a stripper

A technology of demoulding and formwork, which is applied in the field of demoulding, can solve the problems of low pass rate, product breakage, appearance scratches, etc., and achieve the effects of increasing shift production, uniform force, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, the technical solution of the present invention will be described in detail through specific examples.

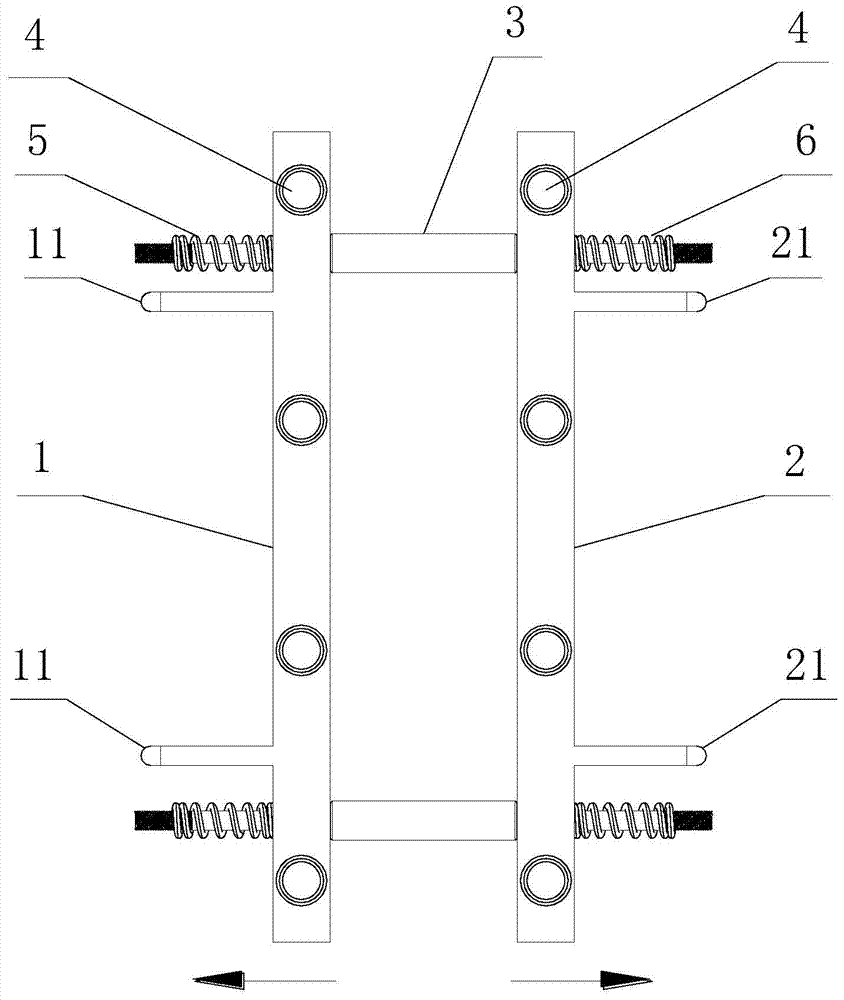

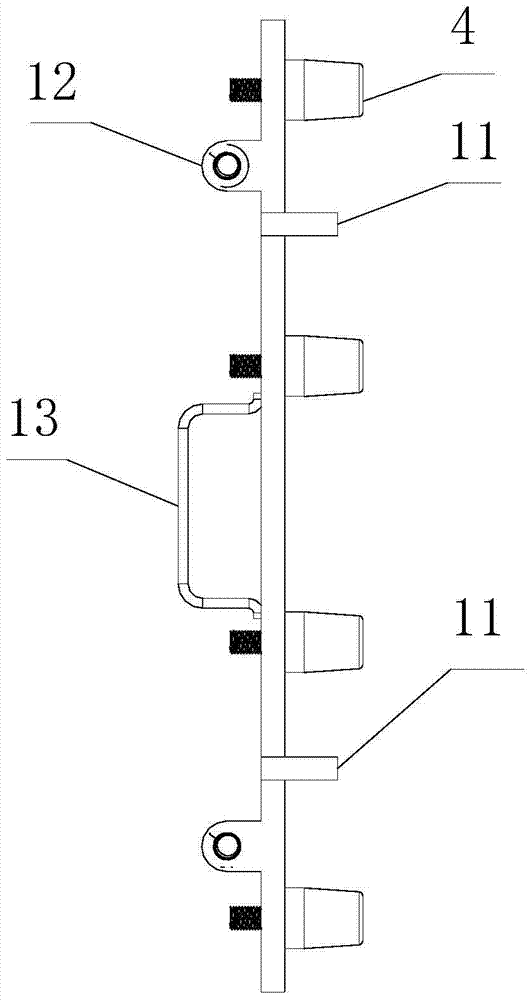

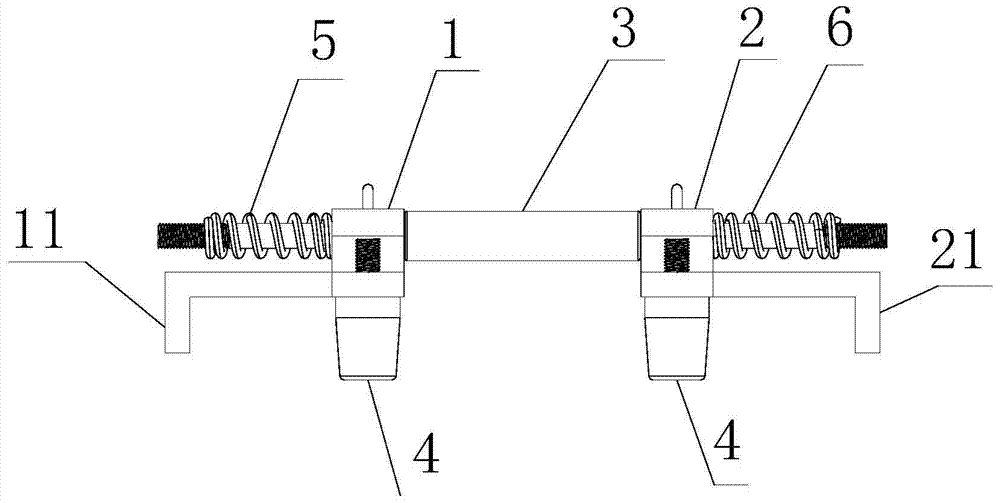

[0022] Such as Figure 1-4 as shown, figure 1 It is a structural schematic diagram of a stripping frame proposed by the present invention; figure 2 A side view of a stripper frame proposed by the present invention; image 3 A top view of a stripping frame proposed by the present invention; Figure 4 It is a schematic diagram of a demoulding frame proposed by the present invention in cooperation with the middle mold.

[0023] refer to Figure 1-3 , a demoulding frame proposed by an embodiment of the present invention, comprising: a first bracket 1, a second bracket 2 and two connecting shafts 3, wherein:

[0024] The two connecting shafts 3 are arranged parallel to each other, and the two connecting shafts 3 include a main body and a first sliding part and a second sliding part located at two ends of the main body; the outer surfaces of the first sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com