A ball milling process and device for iron-based alloy powder

An iron-based alloy and powder technology, which is applied in the field of metal alloy powder manufacturing, can solve the problems of small output unit power consumption, excessive dust in the operation room, and low drum speed, so as to reduce the power consumption of ball mills, high degree of automation, and energy consumption. The effect of power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

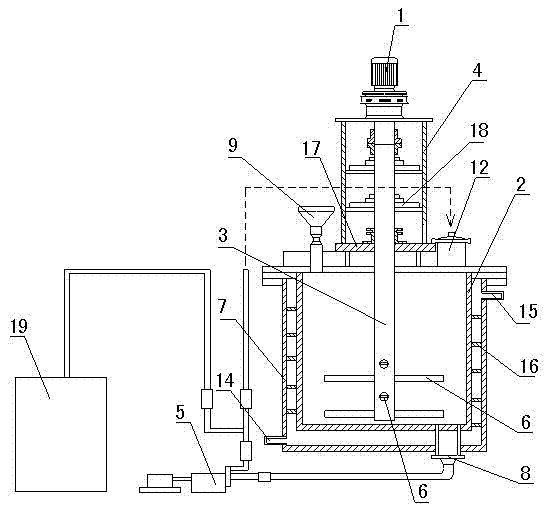

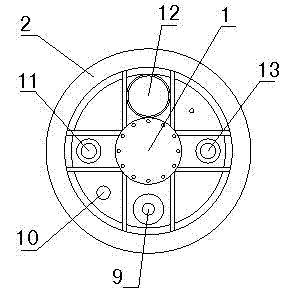

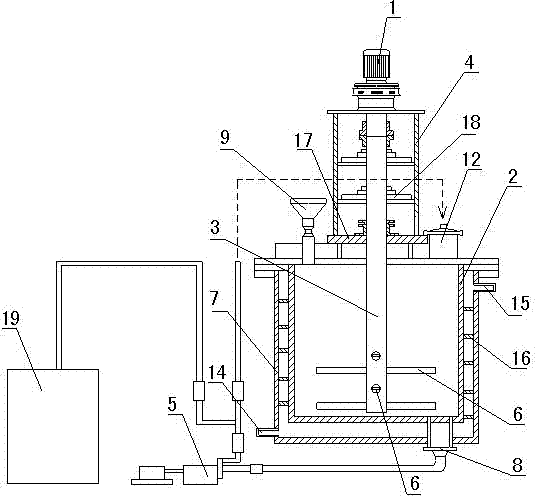

[0027] Example 1: A ball milling device for iron-based alloy powder, such as figure 1 , figure 2 , which includes a wet ball mill and a centrifuge 19, the wet ball mill includes a motor and a speed change device 1, a vertical grinding drum 2, a vertical stirring shaft 3, a body 4 and a slurry pump 5, and the body 4 is installed On the vertical grinding drum 2, the motor and the transmission device 1 are installed on the top of the body 4, and the upper end of the vertical stirring shaft 3 is connected to the output end of the motor and the transmission device 1, passes through the body 4 and extends to the end of the vertical grinding drum 2 At the bottom, the lower end of the vertical stirring shaft 3 is provided with 1 to 8 stirring arms 6. The relative installation angle between the stirring arms 6 is 60 to 90°, and the distance between the stirring arms 6 is not less than 50 mm. The vertical stirring shaft 3 and The vertical grinding cylinder 2 is concentric and perpen...

Embodiment 2

[0044] Example 2: The structure of a ball milling device for iron-based alloy powder is the same as in Embodiment 1.

[0045] A ball milling process for iron-based alloy powders, specifically ball milling iron-based alloy powders containing 85%Fe-9.6%Si-5.4%Al, comprising the following steps:

[0046] (1) Add steel balls, ball milling media, and iron-based alloys with a weight ratio of 10:0.8:1.2 to the aforementioned wet ball mill respectively. The feed particle size of the iron-based alloy is 1.2mm. Among them, the vertical The ratio of the inner diameter and height of the grinding cylinder is 1:1.1;

[0047] (2) Start the motor and adjust the speed of the stirring shaft with frequency conversion (the stirring shaft can also be assembled with a motor and a gearbox to achieve a constant speed);

[0048] (3) Start the slurry pump to make the slurry form a circular ball mill from top to bottom, and control the ball milling time for 1.2 hours.

[0049] (4) Start the centrifu...

Embodiment 3

[0055] Example 3: The structure of a ball milling device for iron-based alloy powder is the same as in Embodiment 1.

[0056] A ball milling process for iron-based alloy powders, specifically ball milling iron-based alloy powders containing 83.7%Fe-7.8%Si-4.4%Al-4.1%Sb, comprising the following steps:

[0057] (1) Add steel balls, ball milling media, and iron-based alloys with a weight ratio of 10:1:1.2 to the aforementioned wet ball mill respectively. The feed particle size of the iron-based alloy is 1 mm. Among them, the vertical wet ball mill The ratio of the inner diameter and height of the grinding cylinder is 1:1;

[0058] (2) Start the motor and adjust the speed of the stirring shaft with frequency conversion (the stirring shaft can also be assembled with a motor and a gearbox to achieve a constant speed);

[0059] (3) Start the slurry pump to make the slurry form a circular ball mill from top to bottom, and control the ball milling time for 30 hours.

[0060] (4) S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com