Position detection equipment and method for detecting jet hole of coater and light spot of laser displacement sensor

A technology of laser displacement and detection equipment, which is applied in the direction of surface coating liquid devices, measuring devices, spraying devices, etc., can solve the problems of long time consumption and low detection accuracy, and achieve improved accuracy and detection time, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

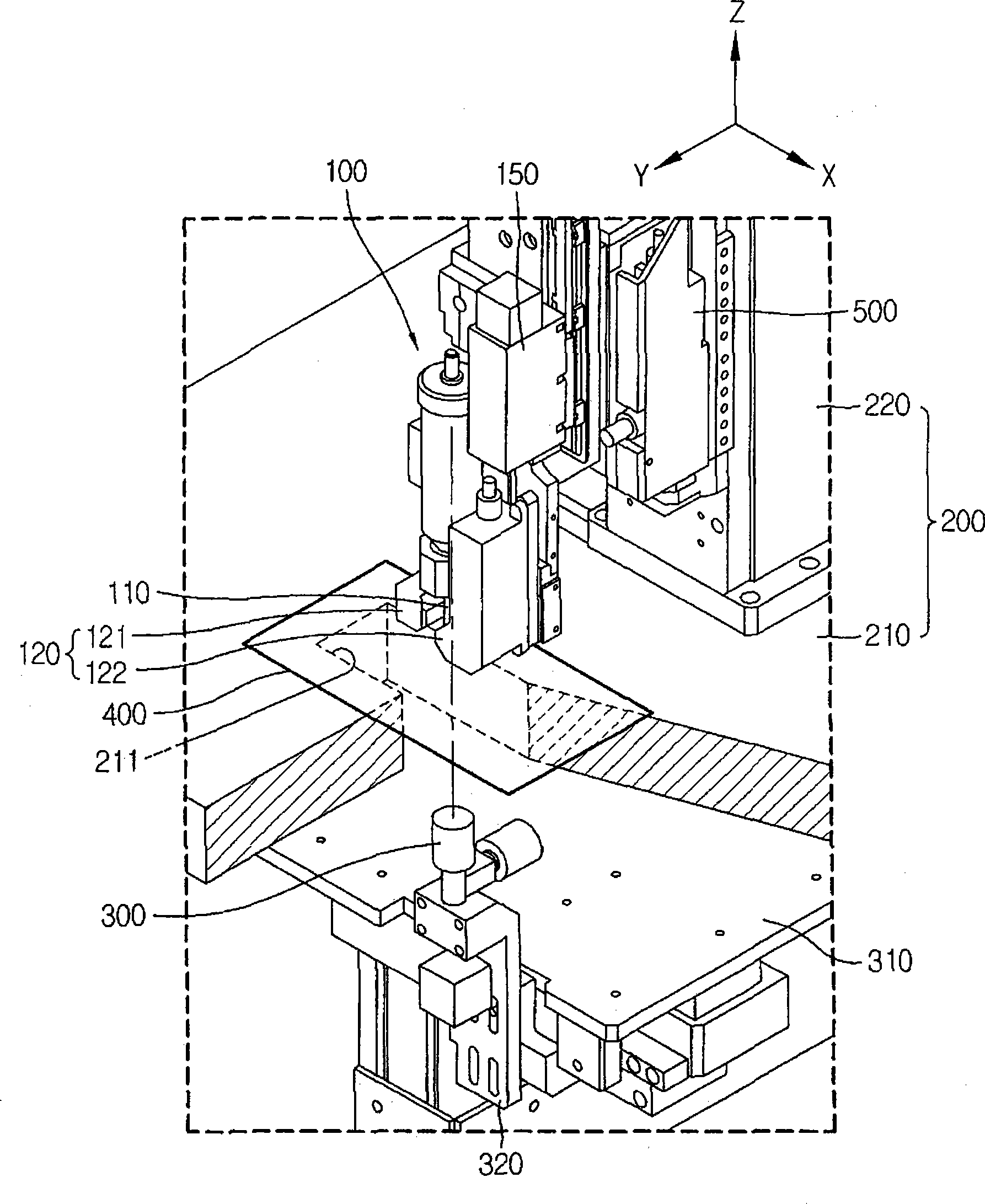

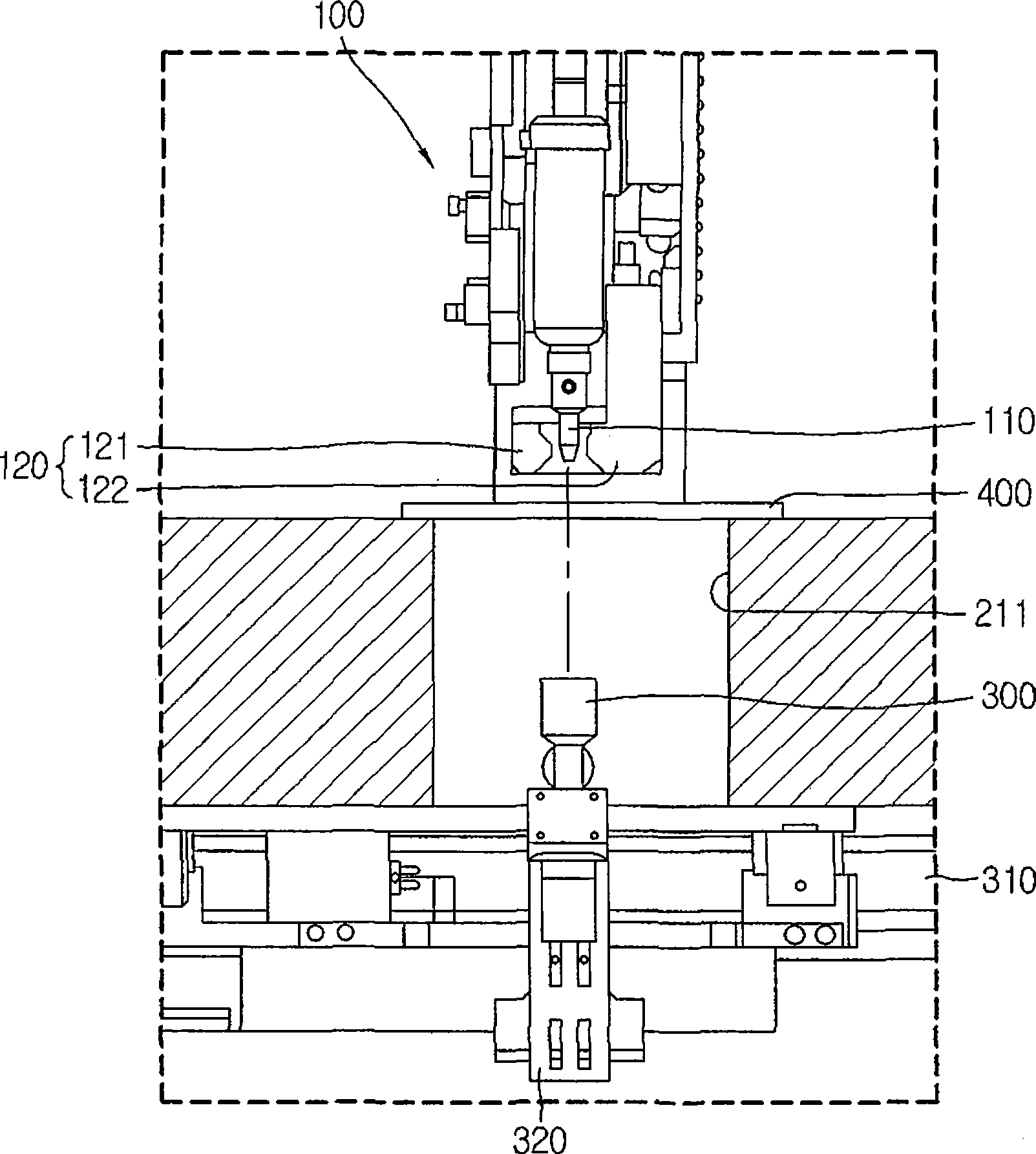

[0036] refer to Figures 1 to 6 , the position detecting device and the position detecting method which detect the positions of the discharge hole of the nozzle of the glue applicator and the light spot of the laser displacement sensor according to the first embodiment will be described.

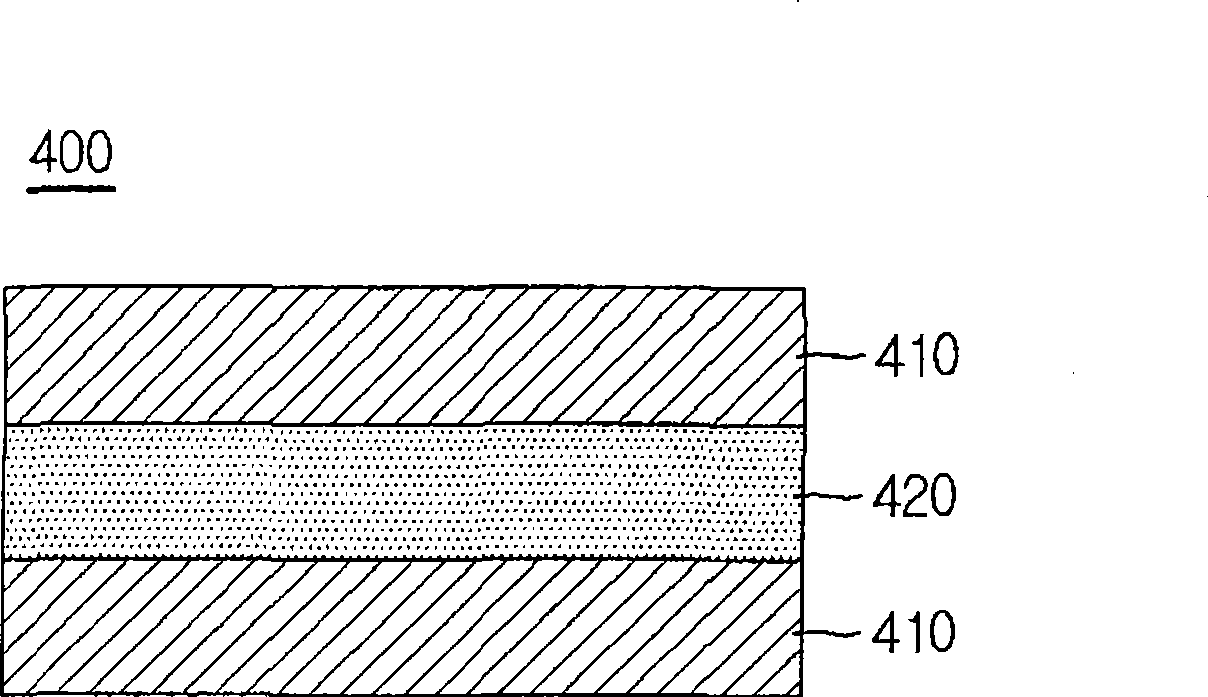

[0037] figure 1 is a perspective view showing a position detection device for detecting the positions of a discharge hole of a nozzle of a glue applicator and a laser displacement sensor according to a first embodiment of the present invention, figure 2 is shown figure 1 Front view of the position detection device shown, image 3 is shown figure 1 A cross-sectional view of the variable transmittance member of the position detection device shown, Figure 4 is shown figure 1 Block diagram of the position detection device shown, Figure 5 is a flowchart showing a position detection method using figure 1 The position detection device is shown to detect the position of the discharge hole ...

no. 2 example

[0059] In the following, reference will be made to Figure 7 A position detection device and a position detection method for detecting the positions of a discharge hole of a nozzle of a glue applicator and a light spot of a laser displacement sensor according to a second embodiment of the present invention are described. In the first embodiment and the second embodiment, the same elements and process steps are denoted by the same reference numerals, and descriptions thereof may be omitted.

[0060] According to the second embodiment, the position detection method detects the positions of the discharge hole 115 of the nozzle 110 and the light spot 125 of the laser displacement sensor 120 using the characteristics of the PDLC element 420 changed from the first state to the second state. In the first state, even without supplying power to the PDLC element 420, if a predetermined pressure is applied to the PDLC element 420, the orientation of the liquid crystal in the PDLC element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com