Pressure-maintained transferring system for deep sea microbes

A transfer system and microbial technology, applied in the field of deep-sea microbial pressure-holding transfer system, can solve the problem of low sample utilization rate, achieve high sample utilization rate, reduce manufacturing cost, and high sub-sampling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

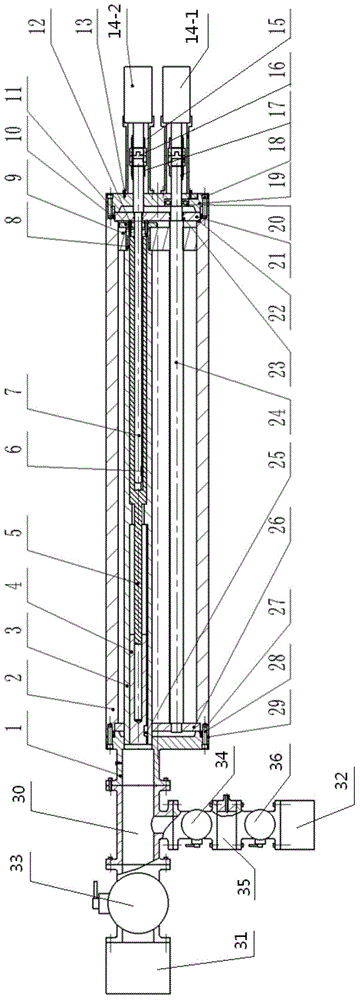

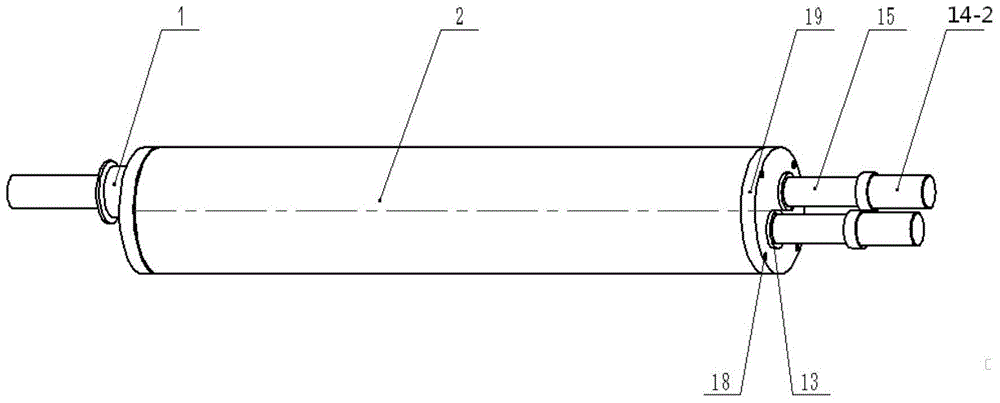

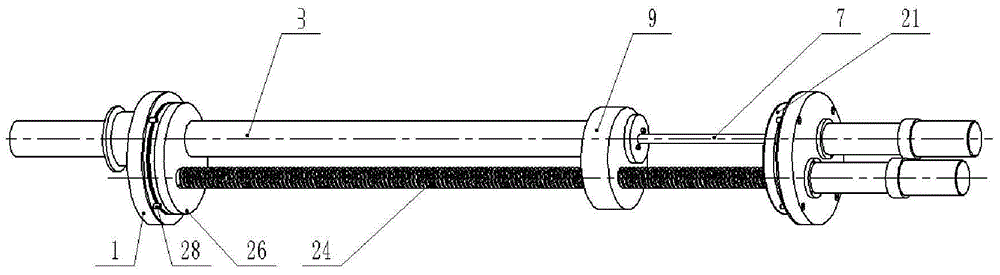

[0045] Such as Figure 1-7As shown, the deep-sea microorganism pressure holding transfer system of this embodiment includes: front end cover 1, pressure holding cylinder 2, sampling cylinder 3, piston 4, sampling transmission rod 5, sampling driving shaft key 6, sampling driving rod 7, screw cap 8 , Slider 9, rear support cover O-ring 10, small baffle 11, small baffle bolt 12, motor fixing frame screw 13, motor 14-1, motor 14-2, motor fixing frame 15, coupling 16. Coupling end key 17, rear end cover screw 18, rear end cover 19, thrust bearing 20, rear end support cover 21, rear end support cover gasket 22, main screw rod O-ring seal 23, screw rod 24 , Piston key 25, front-end support cover 26, front-end cover O-ring 27, front-end cover screw 28, front-end cover sealing ring 29.

[0046] The piston 4 slides in the guide groove in the sampling cylinder 3 through the piston key 25, and the piston 4 and the sampling cylinder 3 have a degree of freedom of movement along the axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com