Automatic assembling system for automobile panel knobs

An automatic assembly and knob technology, applied in the field of machinery, can solve problems such as not being able to meet the assembly quantity requirements of the production line, customer complaints, small fit gaps, etc., and achieve the effects of reducing labor intensity of workers, increasing shift output, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below according to the accompanying drawings.

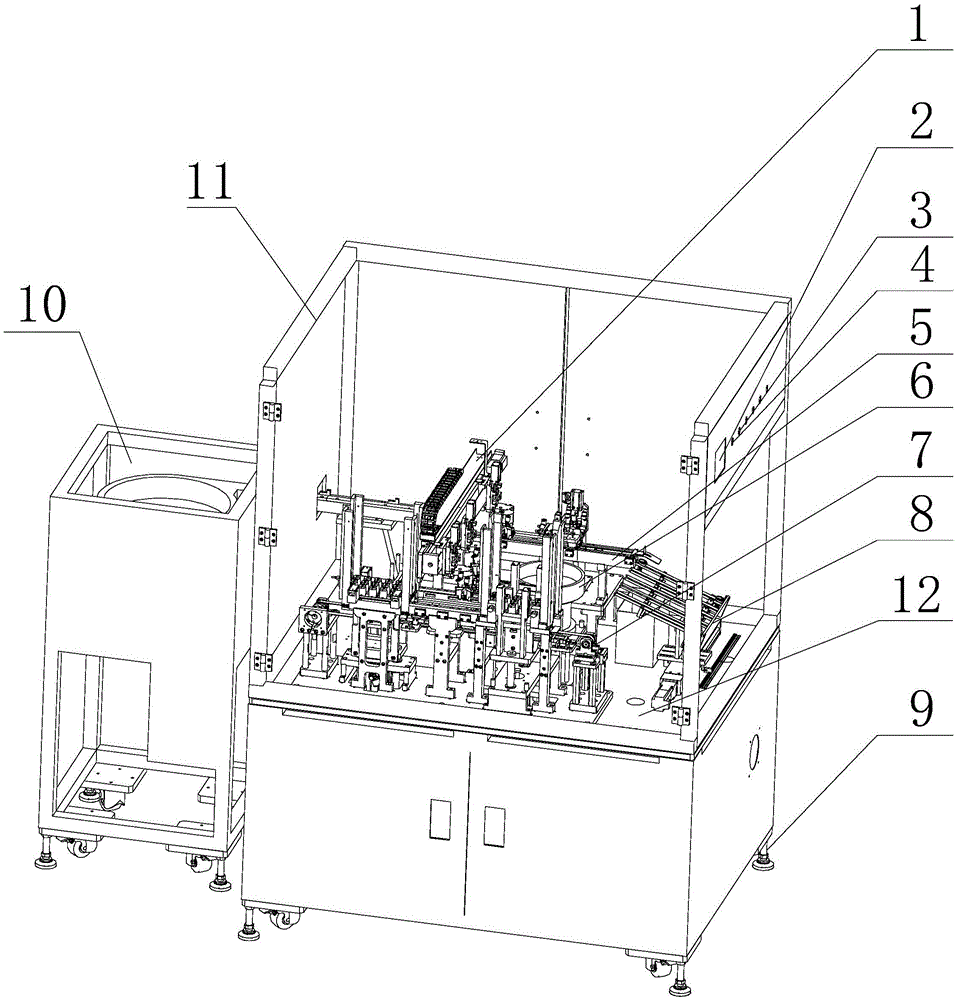

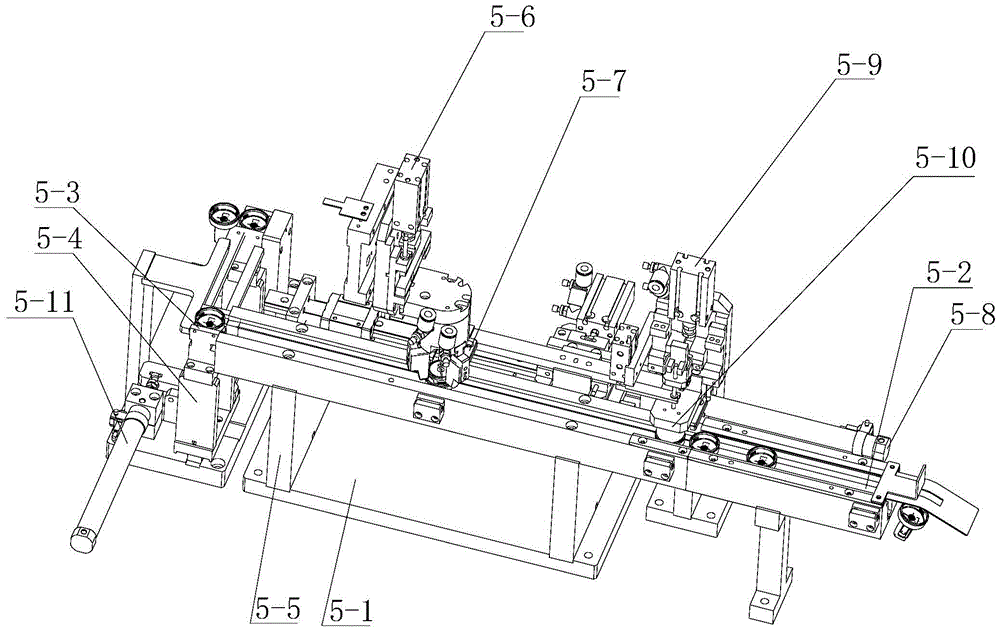

[0038] Such as Figure 1 to Figure 7 As shown, the middle part of the frame 11 is provided with a workbench 12, the center of the workbench 12 is provided with a light guide feeding mechanism 6, and the front side of the light guide feeding mechanism 6 is provided with a knob cover feeding mechanism 7, and the light guide The rear side of the body feeding mechanism 6 is provided with an assembly mechanism 5, and the right side of the light guide body feeding mechanism 6 is provided with a finished product recovery mechanism 8; the upper left side of the assembly mechanism 5 and the knob cover feeding mechanism 7 is provided with a handling mechanism 1; The knob shell feeding mechanism 10 is located on the left side of the frame 11 .

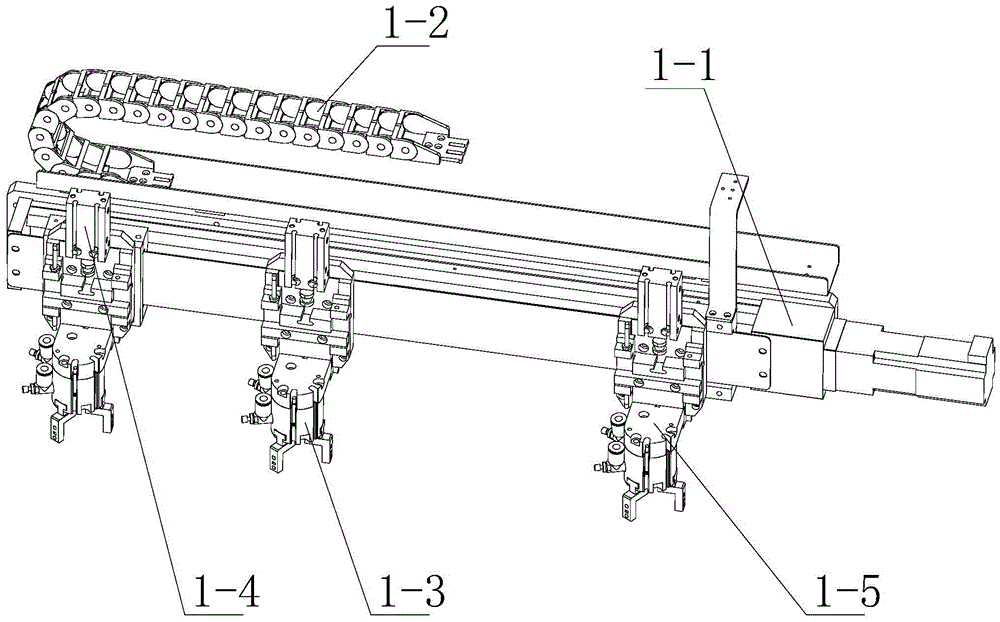

[0039] The transport mechanism 1 includes a mobile electric cylinder, a drag chain, a pneumatic gripper, and a gripper cylinder. The transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com