A sensor structure

A technology for structural parts and sensors, applied in the field of structural parts, can solve the problems of limited height of rectangular holes, limited deformation of webs, limited sensor accuracy, etc., and achieves the effect of reducing assembly difficulty, solving assembly problems, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

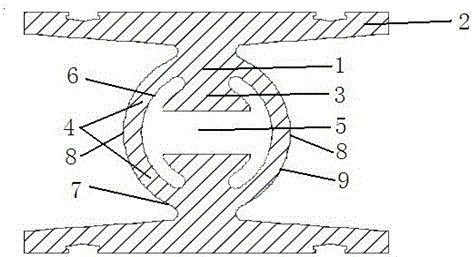

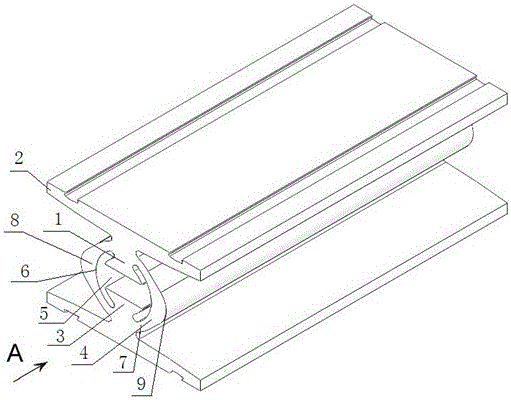

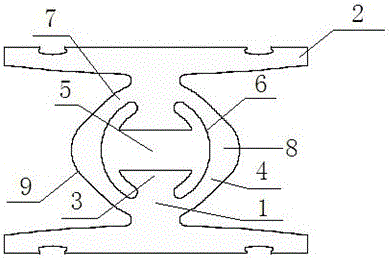

[0025] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0027] In practical applications, in addition to the strength requirements for some bending members, there are also restrictions on their deformation, that is, they are required to have a certain stiffness. In use, excessive bending deformation is harmful. Although some deformation is within the elastic range, it exceeds the allowable value, causing the component to fail to work normally. Therefore, the bending deformation should be controlled so as not to cause harm. Although it is often necess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com