White car body top cover self-positioning tool

A body-in-white and self-positioning technology, applied to auxiliary devices, vehicle parts, manufacturing tools, etc., can solve the problems of large elastic deformation of parts, large area of single parts, cumbersome positioning operations, etc., and achieve accurate and reliable positioning, easy operation, and increased The effect of large assembly space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

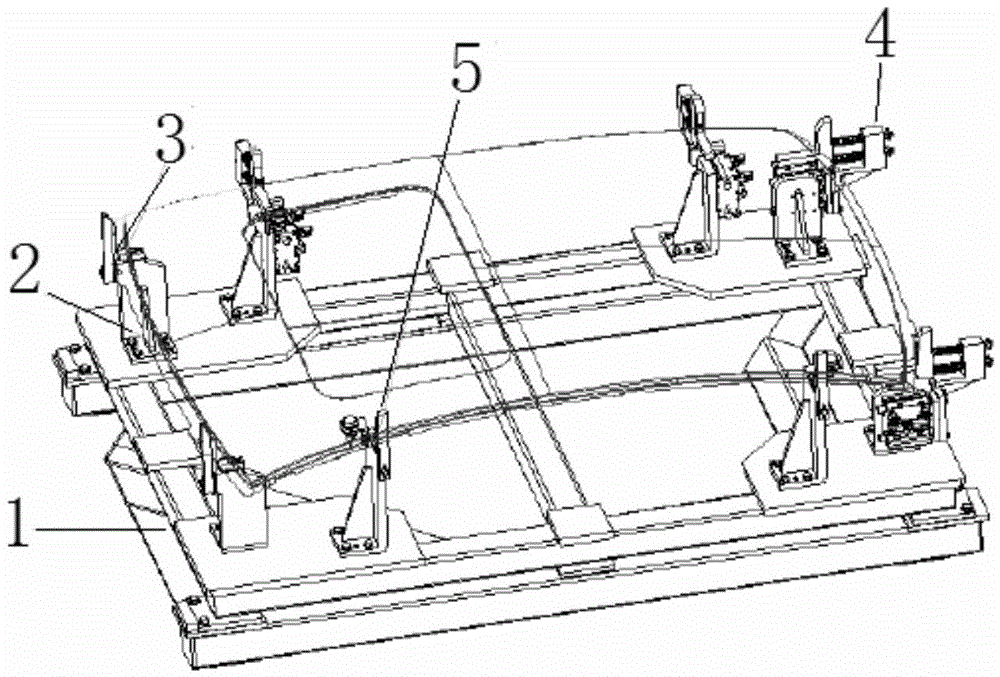

[0021] Such as figure 1 with figure 2 As shown, the self-positioning tool for the roof of the body-in-white includes a fixture base 1 and a support angle seat 2 under the roof; wherein, the fixture base 1 is a rectangular frame structure; there are six support angle seats under the roof, corresponding to the white One side of the roof of the vehicle body is provided with two, and the lower part of the support angle seat under the roof is fixed on the clamp base by bolts.

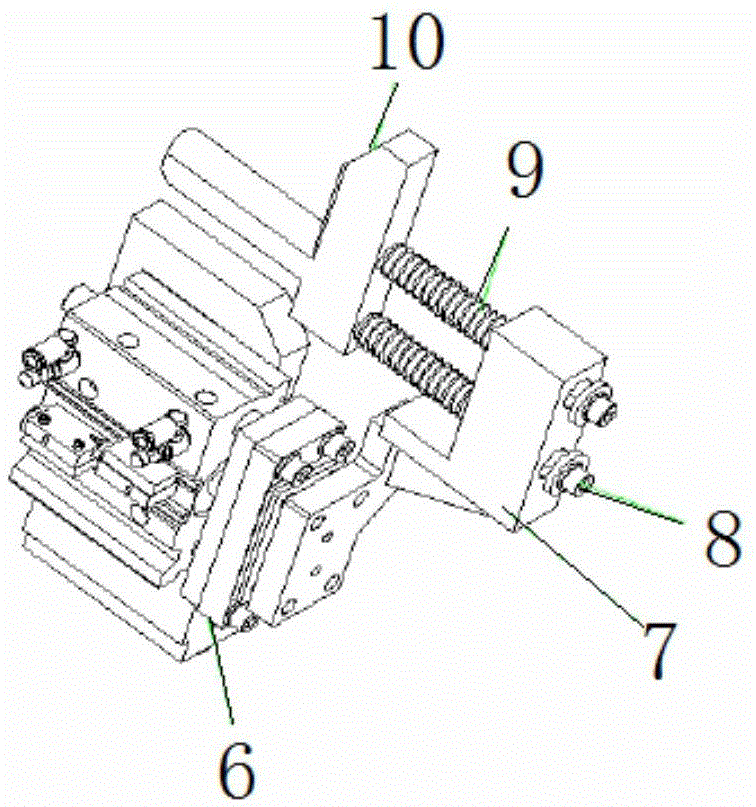

[0022] On the support angle seat 2 under the top cover, the adjacent two sides corresponding to the roof of the body-in-white are provided with side limit reference blocks 5, and the side limit reference blocks 5 are rubber blocks; The reference block is provided with a lower reference block 3 under the roof, and the top s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com