High-speed laser internal diameter detection system

A detection system and technology of inner diameter, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that do not conform to the actual production of the factory, cannot be fully automated, and have low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

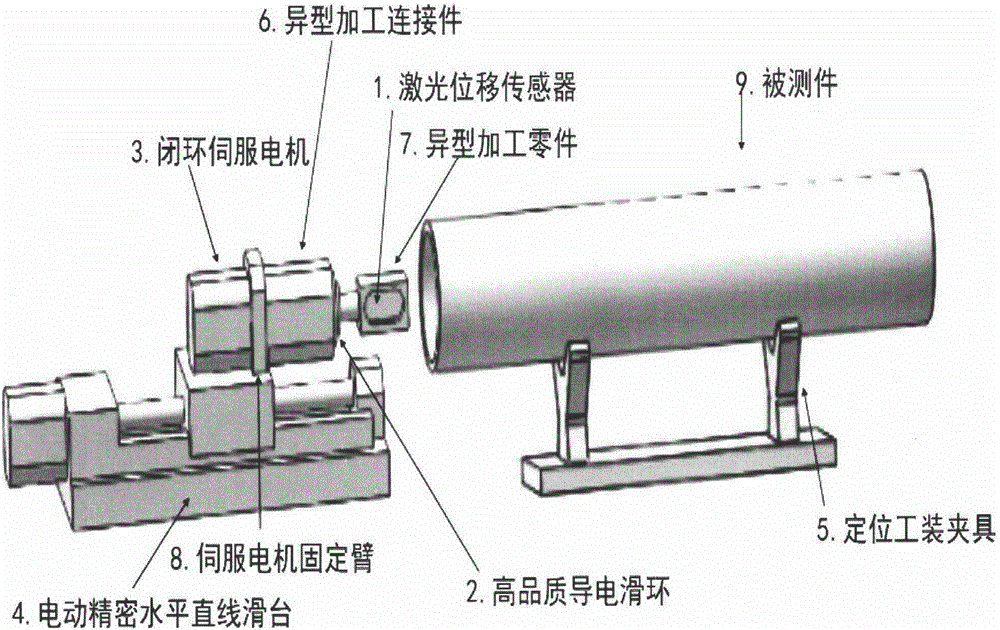

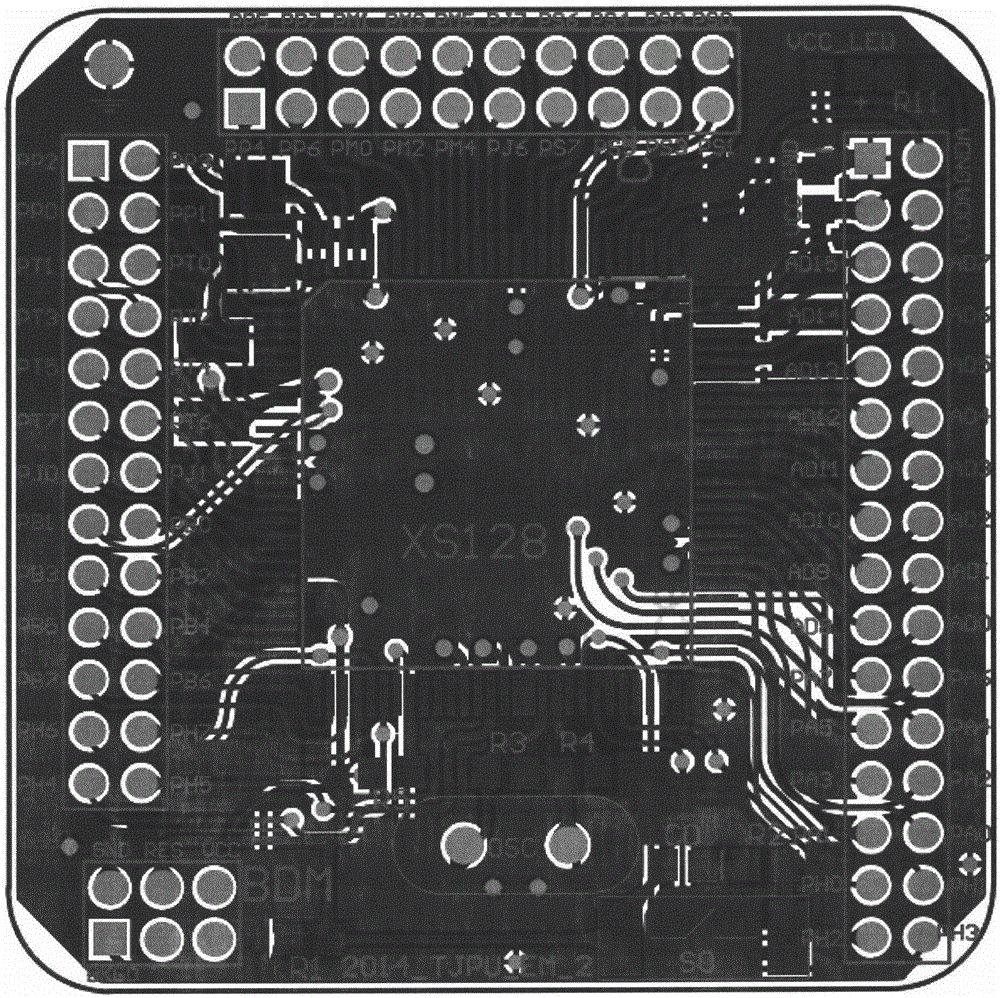

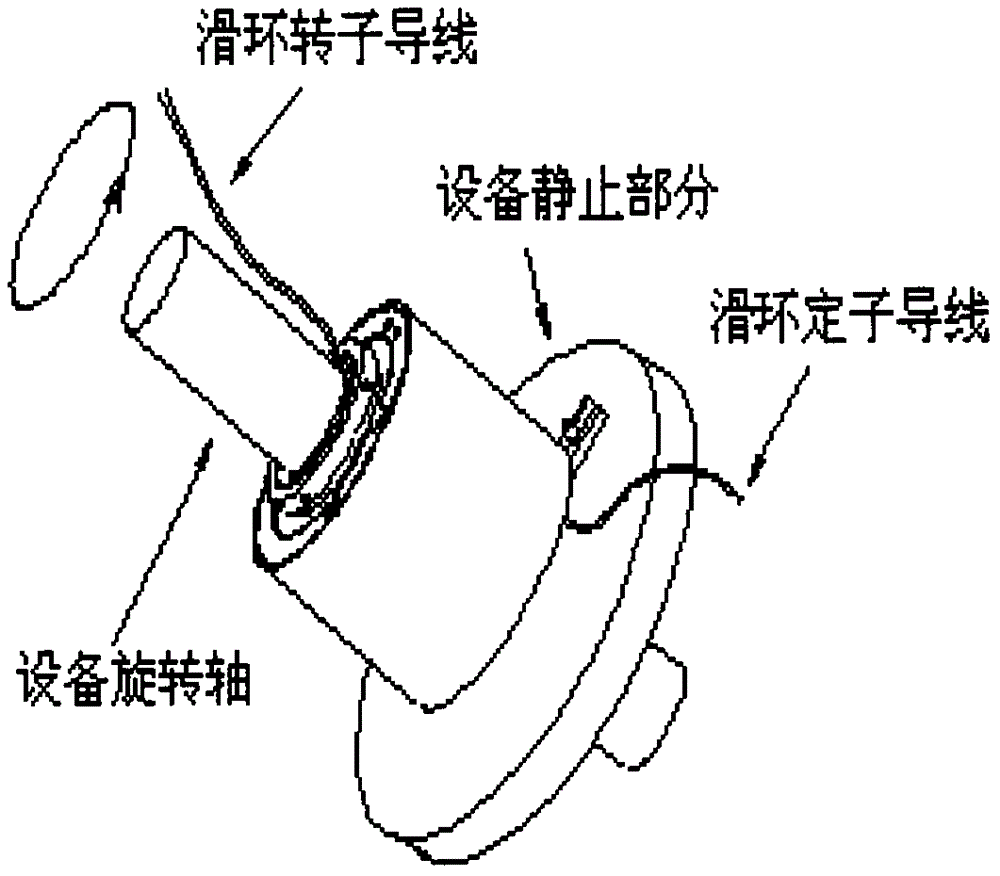

[0048] The invention includes mechanical design, hardware circuit design and software design. Mechanical design and development of a complete set of high-speed laser inner diameter detection system that can operate stably and efficiently, including: (1), high-quality conductive slip ring (2), closed-loop servo motor (3), electric precision horizontal linear slide table (4), positioning Fixtures (5), special-shaped processing connectors (connecting high-quality slip rings and servo motors) (6), special-shaped processing parts (7), and servo motor fixing arms (8). Hardware design and development of the minimum system and peripheral circuits of the robot control system, WiFi network, servo motor drive circuit. The mechanical design and development of a Windows-based upper computer operating platform is used to remot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com