Cell-film bag package method, battery preparation method and battery

A packaging method and cell technology, which is applied in the direction of battery, electrode manufacturing, secondary battery, etc., can solve the problems of increasing the difficulty of welding, reducing the thickness of the battery, and prone to false welding, so as to reduce the overall thickness and reduce the overall Thickness, the effect of simplifying the packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

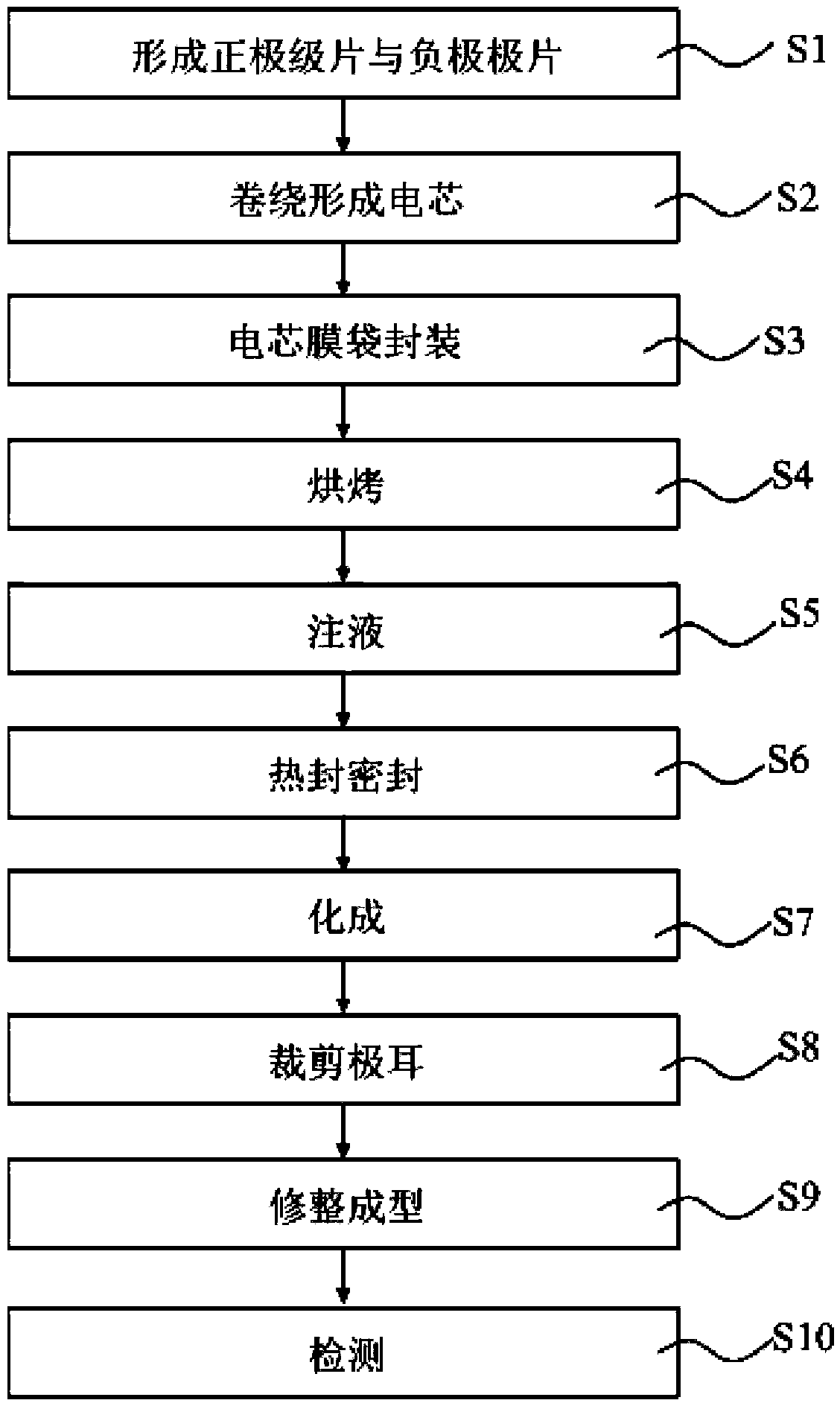

[0050] figure 1 The flow chart of the battery preparation method provided by the embodiment of the present invention, such as figure 1 As shown, this embodiment provides a method for preparing a battery to improve the packaging of the battery, simplify the manufacturing process of the battery and reduce the thickness of the battery.

[0051] Such as figure 1 As shown, the battery preparation method provided in this embodiment includes the following steps:

[0052] Step S1 : forming the positive pole piece 11 and the negative pole piece 12 .

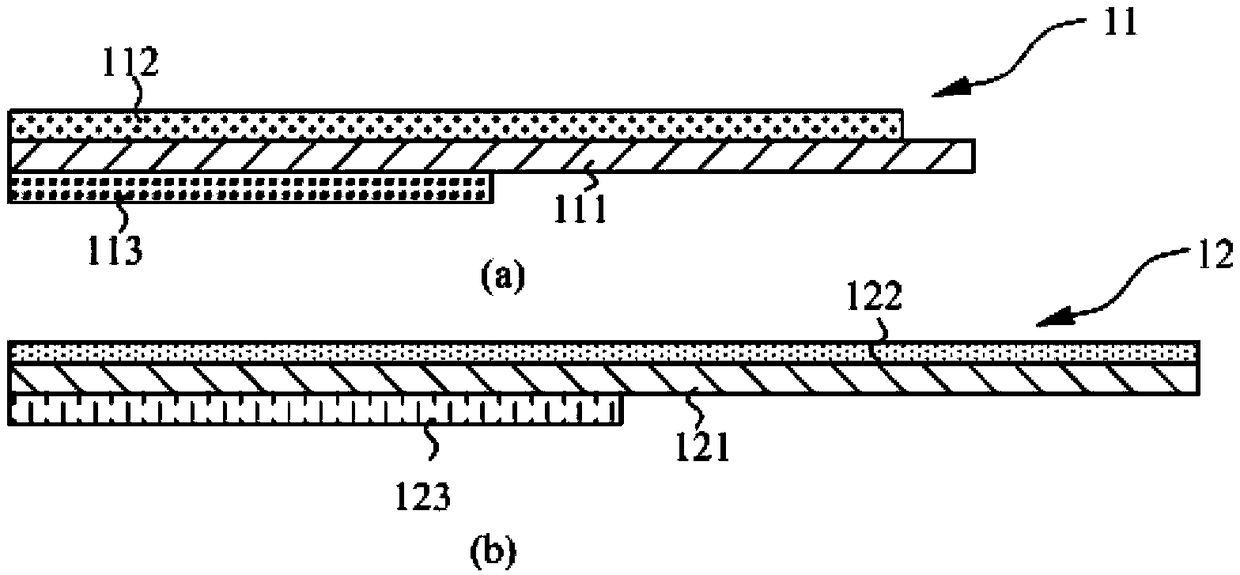

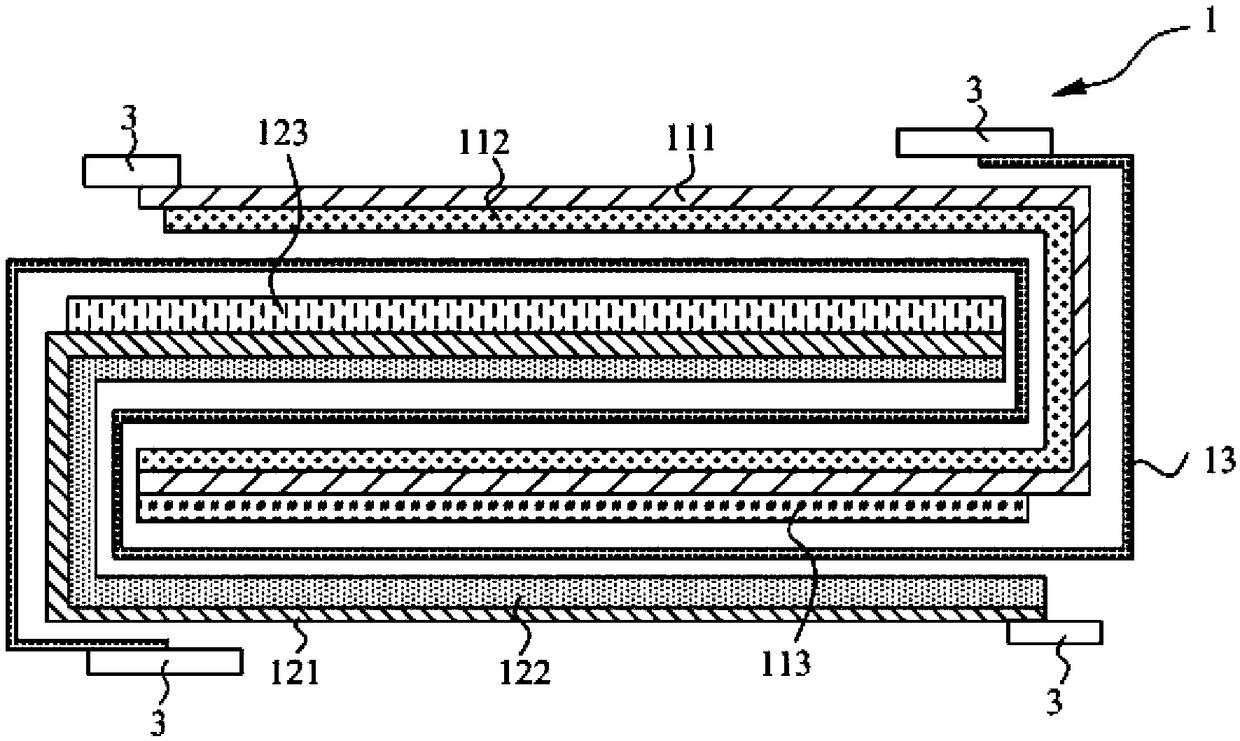

[0053] figure 2 The schematic front view of the positive pole piece 11 and the negative pole piece 12 provided for this embodiment, wherein figure 2 Middle a is a schematic diagram of the positive pole piece 11, figure 2 Middle b is a schematic diagram of the negative pole piece 12, such as figure 2 As shown in figure (a), the positive electrode sheet 11 provided in this embodiment is formed by coating positive electrode paint on ...

Embodiment 2

[0111] Figure 7 The flowchart of the battery preparation method provided by the embodiment of the present invention, such as Figure 7 As shown, this embodiment provides a battery preparation method. Compared with Embodiment 1, the preparation method provided by this Embodiment 2 except for the forming method of the positive pole piece and the negative pole piece in step S1 and the shape of the battery cell in step S2 Except for the different molding methods, other steps are the same as those in the first embodiment, and the same steps as those in the first embodiment will not be repeated in this embodiment.

[0112] Figure 8 Schematic diagram of the structure of the cell provided in this embodiment, such as Figure 8 As shown, the cell provided in this embodiment is formed by stacking positive pole pieces, negative pole pieces and separators. The forming process of the positive pole piece, the negative pole piece and the battery cell is as follows.

[0113] Step S1: For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com