Patents

Literature

33results about How to "Improve shift output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

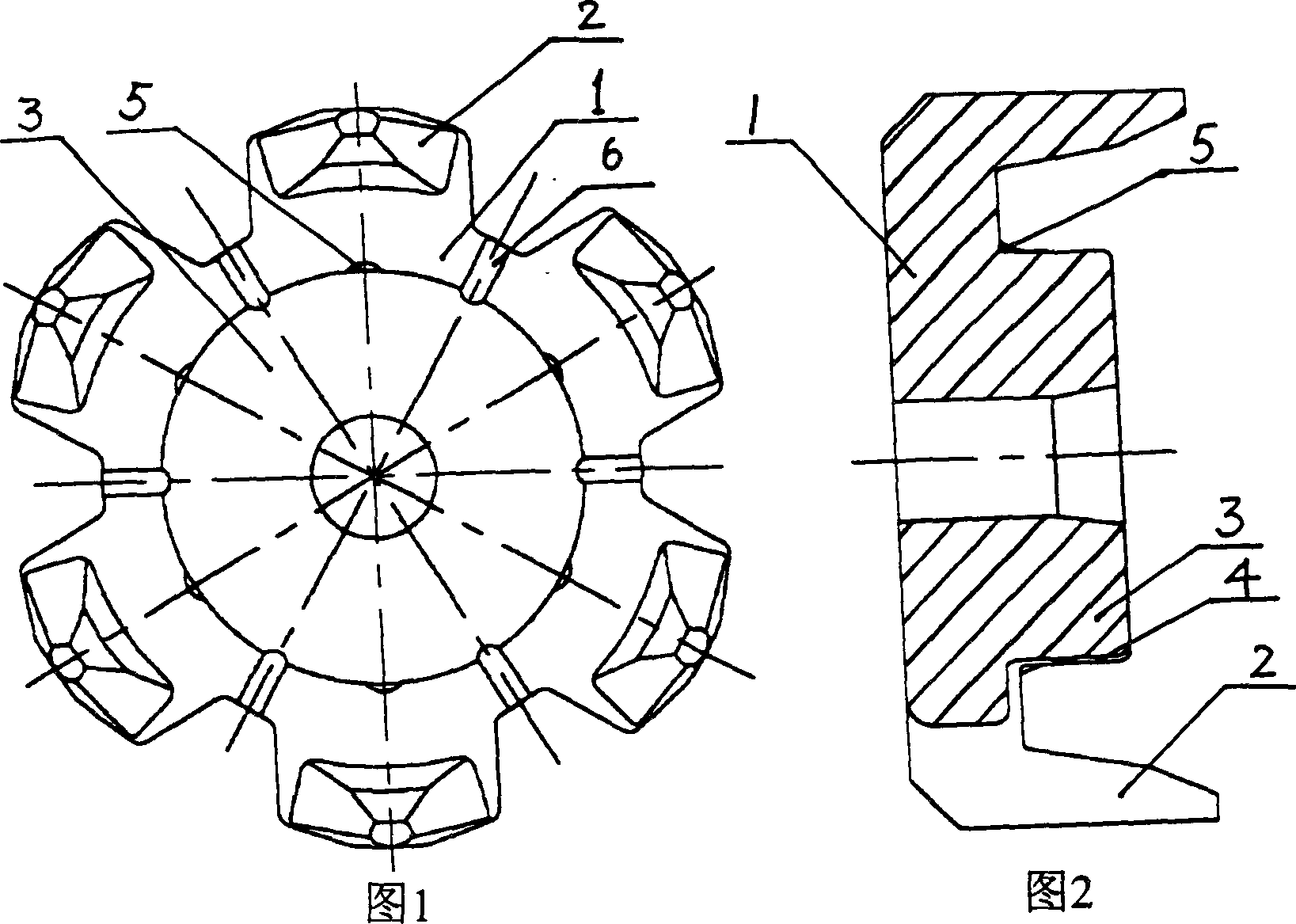

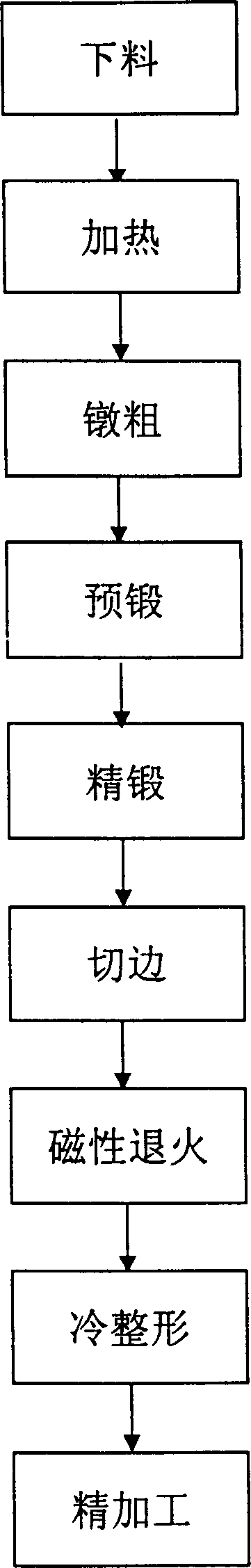

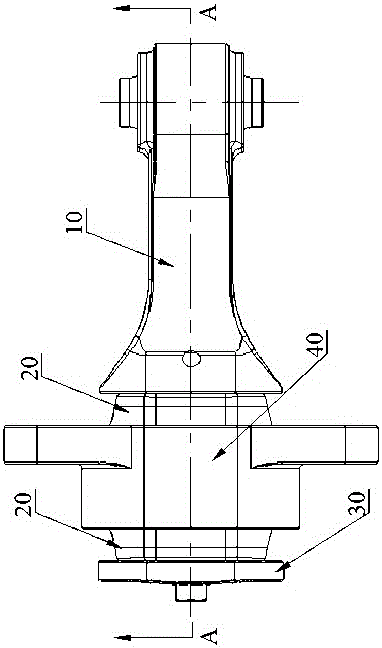

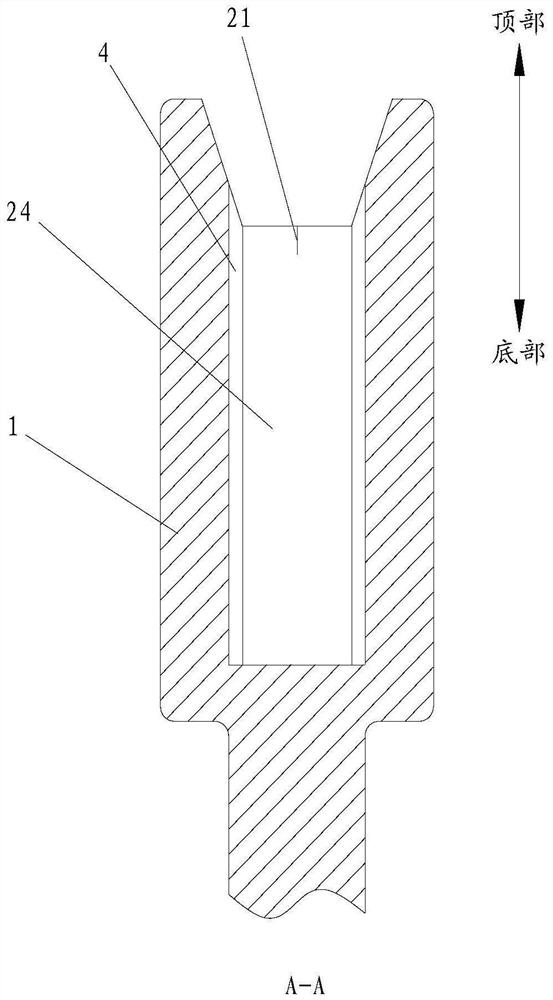

Pawl pole of automobile generator and its manufactura

ActiveCN1772413AIncrease power generationHigh dimensional accuracyManufacturing dynamo-electric machinesOther manufacturing equipments/toolsLacquerEngineering

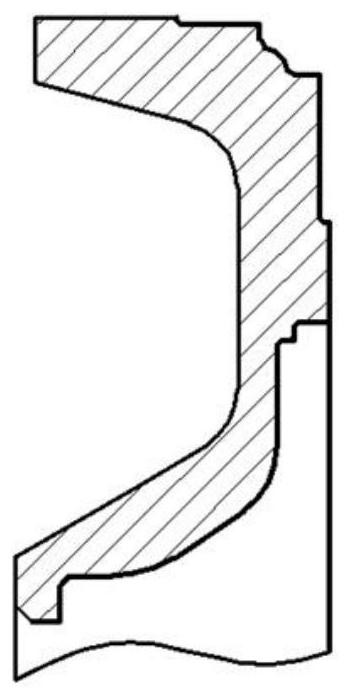

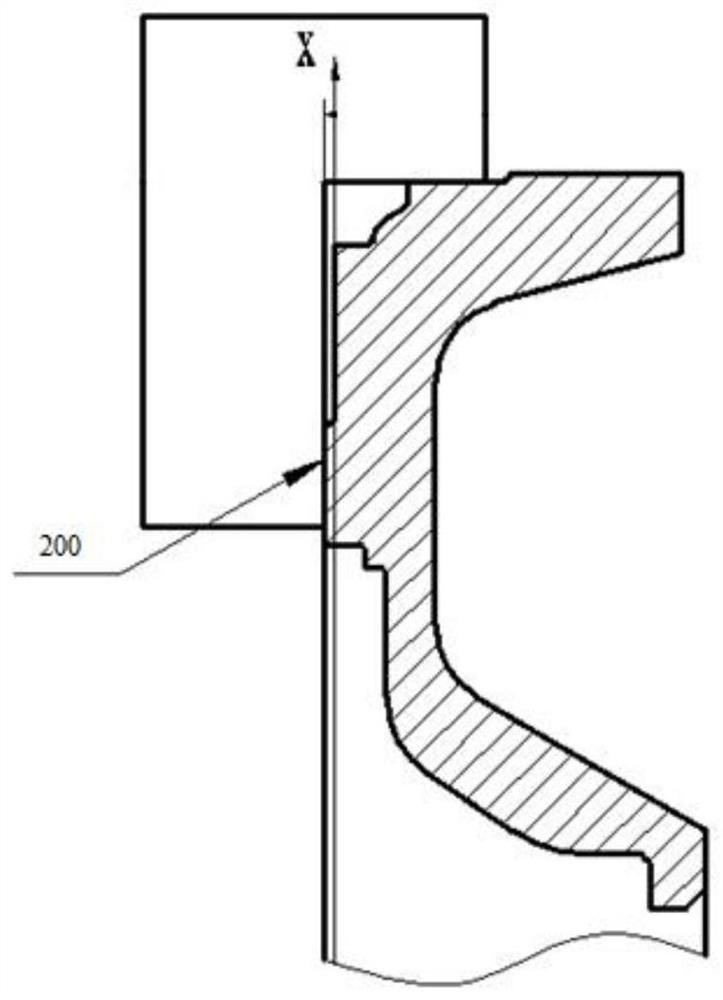

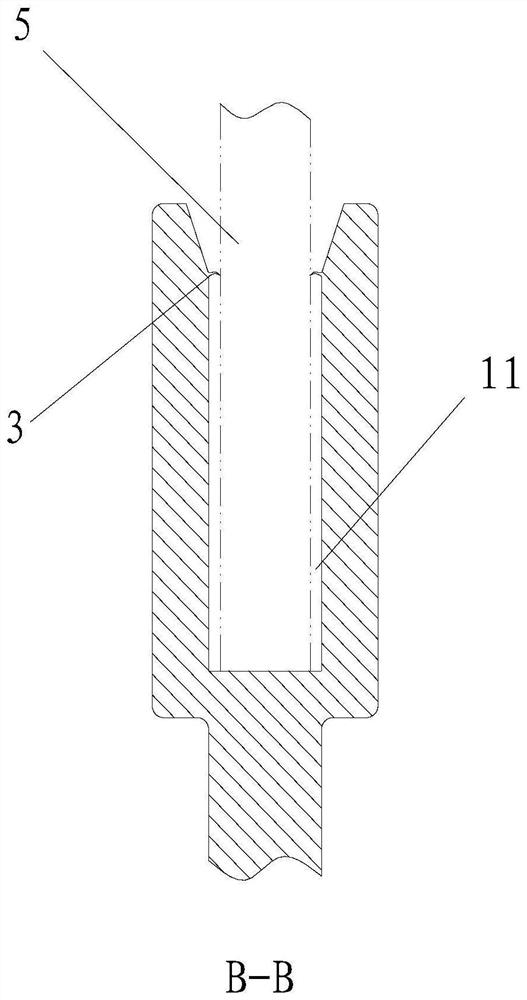

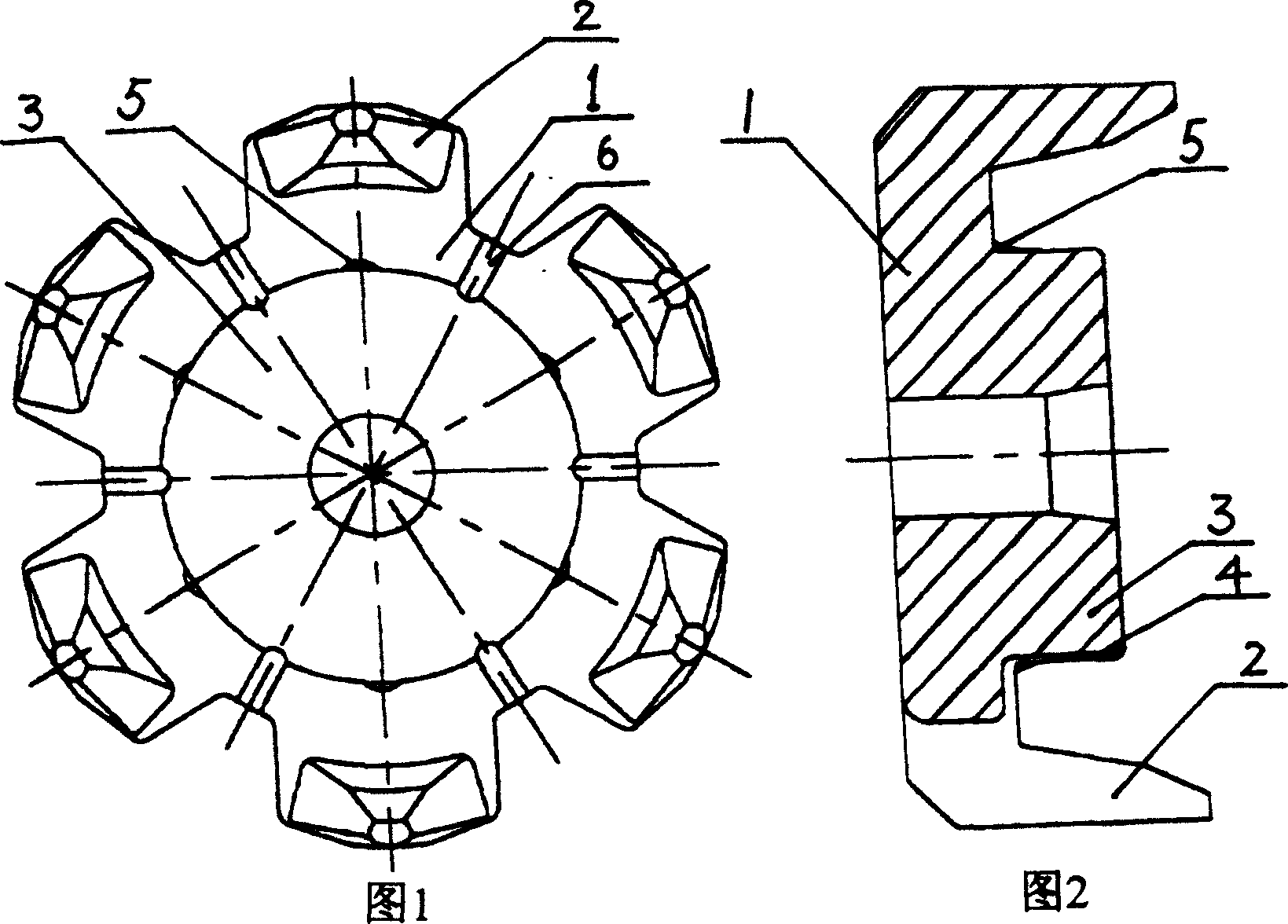

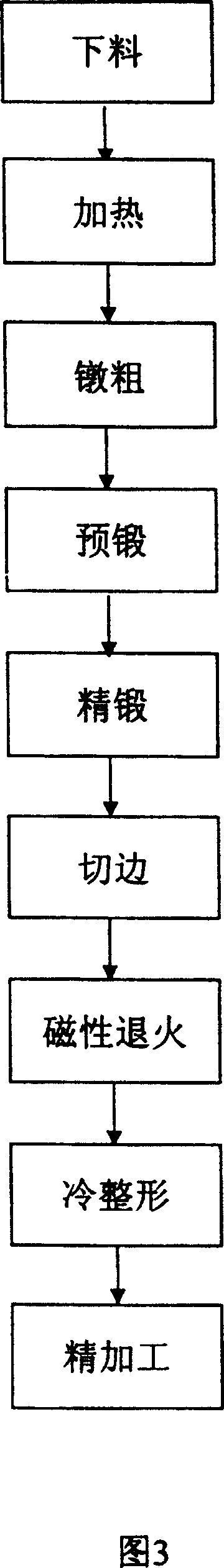

The present invention relates to one kind of of automobile generator and its manufacture. The pawl pole has one bottom plate, one magnetic yoke on the bottom plate, six or eight insulating varnish conducting slots distributed homogeneously on the circumference of the magnetic yoke, six or eight lugs for preventing the rotation of coil, and six or eight insulated wire leading out slots in the bottom of the magnetic yoke. The manufacture of the pawl pole includes the steps of: cutting material, heating, upsetting, pre-forging, finish forging, cutting edge, magnetically annealing, cold shaping, and finishing machining. The manufacture process has low apparatus investment, low mold cost, low heating cost, high output and high product quality. The AC generator with the pawl poles of the present invention has induced electromotive force waveform of quasi-sinusoid wave and great generating power.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

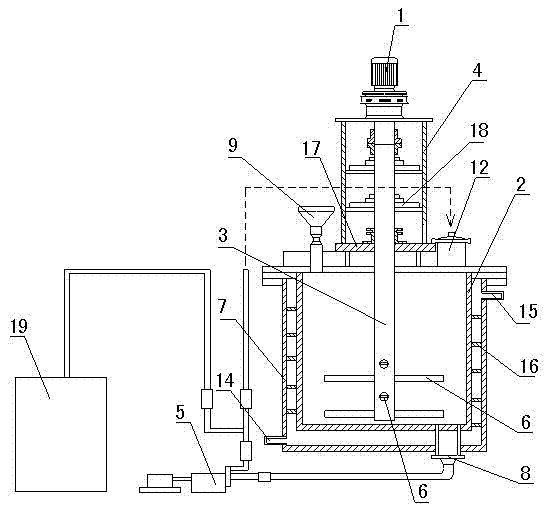

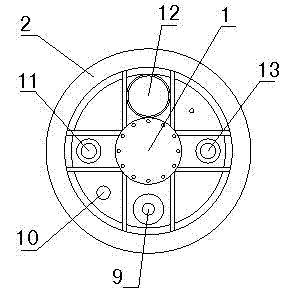

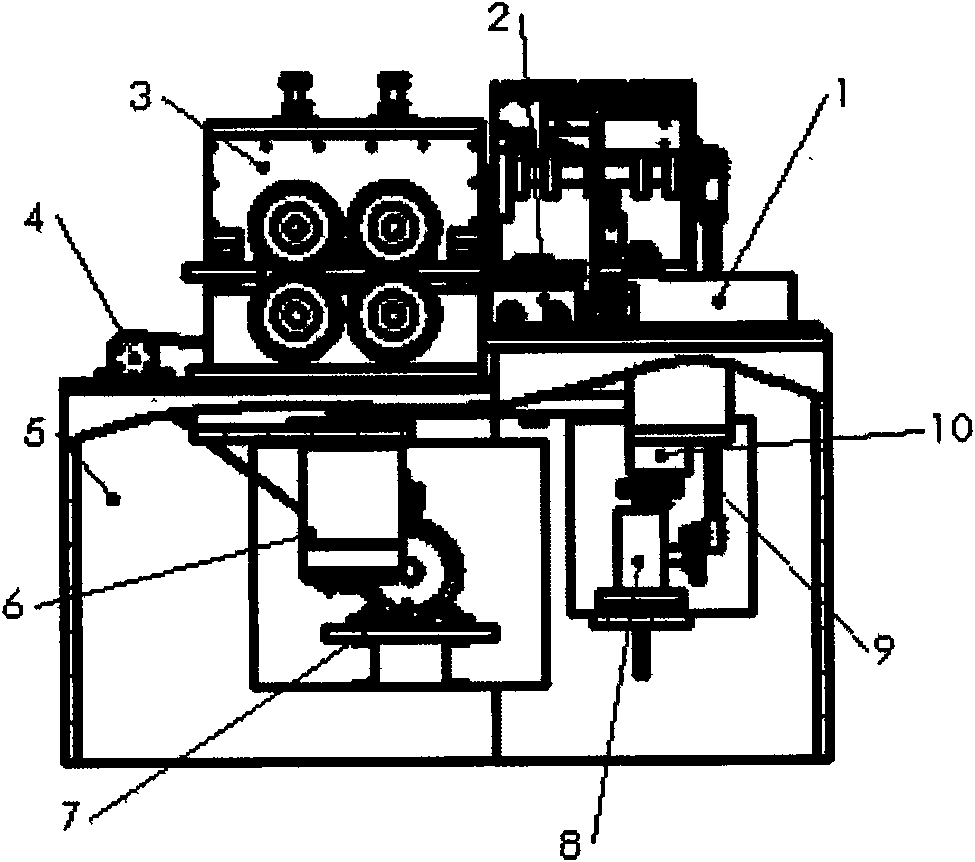

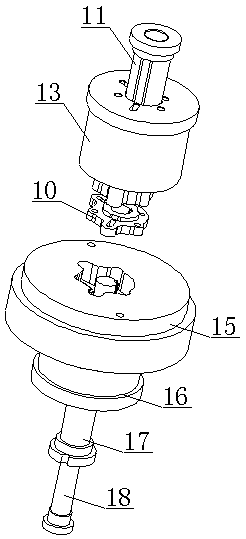

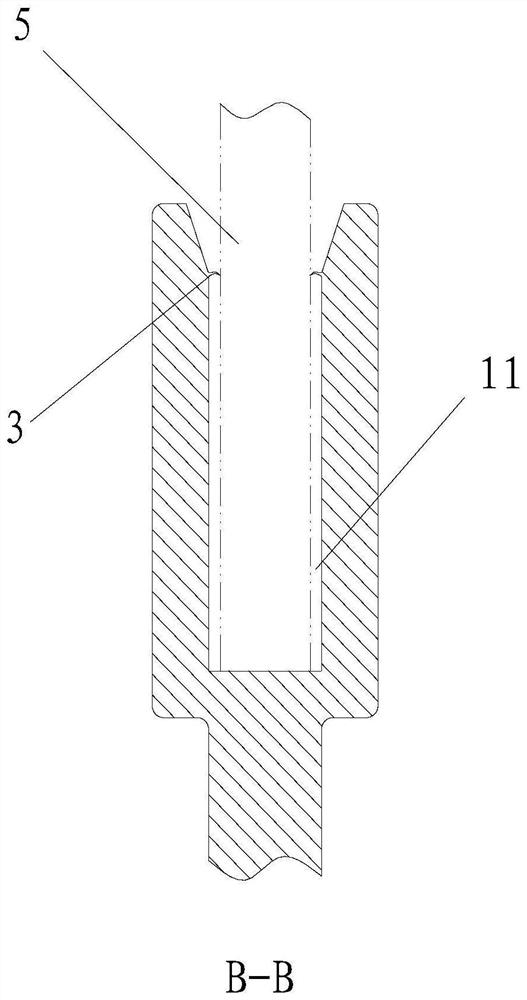

A ball milling process and device for iron-based alloy powder

The invention discloses a ball milling process and device for iron-based alloy powder. The iron-based alloy powder contains more than 80% iron. It includes a wet ball mill and a centrifuge (19). The wet ball mill includes a motor, a speed change device (1), The vertical mill cylinder (2), the vertical stirring shaft (3), the machine body (4) and the slurry pump (5) are subjected to circular ball milling and centrifugal drying to obtain iron-based alloy powder. The beneficial effects of the present invention are: high degree of automation, easy operation, changing the way of discharging, reducing manual operation, shortening the feeding and discharging cycle by 30-50 minutes, increasing the shift output by 20-50%; the milling efficiency is higher by 2 -5 times, the one-time yield is as high as 70%, and the device can run continuously for more than 96 hours, reducing noise and ball mill power consumption, and there is almost no dust in the operation room, reducing power consumption by 60-80%, thereby greatly reducing production cost.

Owner:陈登刚

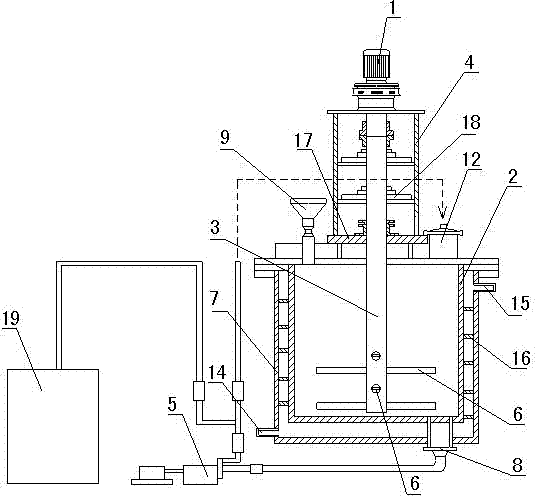

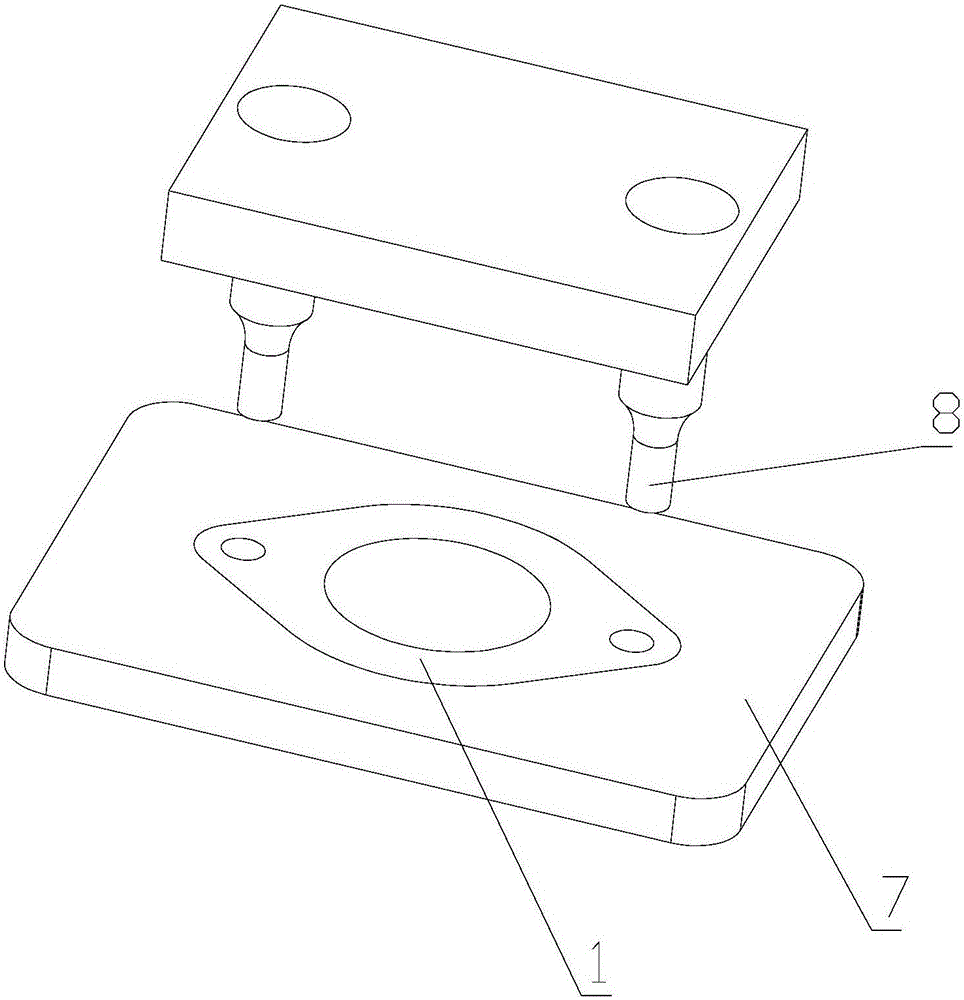

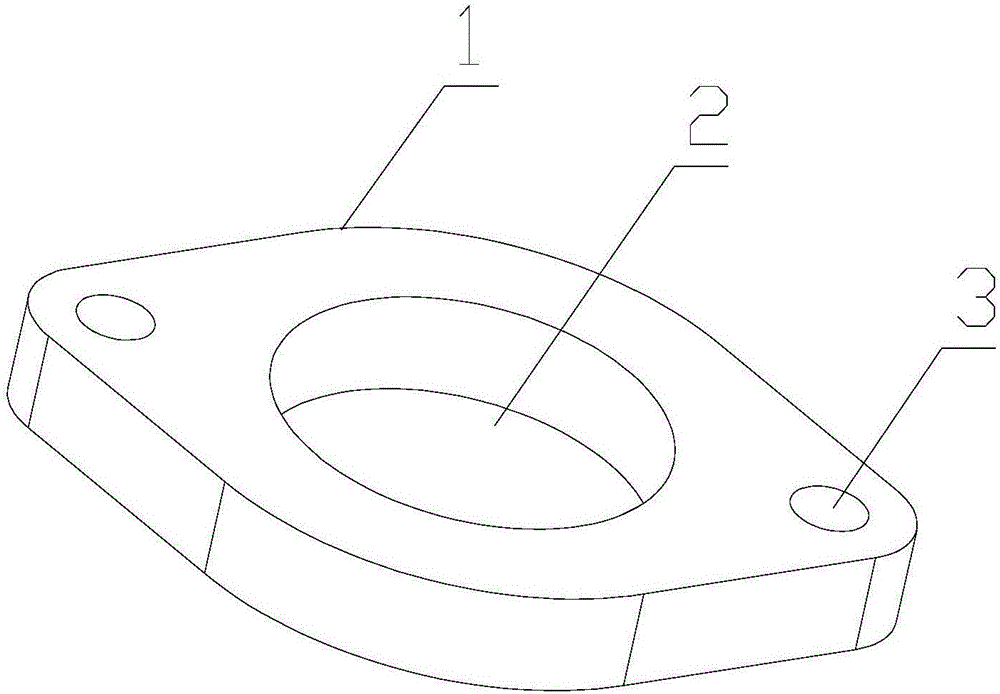

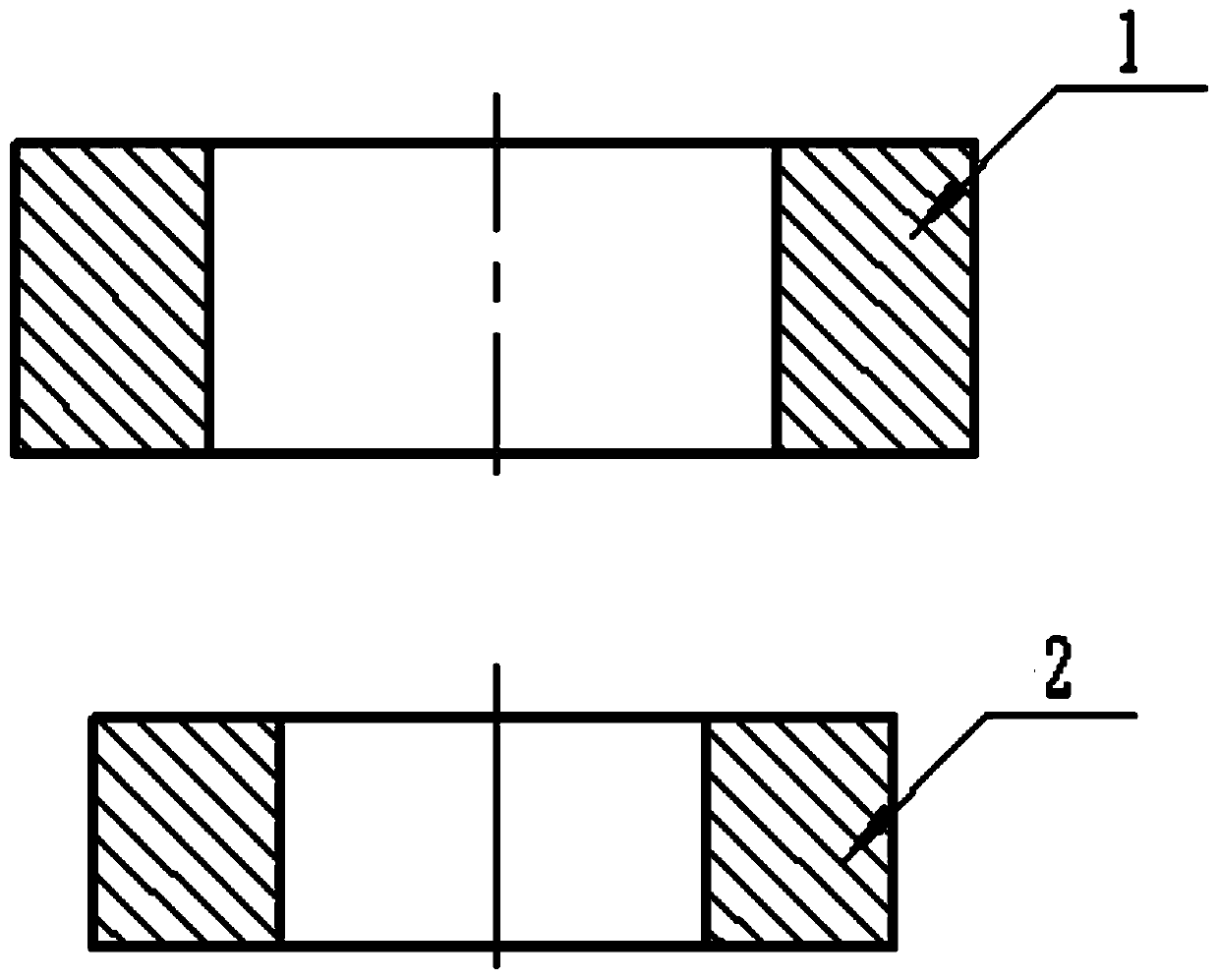

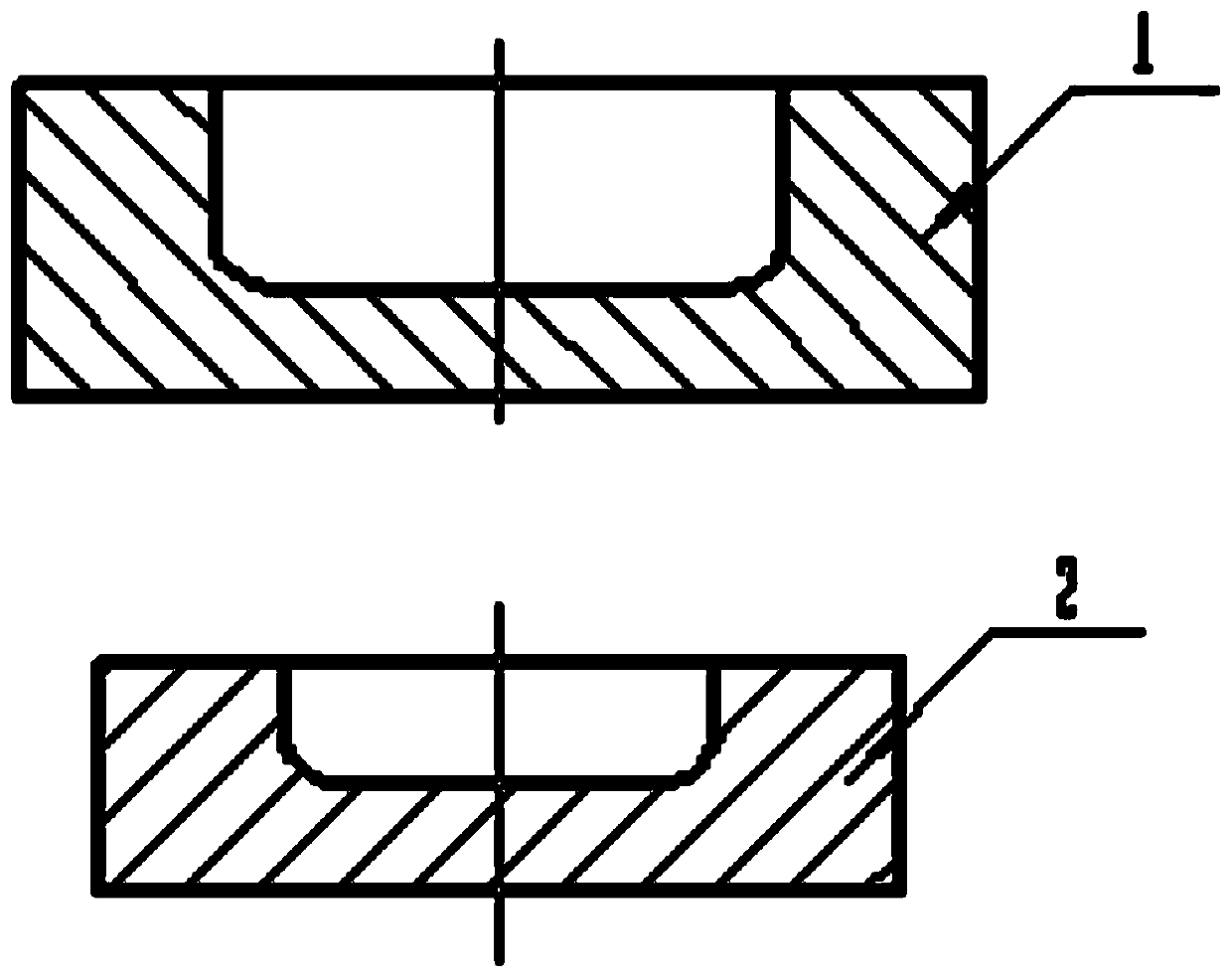

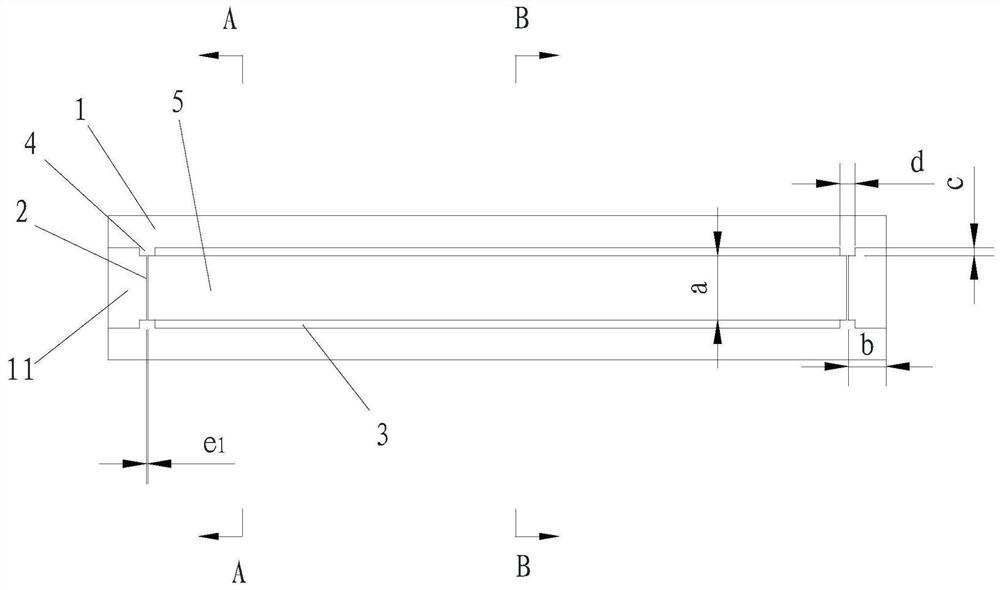

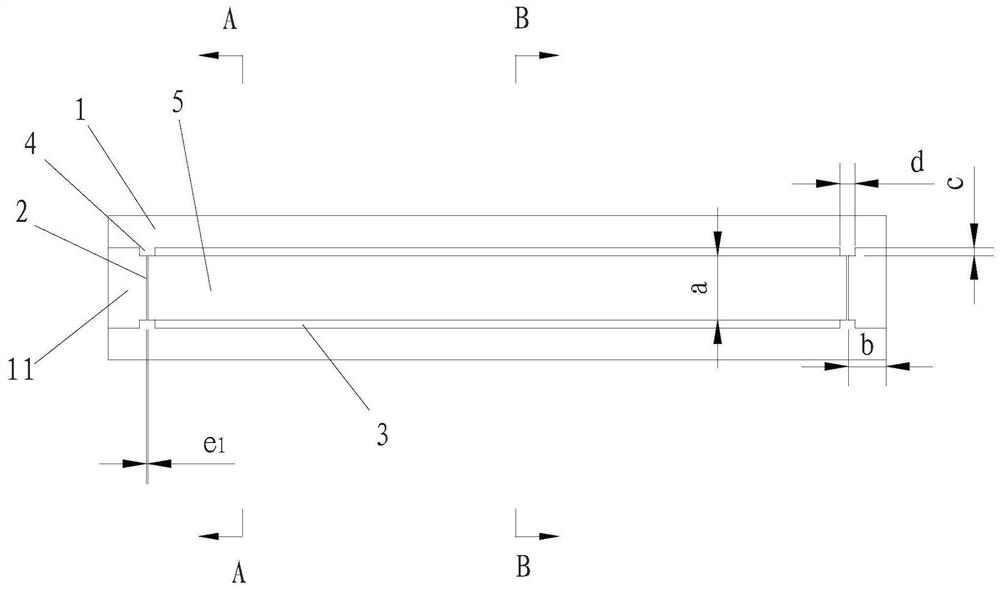

Automobile intake and exhaust flange and forging technology thereof

InactiveCN105921654AIncrease profitSolve the prone to waste edgeExhaust apparatusMetal-working apparatusIntermediate frequencyEngineering

The invention relates to the technical field of mechanical forging, in particular to an automobile intake and exhaust flange and a forging technology thereof. The forging technology comprises the following steps that (a) blanking is conducted, specifically, a rod raw material is sawn into standby blanks with the dimension meeting the technological requirement through a blanking machine or a belt mill; (b) heating is conducted, specifically, the blanks are heated in an intermediate frequency furnace; (c) preforging is conducted, specifically, the heated blanks are pressed to be flat through a die; (d) finish forging is conducted, specifically, the flat blanks are put into a closed-type die cavity to be machined, and workblanks is obtained; (e) middle holesa are punched, specifically, the middle holes in the workblanks are cut off, and finished workblank flanges are obtained; (f) shot blasting is conducted, specifically, burrs on the surfaces of the workblank flanges are removed; (g) arrangement is conducted, specifically, the workblank flanges are arranged in sequence and transferred to a work surface of a hydraulic machine; and (h) an installation hole is punched, specifically, a suction cup sucks one flange and places the flange into a die of the hydraulic machine with a buffer device, and the installation hole (3) in the flange is punched. The technology greatly improves the quality of the flange, increases the utilization rate of the raw material, reduces the cost and enables the product to be more competitive.

Owner:常州市凯国机械制造有限公司

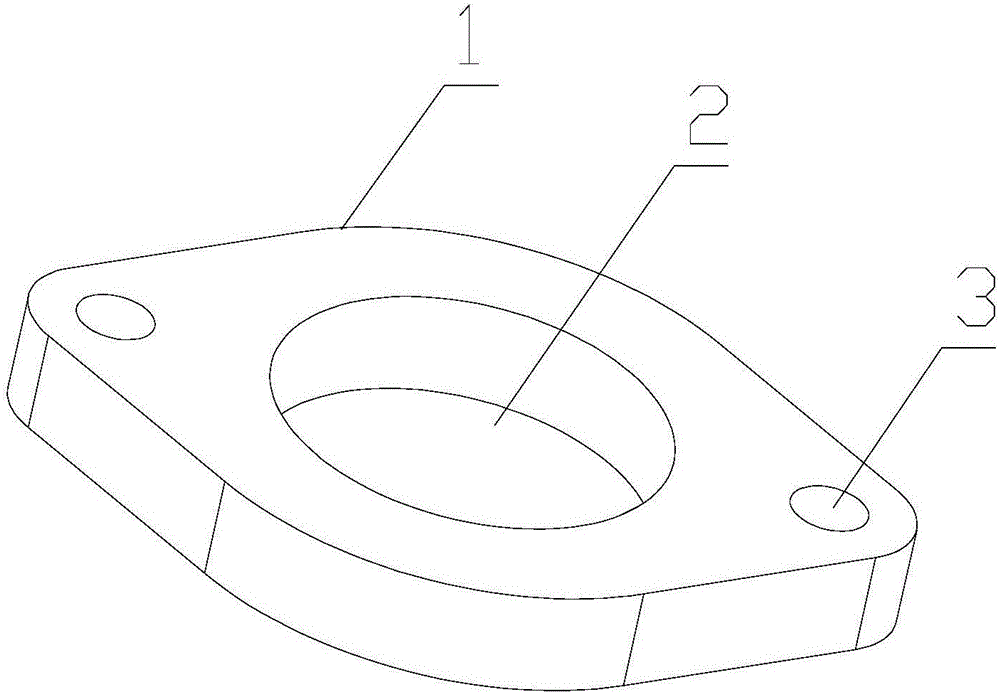

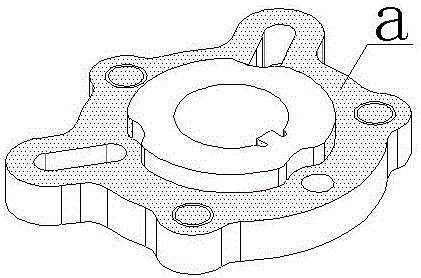

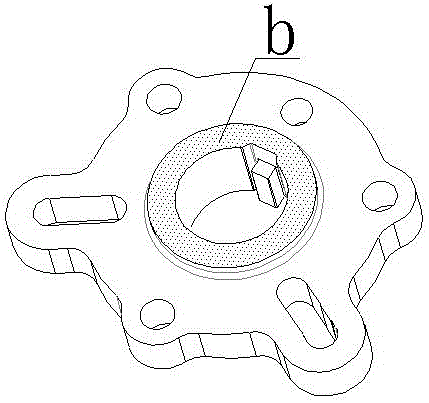

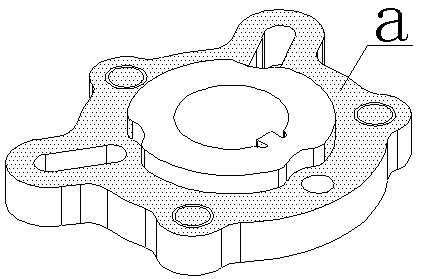

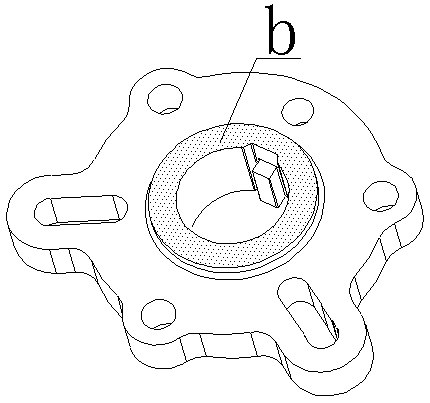

Camshaft toothed wheel hub for automobile engine and powder metallurgical preparation method for camshaft toothed wheel hub

ActiveCN106041094AReduce the amount of processingImprove shift outputTransportation and packagingMetal-working apparatusCamMachining

The invention discloses a camshaft toothed wheel hub for an automobile engine and a powder metallurgical preparation method for the camshaft toothed wheel hub. The method comprises the following steps: S101, preparing materials; S102, pressing and forming; S103, sintering blank; S104, refining and processing; S105, performing steam treatment; and S106, detecting and packaging. The method is linked up orderly, is fewer in processes, and has a material utilization rate higher than 95%. The camshaft toothed wheel hub obtained by the method is less in machining amount, is high in output per shift and is good in consistency, so that the product manufacturing cost is reduced by 50% when various performance requirements of the camshaft toothed wheel hub are met.

Owner:马鞍山市华东粉末冶金厂

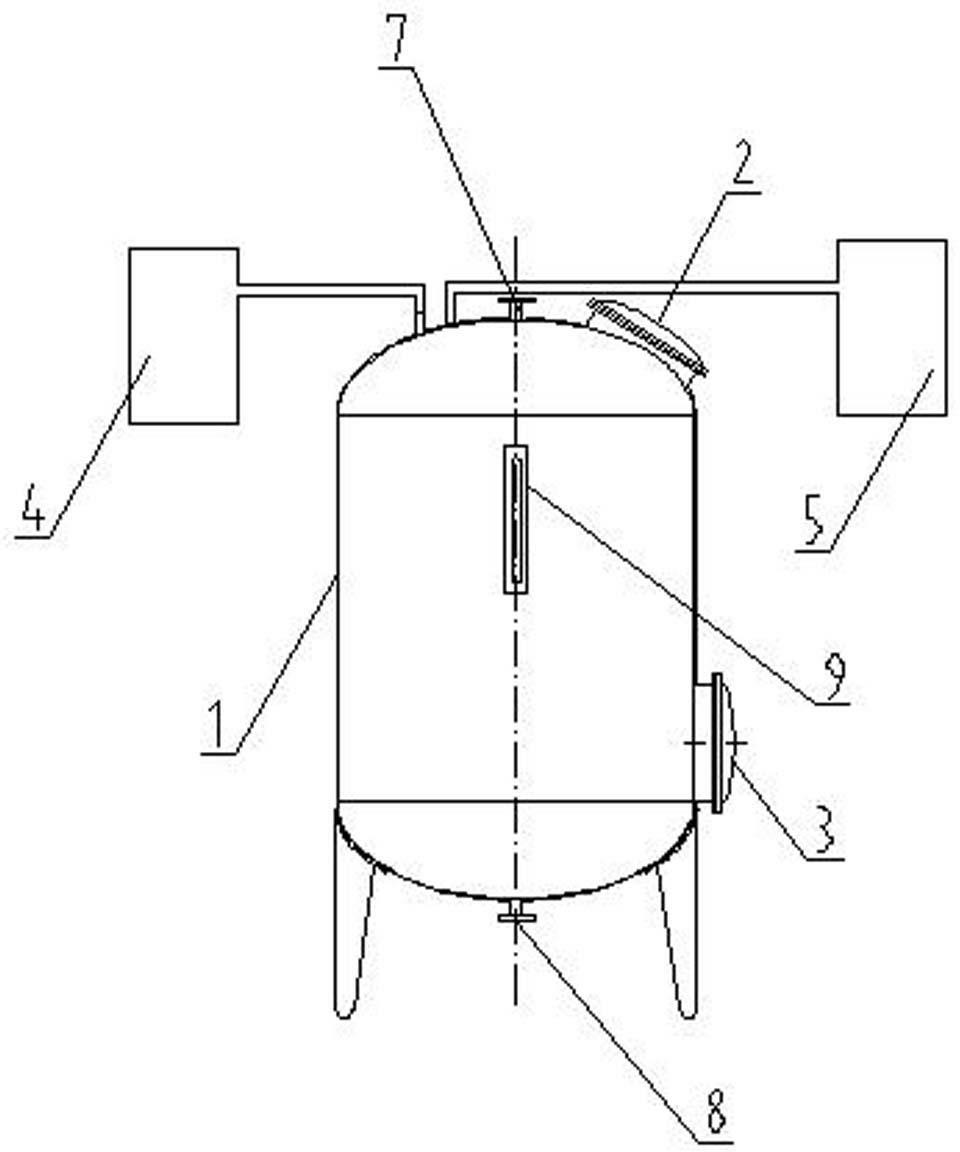

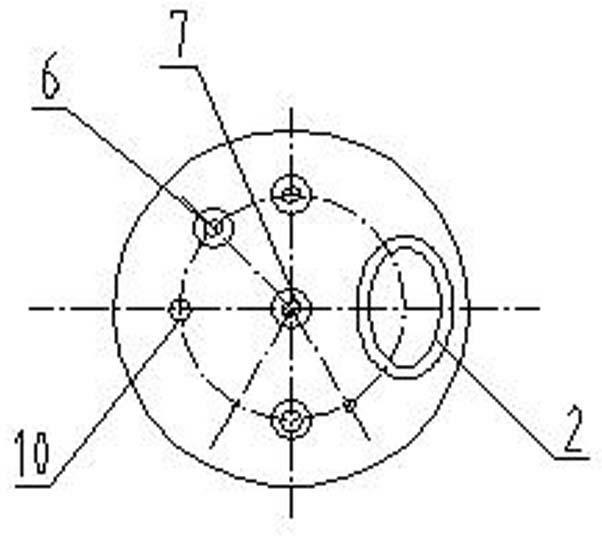

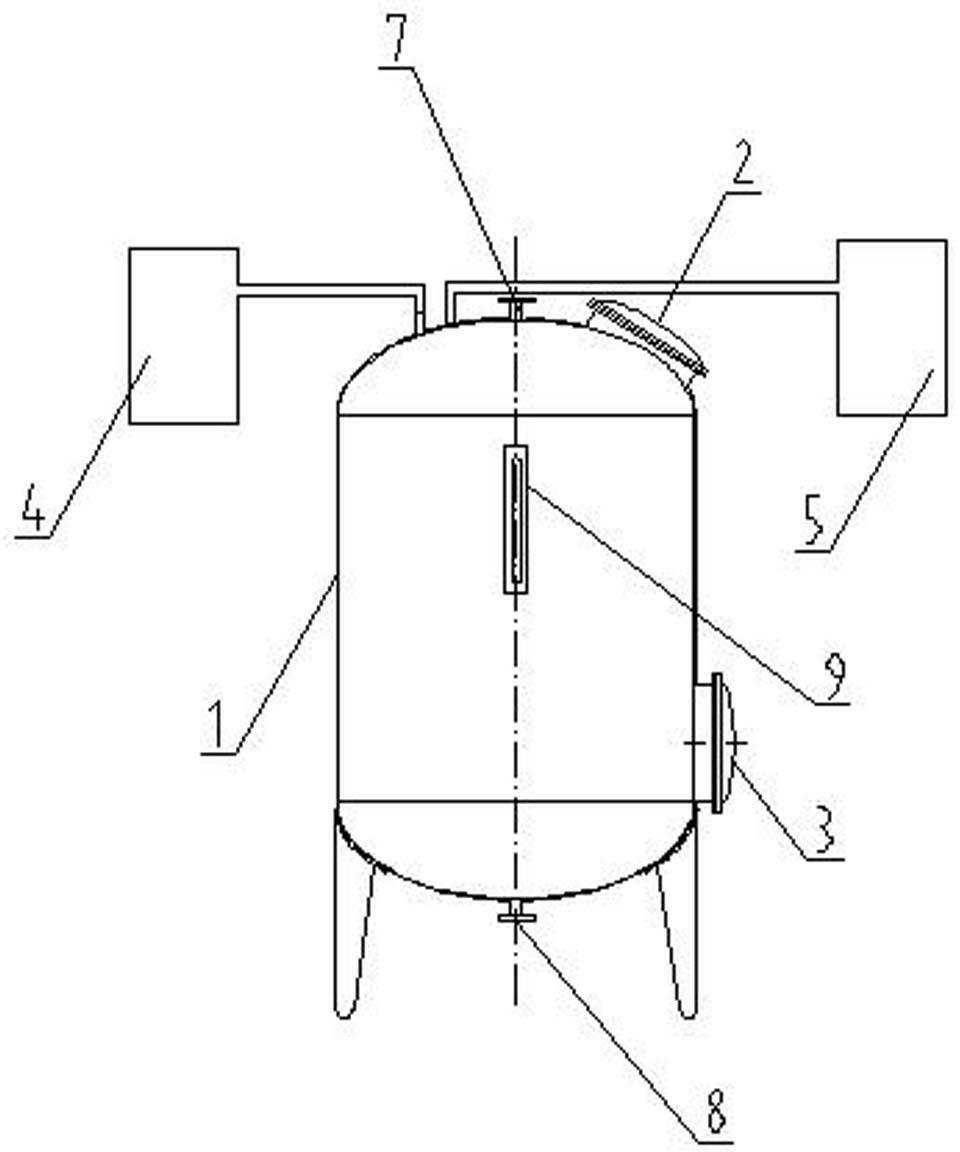

Tasty jar and tasty technology thereof

InactiveCN102318841AQuick taste and good effectFresh Taste JarFood preparationBiochemical engineeringRaw meat

The invention relates to a tasty jar and a tasty technology thereof. At present, the raw meat seasoning tasty technology of the meat production enterprises in China mainly dissolves the spice powder and other auxiliary materials into the water, the raw meat and feed liquid are rolled, tasted and seasoned, and then are carried out standing, quickly freezing, packaging and undergone other processes under a vacuum condition. The tasty jar comprises a jar body with supporting feet, wherein a feed port is arranged at the top of the jar body, a feed outlet is arranged at the lower part of one side of the outside of the jar body, a buffering jar is connected with the jar body through a broken empty opening at the top of the jar body, a vacuum pump is connected with the jar body through a vacuum opening at the top of the jar body, and the tasty technology is completed after the feed liquid extraction, raw material selection, seasoning and tasting, quick freezing and packaging. The invention is tasted through standing, the product state is complete, the appearance naturally presents the natural color, and the production link cannot cause degraded products with appearance defects; and the energy consumption of the equipment is reduced by 60%, the invention has a simple structure, is convenient to operate, is beneficial to cleaning, and cannot cause sanitation dead angles, and the product quality is effectively ensured.

Owner:SHAANXI JIANHE INDAL

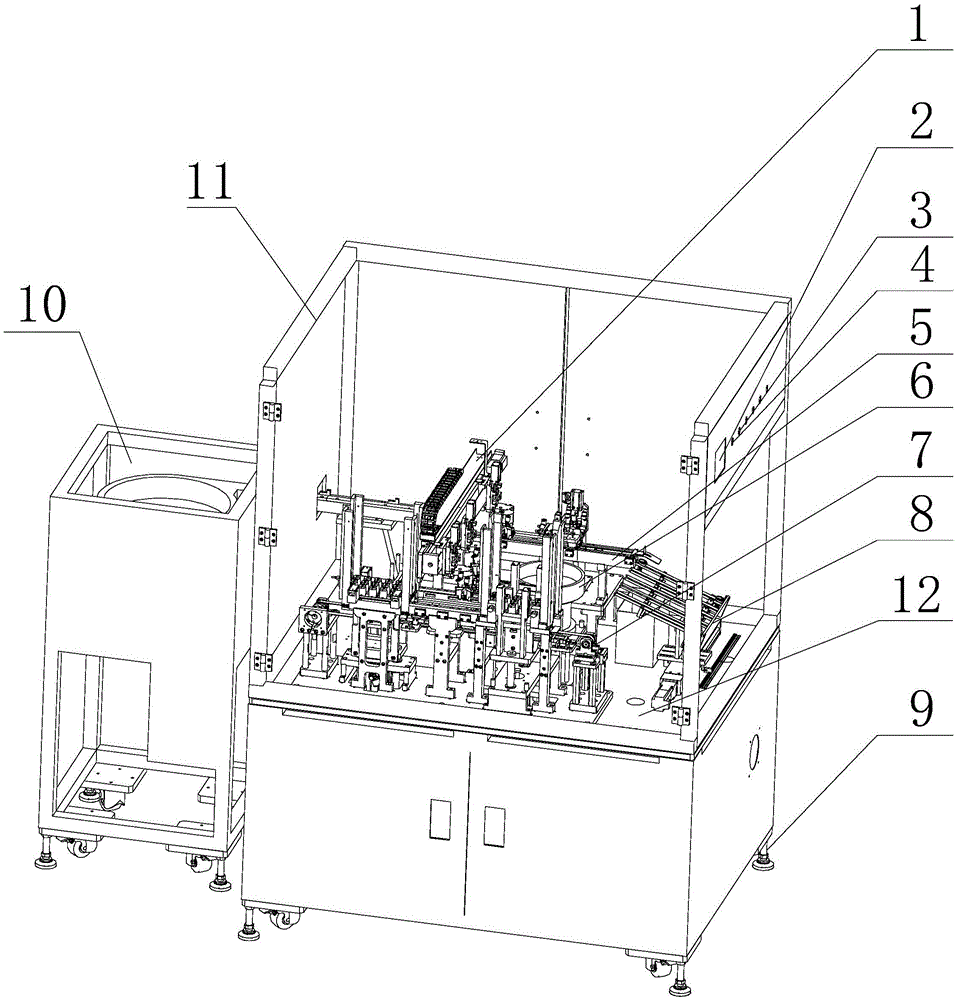

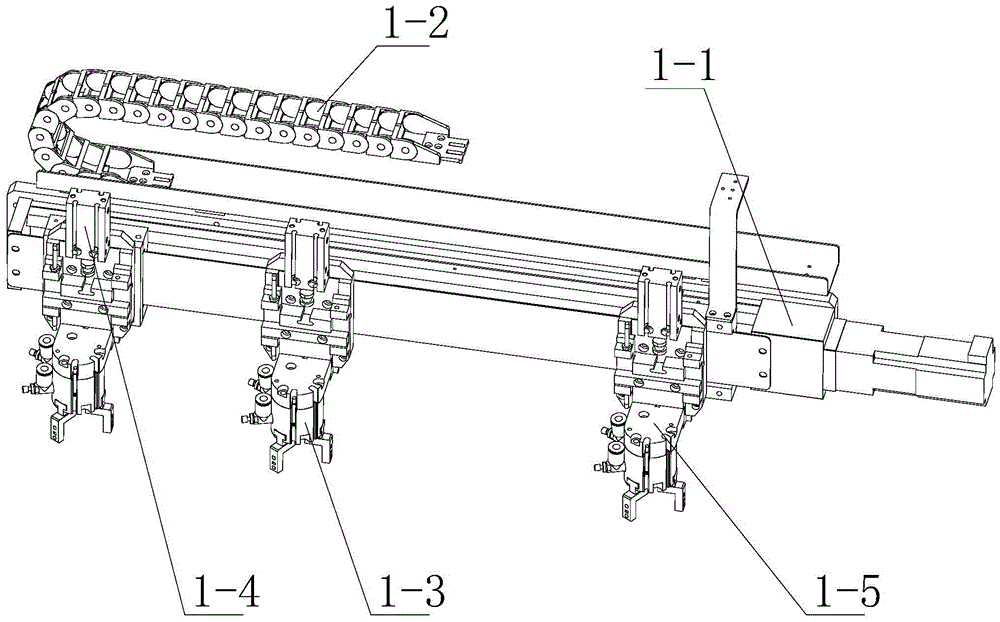

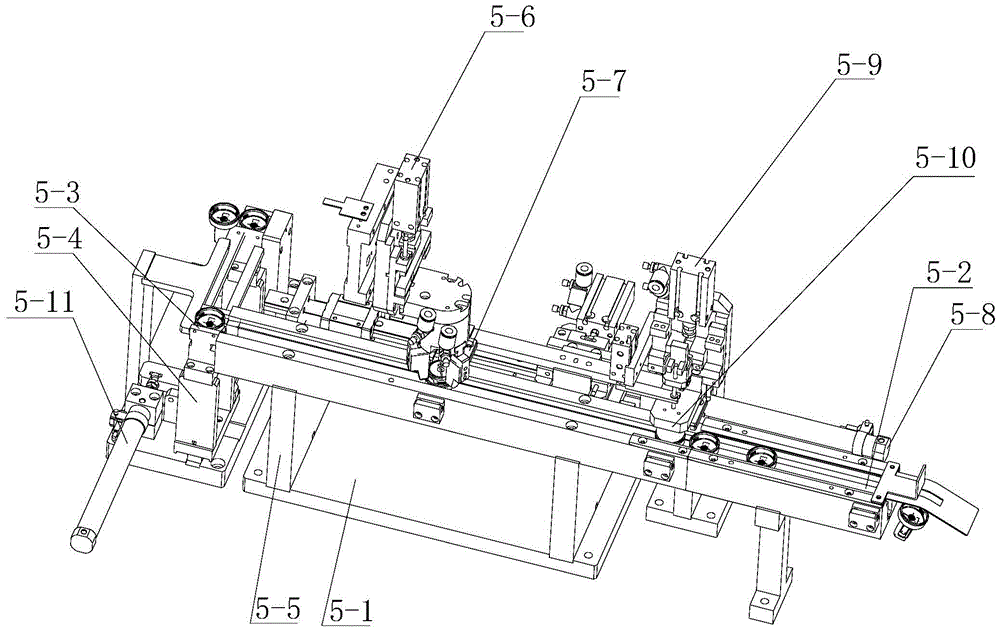

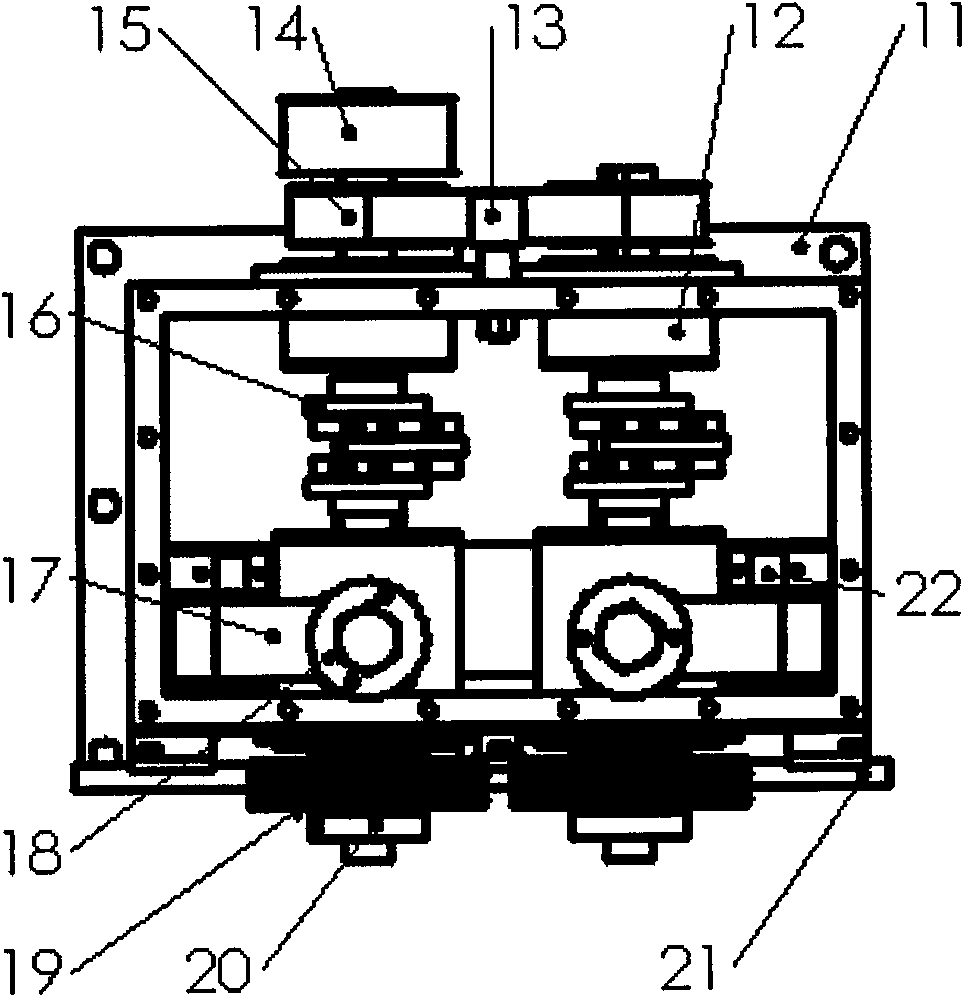

Automatic assembling system for automobile panel knobs

ActiveCN105458691AReduce labor intensityHigh degree of automationAssembly machinesHigh volume manufacturingLight guide

The invention relates to the technical field of machines, in particular to an automatic assembling system for automobile panel knobs. The automatic assembling system for the automobile panel knobs comprises a rack and is characterized in that a working table is arranged in the middle portion of the rack; a light guide body feeding mechanism is arranged in the center of the working table; a knob cover feeding mechanism is arranged on the front side of the light guide body feeding mechanism; an assembling mechanism is arranged on the rear side of the light guide body feeding mechanism; a finished product recovering mechanism is arranged on the right side of the light guide body feeding mechanism; a carrying mechanism is arranged above the left side of the assembling mechanism and the knob cover feeding mechanism; and a knob shell feeding mechanism is arranged on the left side of the rack. Compared with the prior art, the automatic assembling system for the automobile panel knobs is high in automation degree, easy to operate, high in assembling quality and suitable for mass production; and the labor intensity of workers is relieved, the assembling quality is stable, and the output per shift is substantially increased.

Owner:SHANGHAI KEY AUTOMOTIVE PLASTIC COMPONENT

Novel demolding frame

Owner:ANHUI DFSEAL RUBBER SHOCK ABSORBER TECH CO LTD

Closed mold and process for producing automotive intake and exhaust flanges by virtue of closed mold

InactiveCN105880452AIncrease profitSolve the prone to waste edgeForging/hammering/pressing machinesWheelsMaterials preparationPunching

The present invention relates to the technical field of mechanical forging, specifically to a closed mold and a process for producing automotive intake and exhaust flanges by virtue of the closed mold. The process comprises the following steps: (a) material preparation: sawing rod-like raw materials into blanks, in size as required by the process, for use by using a material cutter or a belt-type saw machine; (b) heating: delivering the blanks into an intermediate-frequency furnace for heating the blanks; (c) pre-forging: flattening the heated blanks by using a mold; (d) finish-forging: placing the flattened blanks into a mold cavity of the closed mold and processing the blanks to obtain semi-finished products; and (e) mesopore punching: cutting mesopores in the semi-finished products and obtaining finished flange blanks. By using the processing process with the closed mold, the quality of flange products is greatly improved, the problem of the utilization rate of raw materials is saved, the production cost is reduced, and competitive products are produced.

Owner:常州市凯国机械制造有限公司

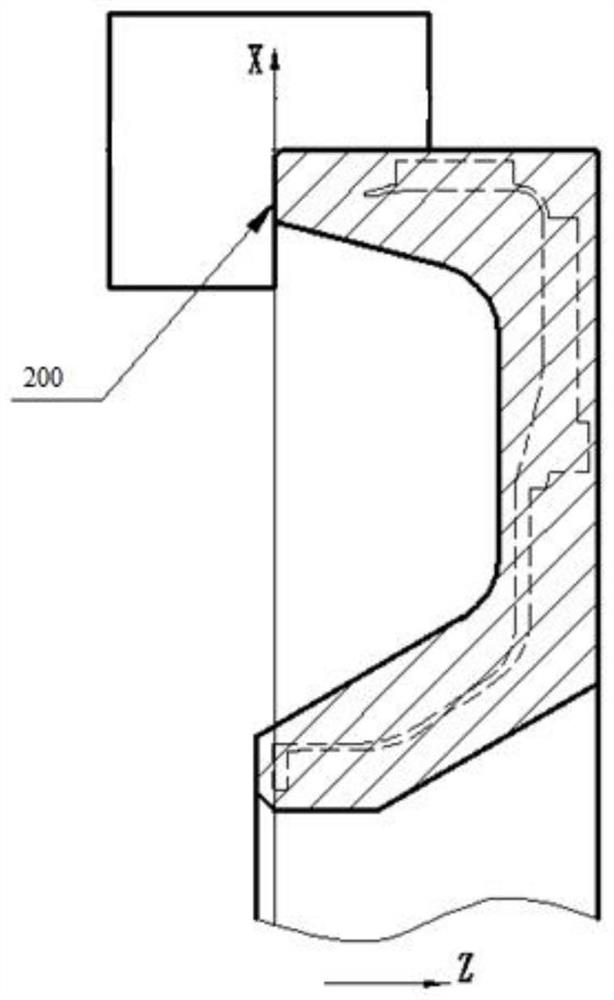

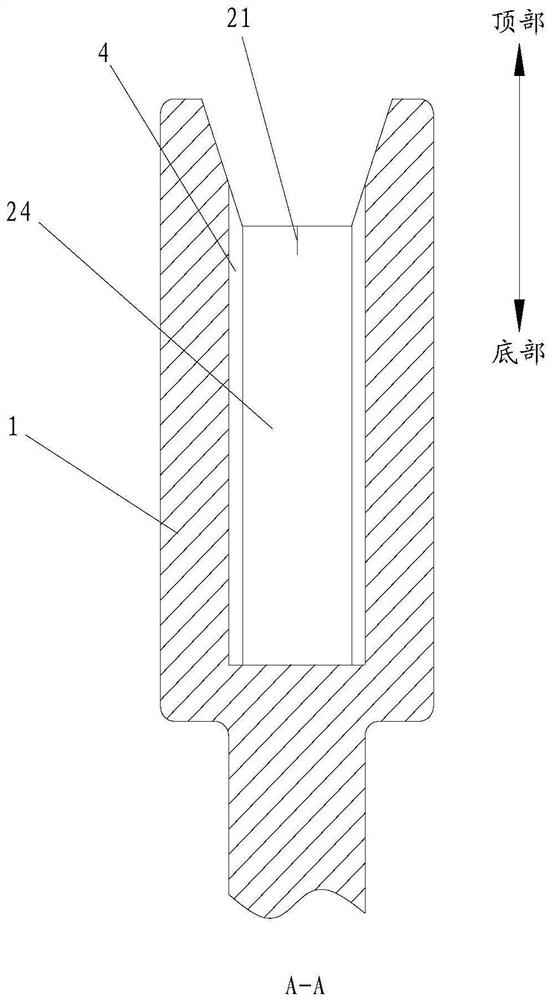

Machining method for large-diameter thin-wall diffuser of aero-engine

InactiveCN111673396AImprove processing efficiencyImprove shift outputStructural engineeringManufacturing engineering

The invention discloses a machining method for a large-diameter thin-wall diffuser of an aero-engine. The machining method comprises the following steps of clamping by using a soft claw, and semi-rough turning a diffuser outer contour; clamping by using the soft claw, and rough turning a diffuser inner contour; clamping by using a clamp, and rough turning the diffuser outer contour; rough millingradial vanes by using a pendulum-type cutter feeding; rough milling axial vanes; clamping by using a clamp, fine turning the radial vanes and an outer circle datum; clamping by using the clamp, fine turning an inner contour outer ring area, and semi-fine turning an inner contour inner ring area; clamping by using the clamp, and semi-fine turning an outer contour; fine-turning end surfaces of radial vanes; fine turning inner contour; fine turning outer contour; fine milling the radial vanes; and fine milling the axial blades. Through the machining method, the numerical milling rough machining efficiency of the radial vanes is high; the output per shift is improved by 150 percent; and the machining cost of components is reduced. The deformation of the diffuser is reduced; the machining quality is ensured; and then, the yield of diffusers is improved.

Owner:HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

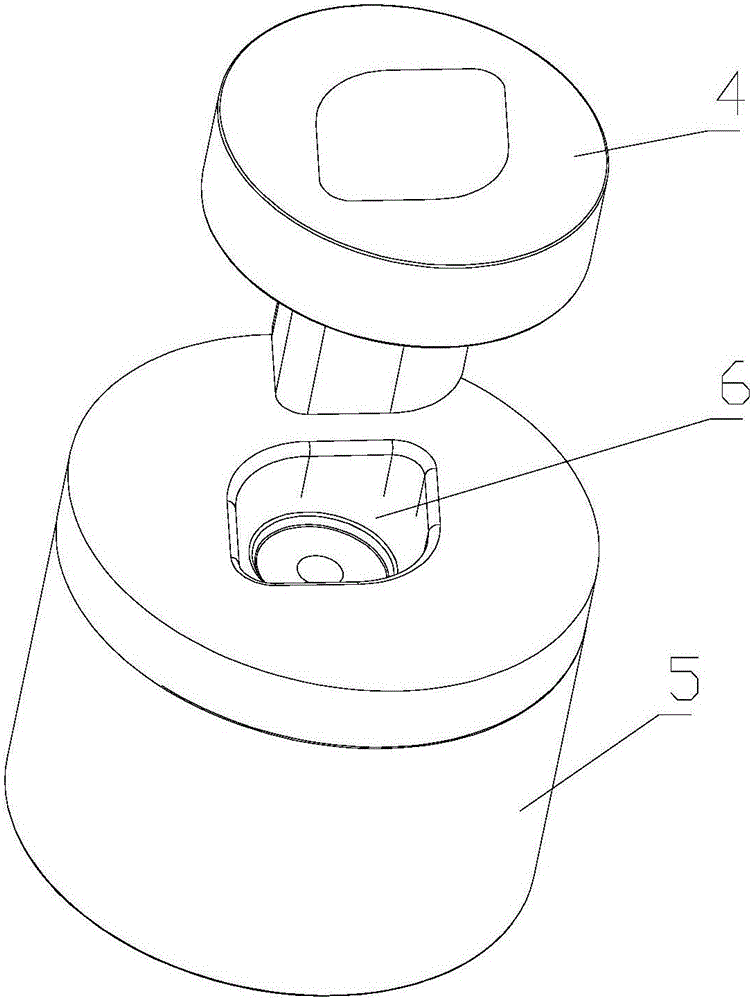

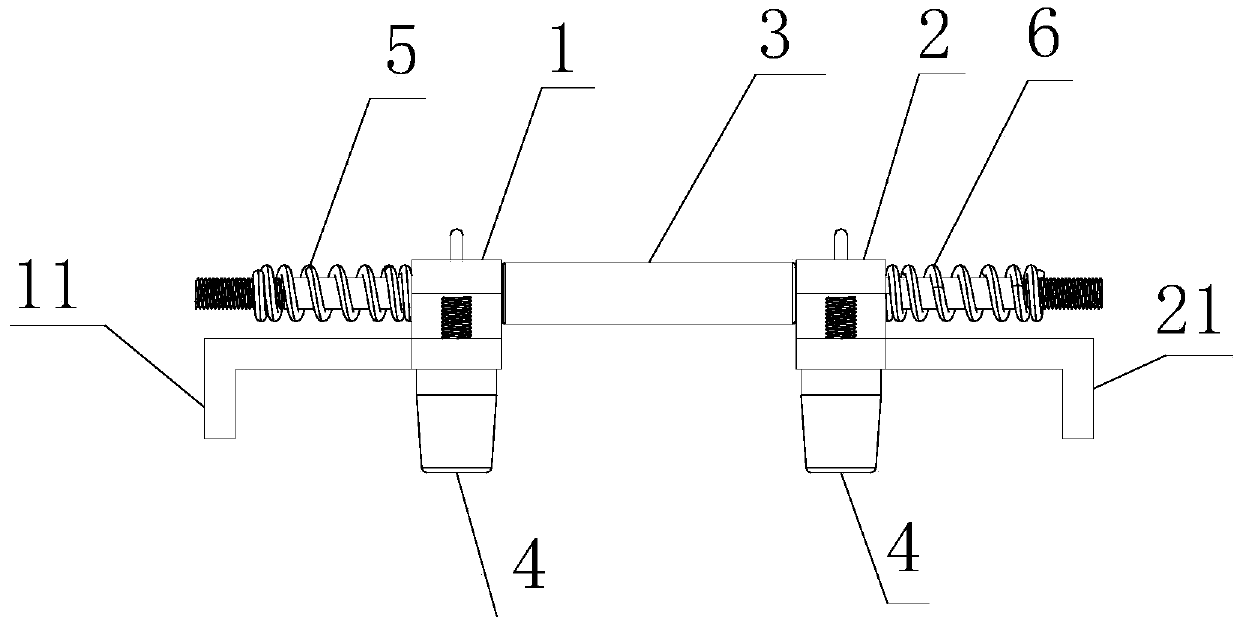

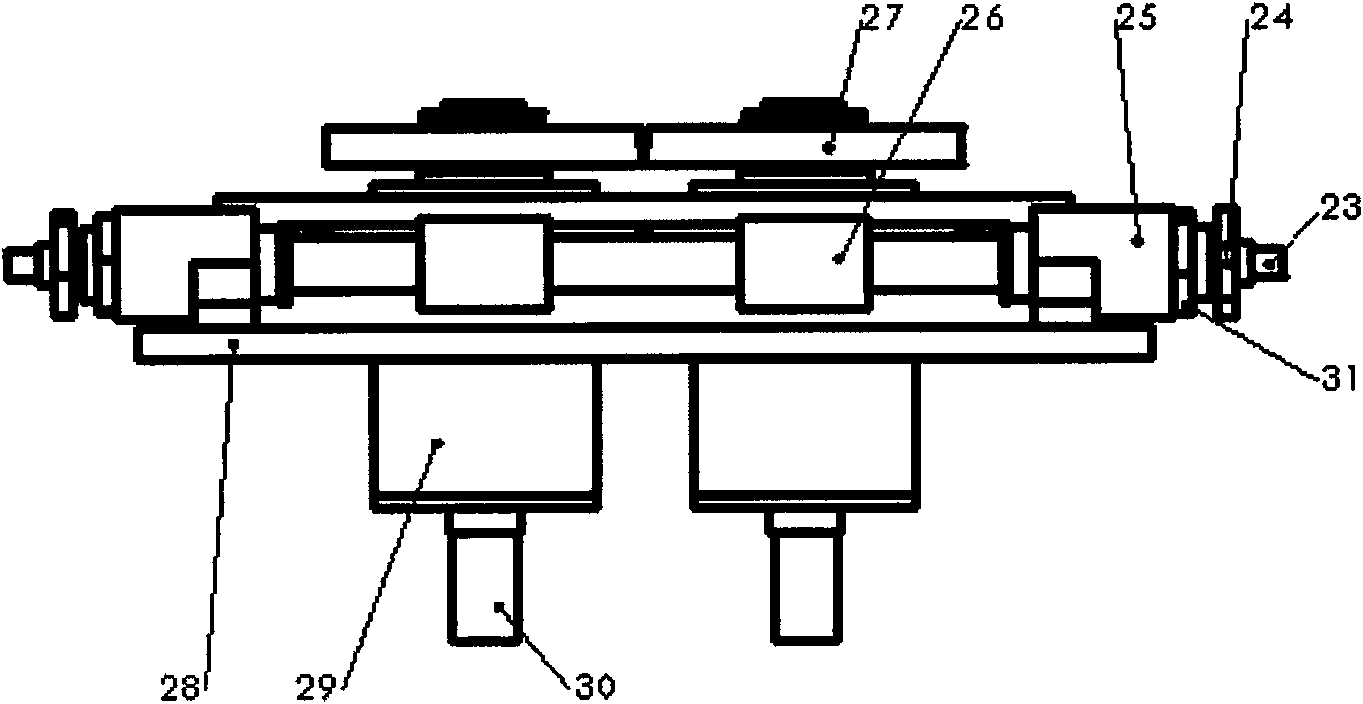

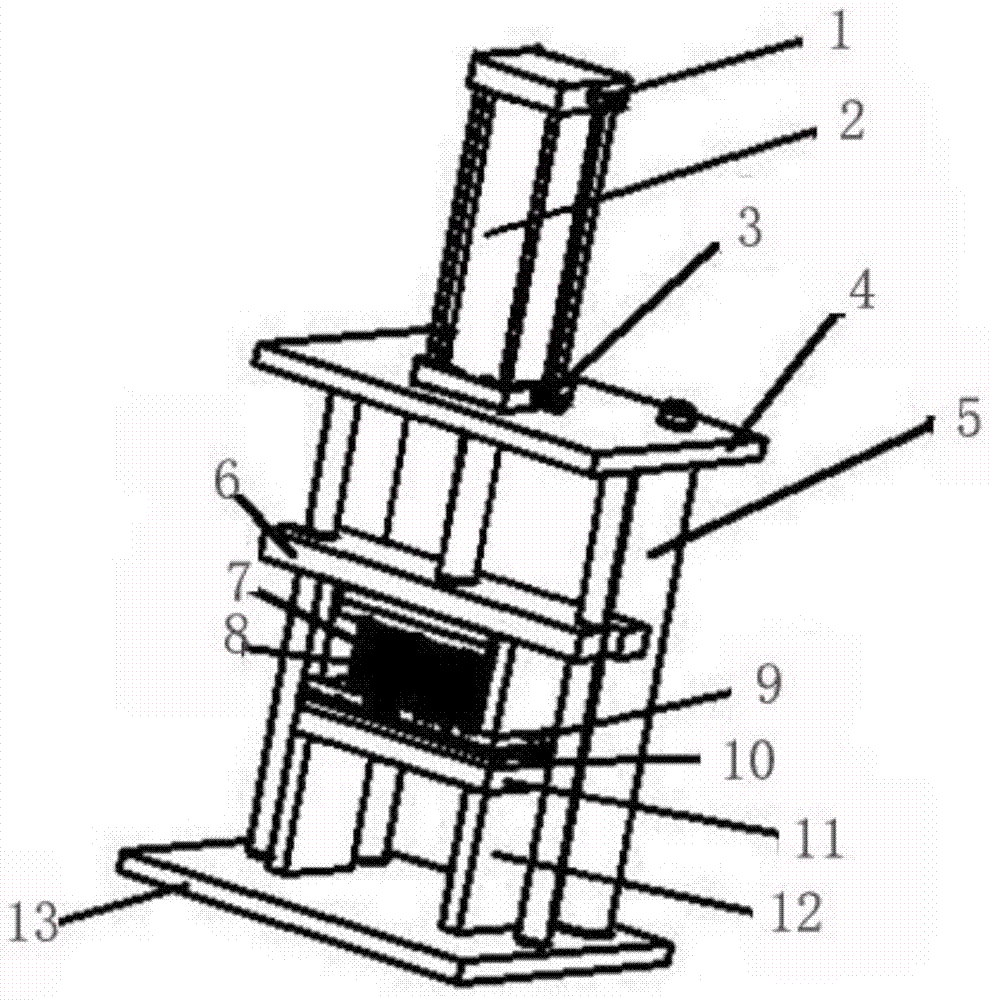

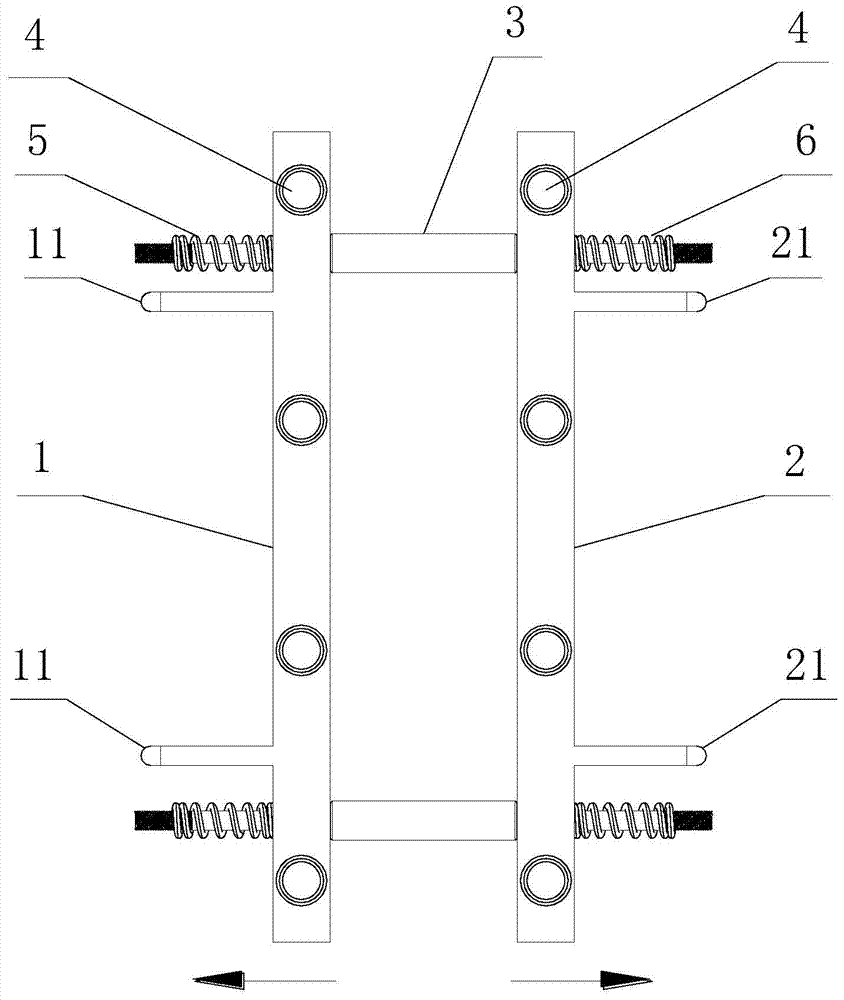

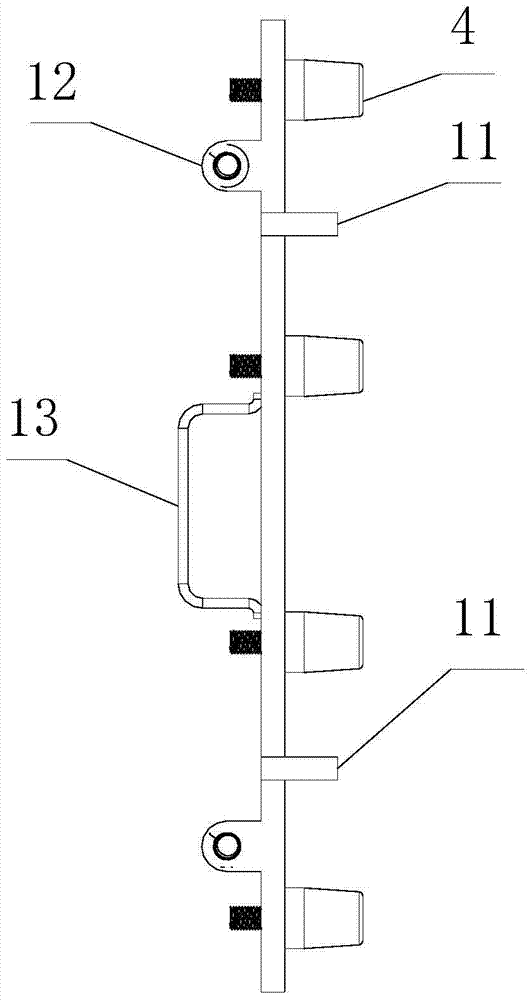

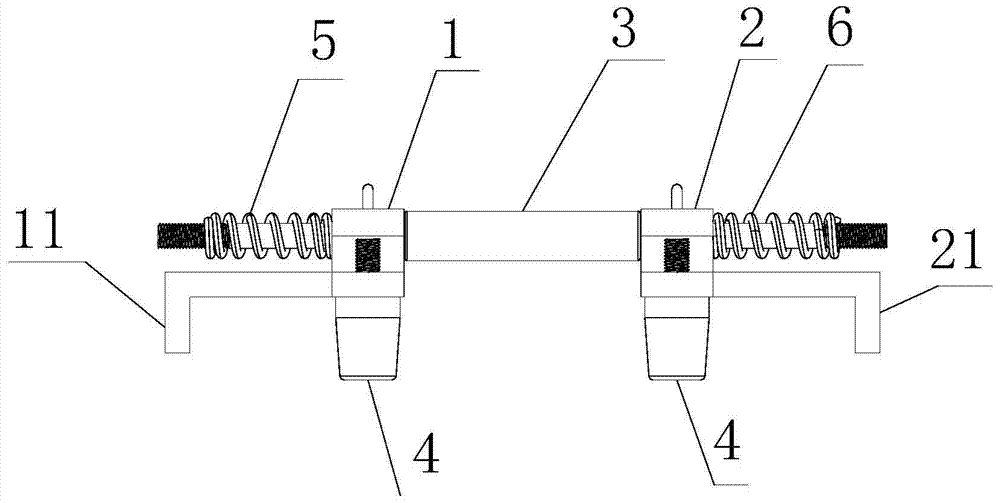

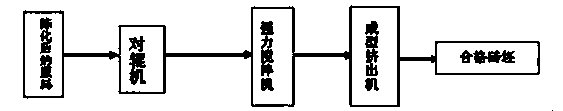

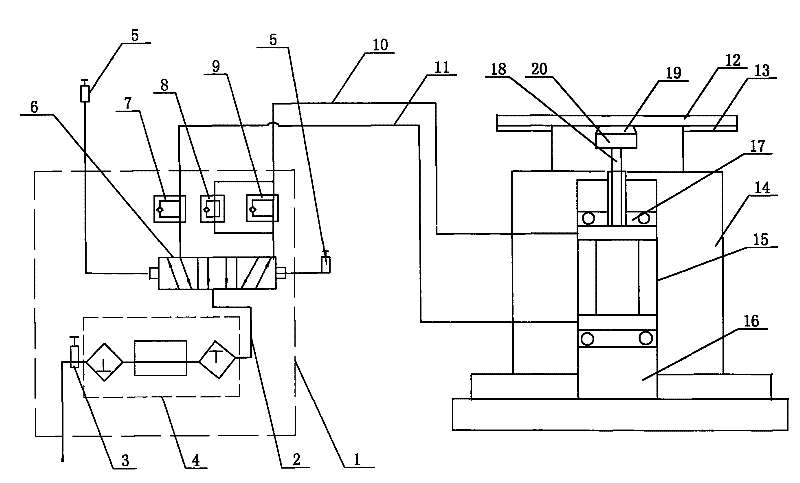

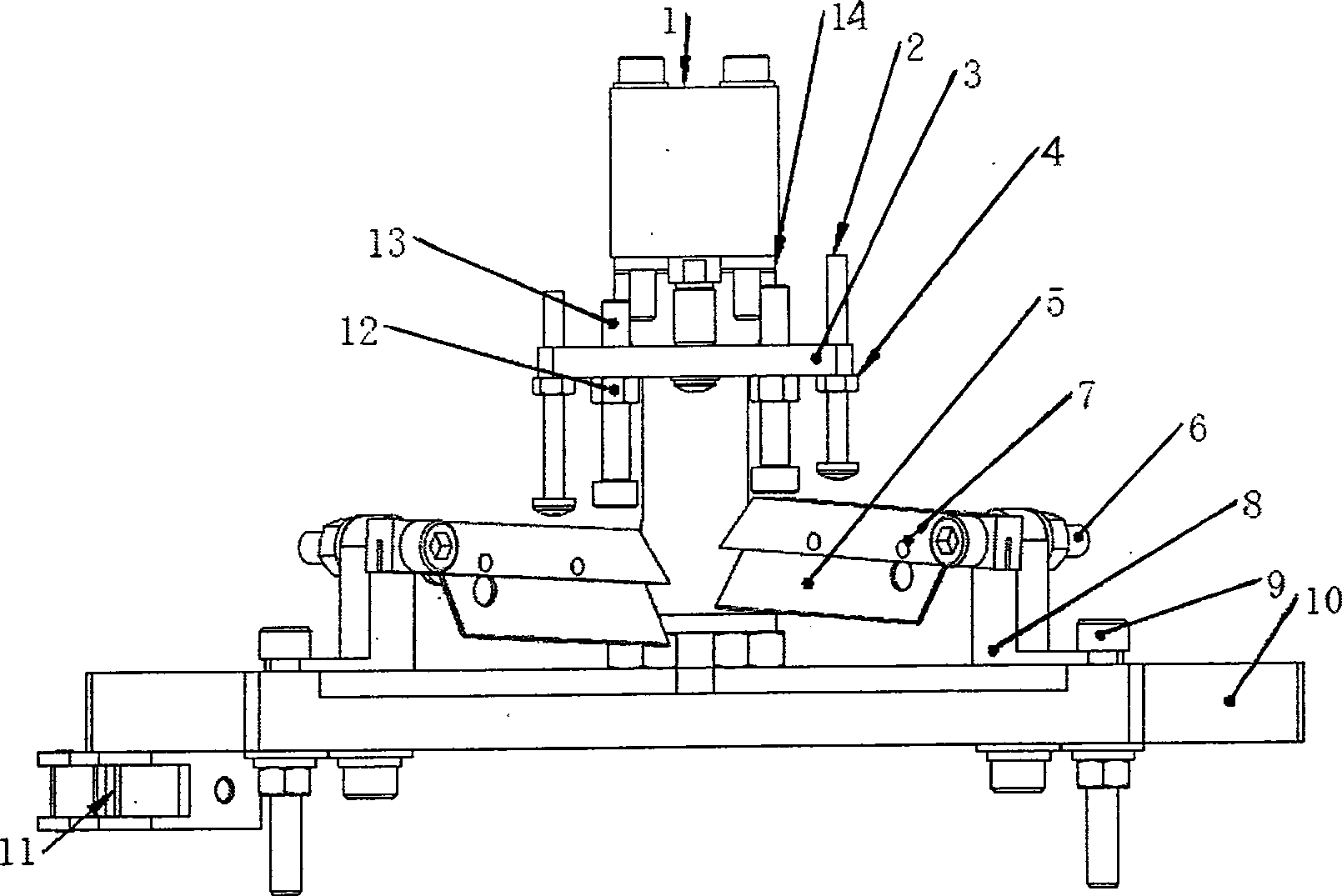

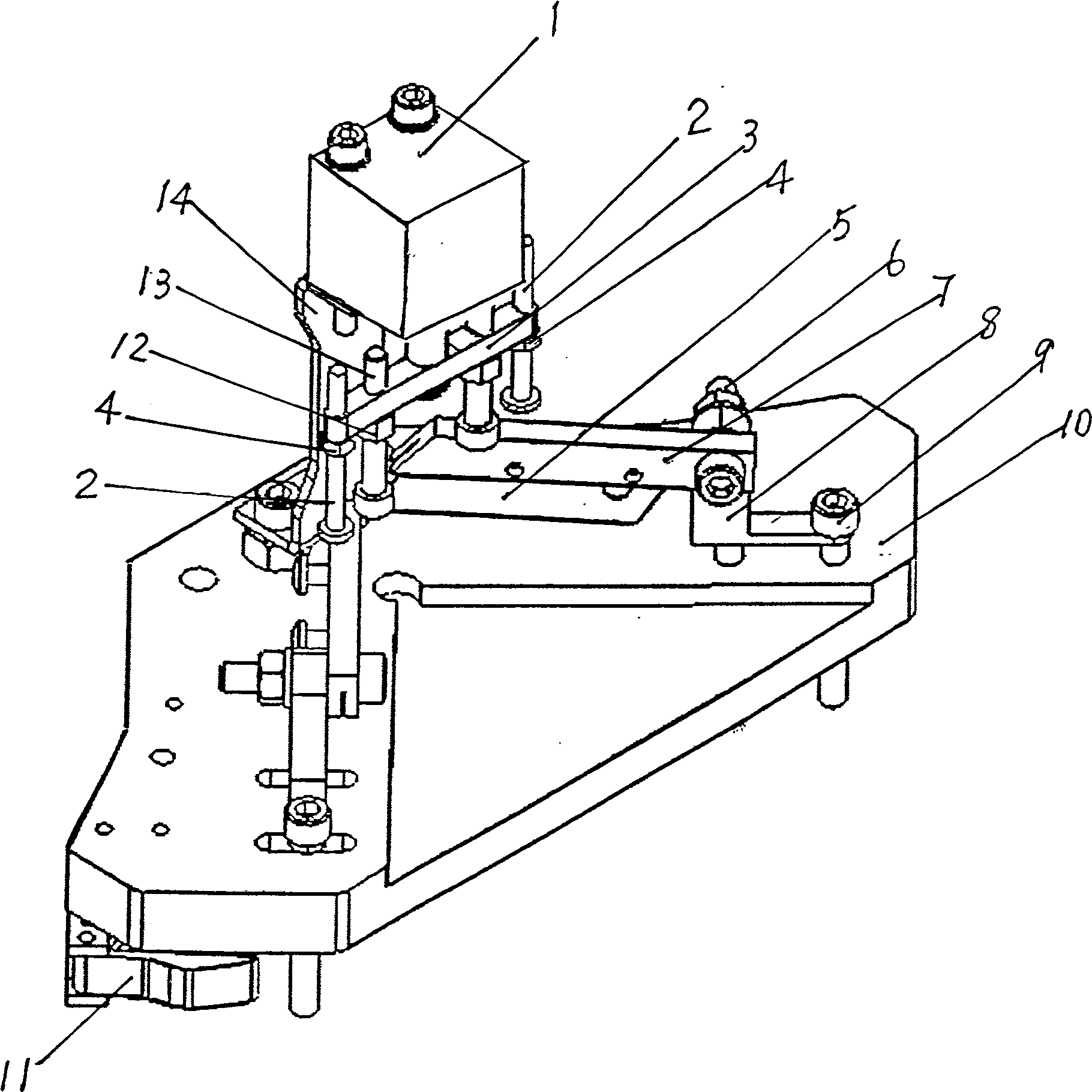

Automatic feeding device for four-column hydraulic column system

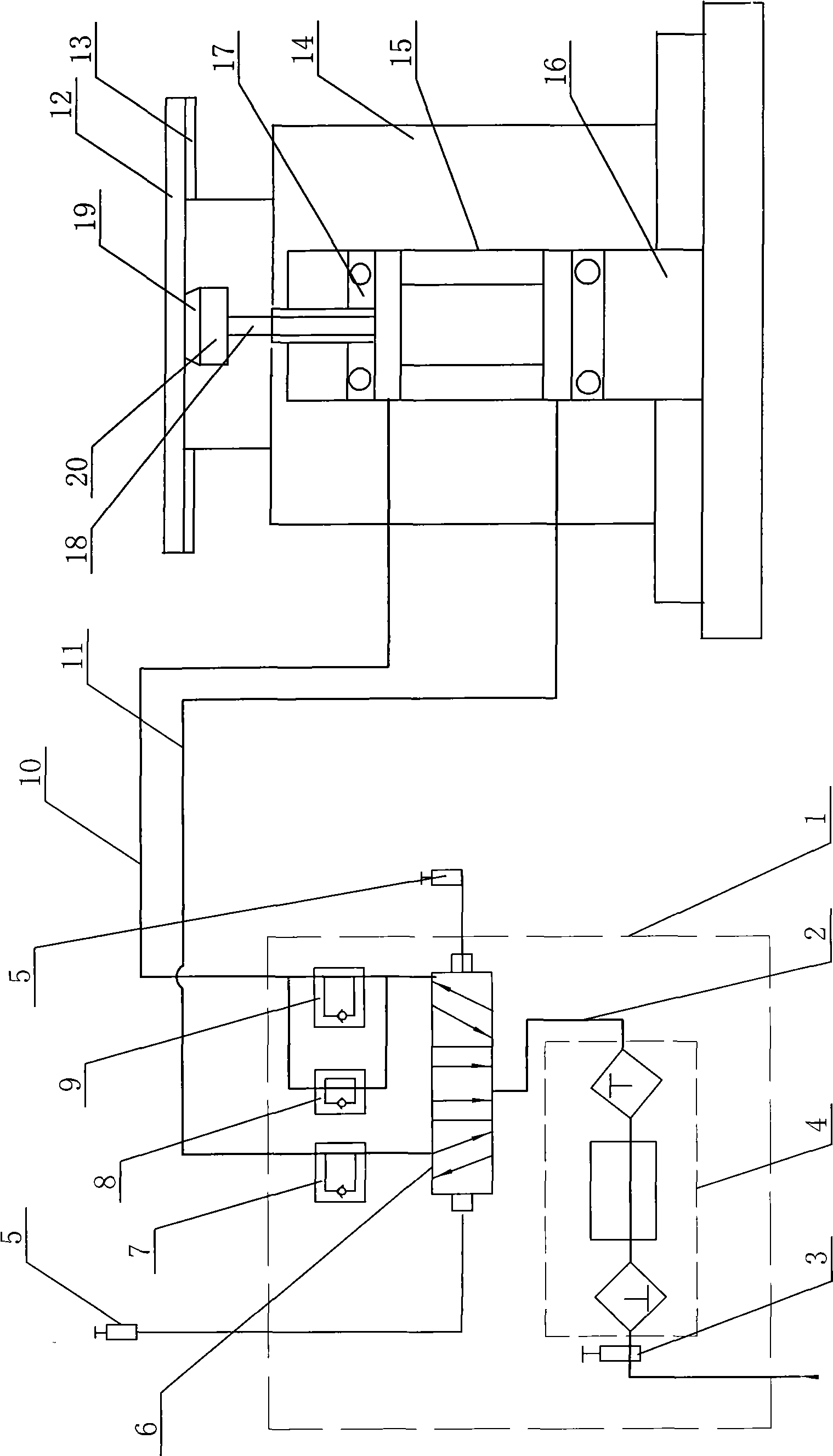

ActiveCN101543751AIncrease labor intensityReduce labor intensityUltra-high pressure processesElectrical controlElectric control

The invention discloses an automatic feeding device for a four-column hydraulic column system, which comprises a power driving part, an electric control part and a mechanical execution part, wherein the power driving part is in driving connection with the mechanical execution part by a pipe, and the electric control part is in electric signal connection with the pipe by a wire. The device has simple structure and convenient operation, fully lowers labor intensity of workers, ensures life safety of the workers, saves raw materials, fully improves production efficiency and enterprise efficiency and has extremely strong practicability and popularization value.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

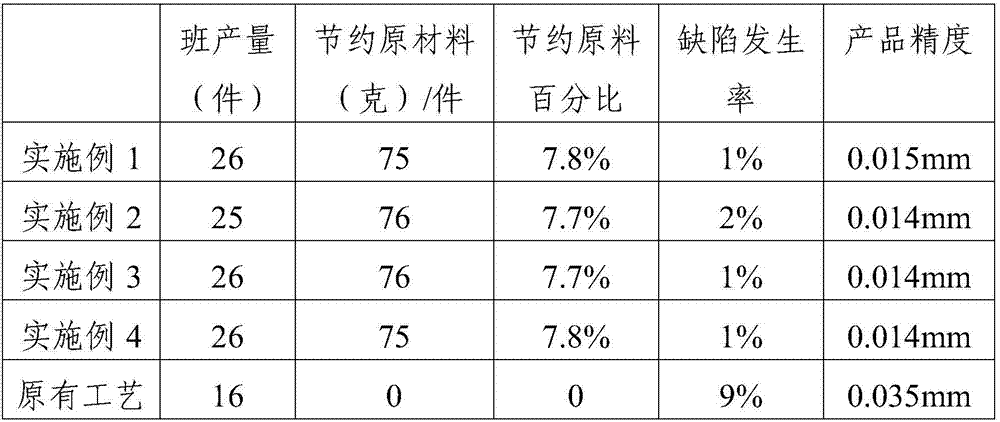

A kind of forging process of left axle shaft of automobile differential gear

ActiveCN107282849BReduce the blanking weightImprove shift outputEngine componentsLeft halfIndustrial engineering

The invention provides a forging process of a left half shaft of an automobile differential mechanism and relates to the technical field of forging. The forging process includes the procedures of feeding, heating, forming, edge cutting, hardening and tempering and shot blasting. A free forging drawing-out mold cavity is designed, it is guaranteed that the drawing-out mold cavity is matched with a finish forging mold cavity, a positioning device is designed and arranged on a drawing-out mold, it is guaranteed that the drawing-out mold cavity is matched with the finish forging mold cavity, and the situation that the size of a forging stock obtained after finish forging does not meet drawing requirements due to the fact that the blank making diameter is large or small is avoided. The positioning device is designed on the drawing-out mold, the axial and radial sizes of the forging stock are controlled, the product accuracy is greatly improved, multiple forging defects caused by the fact that the blank making length is large or small are overcome, effective controllability is brought to the production process, and the output per shift is increased.

Owner:安徽众鑫科技股份有限公司

Forging process of left half shaft of automobile differential mechanism

ActiveCN107282849AReduce the blanking weightImprove shift outputEngine componentsLeft halfControllability

The invention provides a forging process of a left half shaft of an automobile differential mechanism and relates to the technical field of forging. The forging process includes the procedures of feeding, heating, forming, edge cutting, hardening and tempering and shot blasting. A free forging drawing-out mold cavity is designed, it is guaranteed that the drawing-out mold cavity is matched with a finish forging mold cavity, a positioning device is designed and arranged on a drawing-out mold, it is guaranteed that the drawing-out mold cavity is matched with the finish forging mold cavity, and the situation that the size of a forging stock obtained after finish forging does not meet drawing requirements due to the fact that the blank making diameter is large or small is avoided. The positioning device is designed on the drawing-out mold, the axial and radial sizes of the forging stock are controlled, the product accuracy is greatly improved, multiple forging defects caused by the fact that the blank making length is large or small are overcome, effective controllability is brought to the production process, and the output per shift is increased.

Owner:安徽众鑫科技股份有限公司

Loop whee with detachable wearing layer

ActiveCN104056864AReduce the number of replacementsReduce labor intensityFlexible work arrangmentsMetal rolling arrangementsWire rodStructural engineering

The invention relates to a loop wheel with a detachable wearing layer. The loop wheel is characterized by comprising a guide wheel shaft, wherein a bearing is mounted on the guide wheel shaft; a check ring is arranged on the upper part of the guide wheel shaft; the check ring is used for fixing; the loop wheel further comprises a positioning sleeve; the bearing is mounted in the positioning sleeve; a first end cover and a second end cover are respectively arranged at upper and lower ends of the loop wheel. The design is more suitable for the rolling of high-speed wire rod products; the exchanging times of the loop wheel can be greatly reduced; the steel ratio is increased; the yield in one shift is greatly promoted; the labor intensity of on-site workers is relieved; the production is stabilized; at the cost aspect, only the worn sleeve is exchanged, and the other parts can be repeatedly used, so that the cost of spare parts is greatly reduced.

Owner:JIANGSU YONGGANG GROUP CO LTD

Novel wire feeding equipment for production of electric welding rods and operating method thereof

InactiveCN102161140AStable wire feeding speedReduce labor intensityWelding/cutting media/materialsSoldering mediaTransmission beltEngineering

The invention relates to novel wire feeding equipment for production of electric welding rods, and the novel wire feeding equipment provided by the invention is characterized by comprising a rack, a machine head part, a hair wheel part, a material storing hopper, a hair wheel driving motor and a roll driving motor, wherein the material storing hopper is used for storing welding cores and providing the welding cores for the hair wheel part uninterruptedly; the hair wheel part is used for providing horizontal speed for the welding cores vertically falling from the material storing hopper, so that the welding cores enter the roll of the machine head in an accelerating manner in the horizontal direction; the machine head part provides larger horizontal thrust for the welding cores, so that the welding cores enter a powder coating machine under the action of thrust, and become the welding rods after being coated with flux powder on the powder coating machine so as to fall on a transmission belt; and a transmission part provides power for the equipment. The novel wire feeding equipment has the advantages that the synchronous belt transmission is used for replacing gear transmission, a transmission device is simplified, the repair of a correcting machine is strip-block type repair, the labor intensity and time for maintenance and repair are greatly shortened, the high-speed and stable wire feeding speed can be provided for the powder coating machine, and the labor productivity is improved, so that the novel wire feeding equipment is applicable to production of the electric welding rods with various specifications.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

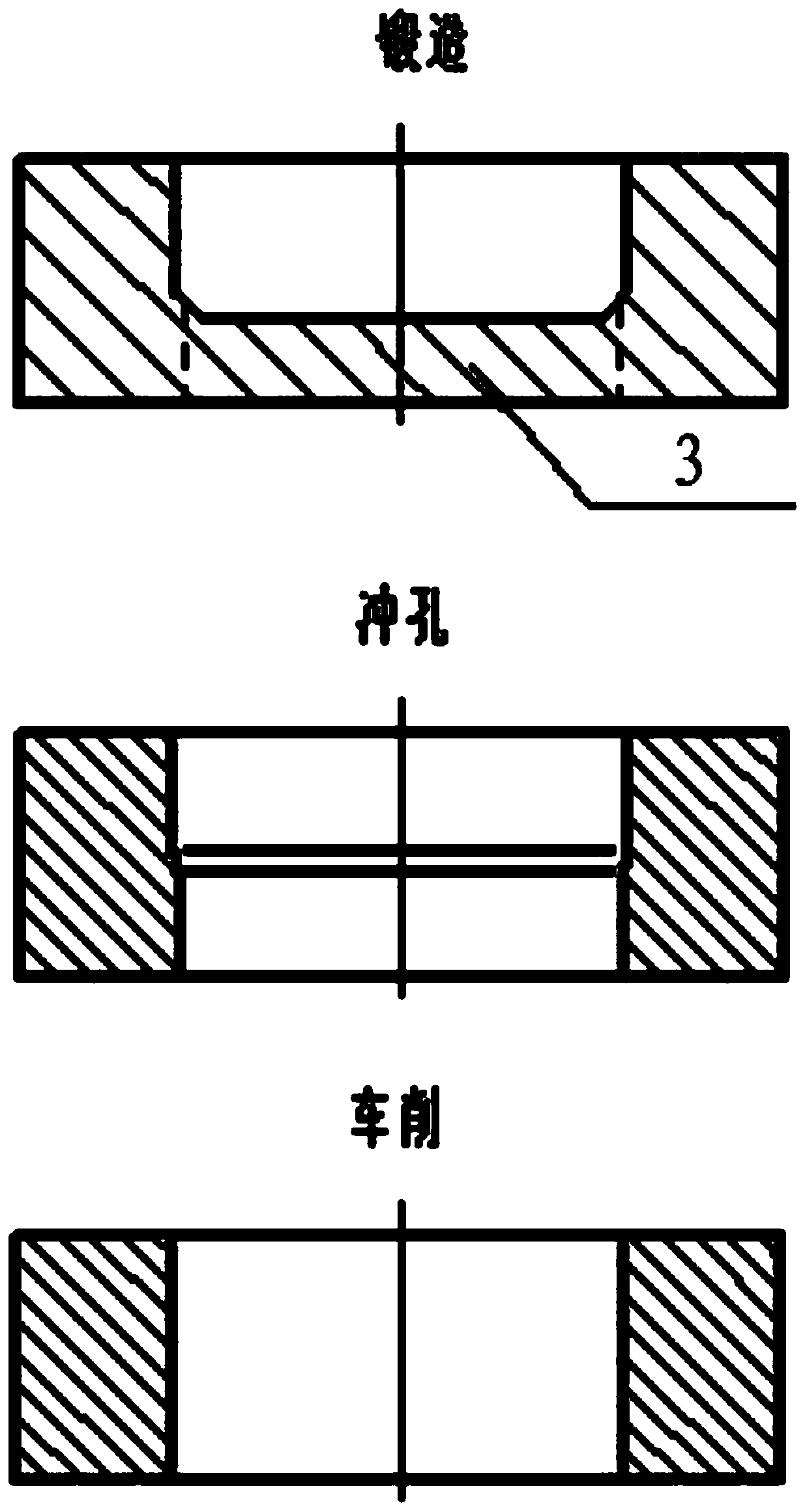

Annular piece combined forging method

InactiveCN110180980AReduce raw material consumptionReduce energy consumptionHandling devicesHeating/cooling devicesEnergy consumptionMaterials science

The invention discloses an annular piece combined forging method, and belongs to the technical field of forging. The problems that two components need to be produced according to the two components, the forging cost is increased, forging energy waste is large, and raw material consumption is large are solved. According to the annular piece combined forging method, a combined production manner is used for combining the two components the same in material for forging, the method comprises the following steps that round steel is arranged in a forging die of a forging press, a first forge piece and second forge piece combined forging force piece ring blank is formed, an annular piece of a combined forging force piece is placed in a punch press to conduct recess punching, the ring blank of thecombined forging force piece is cut off, and a first forge piece blank and a second force piece blank are obtained. By means of the annular piece combined forging method, one punching waste is omitted, raw material consumption is reduced, energy consumption is reduced, the forging manual operation is reduced, the forging efficiency is improved, and output per shift is increased. In addition, the combined force piece is divided into the two components, the method for punching, cutting-off and hobbing through a lathe can be adopted for proceeding, and materials are saved to the maximum degree without procedure increasing.

Owner:CHONGQING JUTAI MACHINERY

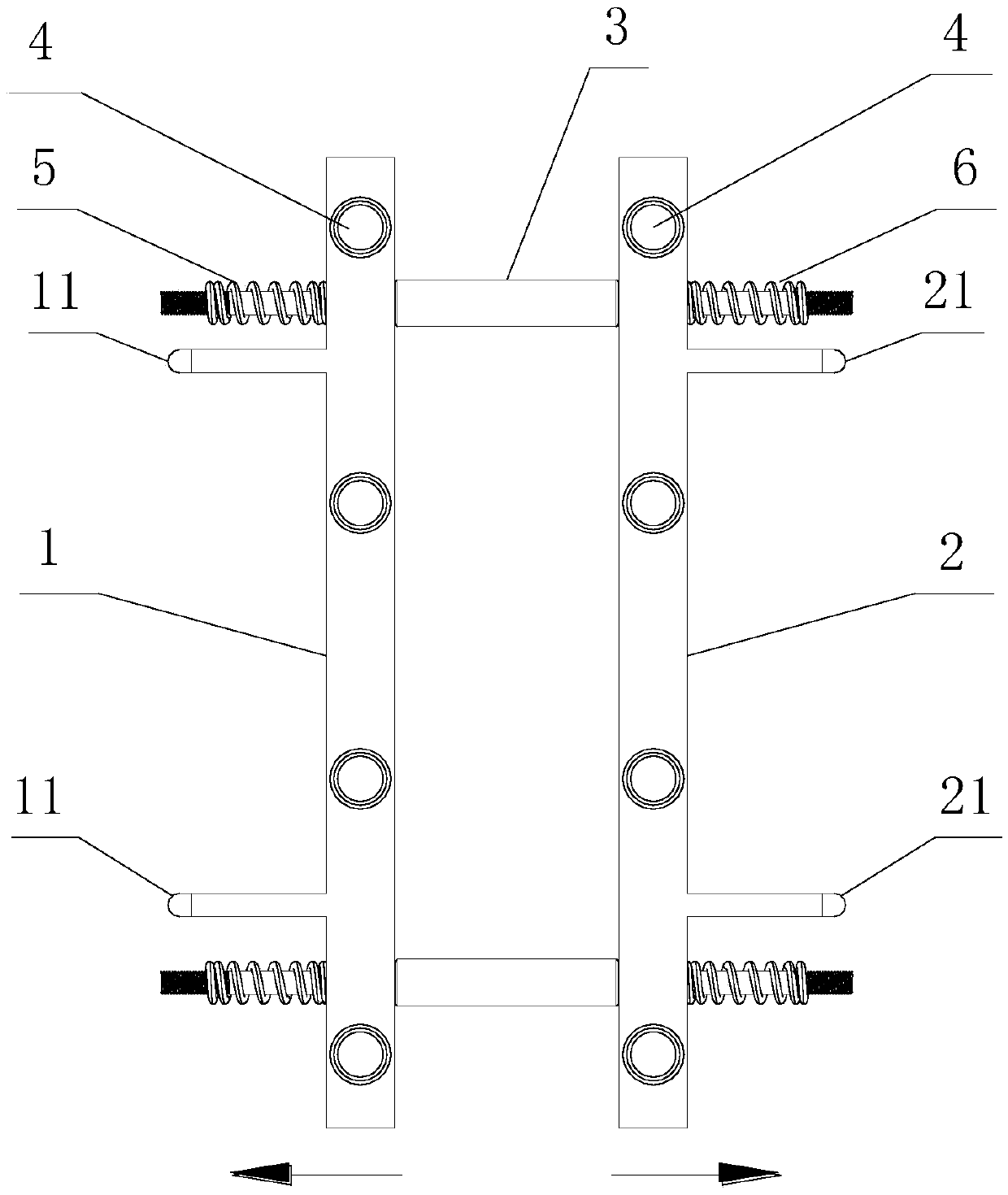

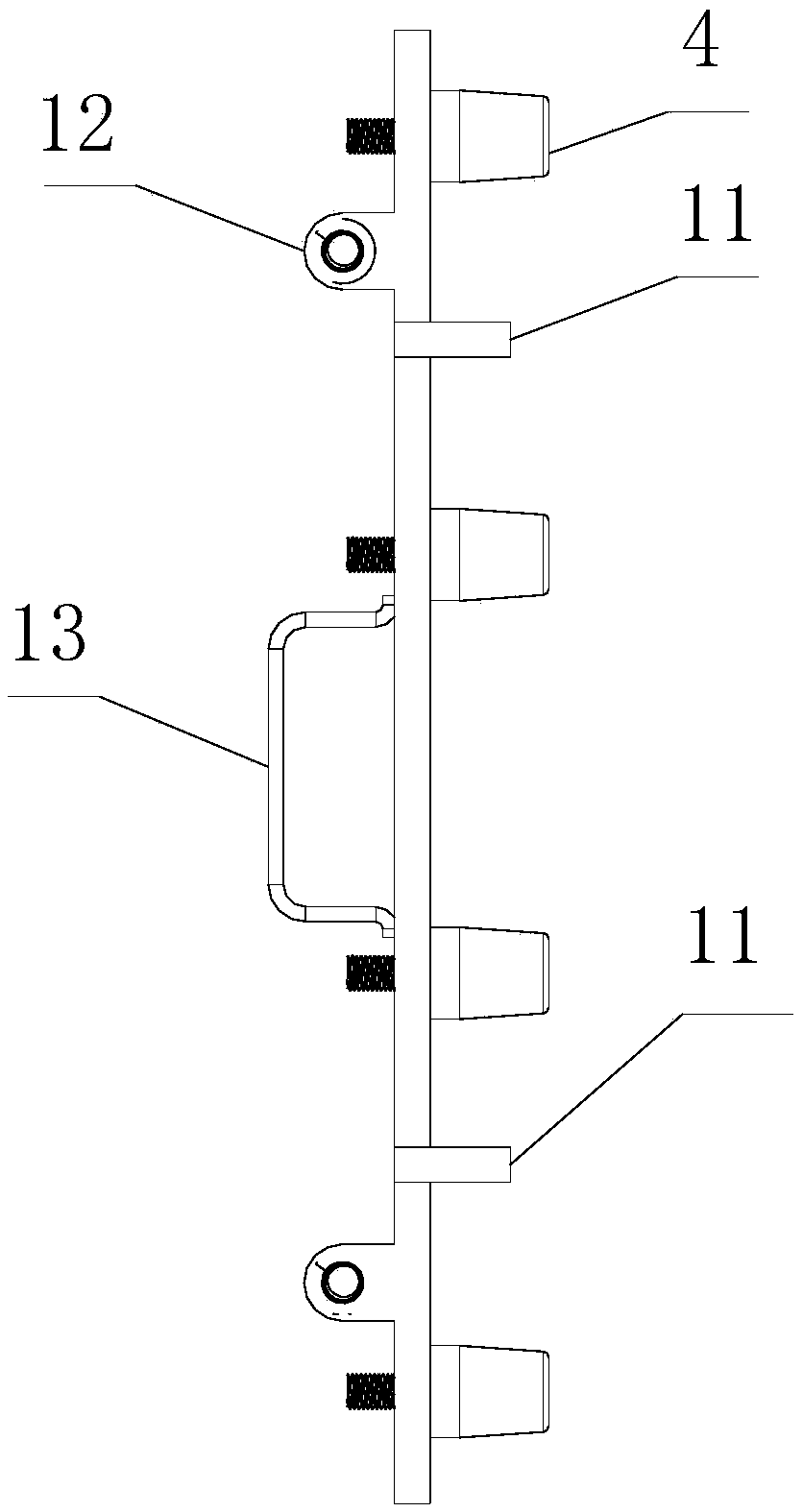

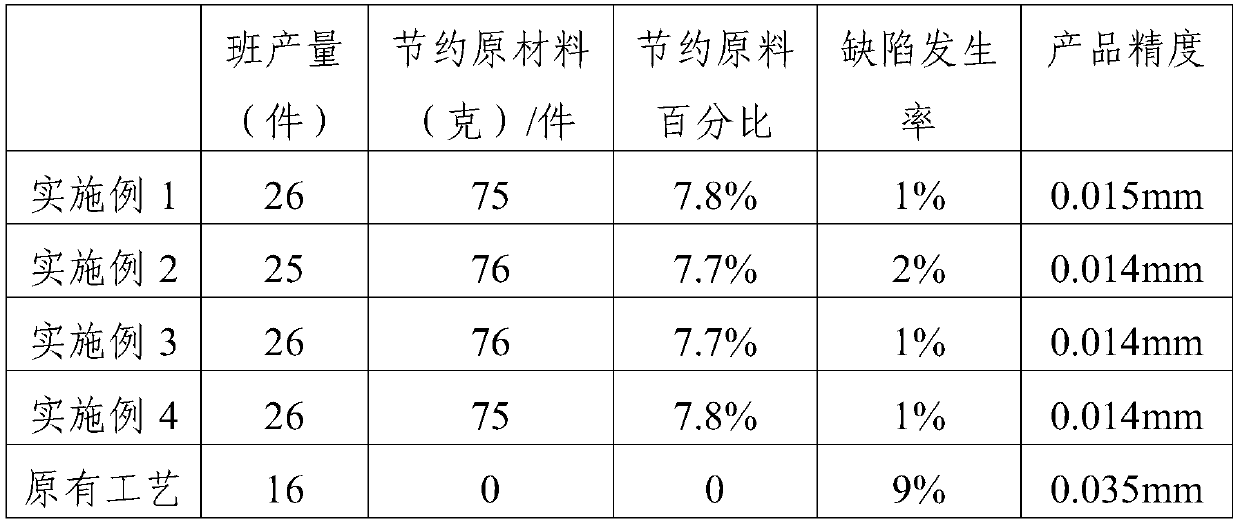

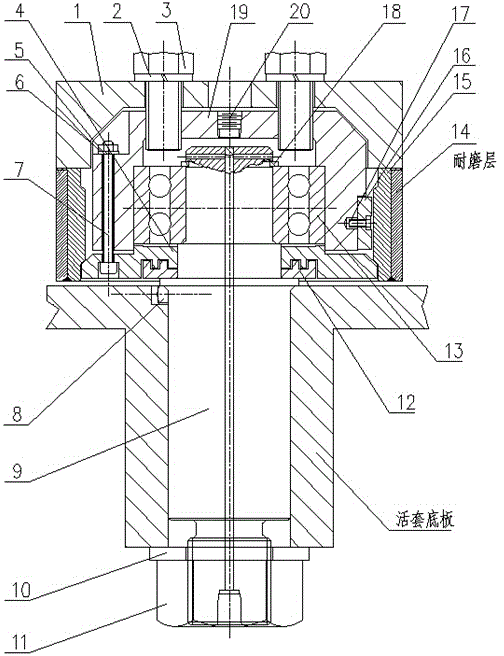

Automatic demolding machine of rubber seal piece

InactiveCN103934936AReduce labor intensitySimple structure setupDomestic articlesEngineeringRejection rate

The invention provides an automatic demolding machine of a rubber seal piece. The automatic demolding machine comprises a demolding device, a support pillar and a guiding pillar, wherein an air cylinder is arranged above the demolding device; a base of the air cylinder is fixed on an upper plate of the demolding device, the upper plate of the demolding device is connected with an upper mould guiding fixed plate through the support pillar, an ejection rod is arranged above a cavity pressing plate, and the ejection rod is connected with the guiding pillar; a cavity support plate is supported by mould legs, and the mould legs are fixed on a lower plate of the demolding device. The automatic demolding machine provided by the invention has the advantages that the structure arrangement is simple, the labour intensity of workers is reduced, a working procedure is saved, 100 or more rubber seal pieces are simultaneously demolded in one second, the shift output is improved by 40%-50%, the rejection rate of a product is also reduced by 2%-3%, the product nearly achieves an exemption degree, and the efficiency of the picking working procedure is also improved by about 50%.

Owner:新乡市方元橡塑密封系统有限公司

a stripper

Owner:ANHUI DFSEAL RUBBER SHOCK ABSORBER TECH CO LTD

Iron alloy-based composite hard alloy roller and production method thereof

The invention discloses an iron alloy-based composite hard alloy roller and a production method thereof. The iron alloy-based composite hard alloy roller is formed by pressing metal powder forming a hard alloy outer ring and metal powder forming an iron alloy inner ring through vacuum pressing and sintering, wherein the hard alloy outer ring consists of 69 to 71 percent of WC, 16 to 18 percent ofCo, 12 to 14 percent of Ni and 0.3 percent of mixed rare-earth powder; and the iron alloy inner ring consists of 20 to 25 percent of TiC, 0.3 percent of Ni, 2.5 to 3.5 percent of Cr, 8.1 to 9.1 percent of W, 0.4 percent of C, 2 to 3 percent of Mo and the balance of Fe. The iron alloy-based composite hard alloy roller has the characteristics of reasonable formula, synchronous vacuum pressing and sintering, energy conservation, solution of iron-based alloy oxidation problem, integrated fusion of diffusion interfaces, safe and reliable combination, high abrasive resistance, good surface quality,high forming precision and good heat cracking resistance and corrosion resistance.

Owner:蓬莱市超硬复合材料有限公司

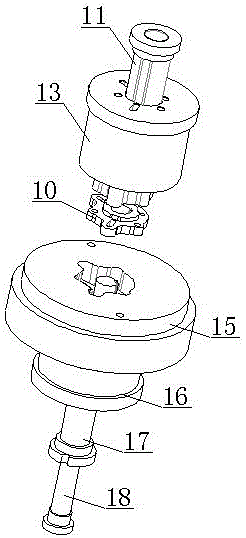

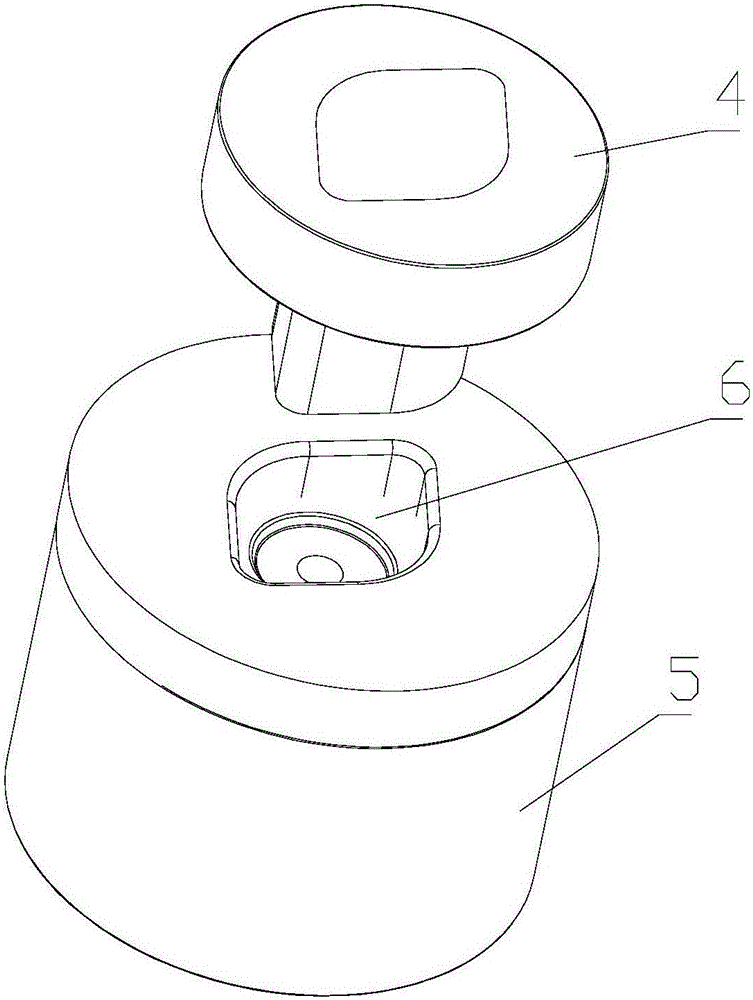

Rear assembled engine foot

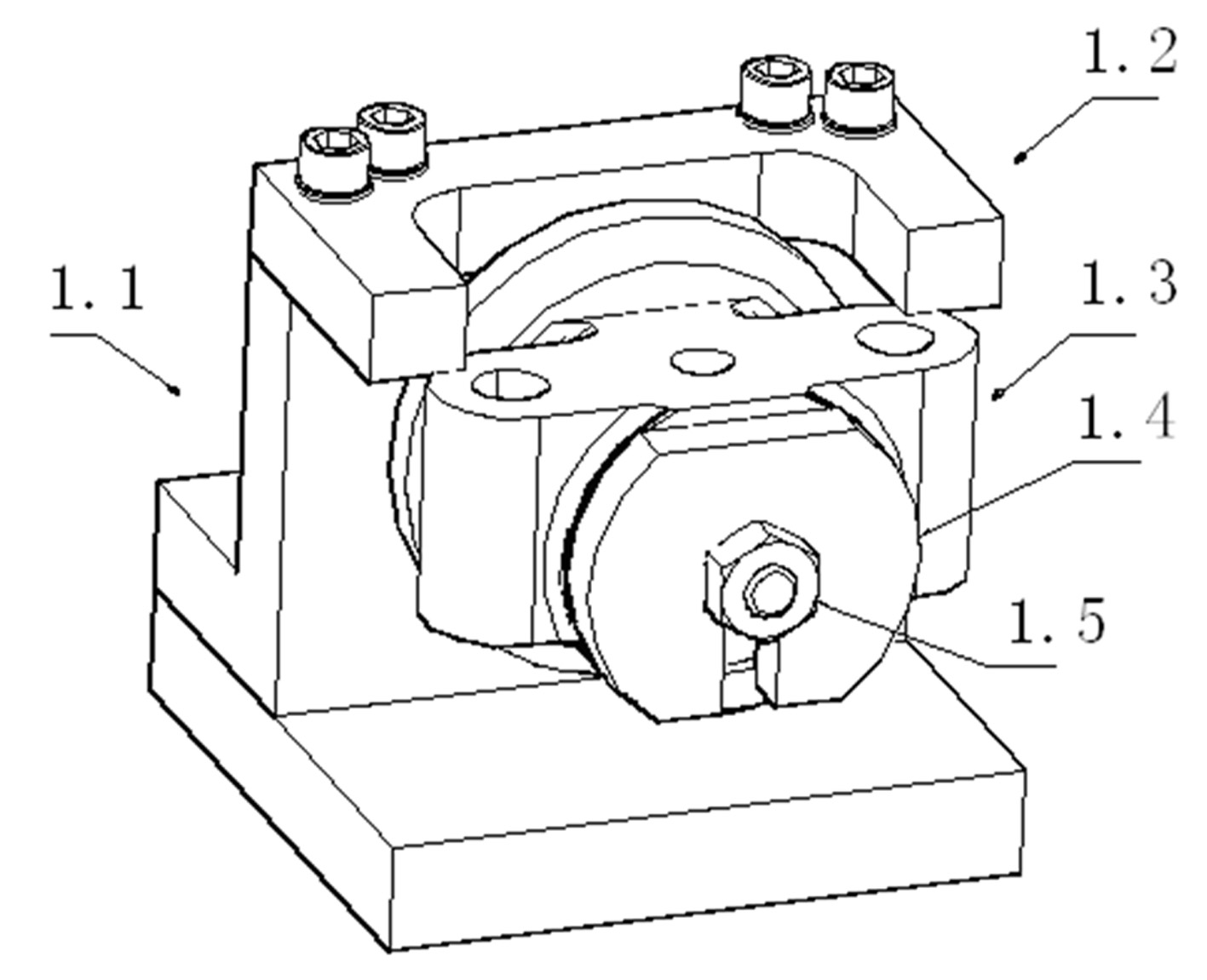

InactiveCN104986025ASimple and reasonable structureSimple mold structureJet propulsion mountingInternal combustion mountingEngineeringSmall caliber

The invention relates to a rear assembled engine foot. The rear assembled engine foot comprises a bracket, two rubber sleeves, a baffle, an outer shell, a bolt and a nut, wherein a connection rotating shaft hole is formed in one end of the bracket, and the central axis of the connection rotating shaft hole is perpendicular to the bracket; a supporting rod is arranged at the other end of the bracket, and a through hole is formed on the central axis of the supporting rod; each rubber sleeve adopts a trumpet-shaped tubular structure; the outer shell is in a cylinder shape; a plate propping ring is arranged on the inner wall of the outer shell and positioned at the middle part of the outer shell, and the plate propping ring and the outer shell are coaxial; the outer shell sleeves the periphery of the supporting rod, and the outer shell and the supporting rod are coaxial; the two rubber sleeves are respectively arranged on both sides of the outer shell; the rubber sleeves sleeve the periphery of the supporting rod, and one side with a large caliber, of each rubber sleeve, is tightly attached to the plate propping ring on the outer shell; the baffle is propped against one side with a small caliber, of the rubber sleeve which is far away from the connection rotating shaft hole, and the small caliber of the rubber sleeve on one side which is close to the connection rotating shaft hole is propped against the bracket; the bolt sequentially penetrates through the through hole in the baffle and the through hole in the supporting rod and is fastened with the nut.

Owner:ANHUI ZHONGDING NVH

Environment-friendly high-strength phenolic resin special for precoated sand

InactiveCN111303361AFast curingImprove shift outputFoundry mouldsFoundry coresManufacturing FactoriesPolymer chemistry

The invention belongs to the technical field of phenolic resin preparation, and particularly relates to environment-friendly high-strength phenolic resin special for precoated sand. The invention discloses a preparation method of the environment-friendly high-strength phenolic resin special for precoated sand. The environment-friendly high-strength phenolic resin is obtained by reacting phenols with formaldehyde in the presence of a catalyst and an additive. The brand-new precoated sand composite resin is prepared by adding a special raw material polyimide to replace original aniline and controlling the temperature and dehydration during synthesis in a reaction kettle, the resin is already used in batches in a precoated sand manufacturing factory, and the original strength and heat resistance defects puzzling people for many years are overcome. Particularly, the curing speed of the precoated sand is increased, the outputs of a sand core and a shell mold are increased, and pungent chokes originally generated by heating the precoated sand in a workshop are replaced by aromatic smells.

Owner:上海坦默新材料科技有限公司

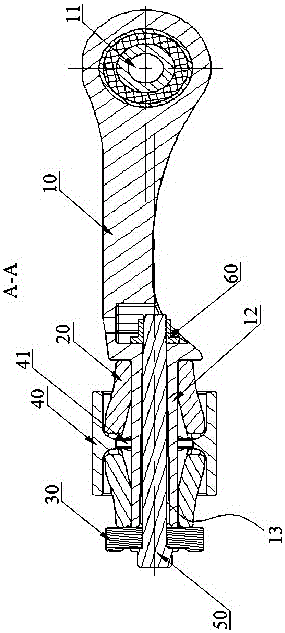

Unburned brick manufacturing device

InactiveCN103802199AImprove the plasticity coefficientGuaranteed to proceed normallyCeramic shaping apparatusBrickProcess engineering

The invention discloses an unburned brick manufacturing device. The unburned brick manufacturing device comprises a strong stirring machine, a forming and extruding machine and a roller machine, wherein the strong stirring machine is used for stirring, extruding and mixing aged raw materials; the forming and extruding machine is used for manufacturing the aged raw materials into unburned bricks after the aged raw materials are processed by the strong stirring machine; the roller machine is used for extruding and crushing the aged raw materials, and the aged raw materials can enter into the strong stirring machine again after the aged raw materials are extruded and crushed by the roller machine. According to the unburned brick manufacturing device disclosed by the invention, the roller machine, such as a strong roller machine, is added in front of the strong stirring machine, the lumpiness of stones can be controlled under 5 mm after the aged raw materials mixed with stones are extruded and crushed when the aged raw materials mixed with the stones pass through a crushing gap of the roller machine, and thus the normal operating of a latter process can be ensured; the aged raw materials are then extruded and mixed again by the strong stirring machine, thus the plasticity coefficient of the aged raw materials can be increased, not only can the unburned brick manufacturing device be protected, but also scrapped unburned bricks can be greatly reduced, and the output in one shift can be increased by 10-12%.

Owner:东海县马陵新型墙体材料厂

Automatic feeding device for four-column hydraulic column system

ActiveCN101543751BIncrease labor intensityReduce labor intensityUltra-high pressure processesElectrical controlEngineering

The invention discloses an automatic feeding device for a four-column hydraulic column system, which comprises a power driving part, an electric control part and a mechanical execution part, wherein the power driving part is in driving connection with the mechanical execution part by a pipe, and the electric control part is in electric signal connection with the pipe by a wire. The device has simple structure and convenient operation, fully lowers labor intensity of workers, ensures life safety of the workers, saves raw materials, fully improves production efficiency and enterprise efficiencyand has extremely strong practicability and popularization value.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

A kind of preparation method of emulsion type pressure-sensitive adhesive

ActiveCN101671533BReduce processing timeImprove shift outputEster polymer adhesivesEmulsionCooling effect

Owner:ZHEJIANG YONGHE ADHESIVE PRODS

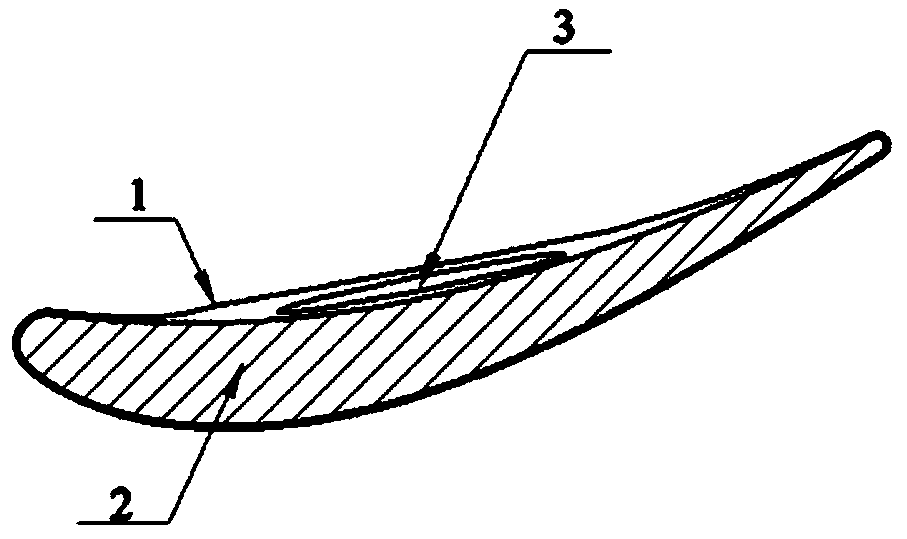

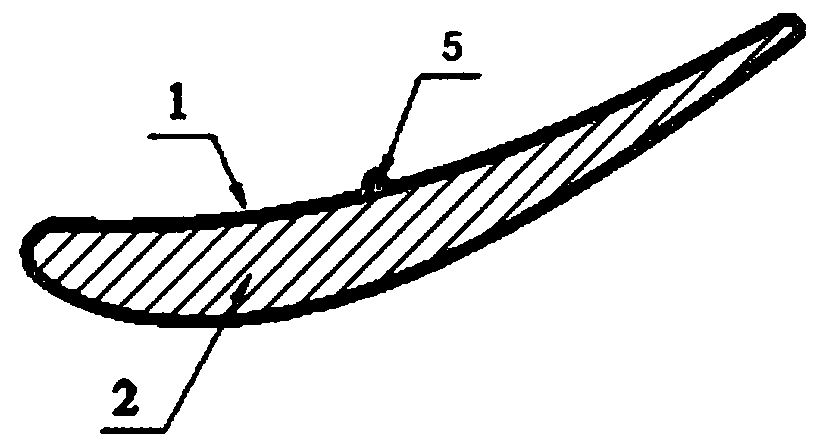

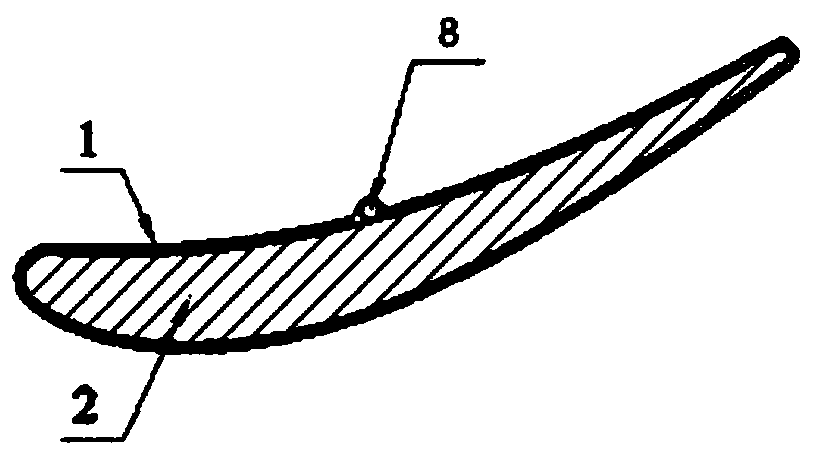

A kind of wax pattern structure and its manufacturing method to prevent the thickening of the precision casting blade basin

ActiveCN108405801BThere is no problem of increased thicknessSolve the succulent defectFoundry moulding apparatusInvestment castingMechanical engineering

The invention provides a wax mold structure for preventing investment casting blade basin thickening and a manufacture method of the wax mold structure. A separation is additionally arranged on a blade basin area on a wax mold, the problem of gaps formed between a wax mold blade basin and a coating layer is solved, and thickening of the blade basin is decreased. The wax mold comprises a wax mold body, a plurality of wax projections are arranged on the surface of the blade basin of the wax mold body, and the surface of the blade basin of the wax mold is divided into a plurality of areas by thewax projections. The manufacture method includes the steps: welding a plurality of wax strips or wax beans on the surface of the blade basin of the wax mold, or dropping liquid wax on the surface of the blade basin of the wax mold to form a plurality of wax beans; dividing the surface of the blade basin of the wax mold into a plurality of areas by the aid of a plurality of wax strips or wax beans.

Owner:AECC AVIATION POWER CO LTD

Camshaft toothed wheel hub for automobile engine and powder metallurgy preparation method thereof

ActiveCN106041094BReduce the amount of processingImprove shift outputTransportation and packagingMetal-working apparatusEngineering

The invention discloses a camshaft toothed wheel hub for an automobile engine and a powder metallurgy preparation method thereof. The method is carried out according to the following steps: step S101, batching; step S102, pressing and forming; step S103, blank sintering; step S104, finishing and processing; step S105, steam treatment; step S106, testing and packaging. The method of the present invention is connected in an orderly manner, with fewer procedures and a material utilization rate of more than 95%. The camshaft toothed wheel hub obtained by the method has less machining volume, high shift output and good consistency. It satisfies various performance requirements of the product. At the same time, the manufacturing cost of the product is reduced by 50%.

Owner:马鞍山市华东粉末冶金厂

A rubber bracket

ActiveCN112588530BExtended service lifeImprove assembly accuracyLiquid surface applicatorsCoatingsStructural engineeringMechanical engineering

The invention discloses a rubber retaining bracket, which comprises a bracket body, a plurality of first rubber retaining parts, a plurality of second rubber retaining parts and a plurality of supporting parts; The installation groove for bonding glass; the inner walls on both sides of the installation groove are respectively equipped with a plurality of support parts; a plurality of the first rubber blocking parts are respectively installed between the two opposite support parts, And one end of the first rubber blocking member is provided with a cutout for installing glass; a plurality of the second rubber blocking members are arranged oppositely on two opposite side walls of the installation groove. The invention overcomes the defects in the prior art that the glue is easy to overflow and the colloid on the surface of the mold or the degumming surface still needs to be cleaned after bonding, and at the same time greatly improves the bonding efficiency.

Owner:FUJIAN FUYAO AUTOMOTIVE ALUMINIUM SYST CO LTD

Portable automobile windscreen fast pneumatic bordering machine

Owner:上海耀皮康桥汽车玻璃有限公司

Pawl pole of automobile generator and its manufactura

ActiveCN100349690CIncrease power generationHigh dimensional accuracyManufacturing dynamo-electric machinesOther manufacturing equipments/toolsEngineeringElectromotive force

The present invention relates to one kind of of automobile generator and its manufacture. The pawl pole has one bottom plate, one magnetic yoke on the bottom plate, six or eight insulating varnish conducting slots distributed homogeneously on the circumference of the magnetic yoke, six or eight lugs for preventing the rotation of coil, and six or eight insulated wire leading out slots in the bottom of the magnetic yoke. The manufacture of the pawl pole includes the steps of: cutting material, heating, upsetting, pre-forging, finish forging, cutting edge, magnetically annealing, cold shaping, and finishing machining. The manufacture process has low apparatus investment, low mold cost, low heating cost, high output and high product quality. The AC generator with the pawl poles of the present invention has induced electromotive force waveform of quasi-sinusoid wave and great generating power.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

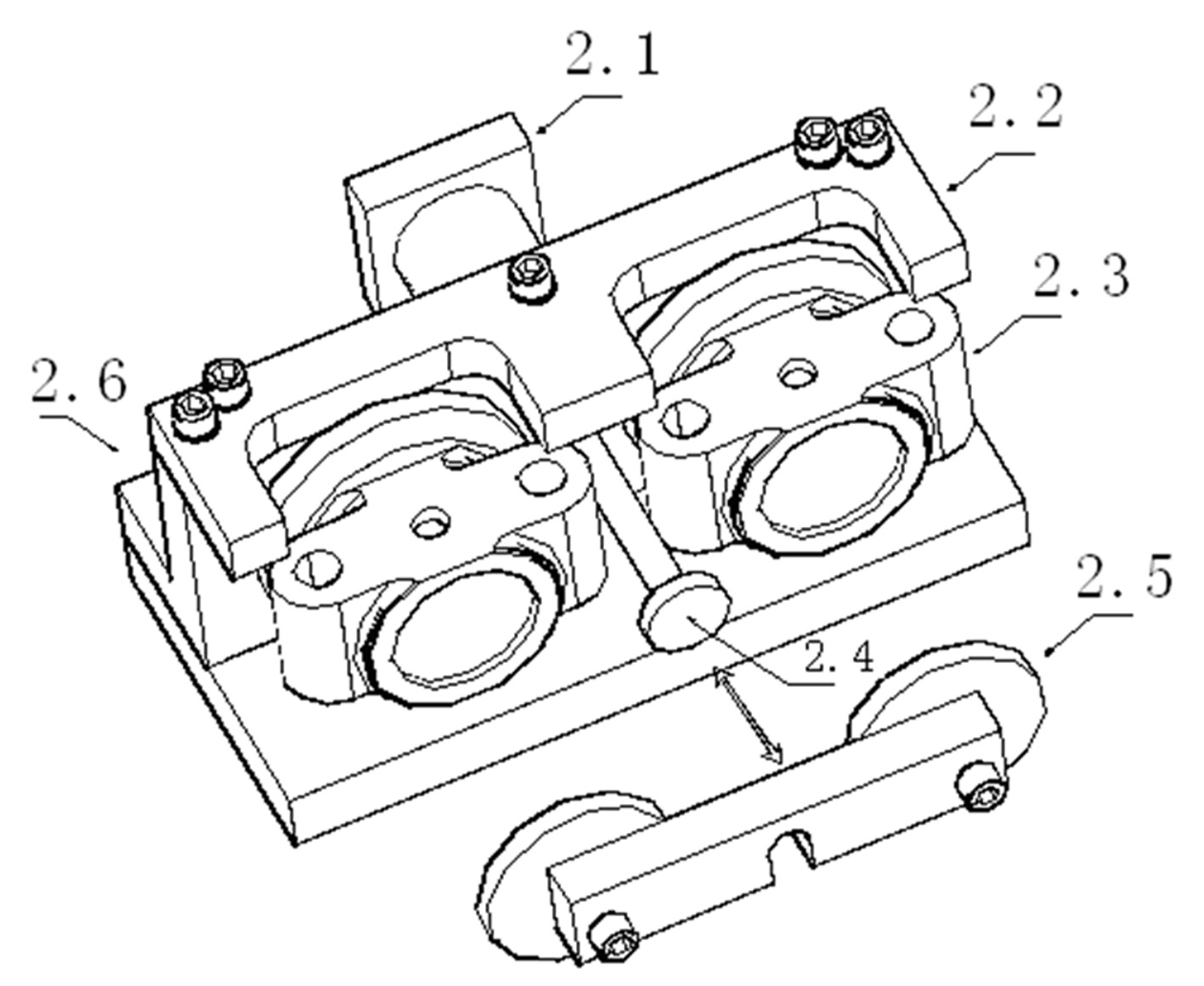

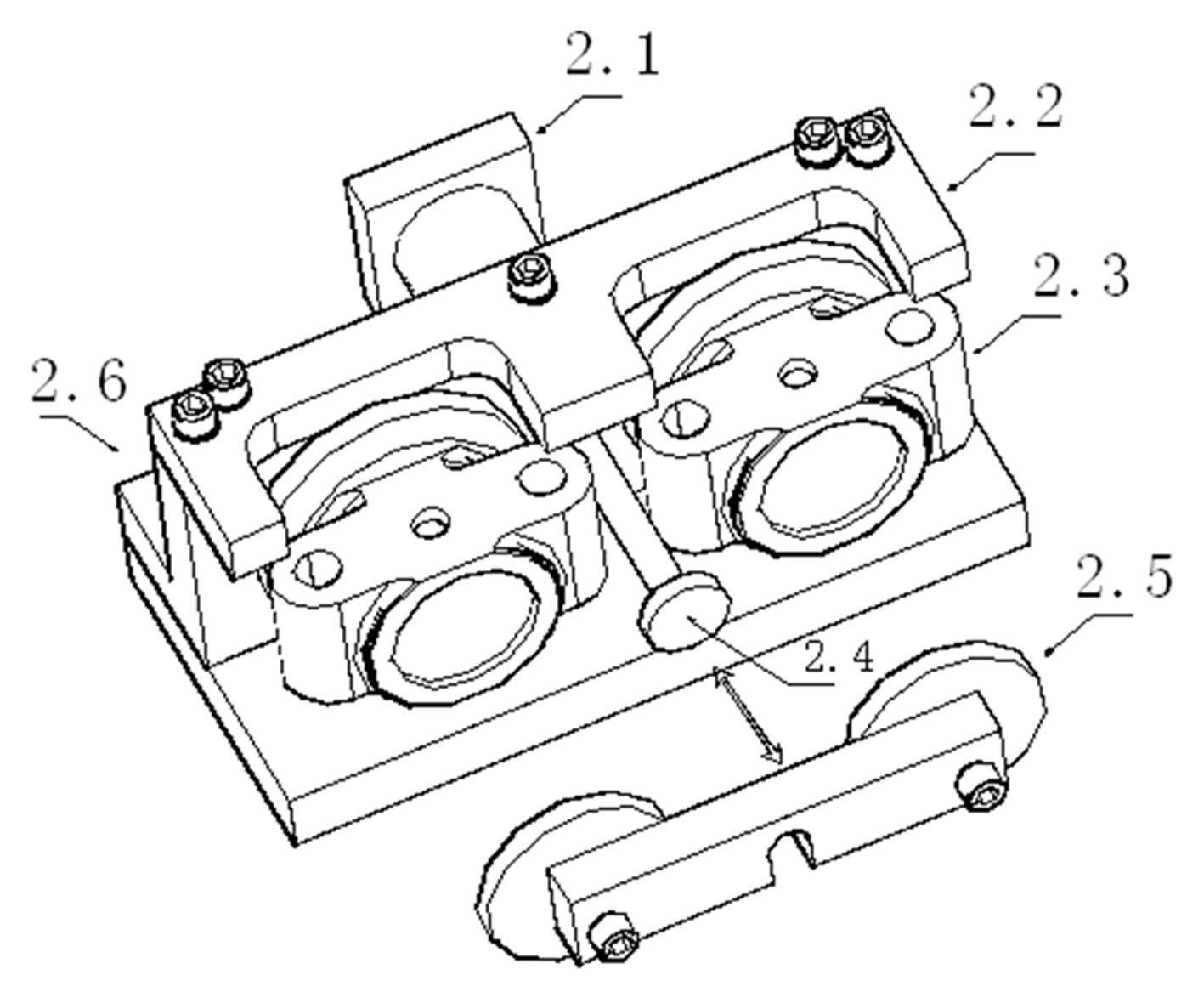

Shaft cover processing tool

InactiveCN101961839AReduce downtimeIncrease profitPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a shaft cover processing tool, which comprises angle iron core rod positioning seats, positioning plates and pressing plates, wherein the positioning plates are connected with the angle iron core rod positioning seats to form shaft cover limit. The tool also comprises a cylinder; two groups of angle iron core rod positioning seats are the same and arranged side by side; a cylinder pull rod is arranged between the two groups of angle iron core rod positioning seats, and the cylinder pull rod is connected on a piston rod of the cylinder and synchronously advances and retreats with the piston rod; the axial direction of the cylinder pull rod is parallel to the axial directions of core rods on the angle iron core rod positioning seats, and the front end of the cylinder pull rod is provided with a baffle plate; the number of the pressing plates is two, and the two pressing plates are interconnected; and the baffle plate is detachably connected with the two pressing plates, namely when the baffle plate and the two pressing plates are in an assembly state, the two pressing plates act under the traction of the cylinder pull rod. After the technical scheme is adopted, two workpieces can be assembled at the same time, the dwell time of a processing center due to assembly and disassembly of the workpieces is saved, the processing center obtains highest utilization rate, and the batch yield is improved.

Owner:溧阳市虹翔机械制造有限公司

Glue blocking bracket

ActiveCN112588530AExtended service lifeImprove assembly accuracyLiquid surface applicatorsCoatingsStructural engineeringMechanical engineering

The invention discloses a glue blocking bracket which comprises a bracket body, multiple first glue blocking pieces, multiple second glue blocking pieces and multiple supporting parts. The top of thebracket body is provided with a mounting groove used for containing glue so as to be bonded with glass. The multiple supporting parts are arranged on the inner walls of the two sides of the mounting groove correspondingly. Each of the multiple first glue blocking pieces is correspondingly arranged between the two corresponding oppositely-arranged supporting parts, and a cutting opening used for mounting glass is formed in one end of each first glue blocking piece. The multiple second glue blocking pieces are oppositely arranged on the two oppositely-arranged side walls in the mounting groove.The defects that in the prior art, glue is prone to overflowing, and glue on the surface of a mold or glue on the de-gluing surface still needs to be cleaned away after bonding are overcome, and meanwhile the bonding efficiency is greatly improved.

Owner:FUJIAN FUYAO AUTOMOTIVE ALUMINIUM SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com