Torsion beam lining component and manufacturing and mounting method thereof

A technology of torsion beam and bushing, applied in vehicle parts, transportation and packaging, elastic suspension, etc., can solve problems such as affecting the performance of the whole vehicle, reliability noise, processing and assembly processes, and difficulty in ensuring shape and position tolerances. Achieve the effect of eliminating the risk of loosening, reducing the press-fitting process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

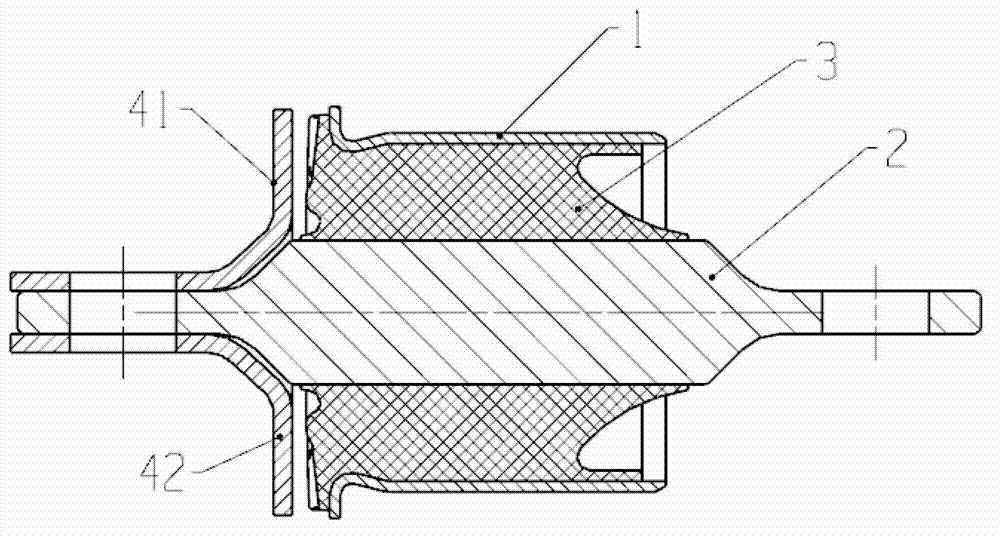

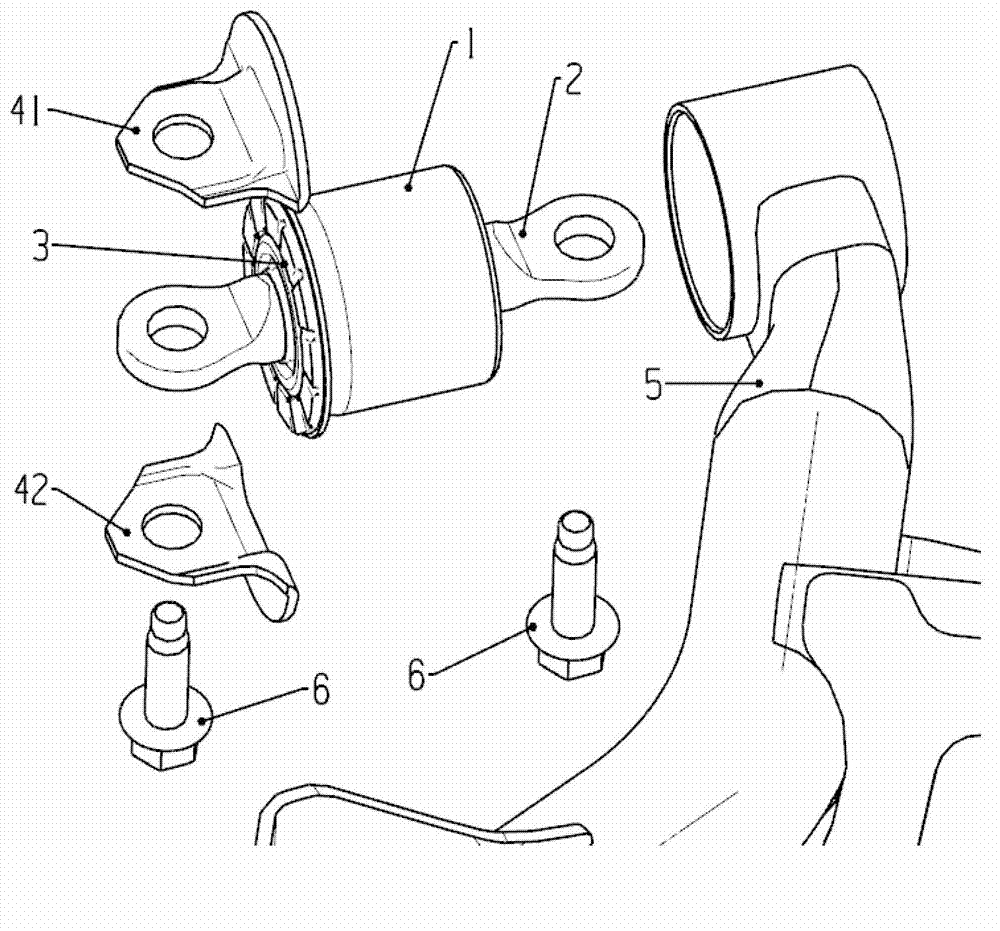

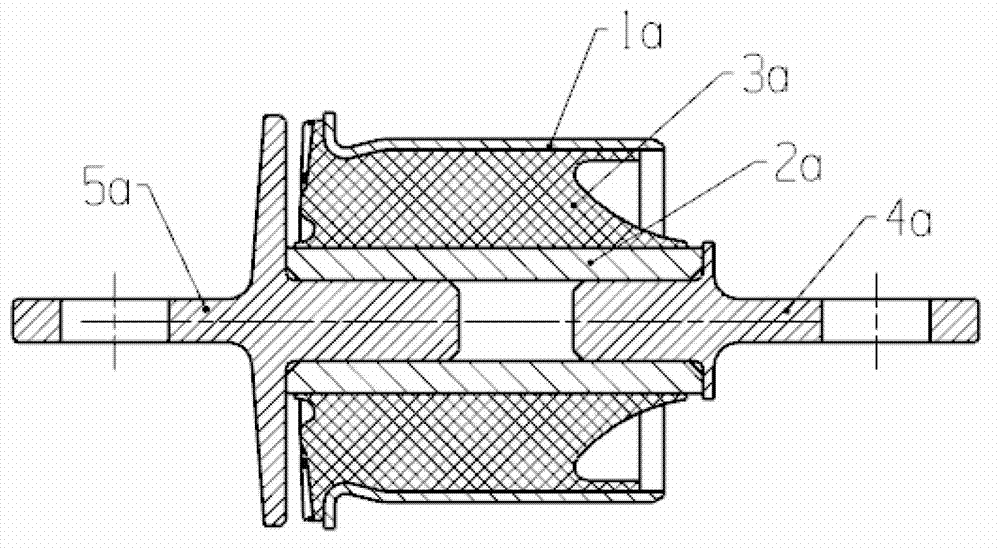

[0031] A torsion beam bushing assembly such as figure 1 As shown, the torsion beam bushing assembly includes a cylindrical body-shaped bushing assembly with mounting lugs and upper and lower limit brackets 41 and 42 located at one end of the cylindrical body-shaped bushing assembly. The cylindrical body-shaped bushing assembly is composed of a bushing outer sleeve 1, an integral shaft-shaped bushing inner sleeve 2, and an axial annular space filled between the bushing outer sleeve 1 and the integral shaft-shaped inner sleeve 2. The rubber material 3 is vulcanized into one piece. The one-piece shaft-shaped bushing inner sleeve 2 is an integral part including the bushing inner sleeve and the support ears at both ends. The upper and lower limit frames 41 and 42 are belts. Install the upper and lower half flanges of the same shape of the lug plate. In the use state, the cylindrical body-shaped bushing assembly is press-fitted to the torsion beam through interference fit, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com