A gear measuring apparatus and measuring method based on active vision

A technology of gear measurement and active vision, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of large amount of calculation, large amount of global image data, and low efficiency, and achieve the effect of improving resolution and reducing calculation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

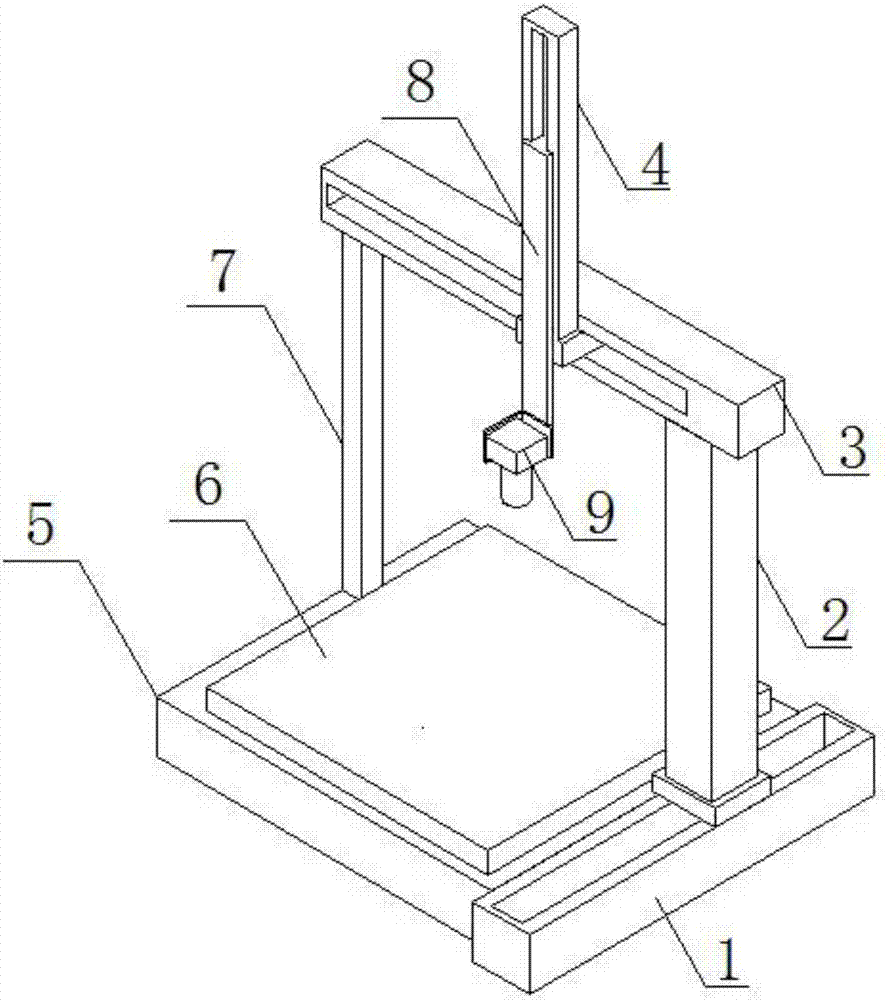

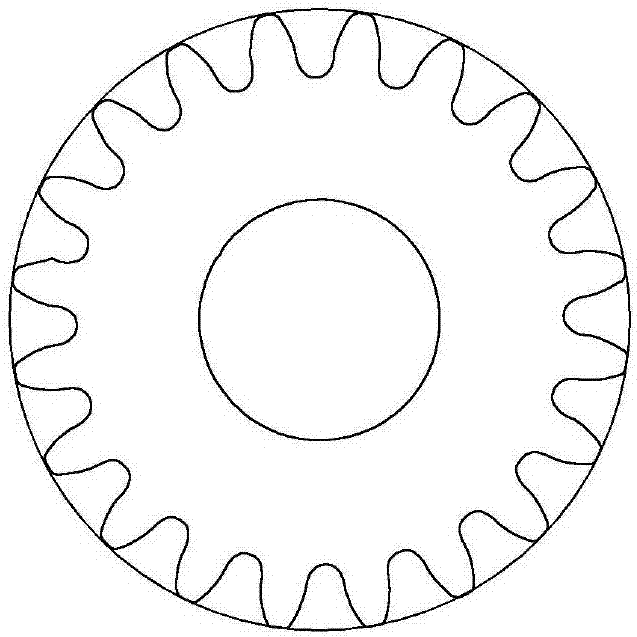

[0086]A gear measurement method based on active vision. The measurement method is based on the gear measurement device of the specific embodiment of the present invention. The industrial camera is fixed on the three-dimensional mobile platform to realize the collection of different partial images of the gear, and the host computer processes the collected images. And adjust the focal length of the camera lens to zoom in and image the gear in real time. The gear measurement method includes global rough measurement and local accurate measurement, and specifically includes the following steps:

[0087] (1) Calibrate and store the lens distortion parameters corresponding to each focal length of the industrial camera; and systemically calibrate each focal length to obtain a pixel equivalent table;

[0088] Select the appropriate focal length according to the size of the gear to be tested so that the camera can capture the global image of the gear, and adjust the distance between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com