Rotor assembly, motor and household electrical appliance

A component and rotor technology, applied in the direction of motors, electric components, magnetic circuit rotating parts, etc., can solve the problems of limited application range of motors, low power density of motors, weak structural strength, etc., to reduce magnetic flux leakage and reduce motor costs , The effect of reducing the shape and position tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

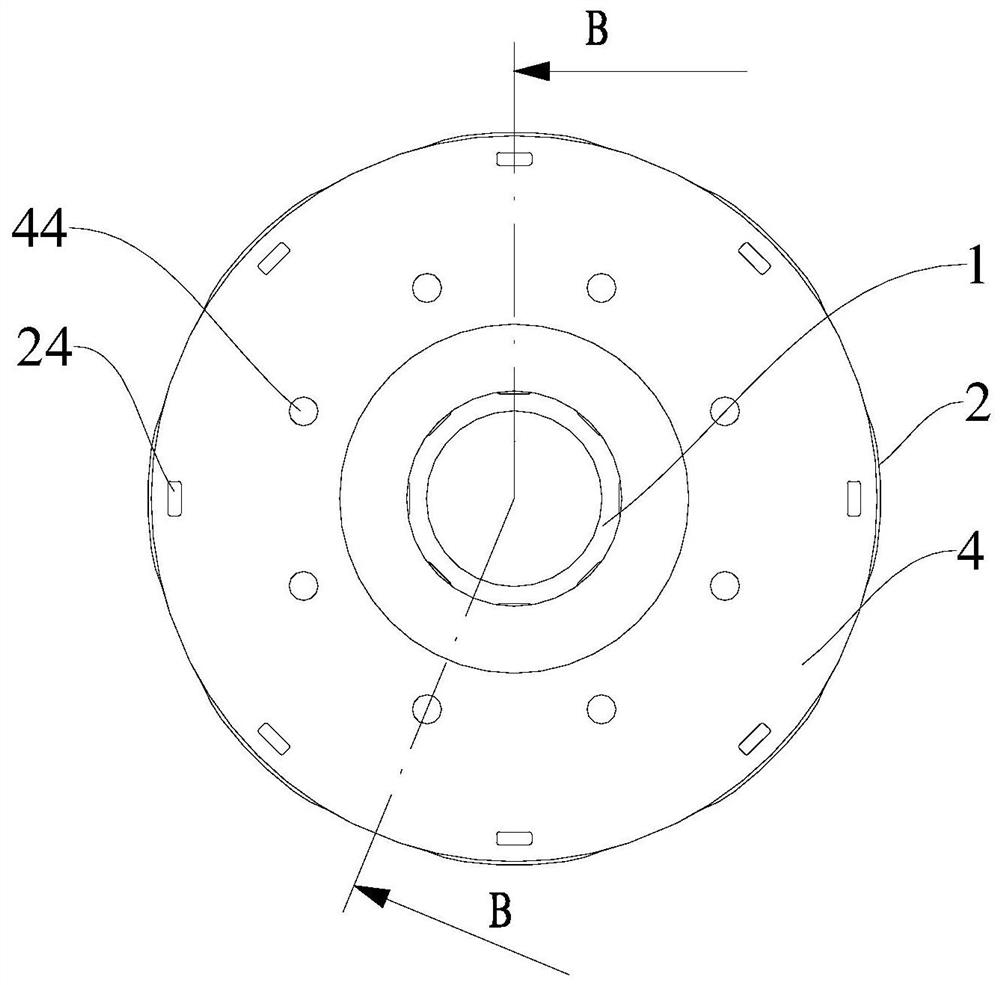

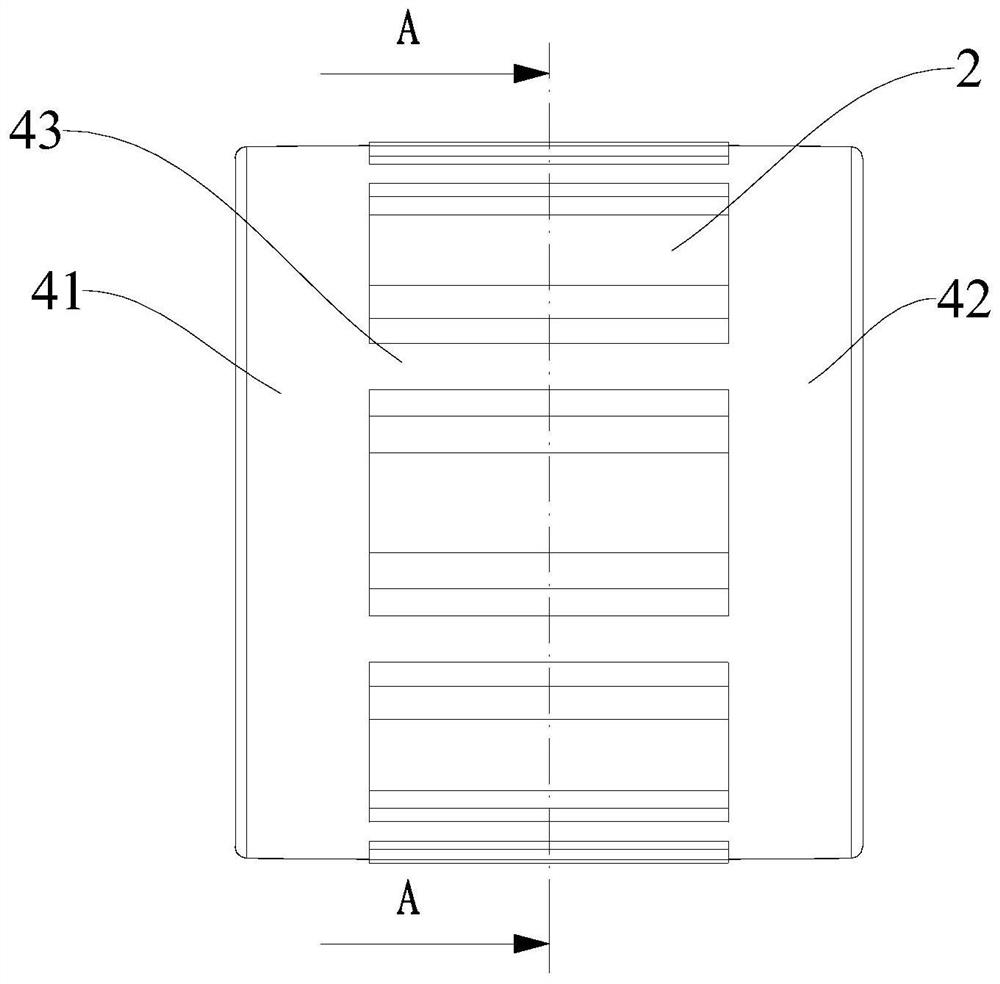

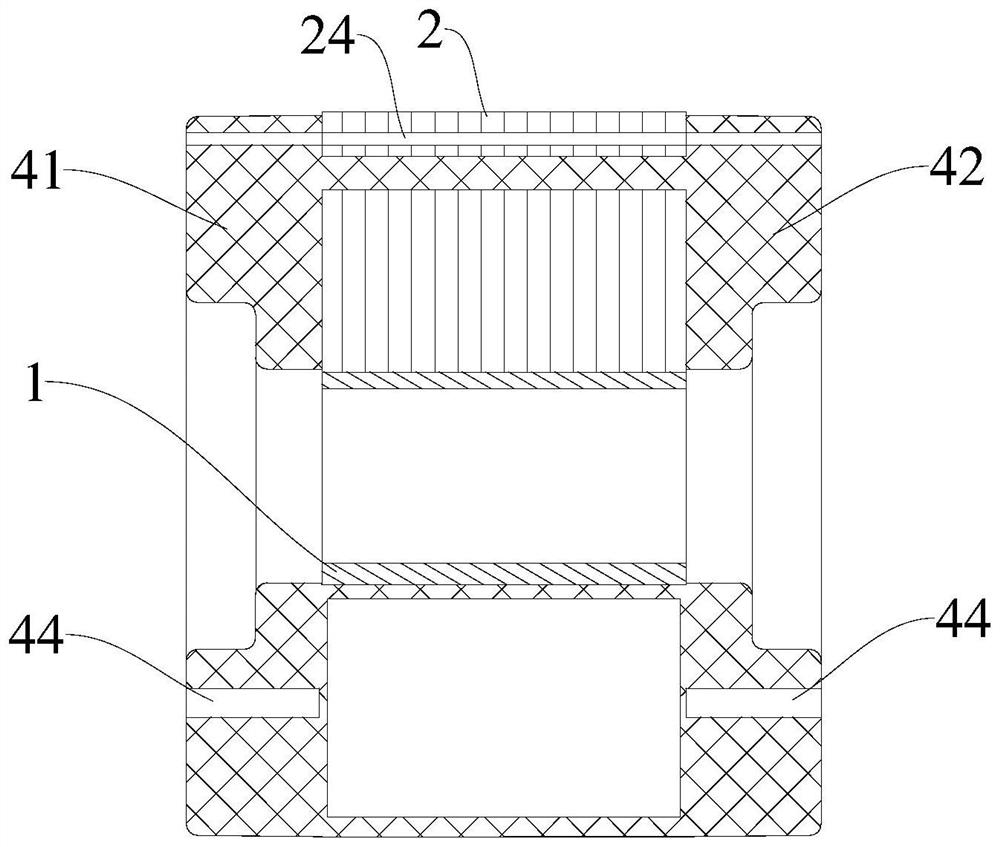

[0036] Refer below Figure 1-Figure 8 Rotor assemblies provided according to some embodiments of the invention are described.

[0037] Such as Figure 1-Figure 4 As shown, the rotor assembly according to the embodiment of the present invention includes a shaft sleeve 1, a reinforcing boss 14, a rotor core 2 and a permanent magnet 3, wherein the shaft sleeve 1 is generally cylindrical, and the reinforcing boss 14, the rotor core 2 and The permanent magnets 3 are all connected to the sleeve 1, and the reinforcement boss 14, the rotor core 2 and the permanent magnet 3 are all located on the peripheral side of the sleeve 1, and the reinforcement boss 14 extends alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com