Double-layer punching tool for control valve deck

A technology for controlling valves and tooling, applied in the direction of drilling molds for workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further illustrate the principle and structure of the present invention, the preferred embodiments of the present invention are now described in detail in conjunction with the accompanying drawings, but the embodiments are only for illustration and explanation, and cannot be used to limit the scope of patent protection of the present invention.

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

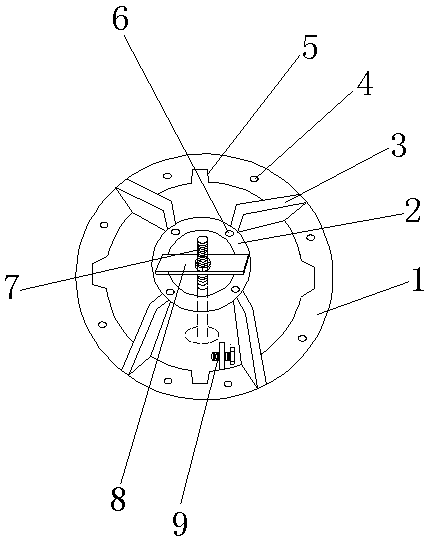

[0014] like figure 1 Shown is a control valve cover double-layer punching tool provided by the present invention, which includes: bottom ring 1, upper ring 2, connecting armature 3, bottom drilling jig 4, positioning groove 5, upper drilling jig 6, Fixed screw rod 7, weight iron 8, positioning pile 9, described bottom ring 1 is an iron ring, and its ring surface is provided with described bottom drilling jig 4 and has described positioning groove 5; 2 is an iron ring, which is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com