A kind of wax pattern structure and its manufacturing method to prevent the thickening of the precision casting blade basin

A manufacturing method and technology of wax molds, applied in the direction of casting and molding equipment, etc., can solve the problems of relying on manual grinding and removal, and achieve the effect of reducing the polishing process, high efficiency and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

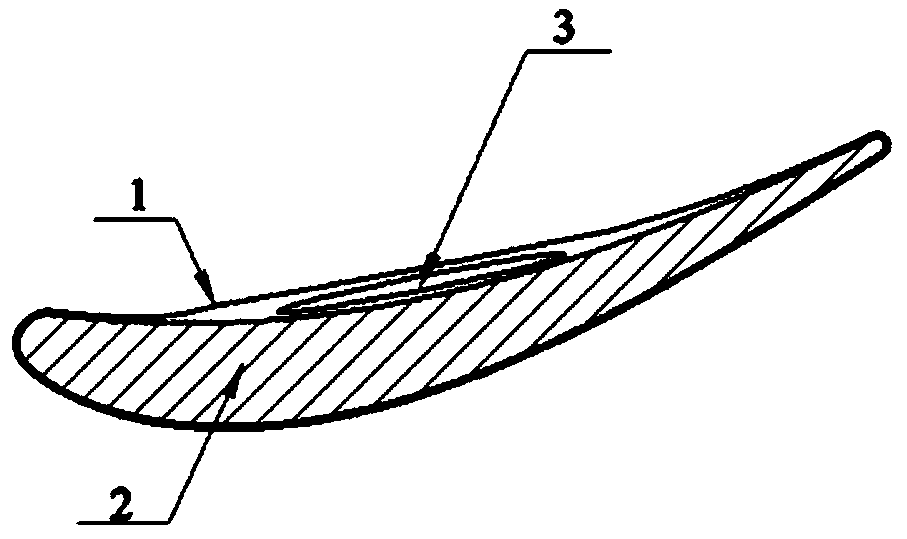

[0042] For the secondary working blade of a certain machine, the manufacturing method of the wax mold structure is as follows:

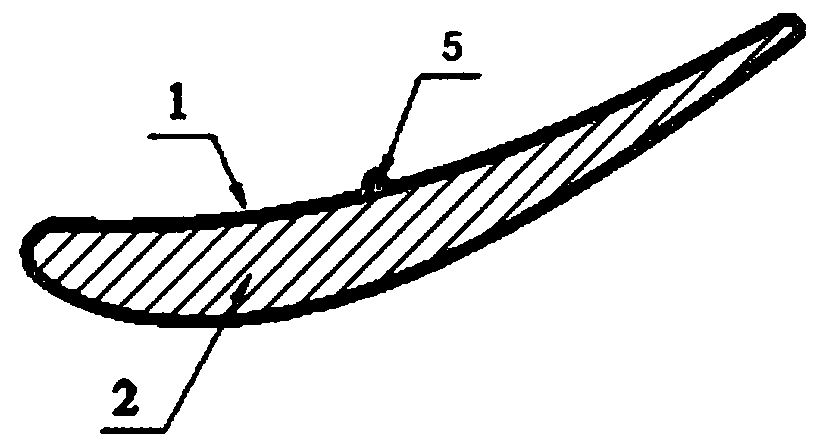

[0043] The chord width of the precision casting blade is narrow, so it is suitable for the anti-expansion method of sticking wax beans 5 or directly using liquid wax to make wax beans 5 . like Image 6 As shown, in the middle of the leaf pot 4, about 50mm away from the tenon and the turning part of the leaf body root, the leaf crown and the turning part of the leaf body root, and at an interval of about 50mm, use liquid wax to make a wax bean 5 with a diameter of Φ3mm and a height of 2mm, a total of 4 indivual. The height of the wax bean 5 can also be 3mm, 5mm, or the like.

Embodiment 2

[0045]The manufacturing method of the wax mold structure for the first-level guide vane of a certain machine is as follows:

[0046] The precision casting blade is a double blade, and the blade chord is long and wide, so it is suitable to use the wax strip anti-expansion method.

[0047] ① Prepare wax strips

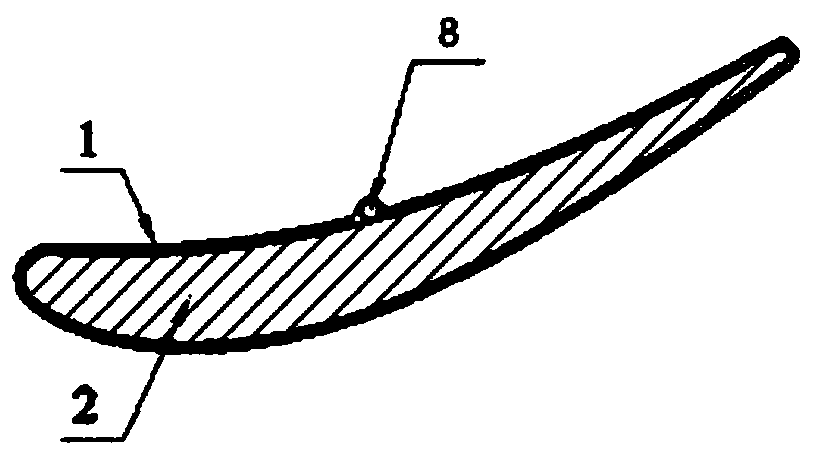

[0048] On the high-pressure wax pressing machine, use special wax mold tooling or directly purchase wax strips 8 of Φ3mm to make rib strips. According to the length of the blade body, intercept the wax strips 8 smaller than the length of the blade body by about 30mm for use;

[0049] ②Weld the wax strip to the blade basin

[0050] like Figure 7 As shown, place the prepared wax strip 8 and the upper inner edge plate of the wax mold body 2 in a direction of about 45° from the direction of the outer edge plate, and place them about 15mm away from the air inlet edge 6 and the exhaust edge 7, and Use an electric soldering iron to weld the wax strip to the above positions ...

Embodiment 3

[0054] The manufacturing method of the wax mold structure for the secondary guide vane of a certain machine is as follows:

[0055] The precision casting blade is a double blade, the volume is the largest type of blade precision casting in the workshop, and the blade chord is long, so it is suitable to use the wax strip anti-expansion method.

[0056] ① Prepare wax strips

[0057] On the high-pressure wax pressing machine, use special wax mold tooling to press or directly purchase Φ3mm wax strips 8 to make rib strips. According to the length of the blade body, intercept the wax strips 8 less than the length of the blade body about 40mm for use;

[0058] ②Weld the wax strip to the blade basin

[0059] Place the prepared wax strip 8 and the upper inner edge plate of the wax mold body 2 in a direction of about 70° from the direction of the outer edge plate, and place them at a distance of about 20mm from the air inlet edge 6 and the exhaust edge 7. The blade body root turning p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com