Portable automobile windscreen fast pneumatic bordering machine

A windshield, pneumatic shearing technology, applied in metal processing and other directions, can solve the problems of great influence on proficiency, large fluctuations in cutting quality, and unguaranteed quality, and achieve good repeatability, good consistency, and shift output. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

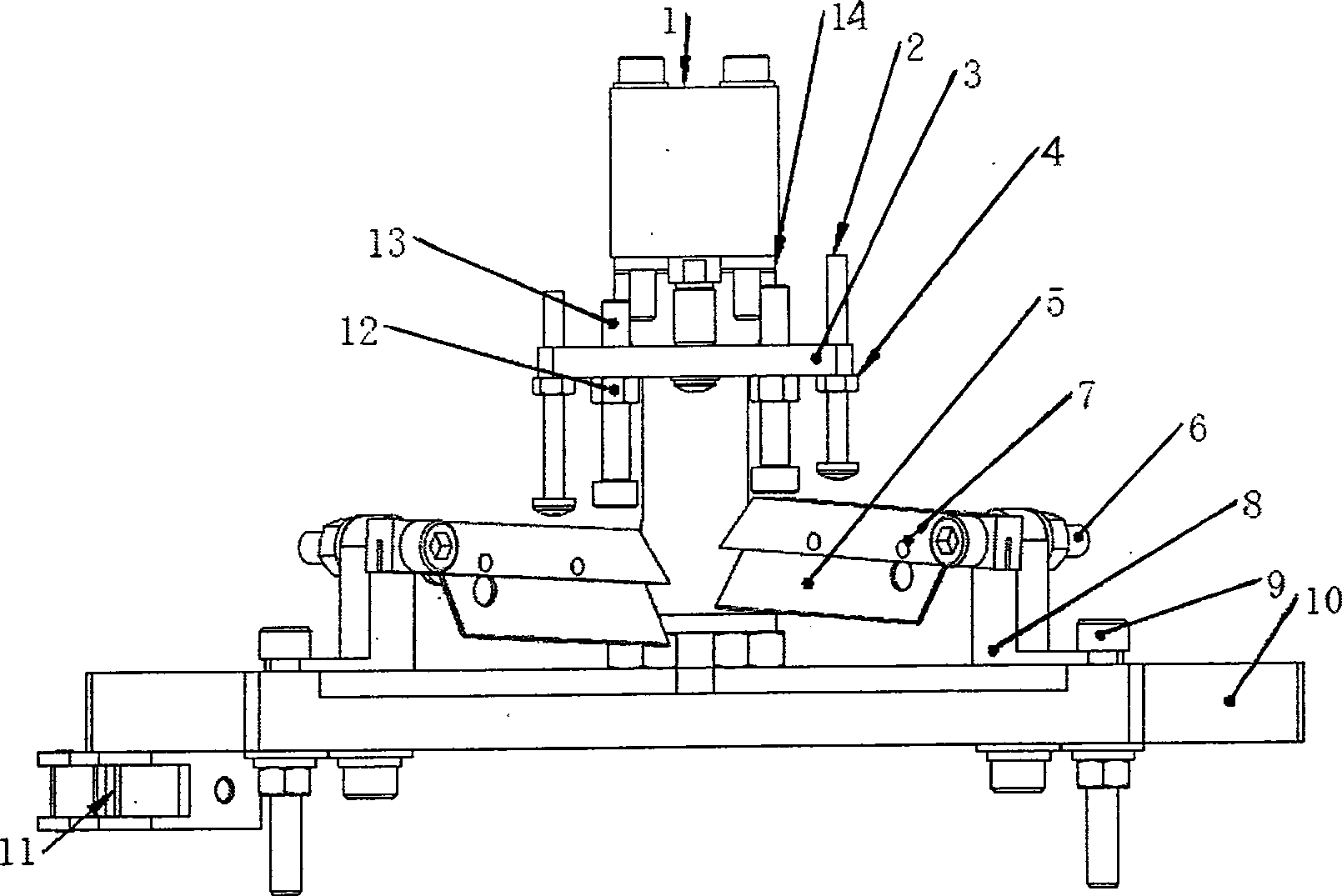

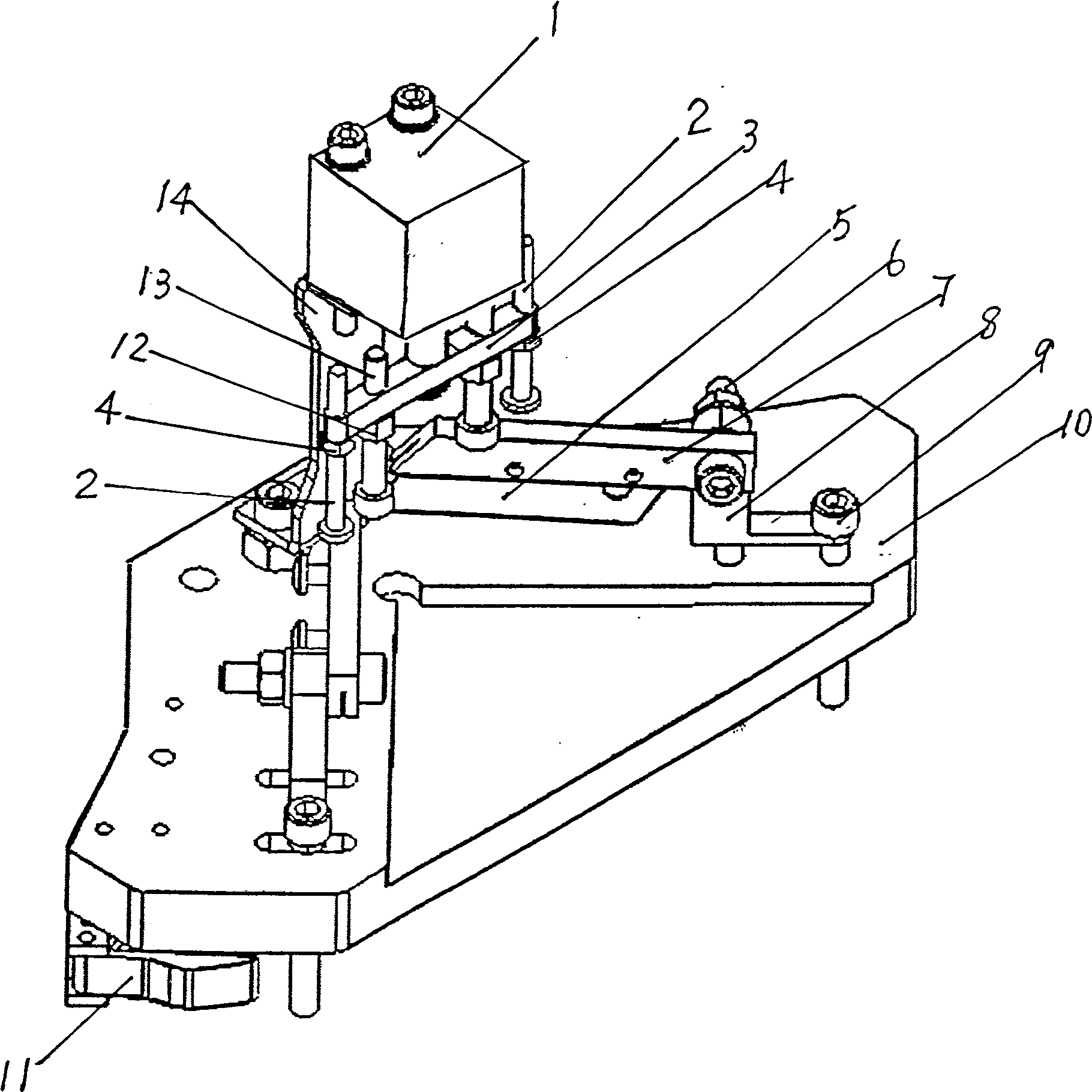

[0026] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] see figure 1 , 2 As shown, the portable fast pneumatic edge trimmer for automobile glass of the present invention consists of a base plate 10, a hinge head 8, a cylinder support block 14, a pneumatic cylinder 1, a knife rest 7, a cutting blade 5, a pneumatic switch 11, and a knife rest fixer 3. It is connected by bolts, nuts and washers, wherein the bottom plate 10 is a V-shaped structure with grooved holes on it, and the hinge head 8 is connected with the bottom plate 10 by the fourth bolt 9, nuts and washers, and is connected with the bottom plate 10. The slotted hole on the base plate 10 can be used to adjust the angle of the tool holder 7 on the bottom plate 10 of the mounting seat, which is convenient for cutting glass edging scraps of different shapes; the cylinder supporting block 14 connected with the bottom plate 10 is used to support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com