Annular piece combined forging method

A ring-shaped piece, forging press technology, applied in the field of forging, can solve the problems of slow turning efficiency and too much waste of forging energy, and achieve the effect of reducing energy consumption and saving raw material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

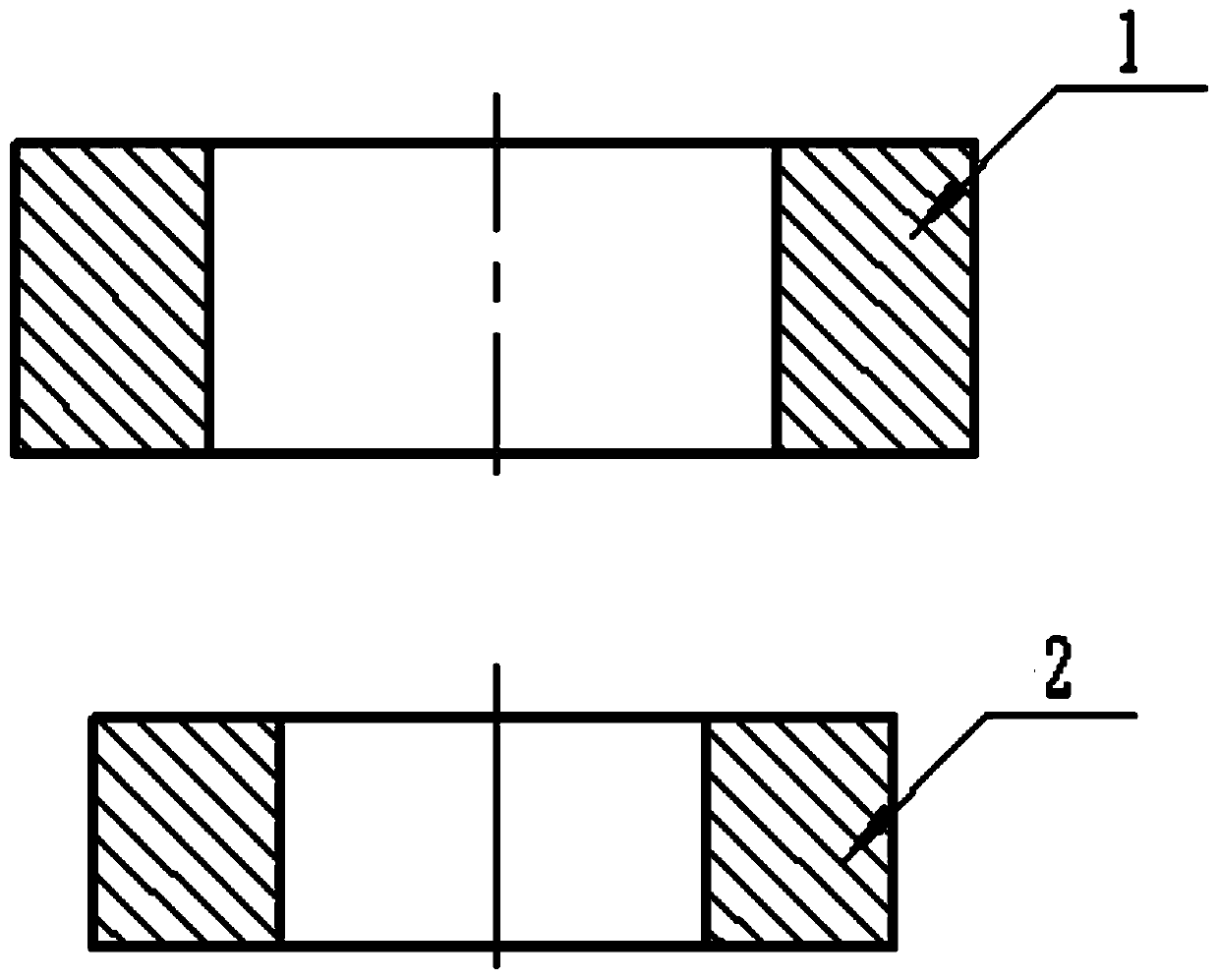

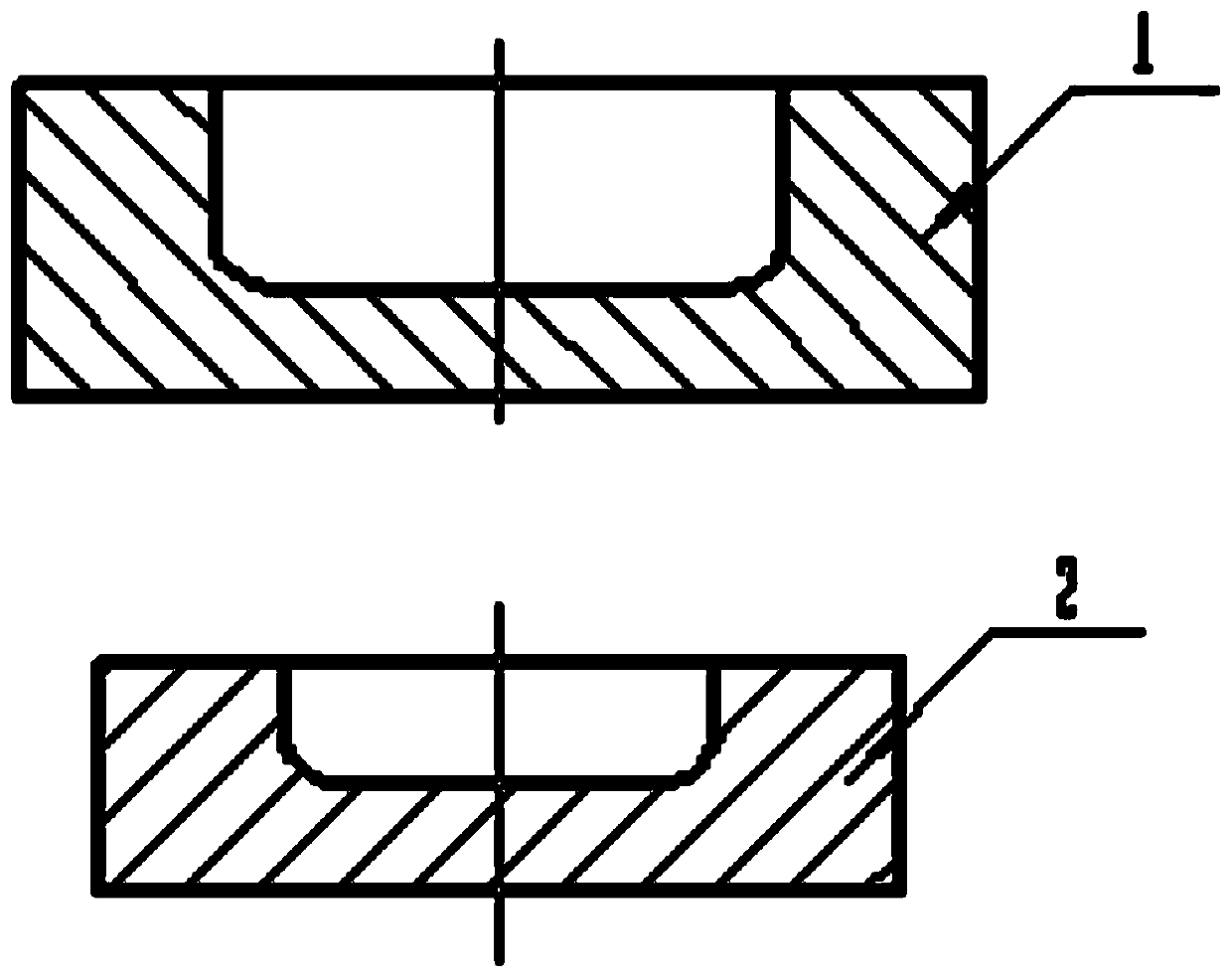

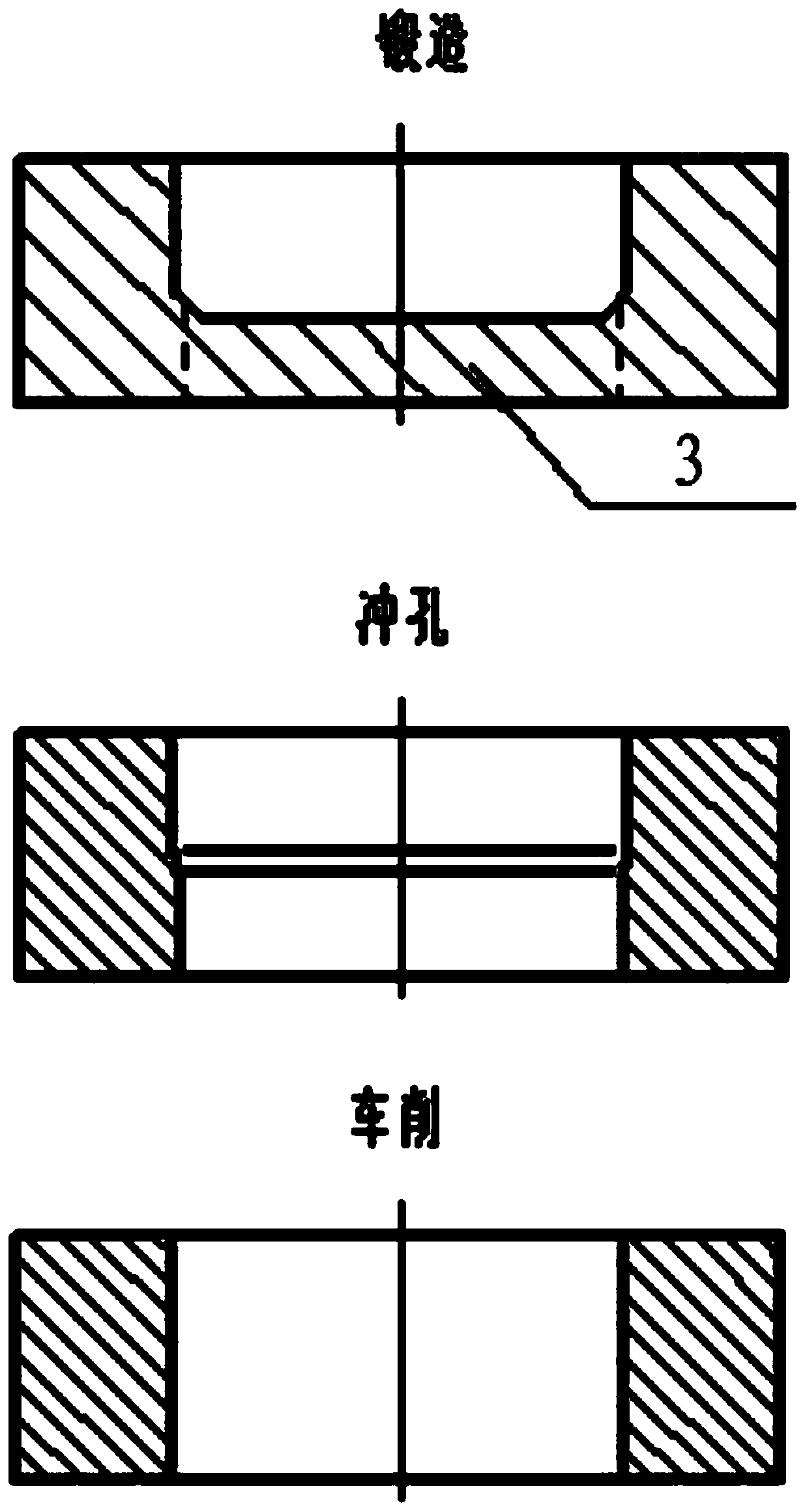

[0035] A combined forging method of a ring-shaped piece, comprising the steps of:

[0036] Step 1. The round steel is heated to the process temperature and kept warm, and then placed into the forging die of the forging press. The upper die is provided with an upper punch, and the middle of the lower die is provided with a lower punch. The upper punch is used to combine forging forgings The upper counterbore and the lower punch are used to combine the lower counterbore of the forging piece. The slider of the forging press drives the upper die to descend. The upper die and the lower die upset the bar and forge the first forging piece and the second forging piece. The combined forging piece is forged. For the ring blank, the center forging of the combined forging part removes the core material to make a combined ring blank;

[0037] The holding time t = heating coefficient η × δ, δ is the cross-sectional diameter of the ring blank, the unit is mm, the heating coefficient η = 0.5,...

Embodiment 2

[0044] A combined forging method of a ring-shaped piece, comprising the steps of:

[0045] Step 1. The round steel is heated to the process temperature and kept warm, and then placed into the forging die of the forging press. The upper die is provided with an upper punch, and the middle of the lower die is provided with a lower punch. The upper punch is used to combine forging forgings The upper counterbore and the lower punch are used to combine the lower counterbore of the forging piece. The slider of the forging press drives the upper die to descend. The upper die and the lower die upset the bar and forge the first forging piece and the second forging piece. The combined forging piece is forged. For the ring blank, the center forging of the combined forging part removes the core material to make a combined ring blank;

[0046] The holding time t = heating coefficient η × δ, δ is the cross-sectional diameter of the ring blank, the unit is mm, the heating coefficient η = 0.8,...

Embodiment 3

[0053] Step 1. The round steel is heated to the process temperature and kept warm, and then placed into the forging die of the forging press. The upper die is provided with an upper punch, and the middle of the lower die is provided with a lower punch. The upper punch is used to combine forging forgings The upper counterbore and the lower punch are used to combine the lower counterbore of the forging piece. The slider of the forging press drives the upper die to descend. The upper die and the lower die upset the bar and forge the first forging piece and the second forging piece. The combined forging piece is forged. For the ring blank, the center forging of the combined forging part removes the core material to make a combined ring blank;

[0054]The holding time t = heating coefficient η × δ, δ is the cross-sectional diameter of the ring blank, the unit is mm, the heating coefficient η1.2, and the unit of the holding time t is min;

[0055] Step 2. Put the combined forging ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com