Tasty jar and tasty technology thereof

A process and tank body technology, which is applied in the field of flavor tanks and flavor technology, can solve the problems of restricting the development of raw meat concoctions, destroying the product appearance, and occupying a large space, so as to achieve fast flavor effects, guaranteed product quality, and equipment The effect of energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

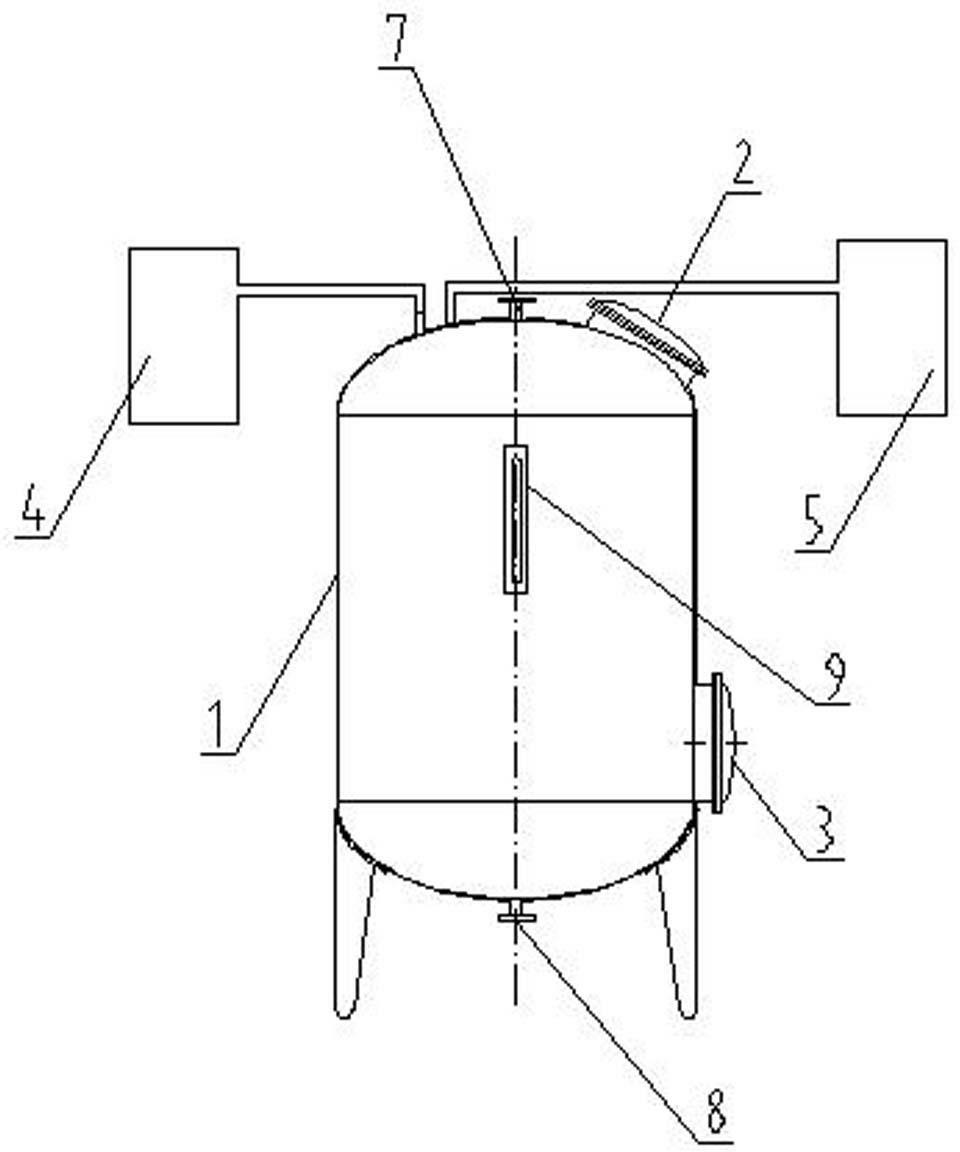

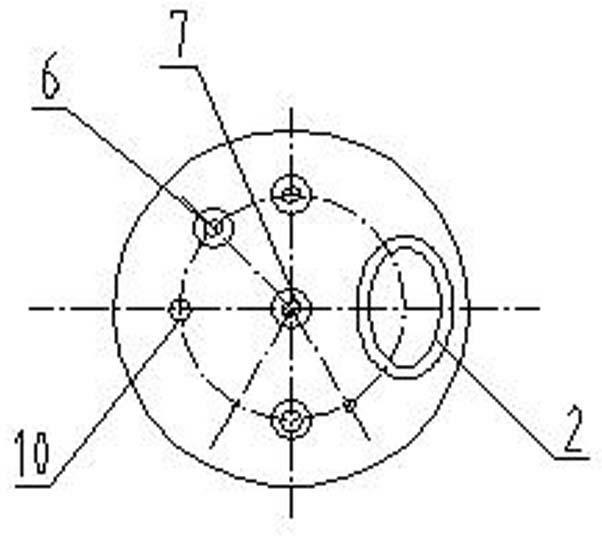

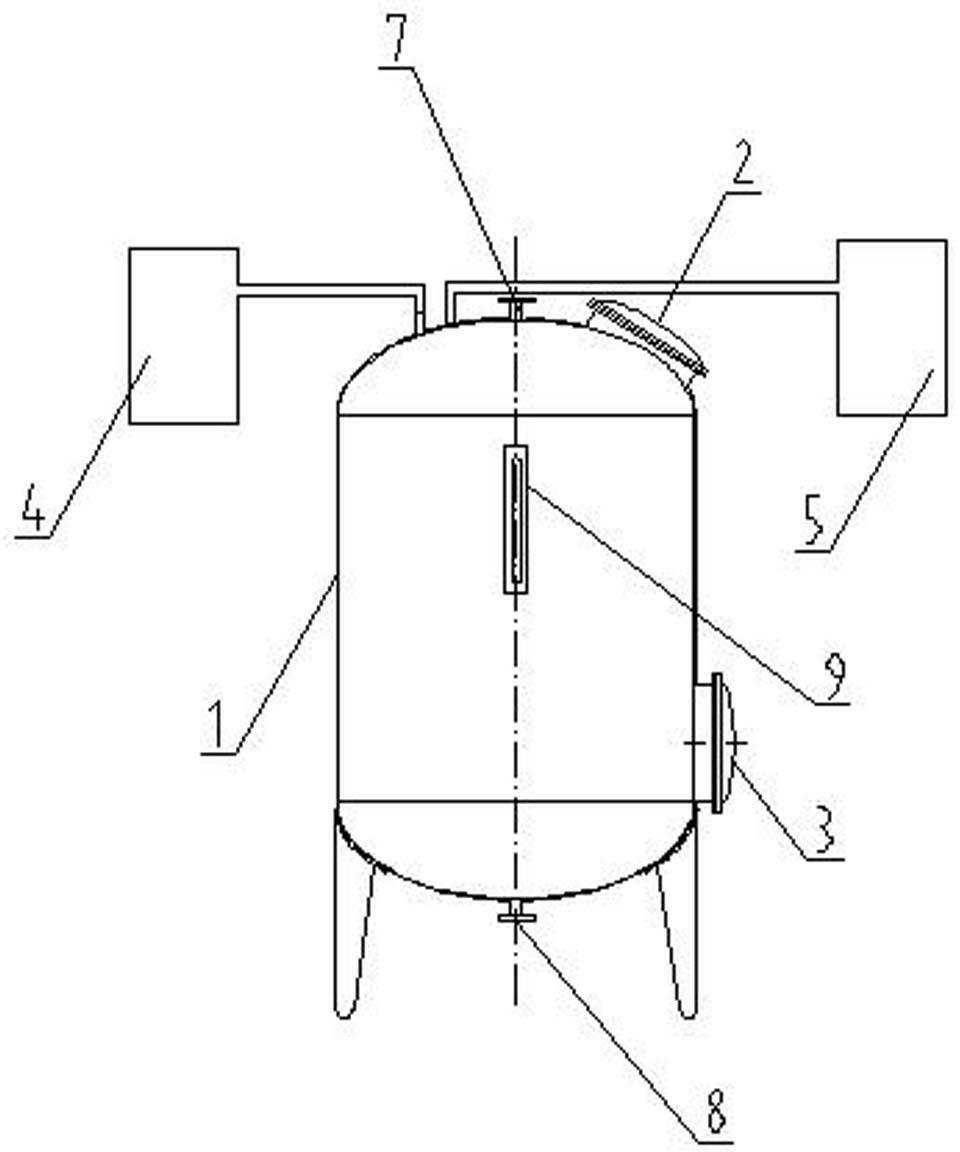

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, whole chicken tastes good

[0044] (1) Material liquid extraction: select the required spices and ingredients according to the required taste, extract with a multi-functional extraction tank, first use 50% alcohol to extract for 4 hours, and then use 8 times of water to extract three times respectively, and extract After the liquid is mixed, add appropriate amount of salt, sugar and other seasonings;

[0045] (2) Raw material sorting: Fresh or thawed whole chicken raw meat is sorted one by one to remove viscera, hair, impurities, etc. and clean them;

[0046] (3) Flavor preparation: Put the qualified raw meat and feed liquid into the flavor tank according to the proportion, and use the method of negative pressure cold taste to marinate. When marinating, when the vacuum pressure in the tank reaches -0.06, cool and marinate Cook for 30-50 minutes; then take out the product, drain the material liquid, pack into bags, and vacuum seal.

[0047] (4) Quick-froz...

Embodiment 2

[0048] Embodiment 2, chicken wings tasty

[0049] (1) Material liquid extraction: Select the required spices and ingredients according to the required taste, extract with a multi-functional extraction tank, first use 52.5 degrees of alcohol to extract for 7 hours, and then use 10 times of water to extract three times respectively, and extract After the liquid is mixed, add appropriate amount of salt, sugar and other seasonings;

[0050] (2) Raw material sorting: Fresh or thawed chicken wing raw meat is sorted one by one to remove hair roots, feathers, impurities, etc. and clean them;

[0051] (3) Prepare the taste: put the qualified raw meat and feed liquid into the taste tank according to the proportion, and use the method of negative pressure cold taste to marinate. When marinating, when the vacuum pressure in the tank reaches -0.53Mpa, cool Marinate for 6-15 minutes; then take out the product, drain the liquid and pack it into a bag for vacuum sealing.

[0052] (4) Quick-...

Embodiment 3

[0053] Embodiment 3, pork flavor

[0054] (1) Material liquid extraction: select the required spices and ingredients, extract with a multi-functional extraction tank, first use 55% alcohol for 10 hours, and then use 12 times of water to extract three times, mix the extracts, Add appropriate amount of salt, sugar and other seasonings;

[0055] (2) Raw material sorting: Fresh or thawed pork raw meat is sorted one by one, after removing hair roots, impurities, etc. and cleaning, cut into pieces according to the order requirements;

[0056] (3) Prepare the taste: put the qualified raw meat and feed liquid into the taste tank according to the proportion, and use the method of negative pressure cold taste to marinate. When marinating, when the vacuum pressure in the tank reaches -1.0Mpa, cool it Marinate for 30 minutes; then take out the product, drain the liquid and pack it into a bag for vacuum sealing.

[0057](4) Quick-frozen packaging: The product is quickly frozen for 10 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com