High-precision real-time laser triangulation method and triangulation device for liquid level

A technology of laser triangulation and laser triangulation, which is used in measurement devices, liquid/fluid solid measurement, lubrication indicating devices, etc., can solve the problems of low measurement accuracy and inability to realize real-time measurement, and achieve a large measurement range, good linearity and precision. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

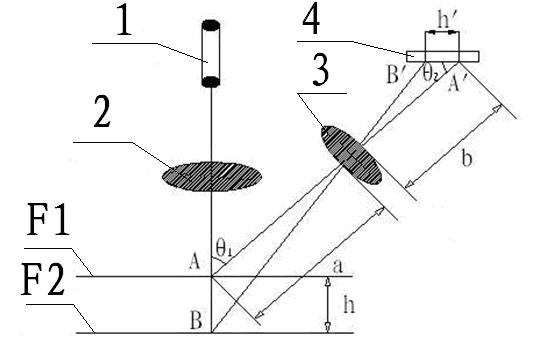

[0030] Such as figure 1 Shown: laser triangular displacement sensor 11 of the present invention comprises laser device 1, convergent lens 2, receiving objective lens 3, CCD 4; After 3, it is imaged on the CCD4; the liquid level changes from the first state liquid level F1 to the second state liquid level F2; using the proportional relationship of each side of the triangle, the displacement formula is calculated and derived as follows:

[0031]

[0032] In the above formula:

[0033] a is the distance from the intersection of the optical axis of the laser beam and the receiving optical axis to the front main surface of the receiving lens;

[0034] b is the distance from the main surface of the receiving lens to the center of the imaging surface;

[0035] is the angle between the optical axis of the laser beam and the optical axis of the receiving lens;

[0036] is the angle between the detector and the optical axis of the receiving lens.

[0037] The time domain sig...

Embodiment 2

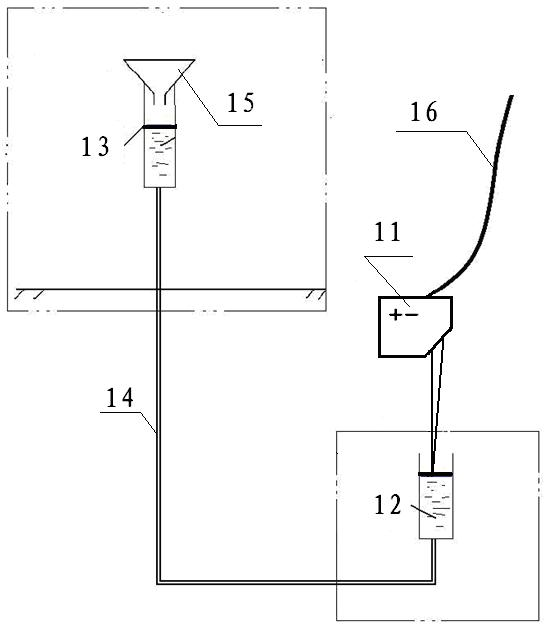

[0045] Such as figure 1 , figure 2 Shown: the present invention is made of laser triangular displacement sensor 11, outdoor liquid-taking test tube 12, indoor liquid-taking test tube 13, U-shaped tube 14, indoor liquid-taking funnel 15, signal line 16; indoor liquid-taking test tube 13 and outdoor liquid-taking test tube 12 is fixedly installed on the detection workbench; the indoor liquid-taking test tube 13 is connected with the outdoor liquid-taking test tube 12 with a U-shaped tube 14; the laser triangular displacement sensor 11 is installed above the outdoor liquid-taking test tube 12; the laser triangular displacement sensor 11 is connected by the signal line 16 is connected with the industrial control electromechanical; the light signal that the laser triangular displacement sensor 11 sends detects the liquid level of the outdoor liquid-taking test tube 12 fixed on the detection workbench.

[0046] The liquid level is imaged on the linear array CCD4 of the laser tria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com