Loop whee with detachable wearing layer

A wear-resistant layer and looper technology, used in bending workpieces, metal processing equipment, metal rolling, etc., can solve the problems of unusable bearings, long repair processing procedures, and high costs, reducing the number of replacements, on-site assembly and maintenance. The effect of convenient replacement and increased shift output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

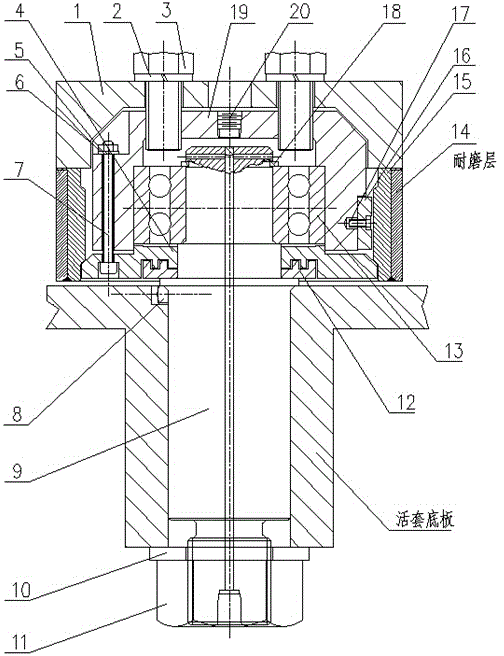

[0016] Example 1 : see figure 1 , a looper wheel with a detachable wear-resistant layer, the looper wheel includes a guide wheel shaft 9, a bearing 13 is installed on the guide wheel shaft, and a retaining ring 18 is arranged on the upper part of the guide wheel shaft, through which the Fixed, the looper wheel also includes a positioning sleeve 19, the bearing is installed in the positioning sleeve 19, the upper and lower ends of the looper wheel are respectively provided with a first end cover 1 and a second end cover 4. The looper wheel also includes a roller 15, on which a wear-resistant sleeve 14 is welded, and the roller is mounted on a positioning sleeve 19 through 13 fixed parts. Wear-resistant cover 14 acts as wear-resistant layer, and in the course of work, wearing and tearing only wears the lower part of this cover, after treating wear and tear, can turn up and down and continue to use, only need cover and roller to be taken off together when replacing and get fina...

Embodiment 2

[0017] Example 2 : see figure 1 , as an improvement of the present invention, the looper wheel further includes a third end cover 12, and the third end cover 12 is arranged at the lower part of the bearing. It plays the role of sealing and dustproof.

Embodiment 3

[0018] Example 3 : see figure 1 , as an improvement of the present invention, the fixed component includes a key 16 and a keyway inside the roller, and the roller is mounted on the positioning sleeve 19 through the key and the keyway inside the roller. Through the cooperation of the key and the keyway, its firmness is enhanced. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com