Harmonic reducer capable of being directly connected with a mechanical arm

A technology of harmonic reducer and manipulator, which is applied in the direction of manipulator, mechanical equipment, program control manipulator, etc. It can solve the problems of time-consuming tightening, low assembly efficiency, and limited rotation angle, so as to reduce production cost and improve product connection accuracy , Reduce the effect of shape and position tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

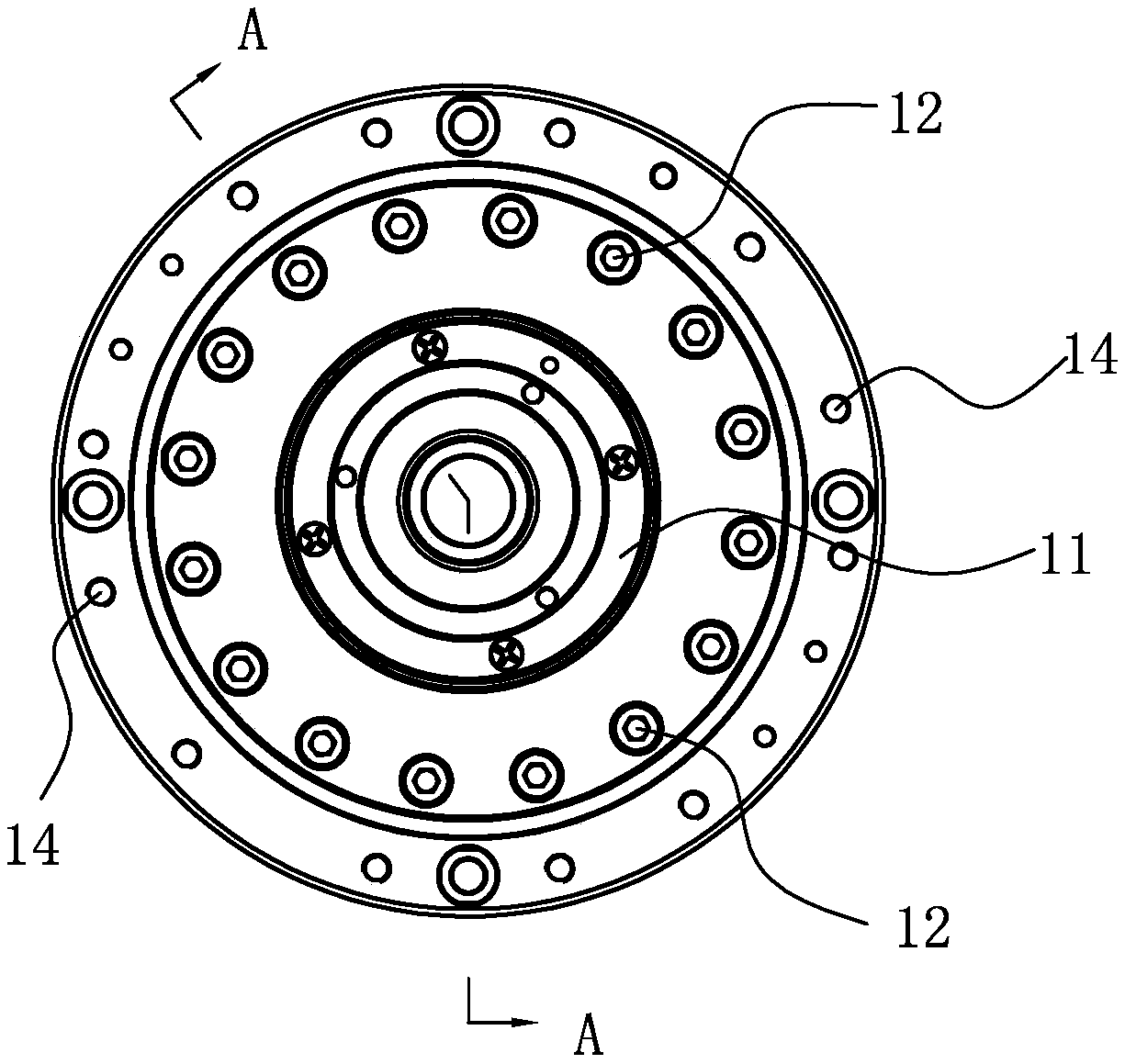

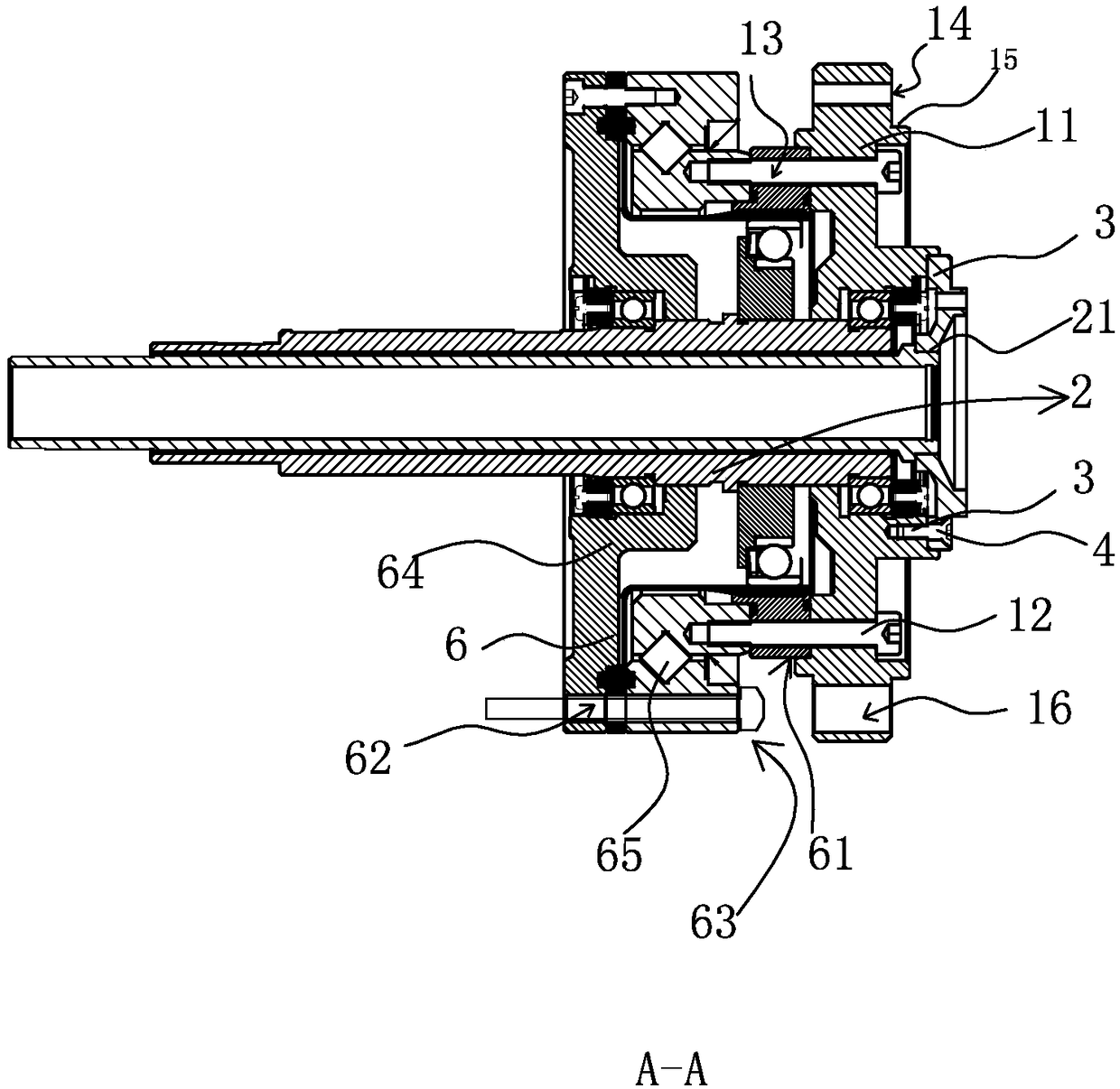

[0018] The rear end of the harmonic reducer 6 on the mechanical arm joint 1 of the present implementation has a rear end cover 11, and the rear end cover 11 has a plurality of circumferentially distributed rear end cover fixing screw holes 13. The harmonic reducer 6 The rigid wheel 61 on the top is also provided with the fixing screw hole corresponding to the rear end cover fixing screw hole 13, and the rear end cover 11 is fixed on the rigid wheel 61 by several rear end cover fixing screws 12; On the rear end cover 11, several circumferentially distributed rear end cover 11 connecting screw holes 14 are arranged to realize the output shaft load connection of the harmonic reducer 6, such as connections of mechanical arms, motors or jaws, etc., the rear end The cover connecting screw holes 14 are arranged in a circumferential direction on the rear end cover 11 .

[0019] The output shaft 2 of the mechanical arm joint 1 in this embodiment has a support rod 21, and the support ro...

Embodiment 2

[0021] The present embodiment is basically the same as embodiment one, except that the scheme of embodiment one also has the following characteristics:

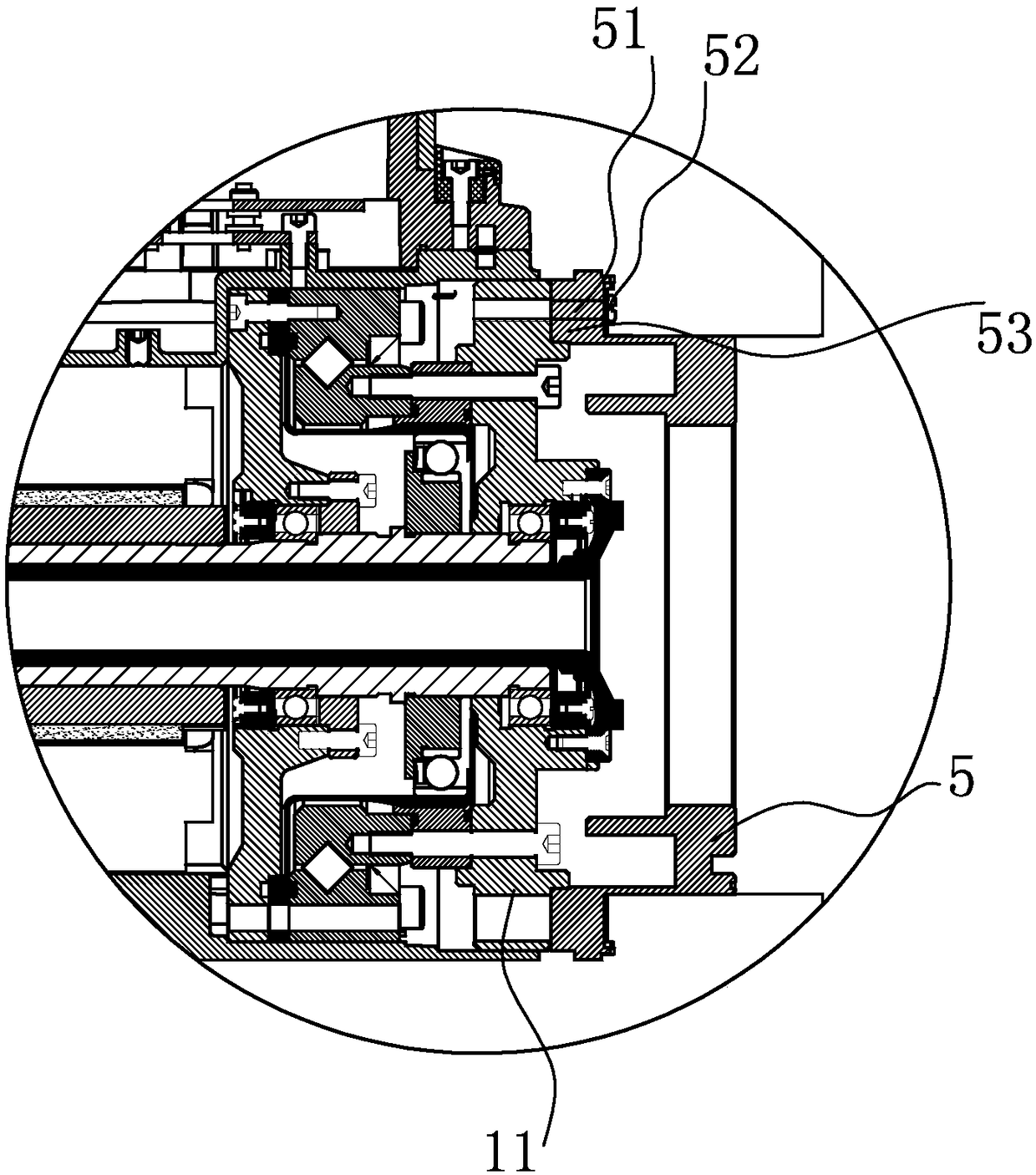

[0022] There is a rear end cover 11 on the rear end of the harmonic reducer 6 of the mechanical arm joint one of the present embodiment. The rear end cover 11 is provided with several connecting screw holes 14 distributed in the circumferential direction. Also be provided with step 15; Joint 2 5 has the joint 2 fixing hole 51 that is arranged correspondingly with connecting screw hole 14, is fixed in the connecting screw hole 14 by joint 2 fixing screw 52 through joint 2 fixing hole 51, thereby realizes rear The connection between end cap 11 and joint two 5.

[0023] The joint two 5 is also provided with a boss 53, the boss 53 is set in cooperation with the step 15, and the setting of the step 15 plays the role of connection and positioning between the rear end cover 11 and the joint two 5, and is a flange connecting with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com