Multi-freedom degree capatitance displacement sensor

A technology of displacement sensor and degree of freedom, which is applied in the direction of using electric/magnetic devices to transmit sensing components, instruments, and electric devices. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

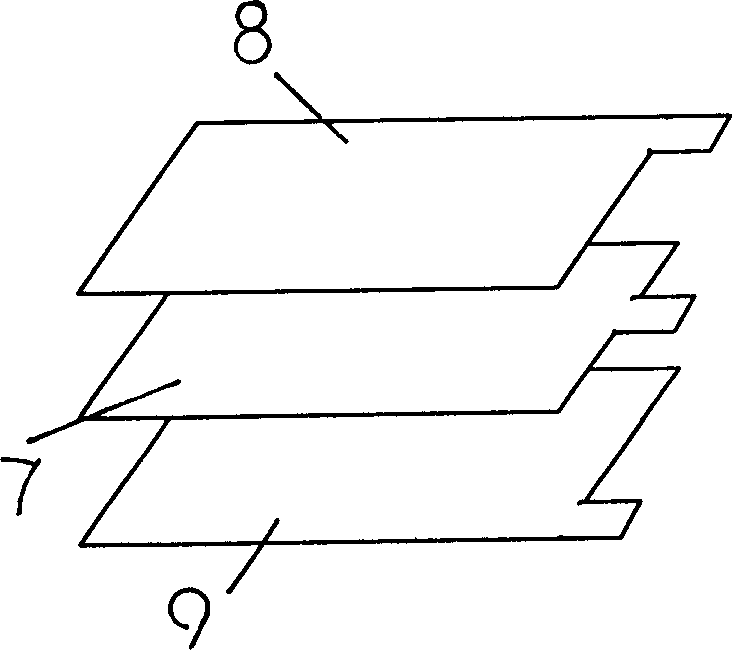

[0027] see image 3 , the present embodiment is made up of moving pole plate 7, A fixed pole plate 8 and B fixed pole plate 9, and the moving pole plate 7 is located in the center, which is a double-sided pole plate; A fixed pole plate 8 and B fixed pole plate 9 are respectively located Both sides of the pole plate 7, and on the side relative to the moving pole plate 7, are single-sided pole plates; surface constitutes a capacitor.

[0028] Referring to Fig. 4, in the present embodiment, each electrode surface of the moving plate 7, the fixed plate A, and the fixed plate B 9 are four plate electrodes independently arranged, wherein,

[0029] As shown in Figure 4 (a), the four plate electrodes in the A fixed plate 8 are marked as 8a, 8b, 8c and 8d respectively;

[0030] As shown in Figure 4(b), the four plate electrodes in the moving plate 7 are marked as 7a, 7b, 7c and 7d respectively;

[0031] As shown in FIG. 4( c ), the four plate electrodes in the B fixed plate 9 are ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com