A kind of preparation method of emulsion type pressure-sensitive adhesive

A pressure-sensitive adhesive and emulsion-type technology, applied in the direction of adhesive type, ester copolymer adhesive, etc., can solve the problems of long production time, long time consumption, low production efficiency, etc., and achieve cooling time and effect The effect of improving and shortening the process time and shortening the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation method of emulsion type pressure sensitive adhesive, the method comprises the following steps:

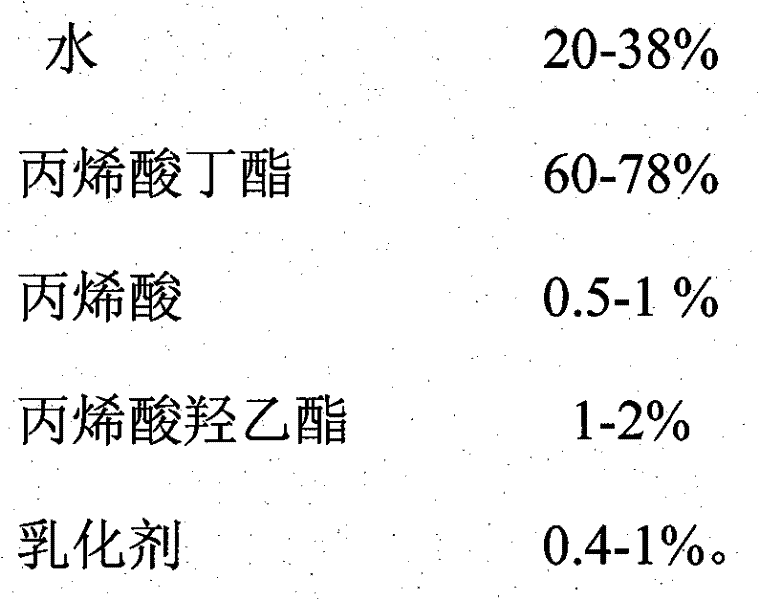

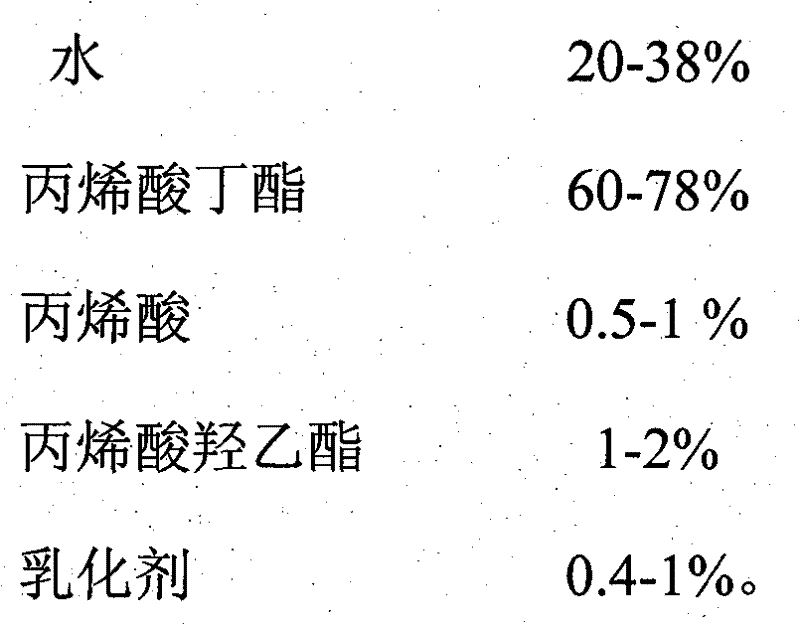

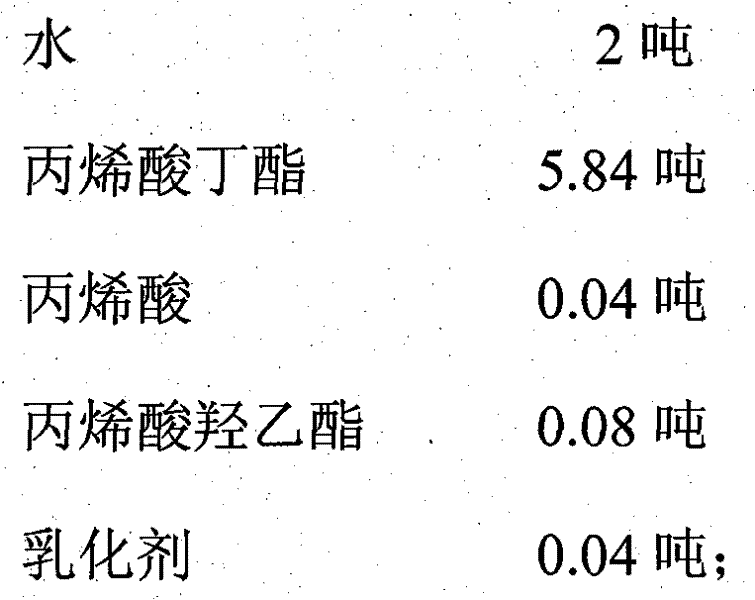

[0019] ① Mix the following ingredients and stir for 30 minutes at a stirring speed of 500-600 rpm to obtain a pre-emulsion:

[0020]

[0021] ② Add 2 tons of water to the reactor, heat it to 80 degrees and add 0.05 tons of ammonium persulfate as an initiator, then add the pre-emulsion to the reactor, the temperature in the reactor is controlled at 85 degrees, and the pre-emulsion is dripped for 4.5 hours After adding, keep warm for 1 hour;

[0022] ③ Pour the emulsion in the reaction kettle for 1 hour into the cooling kettle to cool down, add ammonia water to adjust the pH value, so that the pH value of the emulsion is maintained between 7 and 8, cool down to 45 degrees and pour out the pressure-sensitive adhesive emulsion. manufacture complete.

[0023] The time for making a pot of pressure-sensitive adhesive emulsion according to the above-mentioned embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com