Gear measurement device based on laser displacement sensor and gear measurement method

A laser displacement and gear measurement technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low measurement accuracy and inconvenient measurement, achieve high measurement accuracy, improve measurement accuracy, and simplify the measurement process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

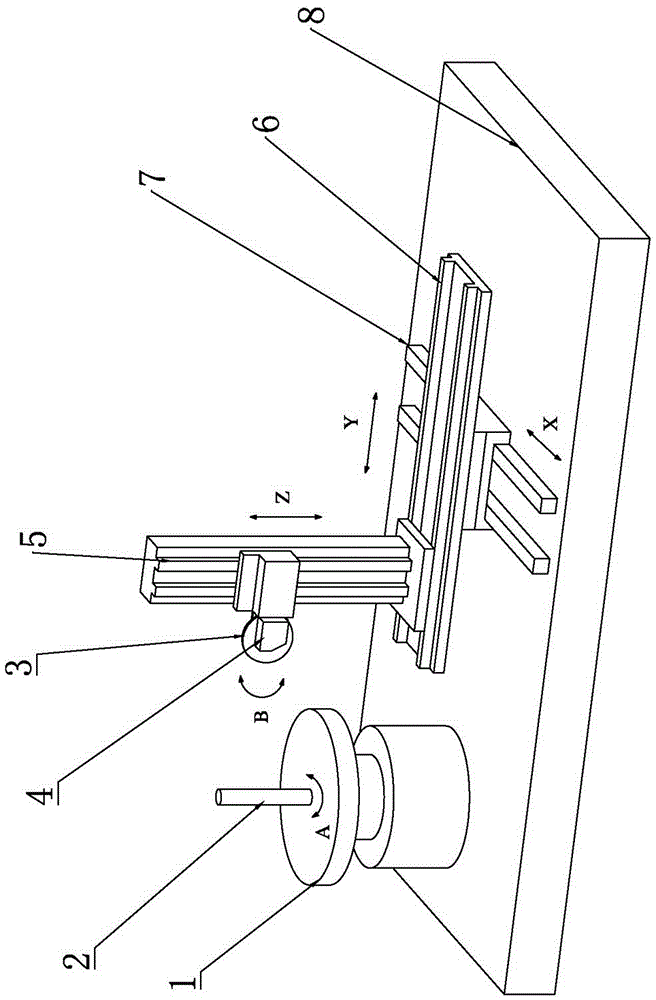

[0024] Such as figure 1 The gear measuring device based on the laser displacement sensor of the present invention includes a worktable 8 on which a workpiece turntable 1 and a three-coordinate translation device with a rotatable measuring head are provided. The workpiece turntable 1 is vertically provided with a mark Zero rotation axis 2, the three-coordinate translation device includes an X-axis guide rail 7 fixed on the worktable 8, a Y-axis guide rail 6 is slid on the X-axis guide rail 7, and a Z-axis guide rail 5 and Z-axis guide are slid on the Y-axis guide rail 6. 5 There is a sliding frame on the sliding frame, and a rotatable laser displacement sensor 4 is arranged on the sliding frame; in order to adjust the angle of laser projection, the sliding frame is equipped with an indexing plate 3, and the laser displacement sensor 3 is set on the indexing plate to follow the points. The dial rotates synchronously; in order to adjust the position of the laser displacement sensor...

Embodiment 2

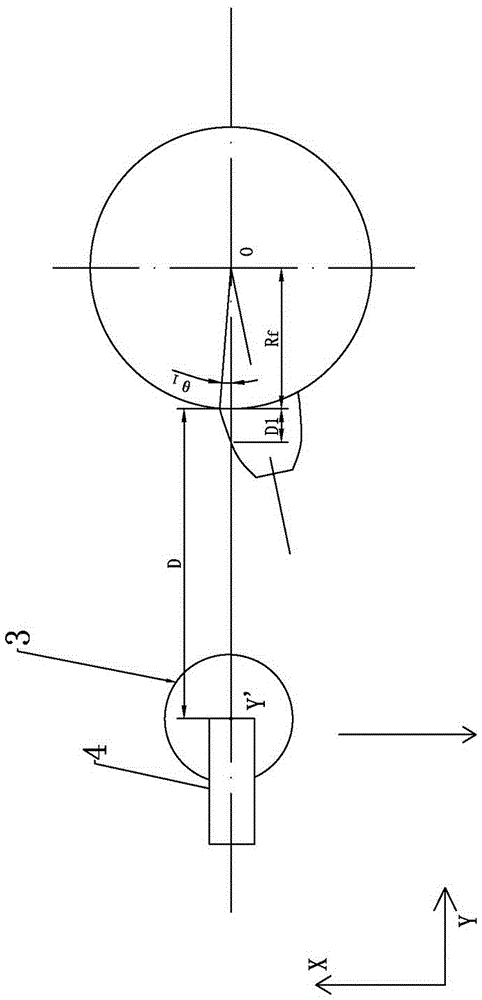

[0027] Such as figure 2 As shown, the method for measuring spur gears or arc gears using the gear measuring device of the present invention is realized by the following steps.

[0028] In the first step, the laser displacement sensor is driven by the servo motor to move along the X-axis and Y-axis rails, and data points on the outer circumference of the zeroing shaft are collected to calibrate the position of the measured gear center axis coordinate system. Specifically, move the laser displacement sensor 4 to the outer circumference of the workpiece turntable 1, rotate the index plate 3 so that the laser beam emitted by the laser displacement sensor 4 is directed horizontally and directly on the circumference of the zeroing axis 2, and then keep the Y and Z guide rails stationary , Move the laser displacement sensor 4 along the X-direction guide 7 to the other side of the circumferential surface at intervals, and collect the interval data points P1, P2, P3...Pn, Pn+1..., when th...

Embodiment 3

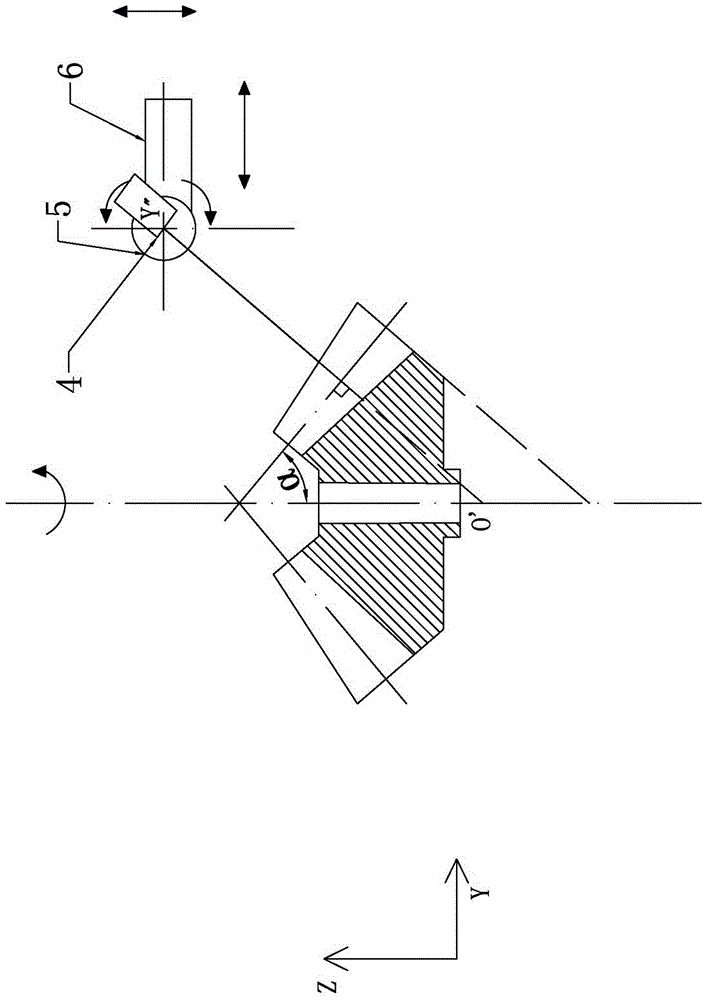

[0033] Such as image 3 As shown, the method for measuring bevel gears by using the gear measuring device of the present invention is realized through the following steps. The difference in Embodiment 2 is embodied in the following steps.

[0034] The second step is to place the measured bevel gear face down on the workpiece turret and adjust it to be coaxial with the zero axis, and move the laser displacement sensor along the Z axis. 0 To be obliquely above the measured gear, the index plate rotates by an angle α, α is the pitch cone angle of the measured bevel gear, adjust along the Y-direction guide so that the laser beam is directly directed on the equivalent tooth profile of the measured gear, and the laser displacement sensor The displacement indication value is zero, then the coordinate of the center point O'of the measured equivalent tooth profile is (X 0 , Y 0 ), the Y of the center point of the laser displacement sensor is marked as Y”. In the third step, the workpiece t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com