor cost is reduced.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

Resin grinding plate for ultraprecise processing of bearing balls and manufacturing method thereof

Owner:SHANDONG TAI GUANGYI GRINDING WHEELS

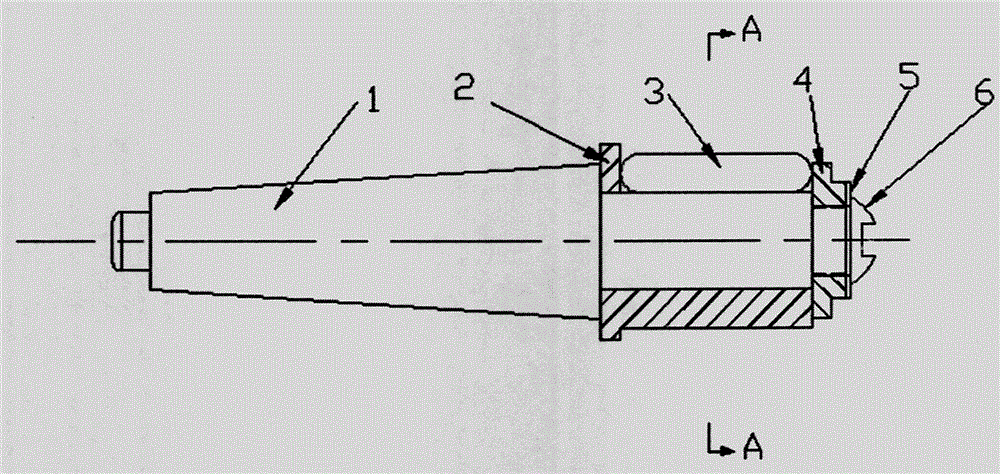

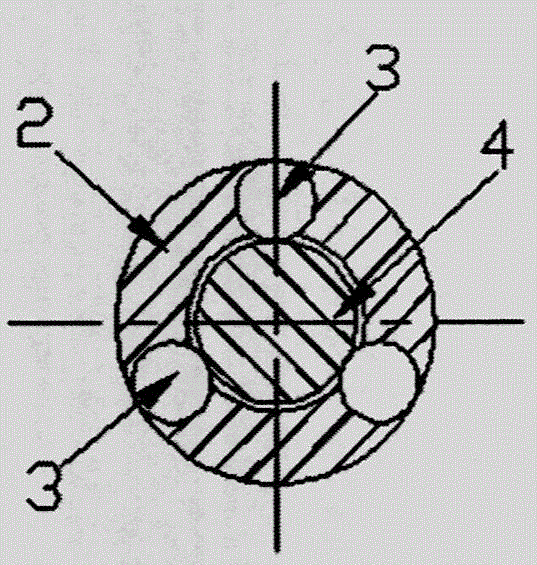

Tool special for rolling small hole through lathe

InactiveCN106002083ASmall shape and position toleranceReasonable structural designAutomatic/semiautomatic turning machinesMorse taperSmall hole

The invention discloses a tool special for rolling a small hole through a lathe. The tool comprises a Morse taper shank (1), a roller pin holder (2) mounted at one end of the Morse taper shank (1) and roller pins (3) mounted at the right end of the roller pin holder (2). The roller pins (3) are fixed to the Morse taper shank (1) through a press cap (4), a gasket (5) and a compression bolt (6). The tool special for rolling the small hole through the lathe is reasonable in structural design, convenient to operate and high in work efficiency; the form and location tolerance of a machined workpiece is small, and the defects of horn mouths and the like are not prone to being formed; and the machined small hole workpiece is high in quality, precision and practicality.

Owner:YANCHENG INST OF TECH

Camshaft toothed wheel hub for automobile engine and powder metallurgy preparation method thereof

ActiveCN106041094BReduce the amount of processingImprove shift outputTransportation and packagingMetal-working apparatusEngineering

The invention discloses a camshaft toothed wheel hub for an automobile engine and a powder metallurgy preparation method thereof. The method is carried out according to the following steps: step S101, batching; step S102, pressing and forming; step S103, blank sintering; step S104, finishing and processing; step S105, steam treatment; step S106, testing and packaging. The method of the present invention is connected in an orderly manner, with fewer procedures and a material utilization rate of more than 95%. The camshaft toothed wheel hub obtained by the method has less machining volume, high shift output and good consistency. It satisfies various performance requirements of the product. At the same time, the manufacturing cost of the product is reduced by 50%.

Owner:马鞍山市华东粉末冶金厂

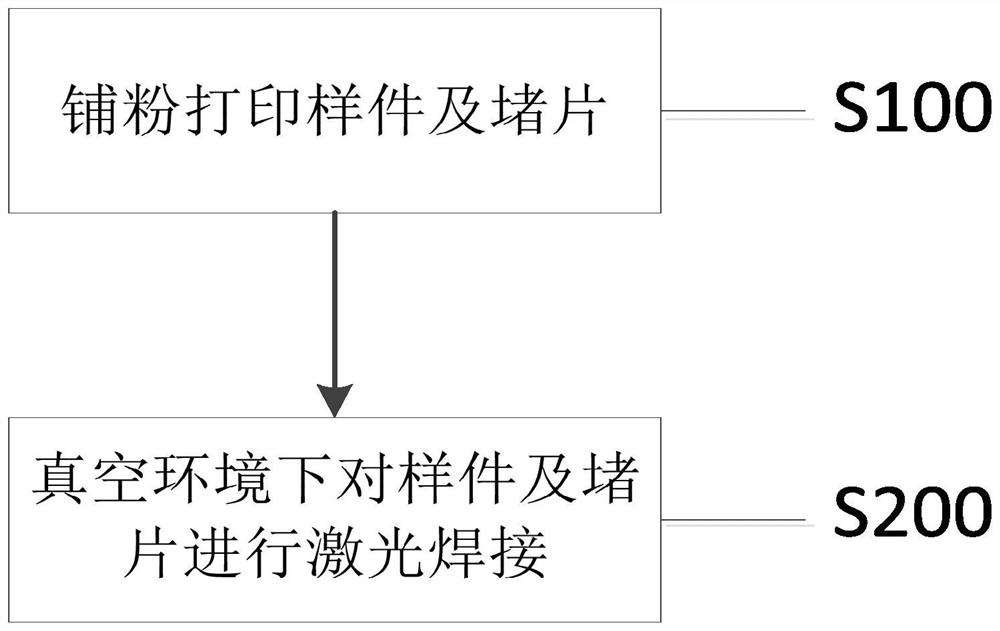

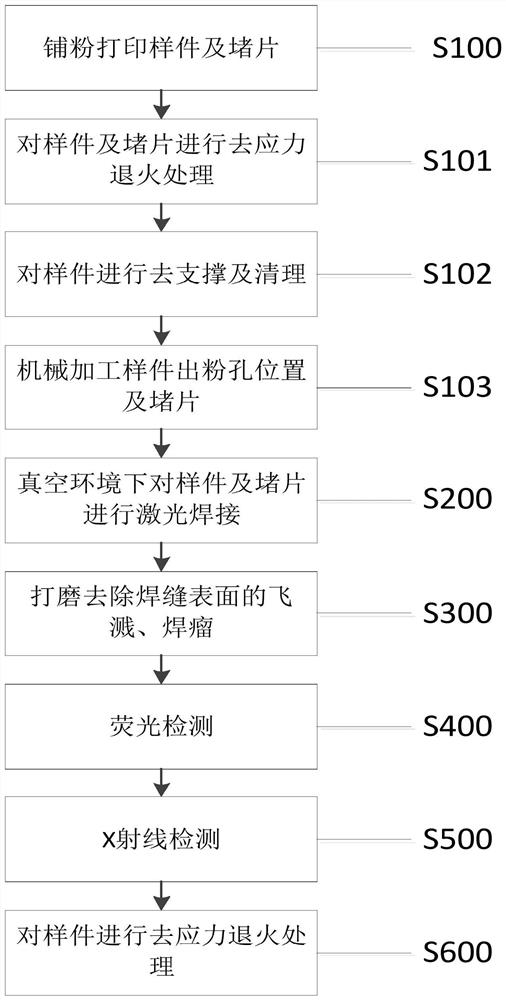

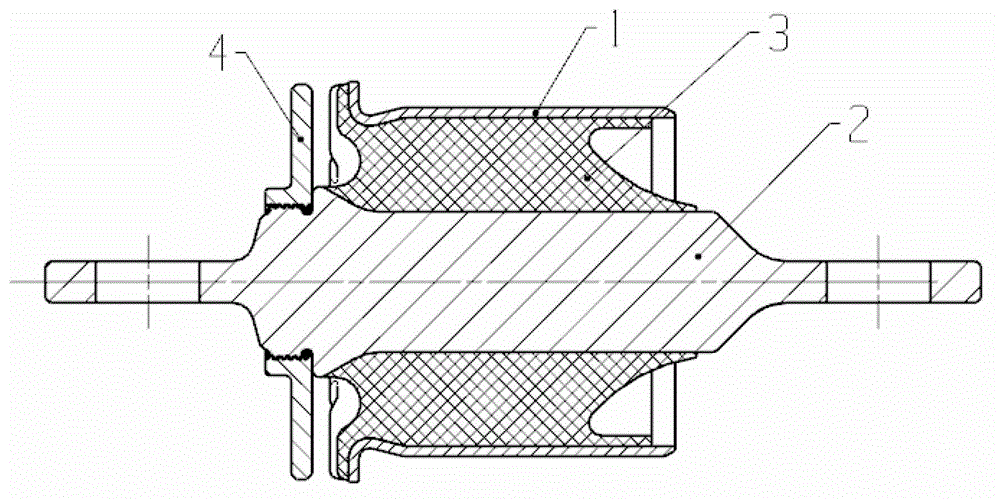

Part powder outlet hole repairing method in powder laying printing

PendingCN113909693ANo gas reactionSmall shape and position toleranceLaser beam welding apparatusLaser solderingWelding

The invention discloses a part powder outlet hole repairing method in powder laying printing, and relates to the technical field of 3D printing. The problem that in traditional powder outlet hole repairing, due to the gas reverse phenomenon generated in welding of a last powder outlet hole, welding cannot be conducted or the welding quality does not reach the standard is solved. The part powder outlet hole repairing method in powder laying printing comprises the steps that a powder laying printing sample piece and a blocking piece are included, a powder outlet hole is formed in the sample piece, and the powder outlet hole is matched with the blocking piece in shape and size; and laser welding is conducted on the sample piece and the blocking piece under the vacuum environment, and the blocking piece blocks the powder outlet hole. The part powder outlet hole repairing method in powder laying printing is used for repairing work of the part powder outlet hole in 3D powder laying printing.

Owner:TSC LASER TECH DEV BEIJING CO LTD

Torsion beam bushing assembly and method for making and installing the same

InactiveCN102865323BImprove performanceImprove reliabilityResilient suspensionsRubber materialInterference fit

A torsion beam bushing assembly, comprising a cylindrical bushing assembly with mounting lugs and a stop ring at one end of the cylindrical bushing assembly, the cylindrical bushing assembly with mounting lugs It is a one-piece component formed by vulcanizing the bushing outer casing, the integrated shaft-shaped bushing inner sleeve and the rubber material filled in the axial annular space between the bushing outer casing and the integrated shaft-shaped bushing inner sleeve. The one-piece shaft-shaped bush inner sleeve is an integral part including the bush inner sleeve and the lugs at both ends, and the stop ring is a flange with threads in the inner hole. In this state, the cylindrical bushing assembly is press-fitted onto the torsion beam through interference fit, and the limit ring is integrated with the integrated shaft-shaped bushing inner sleeve installed on the torsion beam through threaded connection. The torsion beam suspension using the torsion beam bushing assembly improves the assembly accuracy, the performance and reliability of the whole vehicle, and is convenient in processing, manufacturing and installation, and has low cost.

Owner:柳州孔辉汽车科技有限公司

A bearing alloy surface high-frequency impact processing method

The HF impact machining process for the surface of alloy bearing includes: fixing the HF impact head in the cutter holder of a vertical lathe and the bearing workpiece on the rotary table of the vertical lathe; and starting the HF impact head to impact the inner and outer surfaces of bearing bush in the frequency of 20-30 KHz and impact amplitude of 30-50 microns. The present invention has the advantages of capacity of decreasing the number of fine machining equipment, short technological process, high machining precision and long service life.

Owner:DALIAN METALLURGICAL BEARING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com