Torsion beam bushing assembly and method for making and installing the same

An installation method and technology of torsion beam, which are applied in vehicle parts, transportation and packaging, elastic suspension, etc., can solve problems such as affecting the performance of the whole vehicle, reliability noise, processing and assembly processes, and difficulty in ensuring shape and position tolerances. Achieve the effect of eliminating the risk of loosening, reducing the press-fitting process and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

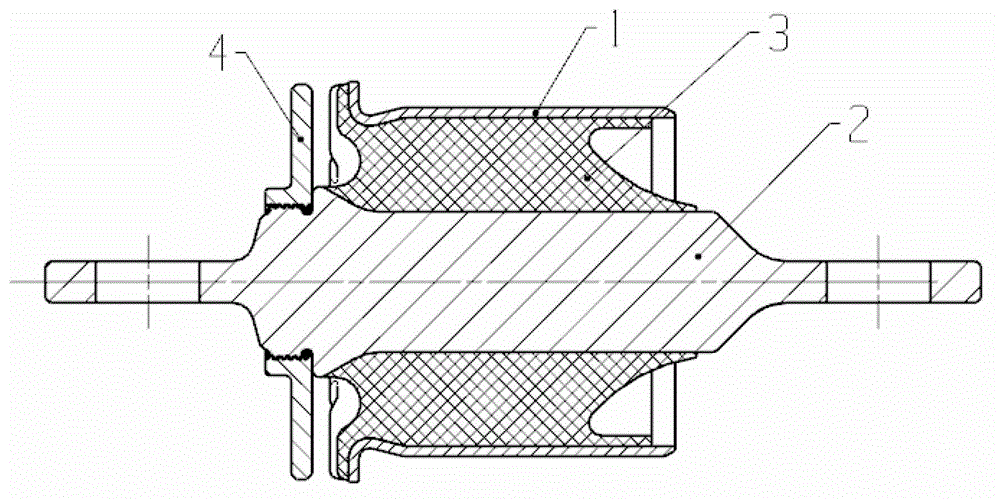

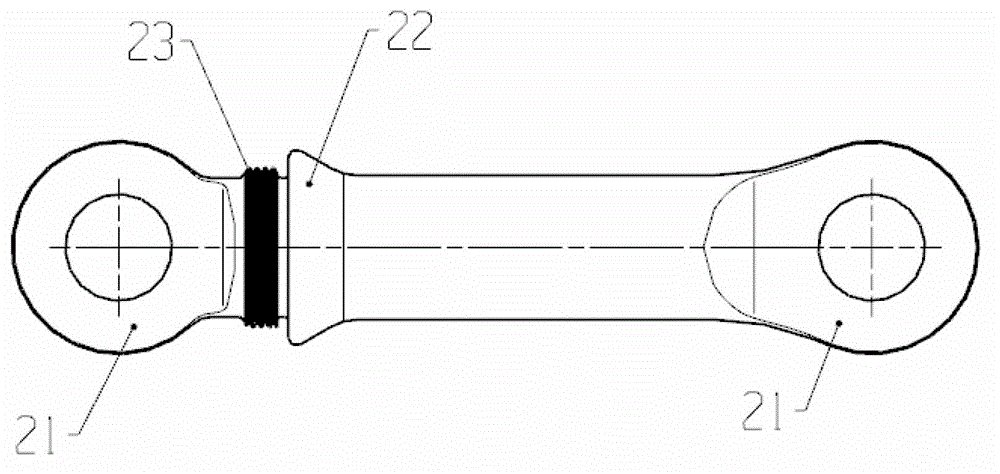

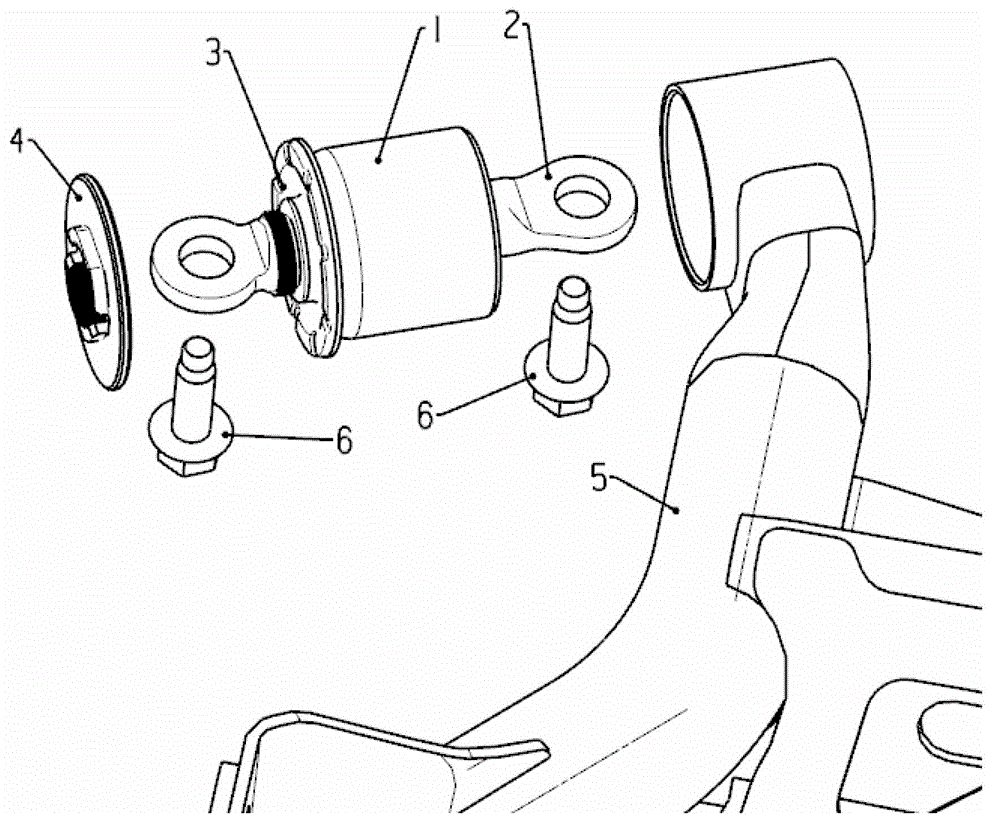

[0033] A torsion beam bushing assembly, such as figure 1 As shown, the torsion beam bushing assembly includes a bushing outer sleeve 1, an integral shaft-shaped bushing inner sleeve 2, a rubber material 3, and a limiting component 4. The integral shaft-shaped bushing inner sleeve 2 includes a lining One-piece parts including the inner sleeve and the lugs at both ends, such as figure 2 As shown, both ends of the integrated shaft-shaped bushing inner sleeve 2 are mounting lugs 21 with mounting holes, and between one end of the round shaft body and the mounting lugs is a conical transition section 22. The conical transition section There is a section of cylinder between 22 and the mounting ear plate 21, and an external thread 23 is opened on the cylinder, which is composed of a bushing outer sleeve 1, an integral shaft bushing inner sleeve 2 and filling in the bushing outer sleeve and the integral shaft bushing The rubber material 3 in the axial annular space between the sleeves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com