Tool special for rolling small hole through lathe

A special tool and lathe technology, which is applied in the field of special tools for rolling small holes in lathes, and achieves the effects of high work efficiency, convenient operation and small tolerance of shape and position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

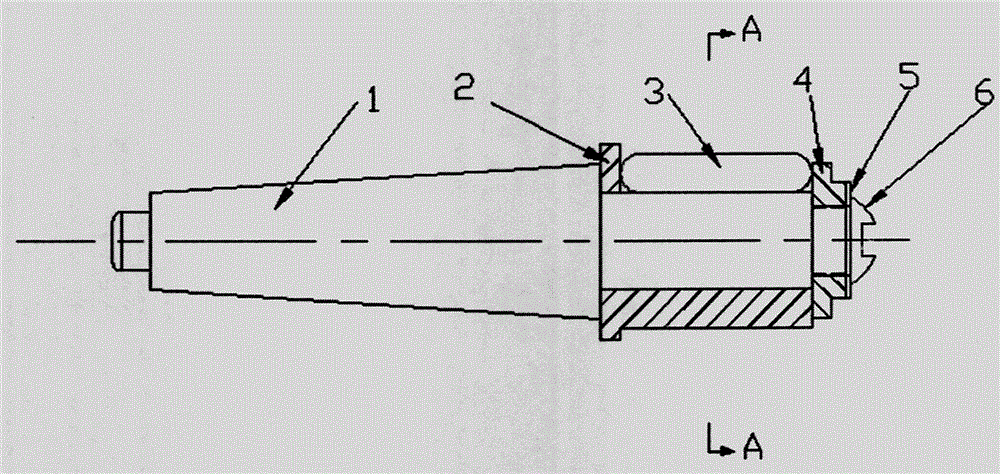

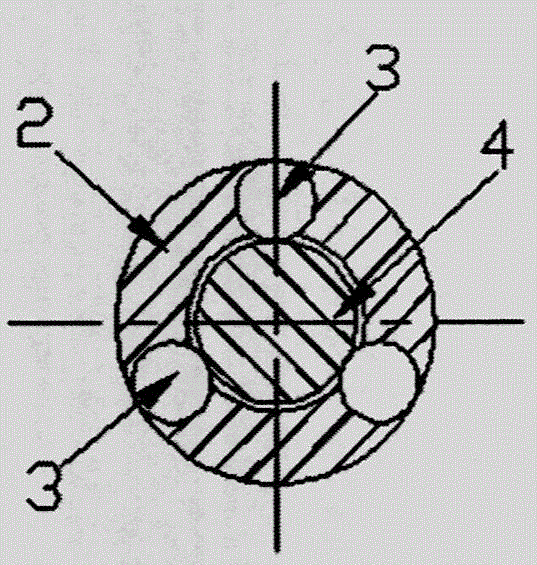

[0019] Such as figure 1 As shown in Figure 2, a special tool for lathe rolling small holes, it includes a Morse taper handle (1), a needle roller cage (2) installed at one end of the Morse taper handle (1), installed on the needle roller The three needle rollers (3) at the right end of the cage (2), the needle rollers (3) are fixed on the Morse taper handle (1) through the pressure cap (4), the gasket (5) and the compression bolt (6). )superior.

[0020] In the special tool for lathe rolling small holes described above, the left end of the Morse taper shank (1) is installed in the taper hole of the tailstock of the lathe.

[0021] According to the special tool for rolling small holes on a lathe according to the present invention, the diameter D of the needle roller (3) is less than or equal to 5mm, and the ratio of the length to the diameter of the needle roller (3) is greater than 2.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com