Inner bore measuring head inherent geometrical parameter calibration method based on laser triangulation

A technology of laser triangulation and calibration method, which is applied in the field of calibration of the inherent geometric parameters of the inner hole probe, can solve the problems of eccentricity and difficulty in ensuring coplanarity, and achieve the effects of easy processing, easy grasp, and flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

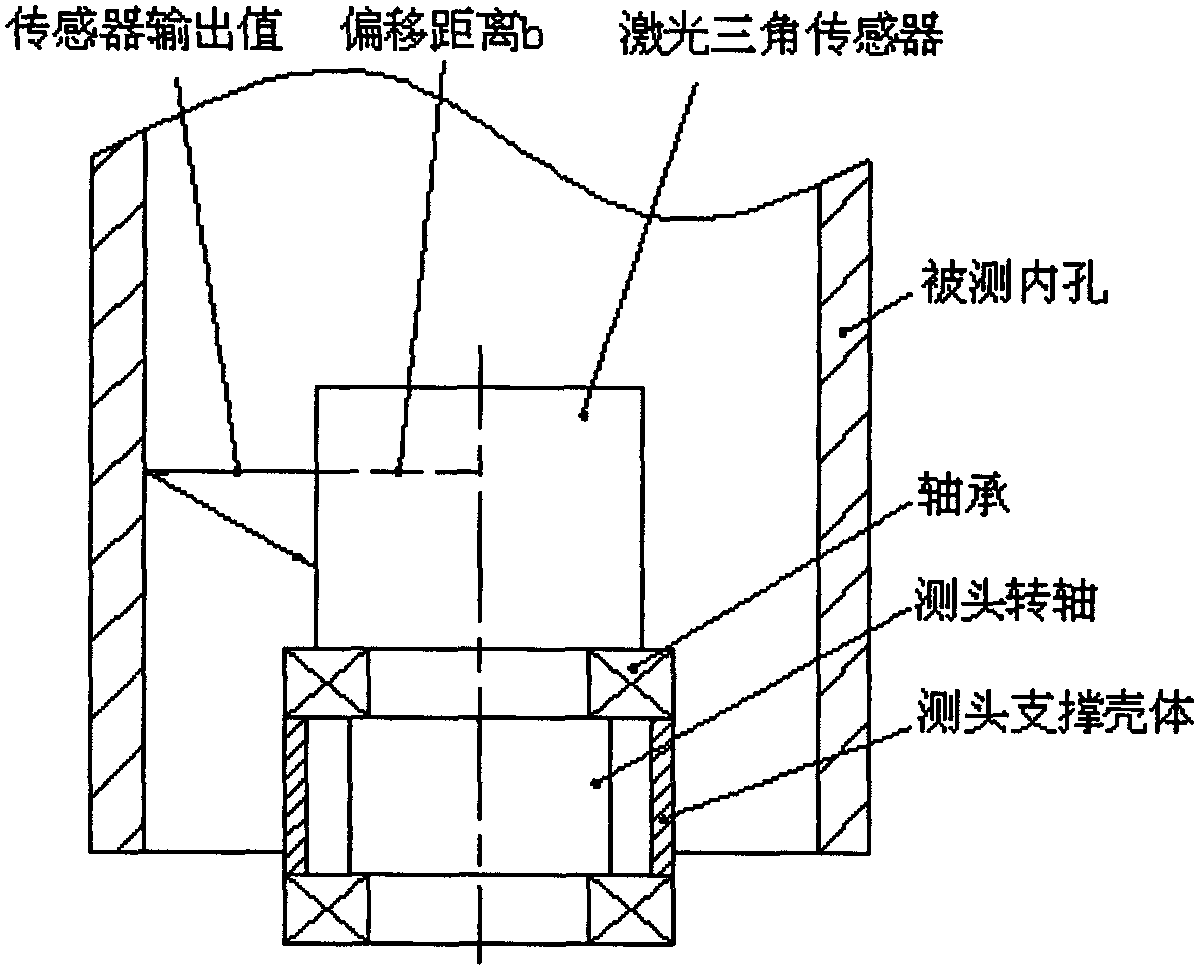

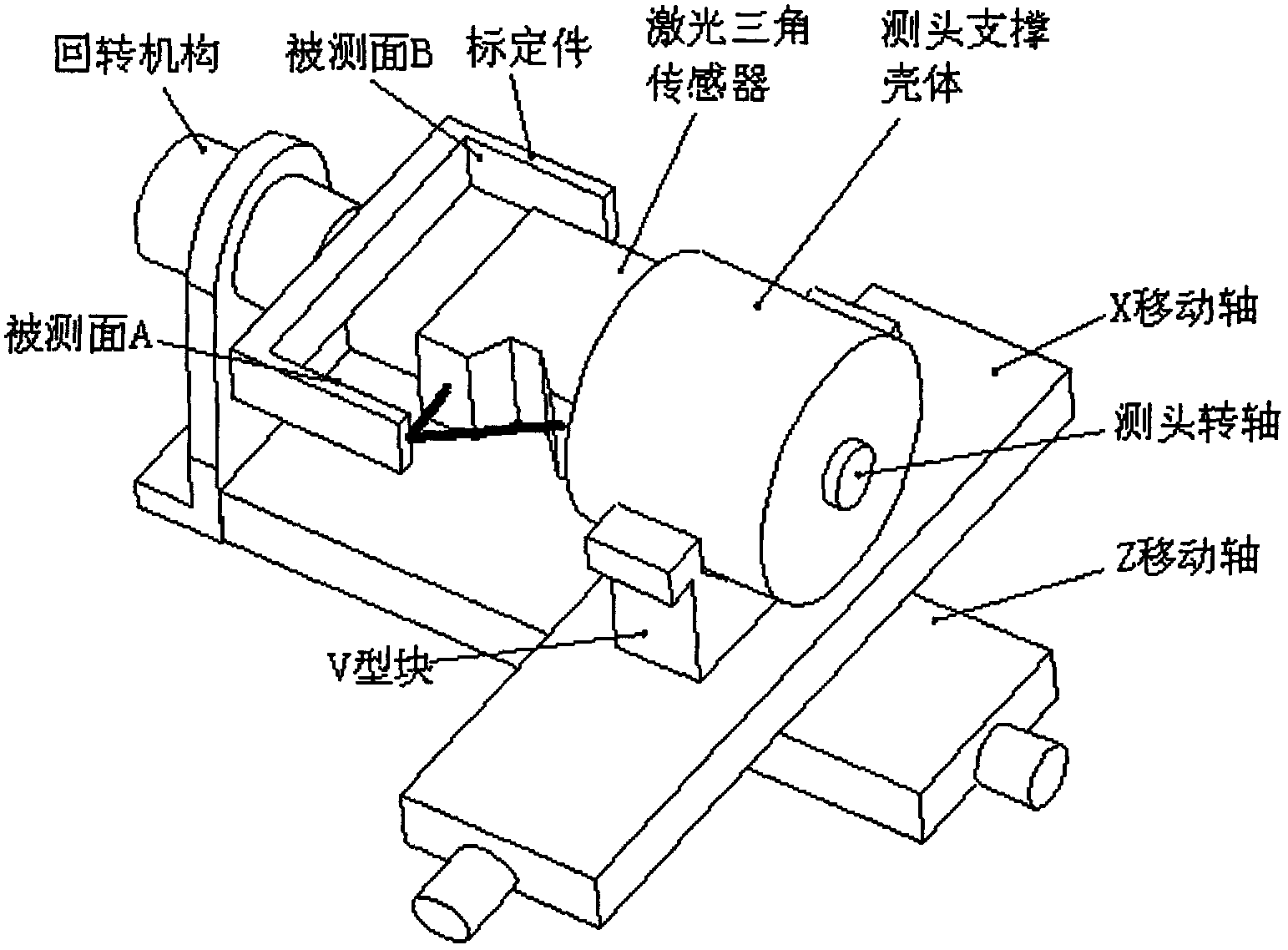

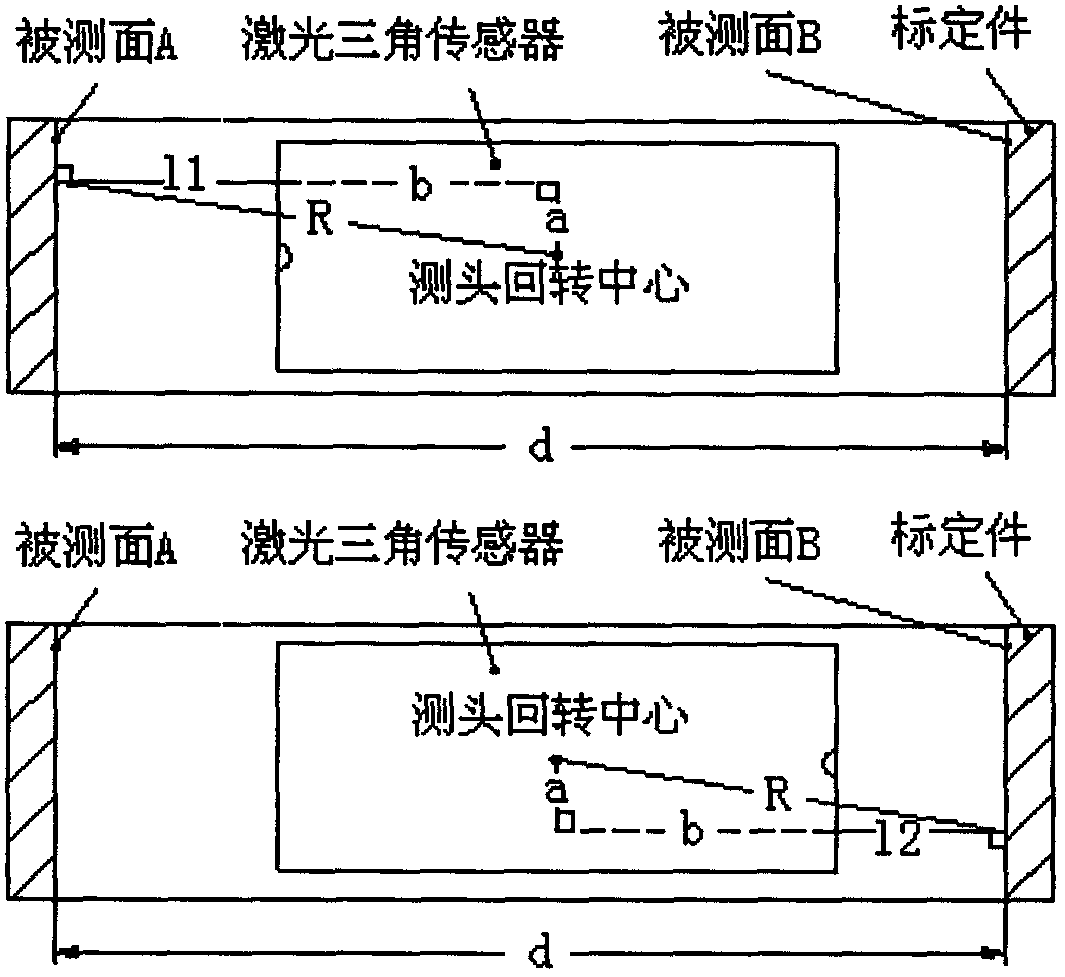

[0024] Attached below Figure 2-4 The specific embodiment of the present invention is described in detail:

[0025] (1) Install the calibration piece on the three-jaw chuck of the rotary mechanism, and the rotary mechanism drives the calibration piece to rotate, so that the two measured surfaces inside the calibration piece are perpendicular to the working table;

[0026] (2) Place the probe supporting shell above the plane of the workbench through the V-shaped block, the probe should be located in the two measured surfaces of the calibration part, and control the figure 2 When the probe moves along the Z direction, observe the readings of the laser triangular displacement sensor. If there is a large change, adjust the probe on the worktable until the laser triangular displacement sensor moves along the Z axis. If the reading changes very little (for example, within 5um), it means that the rotation axis of the probe is parallel to the rotation axis of the calibration part, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com