Production process of FPC board

A production process and substrate technology, applied in the field of FPC board production process, can solve the problems of insufficient adhesion of film and copper layer, unclear exposure margin, incomplete line corners, etc., to achieve clear lines, good exposure accuracy, No corner missing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

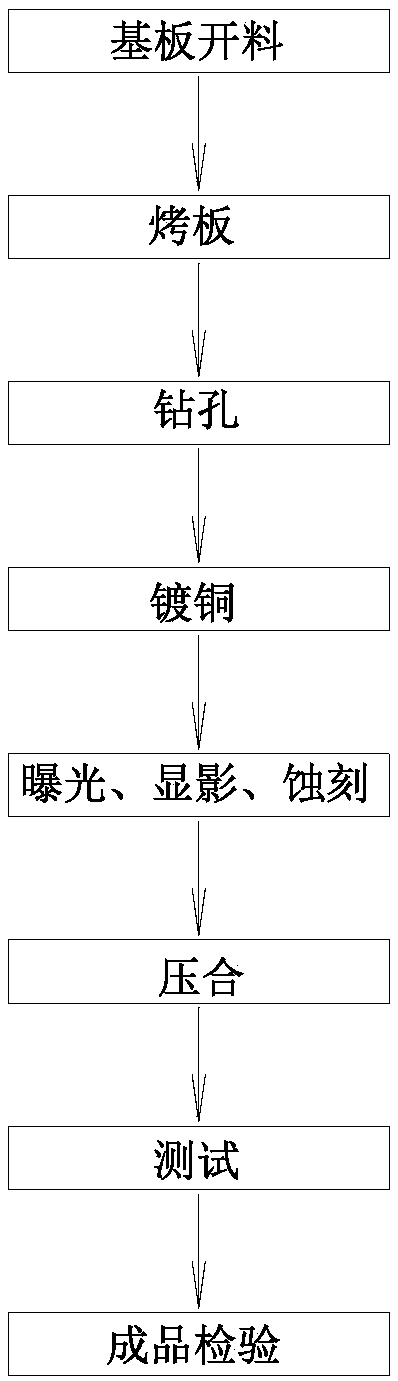

[0019] like figure 1 As shown, a FPC board manufacturing process includes the following steps a to e.

[0020] In step a, a substrate including a fiber layer and a copper foil layer is selected, and the copper foil layer is arranged on the upper end surface and / or the lower end surface of the fiber layer; the thickness of the copper layer is 9-12um, and the thickness of the base material is 46-55um.

[0021] In step b, 2 to 13 substrates are stacked and baked at a temperature of 100 to 140° C. for 45 to 75 minutes. Considering the stacking density and the temperature and time of the baking plate comprehensively, the quality of the baking plate and the efficiency of the baking plate are guaranteed, and manpower and material resources are saved; the internal stress of the substrate is eliminated through the baking plate, which facil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com