Unburned brick manufacturing device

A technology for preparing device and brick blanks, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., to achieve the effects of improving plastic coefficient, reducing scrap brick blanks, and increasing output

Inactive Publication Date: 2014-05-21

东海县马陵新型墙体材料厂

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, small stones in the aged raw materials mixed into the forming extruder, such as shale or coal gangue, are often larger than 20 mm in size. When passing through the forming extruder, they are often stuck in the solid brick or porous brick. Between the porcelain heads, the brick adobe is scrapped

The general way to deal with this kind of failure is to remove the machine mouth, clean up the stones inside and then install it, which not only affects the output but also damages the porcelain head.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

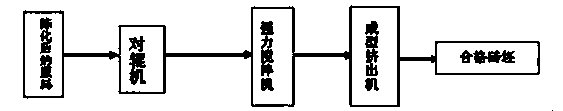

The invention discloses an unburned brick manufacturing device. The unburned brick manufacturing device comprises a strong stirring machine, a forming and extruding machine and a roller machine, wherein the strong stirring machine is used for stirring, extruding and mixing aged raw materials; the forming and extruding machine is used for manufacturing the aged raw materials into unburned bricks after the aged raw materials are processed by the strong stirring machine; the roller machine is used for extruding and crushing the aged raw materials, and the aged raw materials can enter into the strong stirring machine again after the aged raw materials are extruded and crushed by the roller machine. According to the unburned brick manufacturing device disclosed by the invention, the roller machine, such as a strong roller machine, is added in front of the strong stirring machine, the lumpiness of stones can be controlled under 5 mm after the aged raw materials mixed with stones are extruded and crushed when the aged raw materials mixed with the stones pass through a crushing gap of the roller machine, and thus the normal operating of a latter process can be ensured; the aged raw materials are then extruded and mixed again by the strong stirring machine, thus the plasticity coefficient of the aged raw materials can be increased, not only can the unburned brick manufacturing device be protected, but also scrapped unburned bricks can be greatly reduced, and the output in one shift can be increased by 10-12%.

Description

technical field [0001] The invention relates to a device for preparing brick adobe, in particular to a brick adobe preparation device. Background technique [0002] In the prior art, the preparation of adobe is generally to age the raw materials first, then use a powerful mixer to stir, extrude and mix the aged raw materials, and then pass through a forming extruder to make adobe that meets the requirements, such as solid Adobe or perforated adobe, etc. However, small stones in the aged raw materials mixed into the forming extruder, such as shale or coal gangue, are often larger than 20mm in size. When passing through the forming extruder mouth, they are often stuck in the solid brick or porous brick. Between the porcelain heads, adobes are formed and scrapped. The general way to deal with this kind of failure is to remove the machine mouth, clean up the stones inside and then install it, which not only affects the output but also damages the porcelain head. Contents o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B28B3/20

CPCB28B3/20

Inventor 赵永周舒阳舒子杨

Owner 东海县马陵新型墙体材料厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com