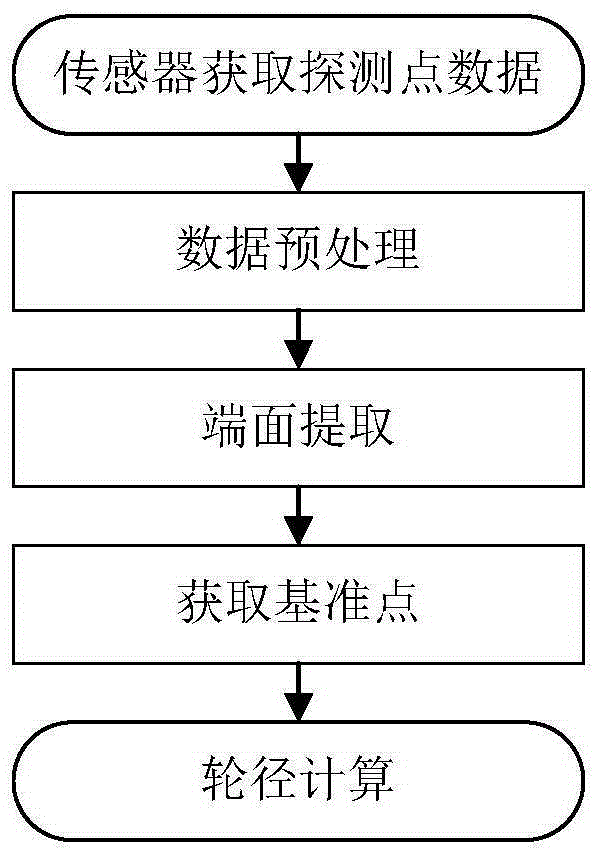

Online detection method for diameters of wheels of urban rail vehicle based on laser displacement sensors

A technology of laser displacement and detection method, which is applied in the direction of rim measurement/measurement, etc., can solve problems such as being susceptible to environmental interference, low repeat measurement accuracy, complex system structure, etc., and achieve the effect of simple measurement principle, stable system, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

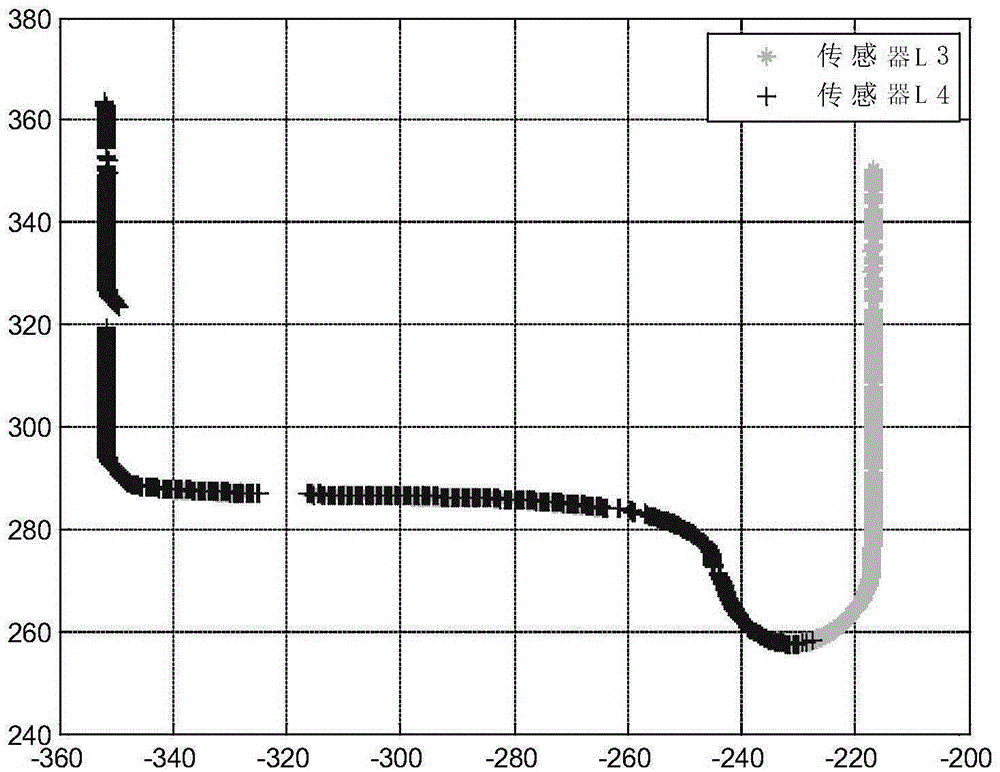

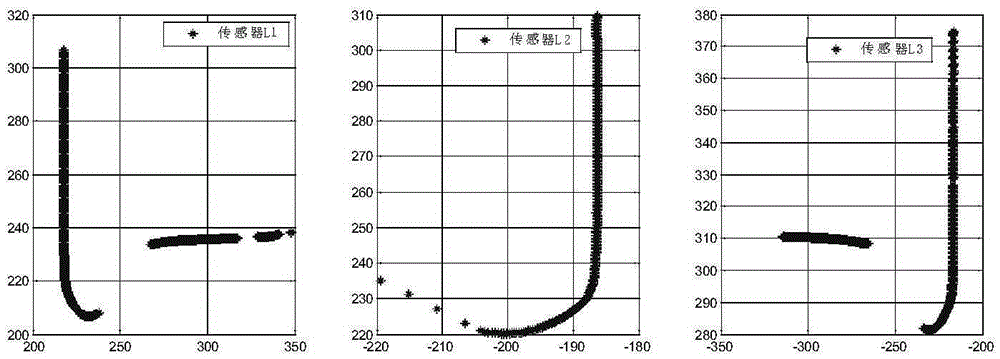

[0057] combine Figure 2~3 , two laser displacement sensors are installed on both sides of the track at an angle of 45° to the track, then β 3 , β 4 is 45°, the sampling frequency of the laser displacement sensor is 200Hz, and the vertical distance between the four laser displacement sensors and the rail is 300mm.

[0058] First, when the wheel passes through the effective measurement range of the four laser displacement sensors, the wheel is detected, and the coordinates of the detected data points are changed according to the following formula,

[0059]

[0060] The data of the fourth laser displacement sensor L4 is translated according to the following formula to fuse with the data points of the third laser displacement sensor L3 to obtain the wheel tread profile. Depend on Figure 4 The obtained wheel height is 28.63mm.

[0061] u n = u n ( 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com