The Method of Machining Roll Involute Splines Using CNC Double-sided Milling Machine

A technology of involute spline and milling machine processing, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of low production efficiency and difficulty in guaranteeing machining accuracy, so as to improve production efficiency and reduce the number of clamping , the effect of reducing the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

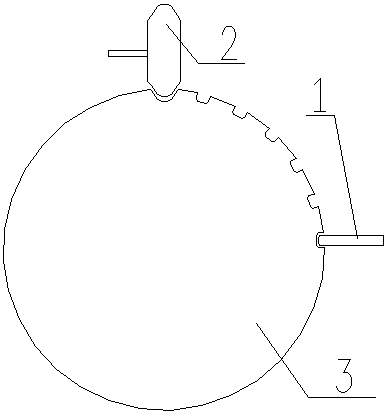

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment the present invention is described in further detail:

[0023] In this embodiment, the spline is processed on a CNC double-sided milling machine. The CNC double-sided milling machine has two main shafts distributed on both sides of the workbench, and can simultaneously complete the rough milling and semi-finishing processing procedures. Specifically The process steps are as follows:

[0024] a. Clamping and alignment, the roll 3 is clamped on the double-sided milling machine through the supporting device and the axis of the roll 3 is kept parallel to the worktable of the double-sided milling machine. The prime line is aligned so that the side prime line is parallel to the spindle of the double-sided milling machine and the upper prime line is kept perpendicular to the spindle of the double-sided milling machine; the support device is a numerically controlled dividing head that supports the fixed structure and controls the rotation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com