Production process of movable arm of forklift loader/loading machine and fine processing fixing tooling of movable arm

A technology for fixing tooling and production processes, applied in metal processing equipment, metal processing mechanical parts, clamping and other directions, it can solve the problems that the boom cannot meet the requirements, the production efficiency of the boom is low, and the coaxiality is not ideal, so as to reduce the The effect of calibration workload and after-sales service workload, low tooling cost and excellent adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

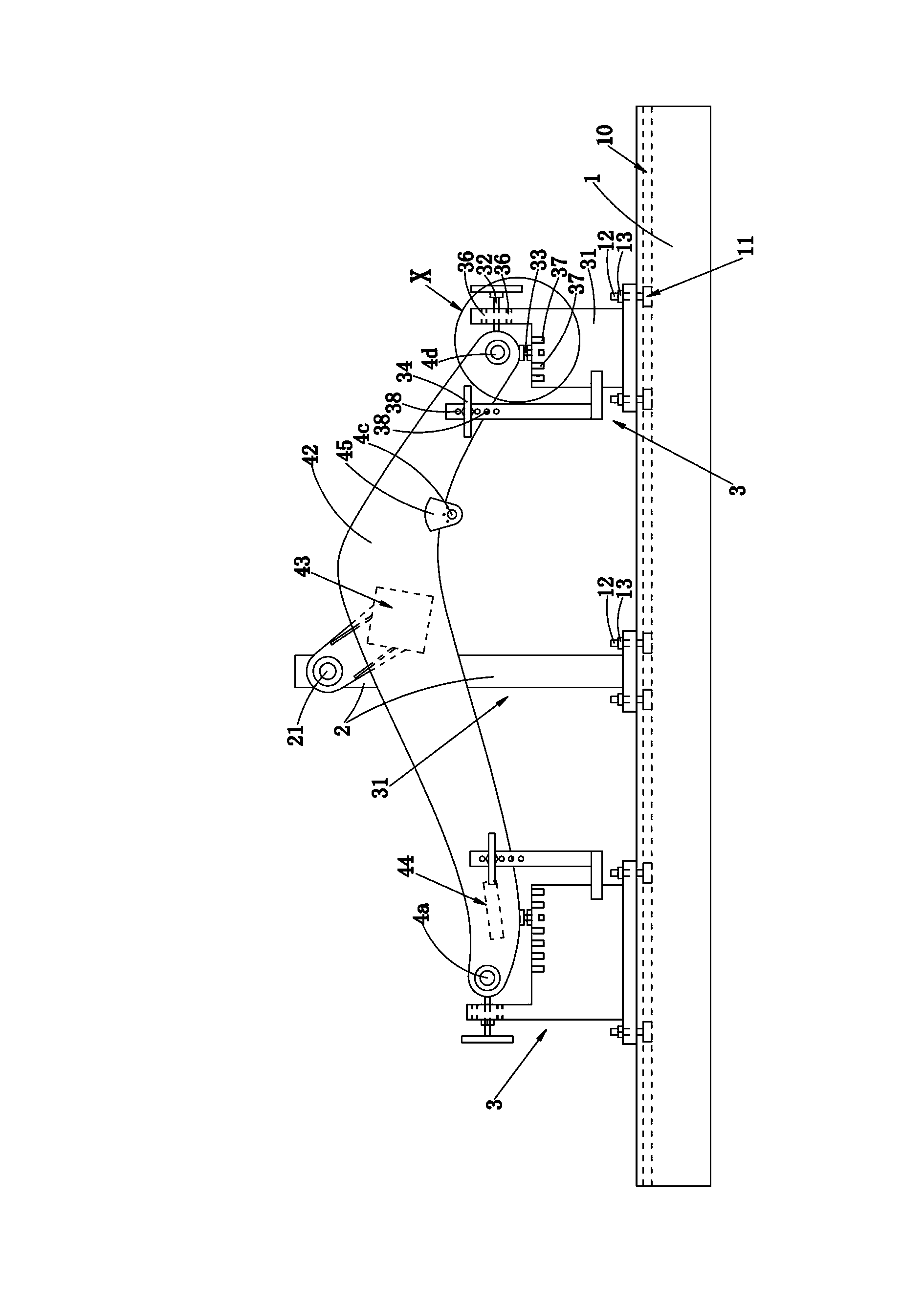

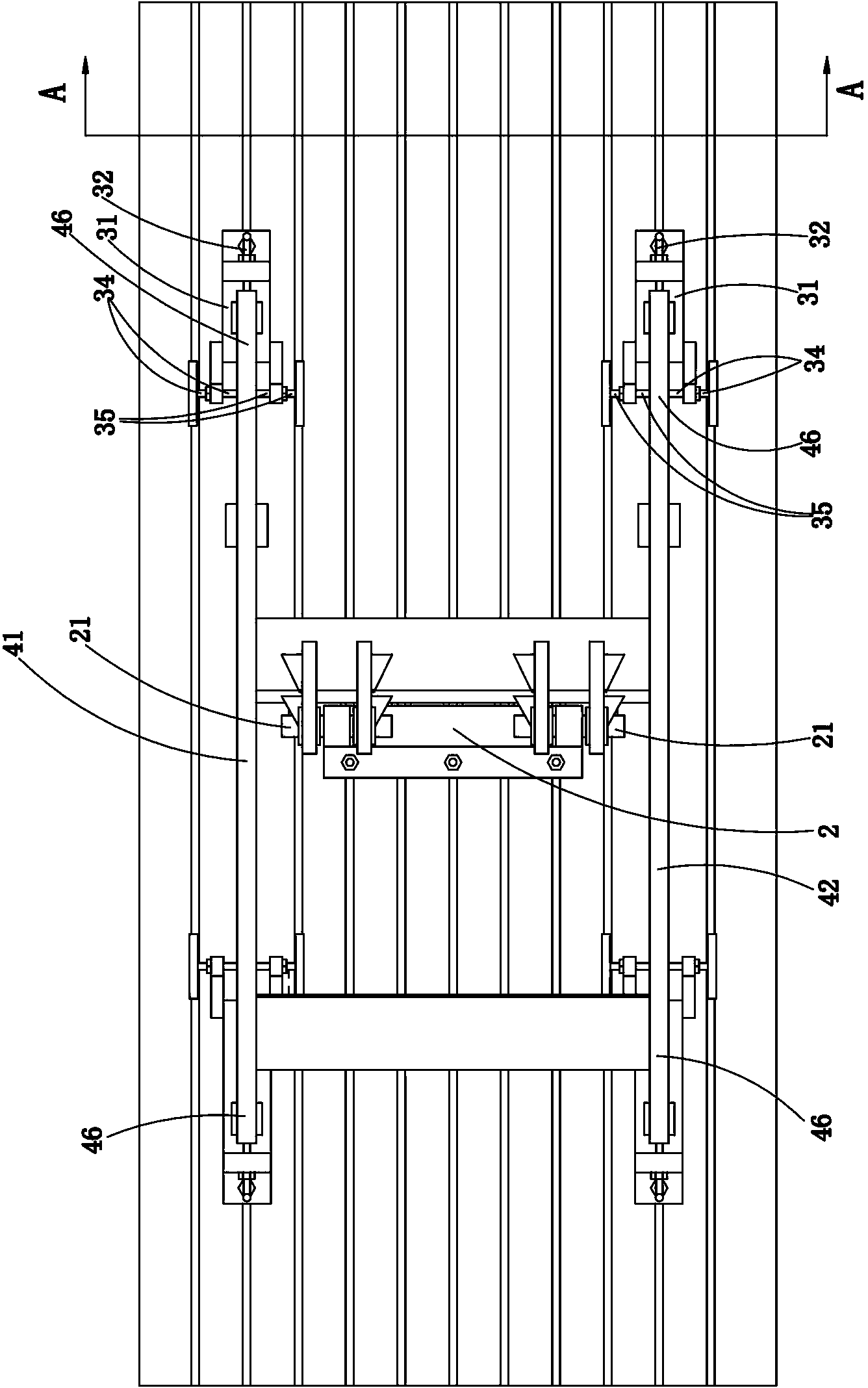

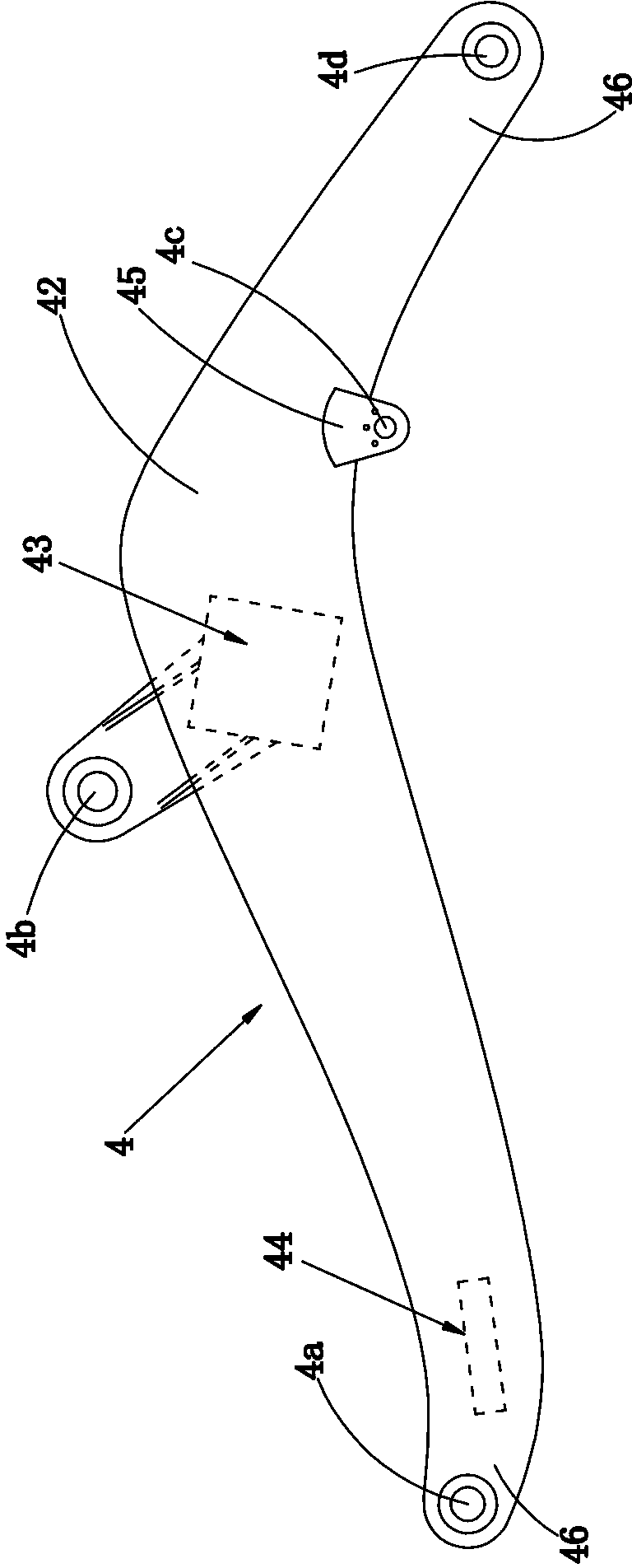

[0022] refer to figure 1 , figure 2 , Figure 5 , the finishing fixture of the boom of the forklift truck / loader, the fixture includes a base 1, a main support frame 2 and four fixing mechanisms 3 assembled on the base 1; the rocker arm of the boom 4 is connected The hole 4b is assembled on the top of the main support frame 2 through the pin shaft 21, and the diameter of the pin shaft 21 matches the diameter of the rocker arm connection hole 4b; the four fixing mechanisms 3 are respectively used to fix the four arms of the boom 4 End 46.

[0023] Continue to refer to figure 2 , Figure 4 , more specifically, the top surface of the above-mentioned base 1 is provided with eleven chutes 10 arranged in parallel at equal intervals (the number of chutes 10 can also be modified according to the production needs of the project, such as two, five, eight, etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com