High precision hole system machining method

A processing method and high-precision technology, which can be used in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., and can solve problems such as easy deformation and excessive geometric tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

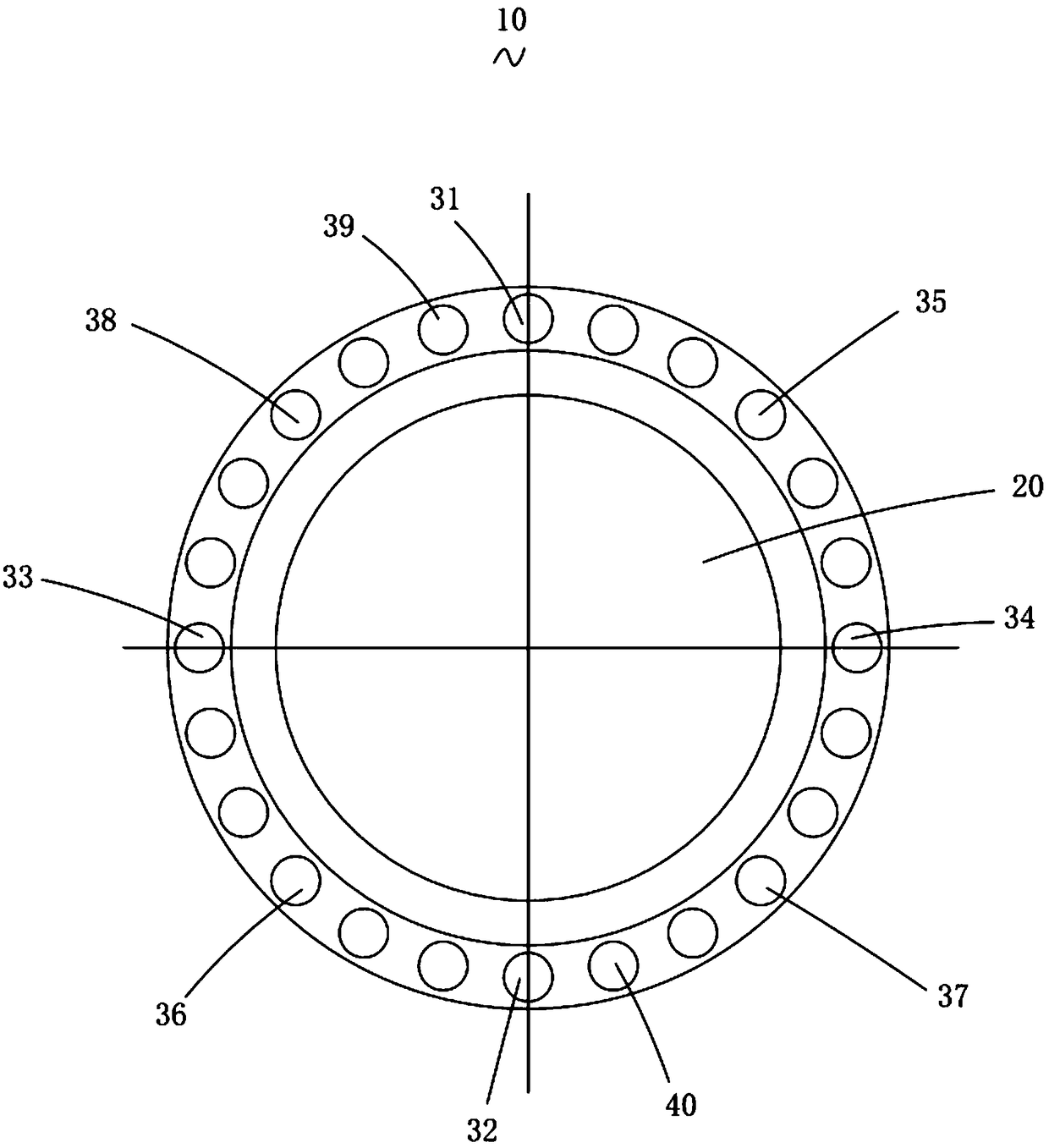

[0023] see figure 1 , take the center of the through hole 20 in the center of the reducer housing 10 as the positioning reference to locate the spindle of the machining center, and then determine the position of the first hole 31, the center of the first hole 31 is in the through hole in the center of the reducer housing 10 On a diameter of 20, use a drill bit for pre-drilling. The drilling diameter of the drill bit is 2 / 3 of the diameter of the first hole 31 to be processed. 0.10mm, feed rate ≤ 0.15mm to bore the first hole 31 according to the target diameter, after machining the first hole 31, move the spindle of the boring tool to the upper part away from the center of the reducer housing 10, and process The second hole 32, setting the coordinate axis of the second hole 32;

[0024] The center of circle of the second hole 32 is on the same diameter as the center of circle of the first hole 31, and the distance from the center of circle of the second hole 32 to the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com