Novel wire feeding equipment for production of electric welding rods and operating method thereof

A welding rod and wire feeding technology, applied in welding equipment, metal processing equipment, welding medium, etc., can solve the problems of worn equipment, lubricating oil deterioration, long maintenance time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

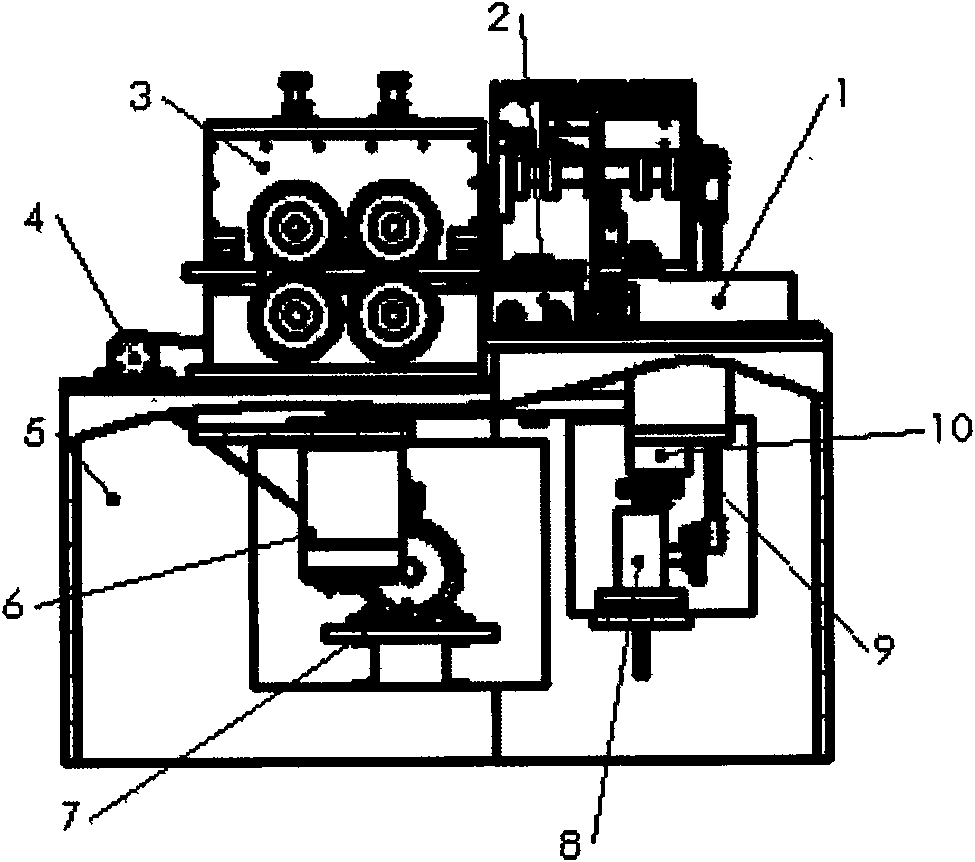

[0025] Embodiment: a kind of novel wire feeding equipment for electrode production (see figure 1 ), is characterized in that it is made of frame 5, head part 3, hair wheel part 2, storage hopper 1, hair wheel drive motor 6 and roll drive motor 7; said head part 3, hair wheel part 2, storage The hopper 1, the hair wheel drive motor 6 and the roll drive motor 7 are fixed on the frame 5; the output end of the storage hopper 1 is corresponding to the input end of the hair wheel part 2; the output end of the hair wheel part 2 is connected to the machine The input end of the head part 3 is corresponding; the wool wheel drive motor 6 is respectively connected to the storage hopper 1 and the wool wheel part 2 ; the roll drive motor 7 is connected to the machine head part 3 .

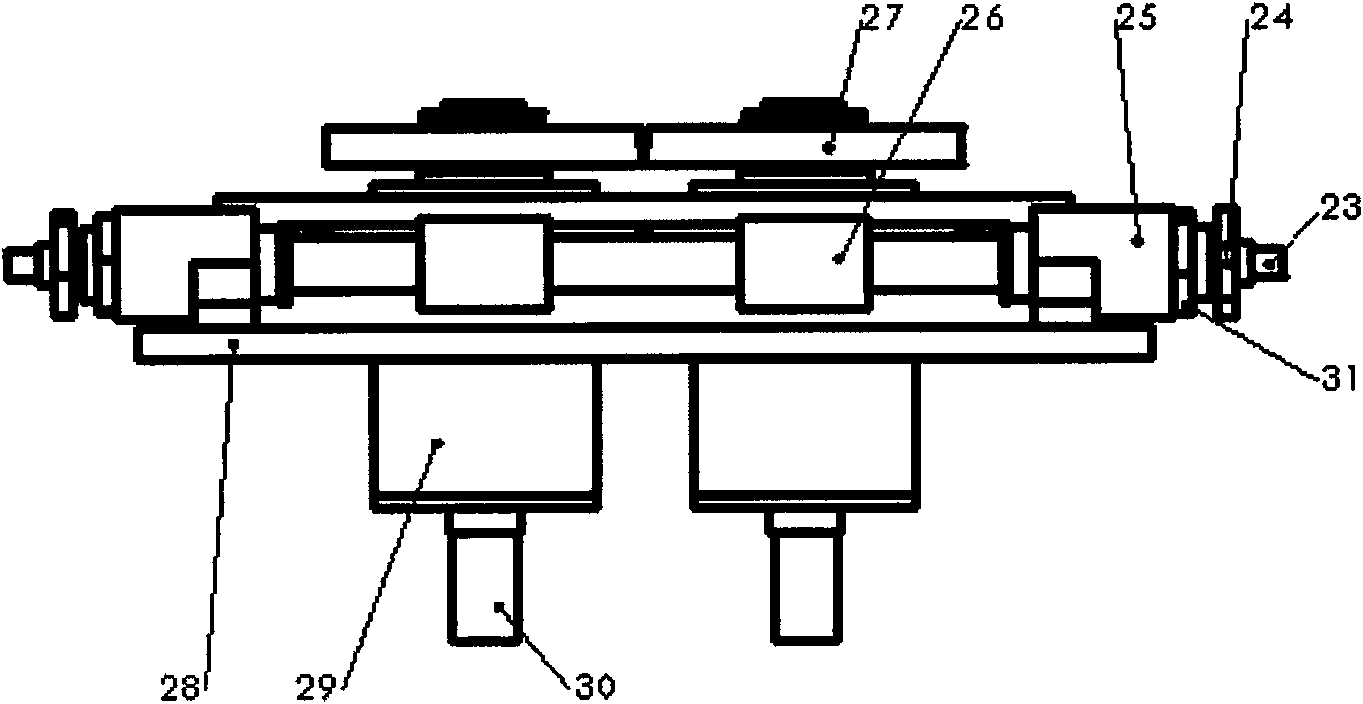

[0026] The above-mentioned storage hopper is composed of a slide plate seat 33, a base 32, a small connecting rod 34, a swing arm 35, a swing shaft bearing chamber 36, a swing shaft 38, a vertical bar and an adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com