Manufacturing method of rapid power concentrated rail motor coach motor car carbon fiber locomotive door

A technology of power concentration and manufacturing method, which is applied to door devices, railway car body parts, household components, etc., can solve the problems of large shape and position tolerance, low manufacturing precision, complex structure, etc., and achieves small shape and position tolerance and high manufacturing precision. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

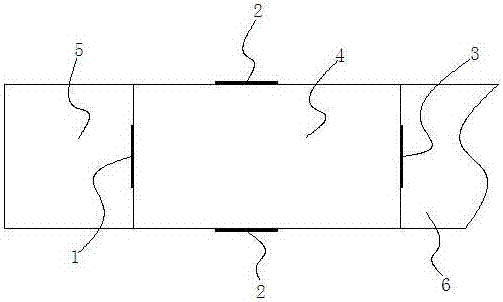

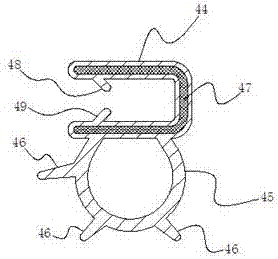

[0068] Embodiment 1: as Figure 2 to Figure 6 As shown, the locomotive door is a corridor door 1, and the door body skeleton 7 includes a skeleton frame body 8, a window frame body 9 located in the skeleton frame body 8 and close to the upper part of the skeleton frame body 8, and a In the frame body-8 and near the lower beam-10 at the lower part of the frame body-8, a corridor door sealing strip around the entire circumference of the frame body-8 is also arranged on the outer peripheral surface of the frame body-8 11. Window frame one 9 is used for installing glass windows, one side of window frame one 9 is connected with the inner side of skeleton frame one 8 through crossbeam one 12, and the other side of window frame one 9 is through crossbeam two 13 It is connected to the other side of the skeleton frame 8, one end of the lower beam 10 is connected to the inner side of the skeleton frame 8, and the other end of the lower beam 10 is connected to the other side of the skele...

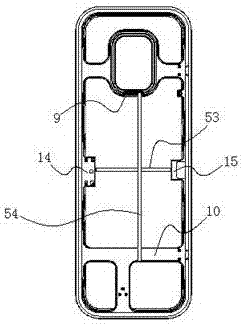

Embodiment 2

[0086] Embodiment 2: as Figure 11 As shown, compared with Embodiment 1, the difference is that: a transverse reinforcing rib 53 is provided between the lock body projection one 14 and the lock body projection two 15, and the window frame body one 9 and the lower beam one 10 A longitudinal reinforcing rib 1 54 is arranged between them. The transverse ribs one and the longitudinal ribs one mainly strengthen the panel and further increase the strength of the panel. In this embodiment, the first transverse reinforcing rib and the first longitudinal reinforcing rib are arranged on one side close to the inner panel, and mainly play a role in strengthening the strength of the inner panel.

Embodiment 3

[0087] Embodiment 3: as Figure 12 to Figure 14 As shown, compared with Embodiment 1, the difference is that: the locomotive door is an entrance door, and the door body skeleton includes a skeleton frame body 2 55 and is located in the skeleton frame body 2 55 and is close to the skeleton frame body 2 55 The upper cross beam 56 at the top, one end of the upper cross beam 56 is connected with the inner side of the skeleton frame body two 55, and the other end of the upper cross beam 56 is connected with the inner other side of the skeleton frame body two 55; The middle position of 55 and is positioned at the inner side of skeleton frame body 2 55 and is provided with lock body projection 3 57, between lock body projection 3 57 and the inner other side of skeleton frame body 2 55, middle crossbeam 1 is arranged 58, at the lower part of the skeleton frame body two 55 and on the inner side of the skeleton frame body two 55, a lock body projection four 59 is arranged, and on the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com