Pipe-type PECVD graphite boat assembling and disassembling piece system and process

A technology of graphite boat and tube type, which is applied in the graphite boat loading and unloading system and its technology field, which can solve the problems of high labor intensity of manual loading and unloading, narrow gap between graphite boat electrode sheets, and low production efficiency, etc., and achieve linear movement efficiency High, improve market competitiveness, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

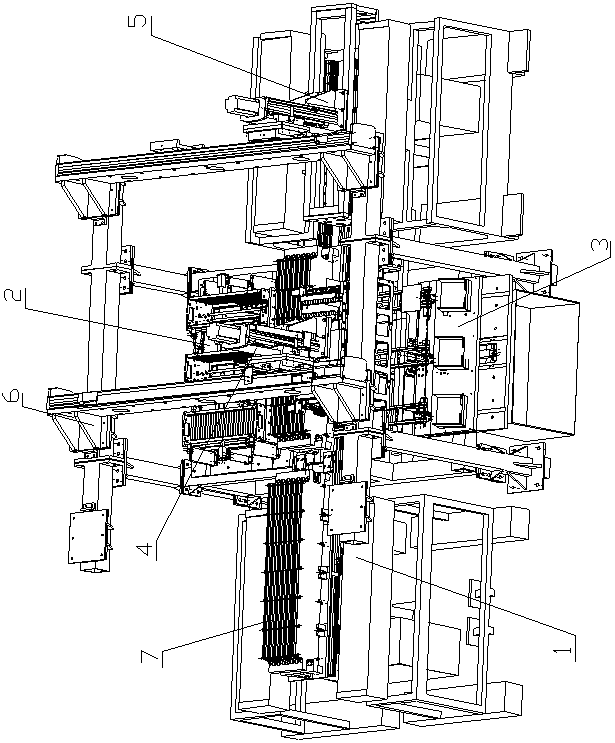

[0045] see Figure 1~8 , a tubular PECVD graphite boat loading and unloading system related to the present invention, said system includes a graphite boat transfer mechanism 1, a silicon wafer loading mechanism 2, a silicon wafer unloading mechanism 3, a silicon wafer grabbing and transferring mechanism 4 and Graphite boat loading and unloading mechanism 5,

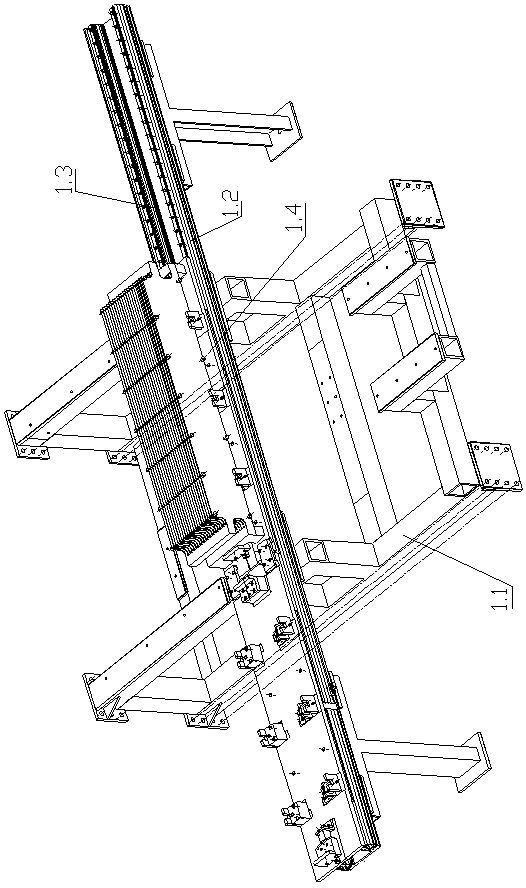

[0046] see figure 2, the graphite boat transfer mechanism 1 includes a track groove plate 1.2 installed on the support 1.1, two linear guide rails 1.3 are installed along the length direction of the track groove plate 1.2, and the slide block of the linear guide rail 1.3 is installed There is a transfer carrier plate 1.4, and the graphite boat is placed on the above-mentioned transfer carrier plate 1.4. Preferably, the above-mentioned transfer carrier plate 1.4 is equipped with a positioning mechanism to position and fix the graphite boat. The positioning mechanism includes a frame composed of a plurality of positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com