Shaft cover processing tool

A shaft cover and tooling technology, applied in metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve the problems of the machining center not getting the maximum utilization rate, frequent starting and stopping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

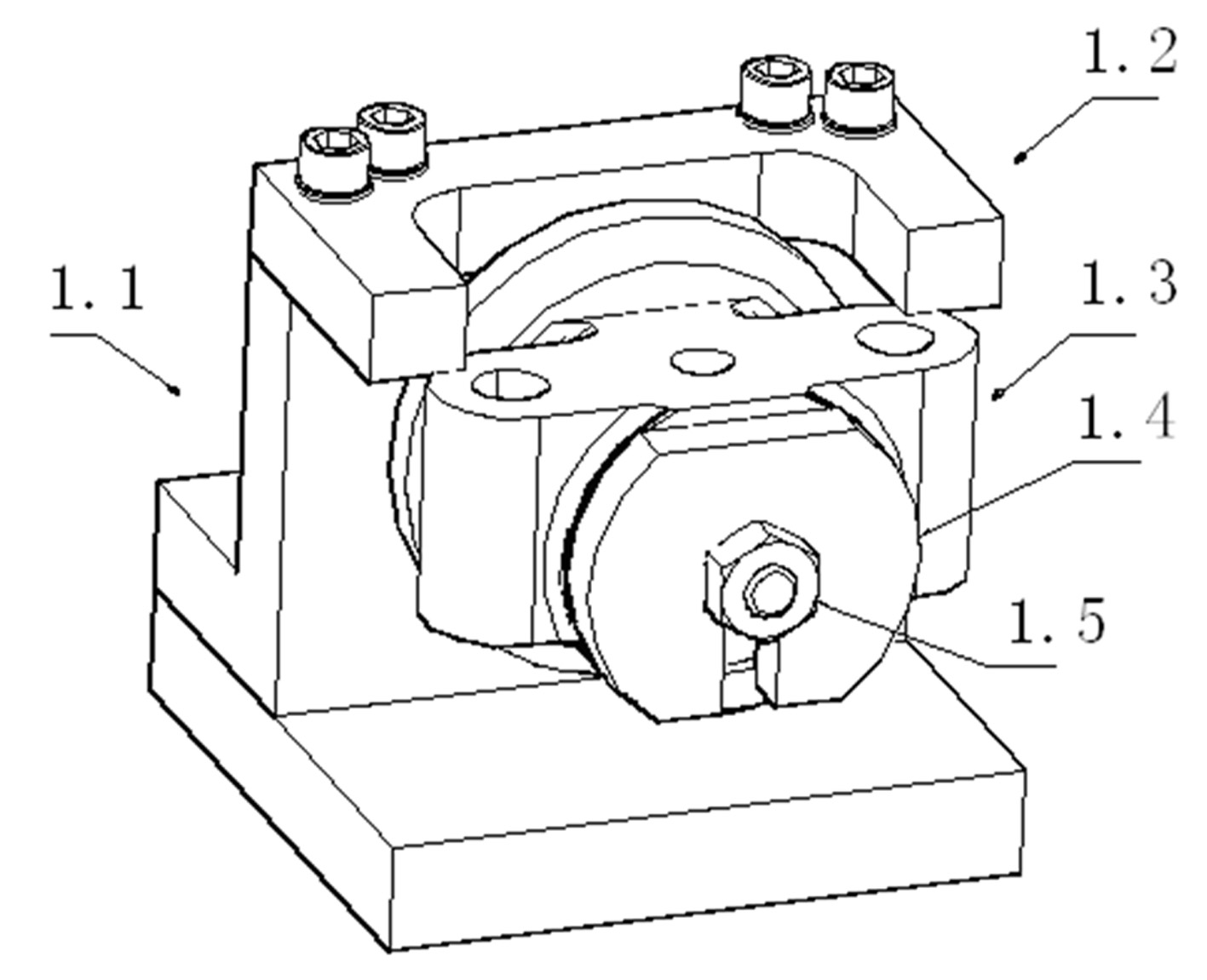

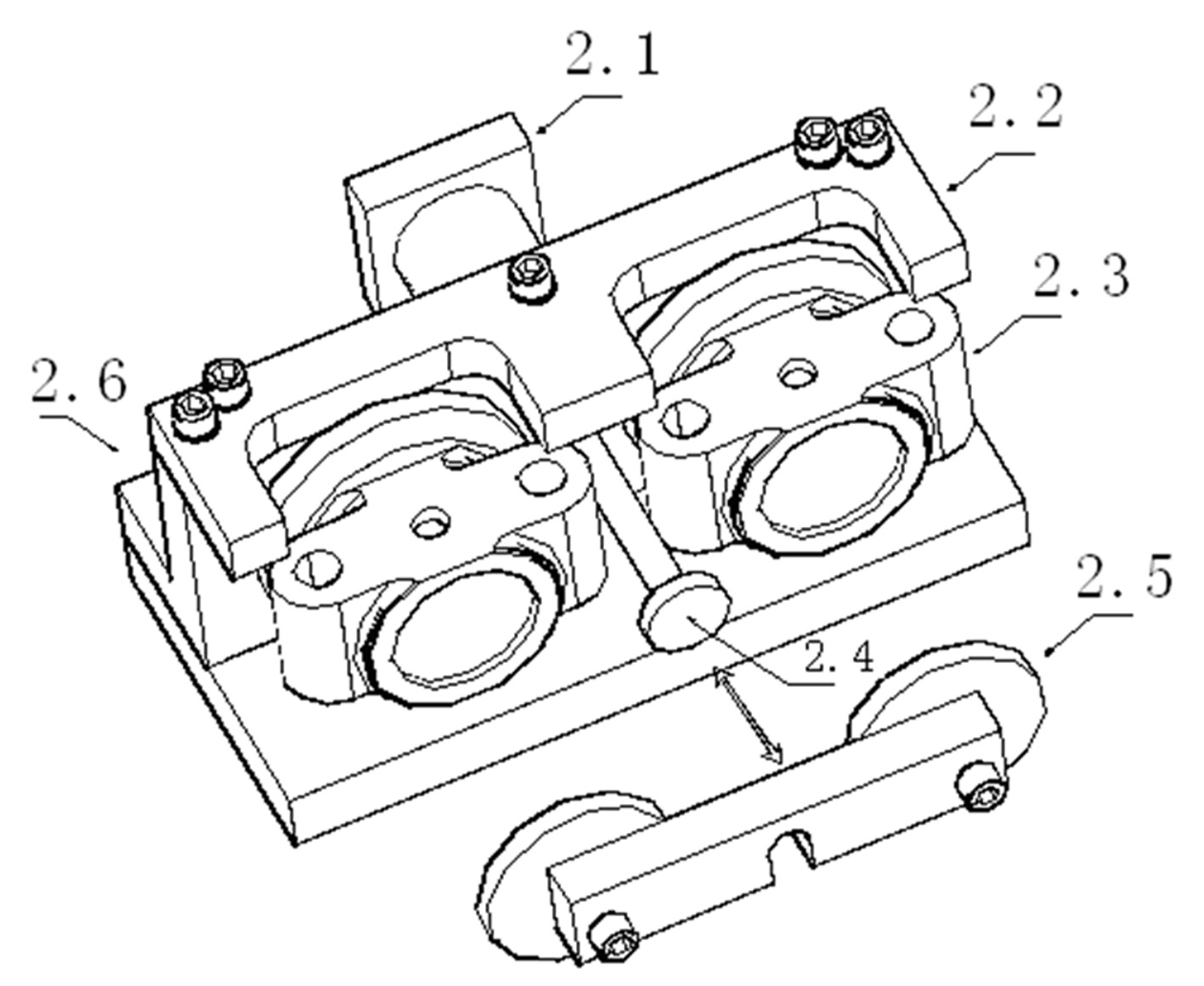

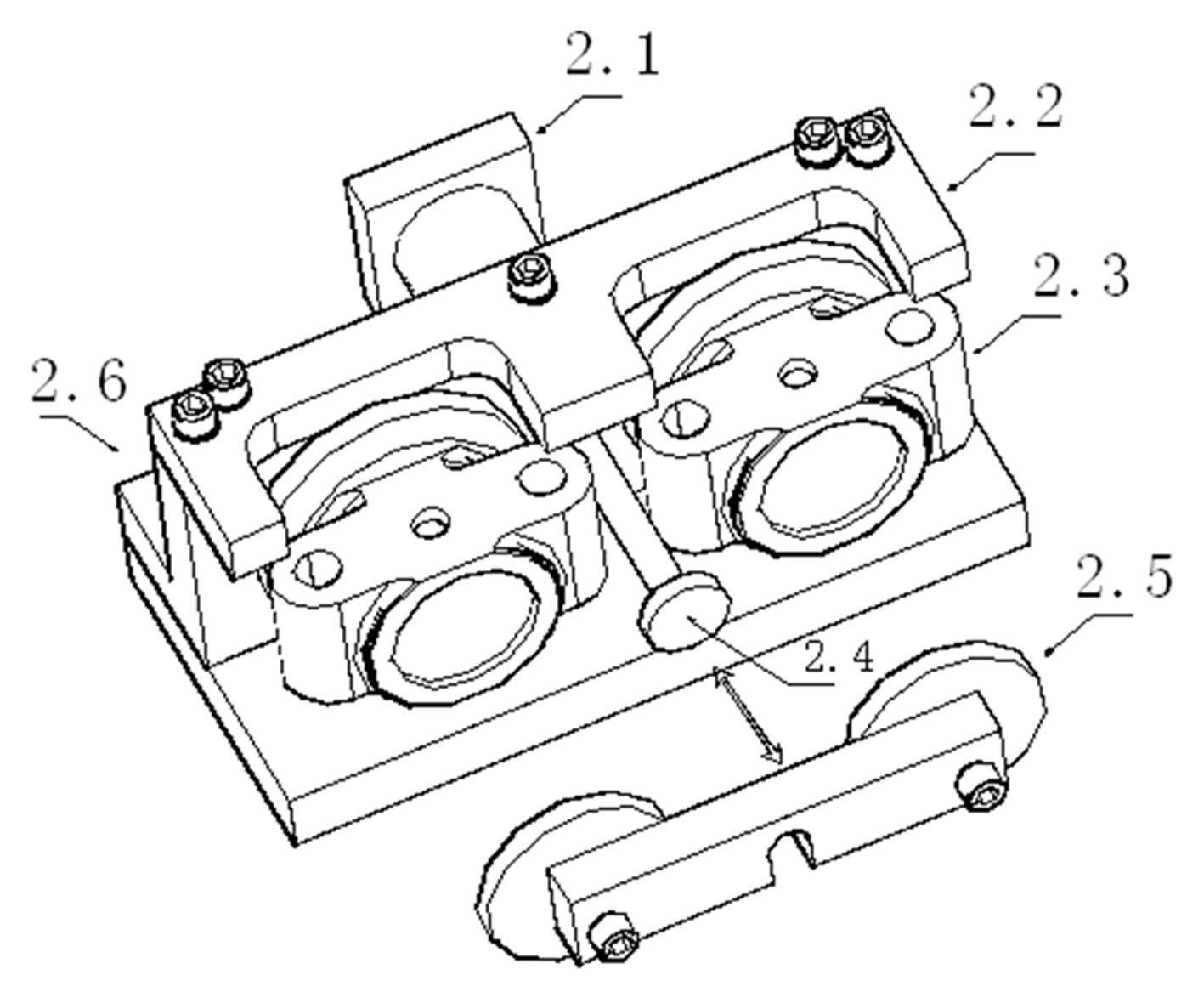

[0012] A shaft cover processing tool, including an angle iron mandrel positioning seat 2.6, a positioning plate 2.2 and a pressure plate 2.5, the positioning plate 2.2 is connected to the angle iron mandrel positioning seat 2.6 to form a space for limiting the shaft cover 2.3. It also includes a cylinder 2.1; the angle iron mandrel positioning seat 2.6 has the same two groups, and the two sets of angle iron mandrel positioning seats 2.6 are arranged side by side; a cylinder pull rod 2.4 is arranged in the middle of the two sets of angle iron mandrel positioning seats 2.6, The cylinder rod 2.4 is connected to the piston rod of the cylinder 2.1, and advances and retreats synchronously with the piston rod; the axial direction of the cylinder rod 2.4 is parallel to the axial direction of the mandrel on the angle iron mandrel positioning seat 2.6; the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com