Patents

Literature

38results about How to "The process is simple and smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

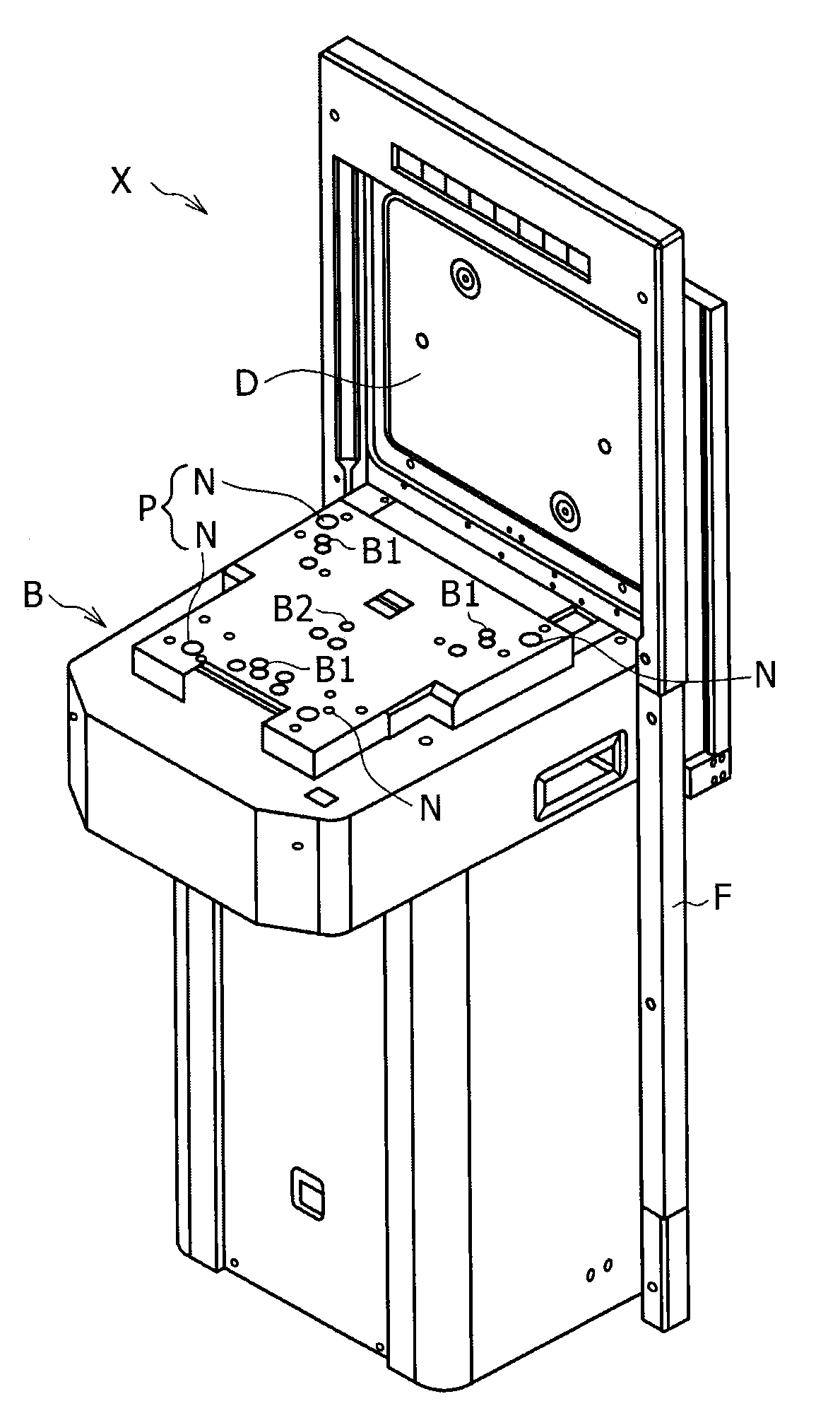

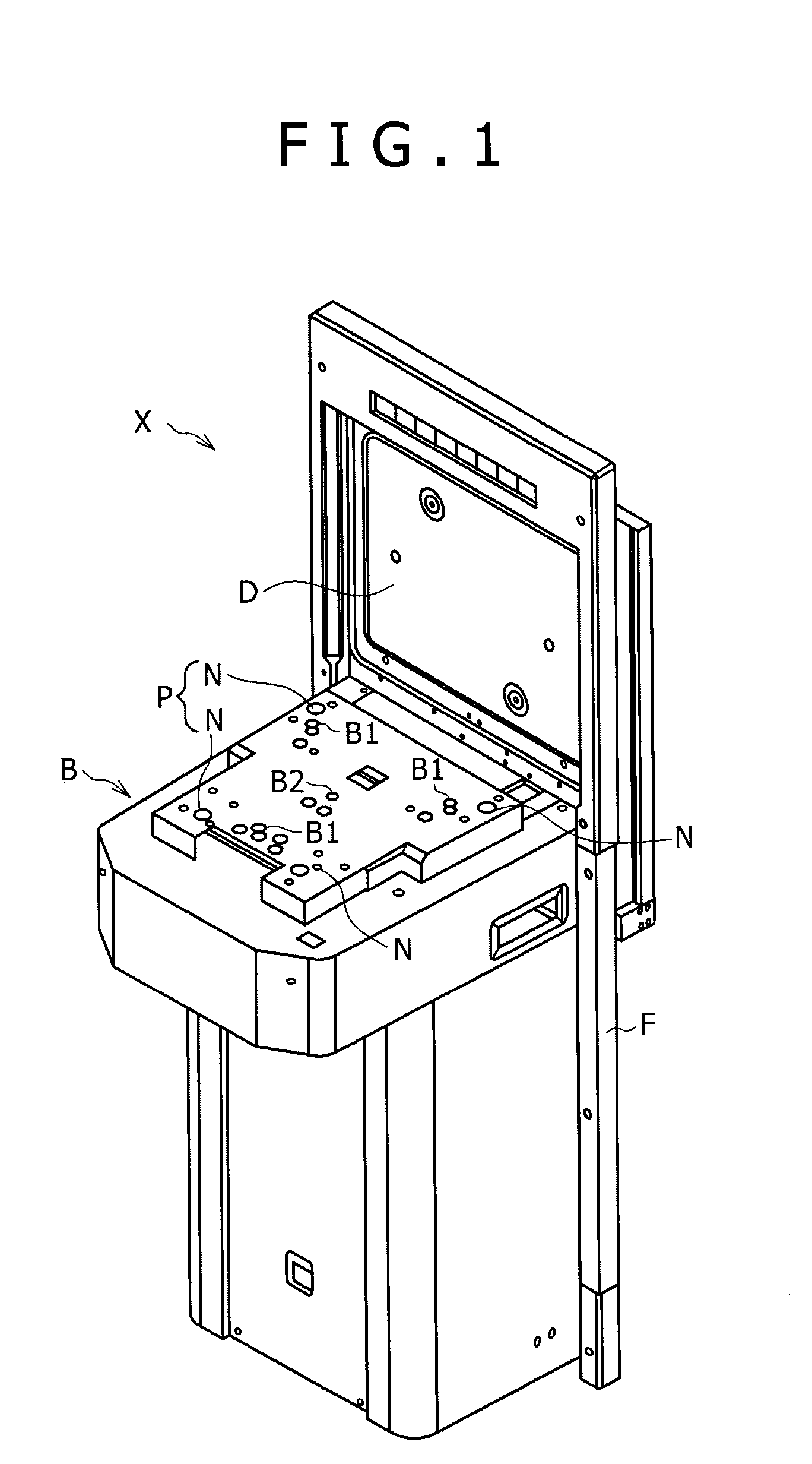

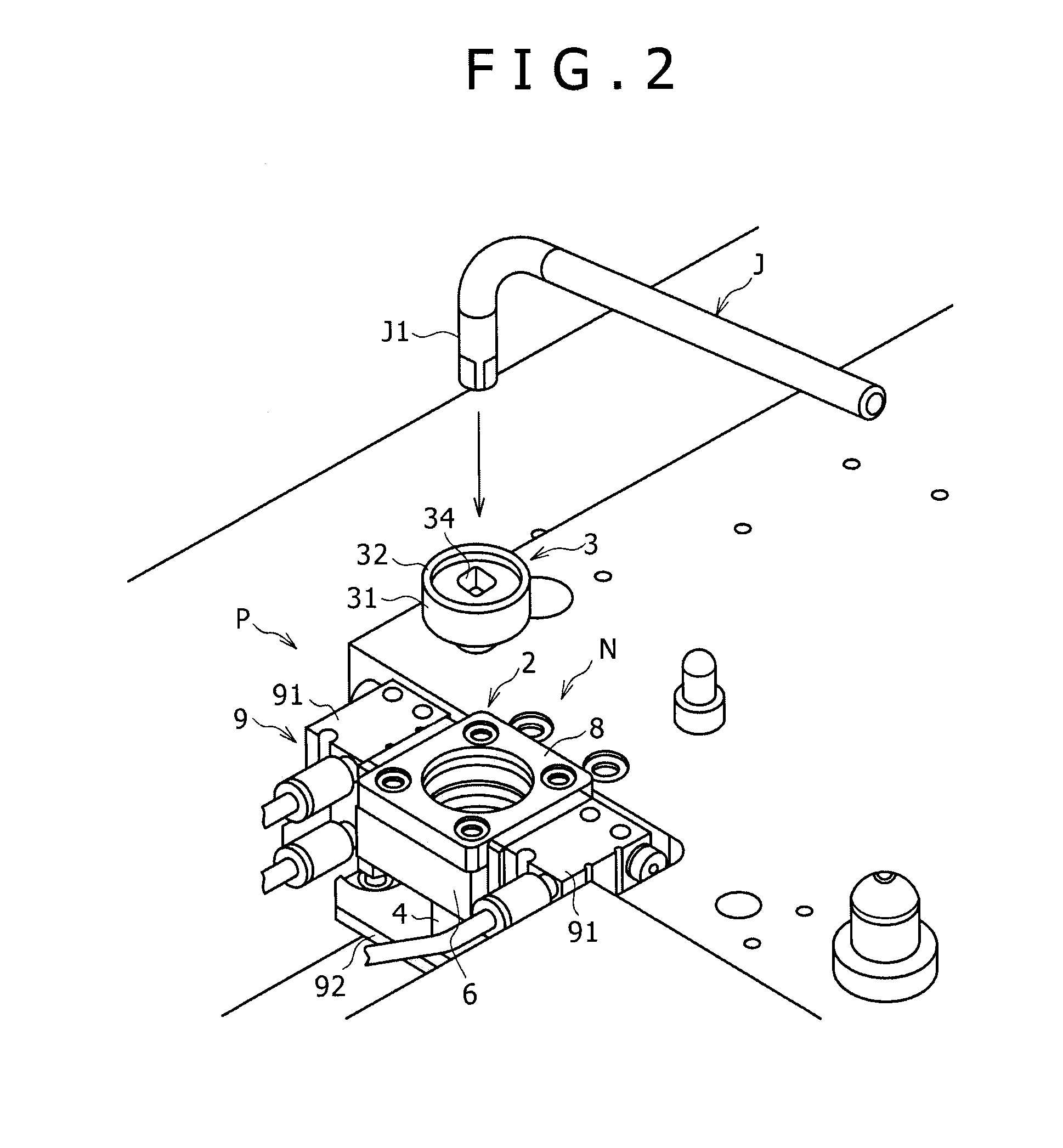

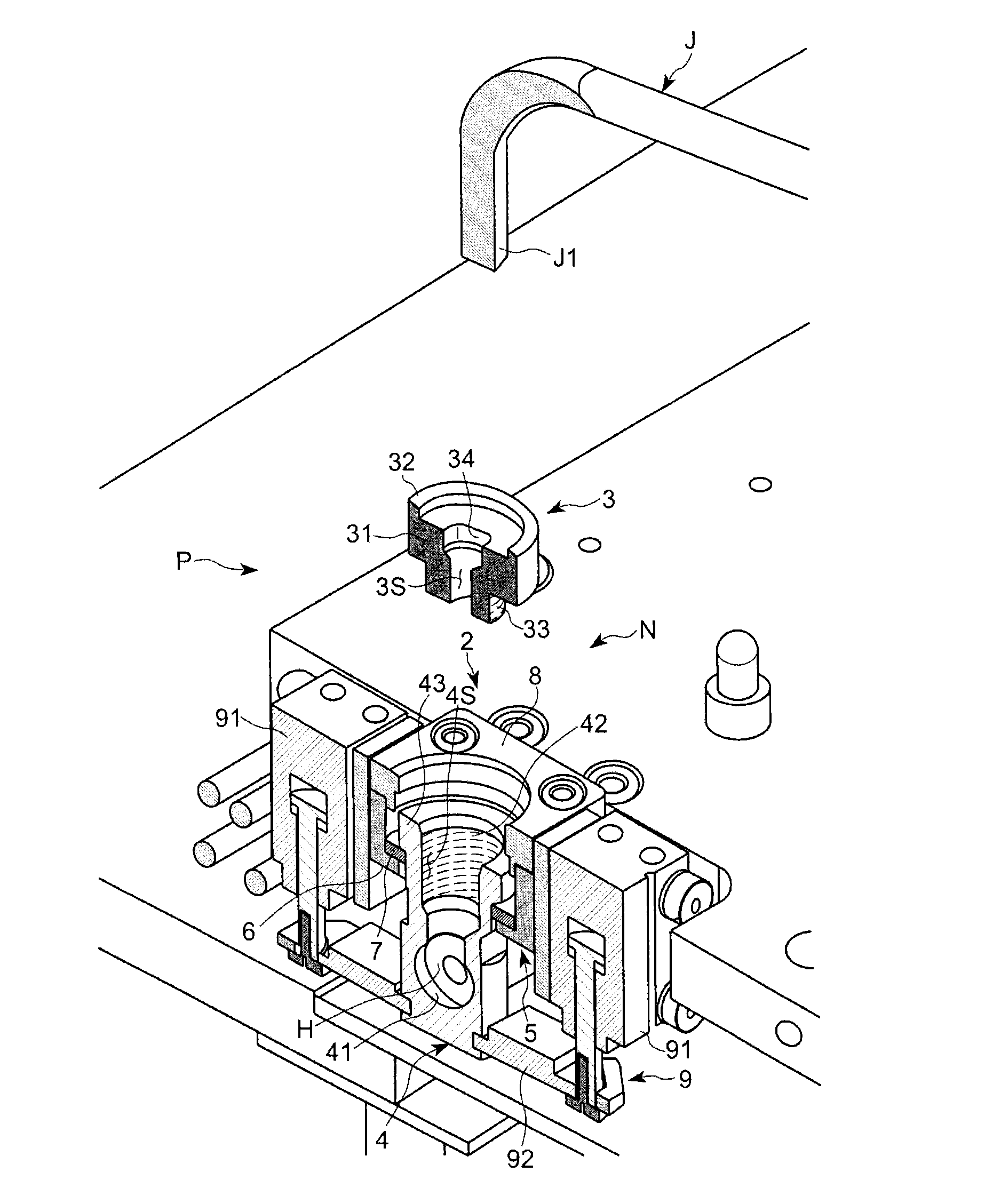

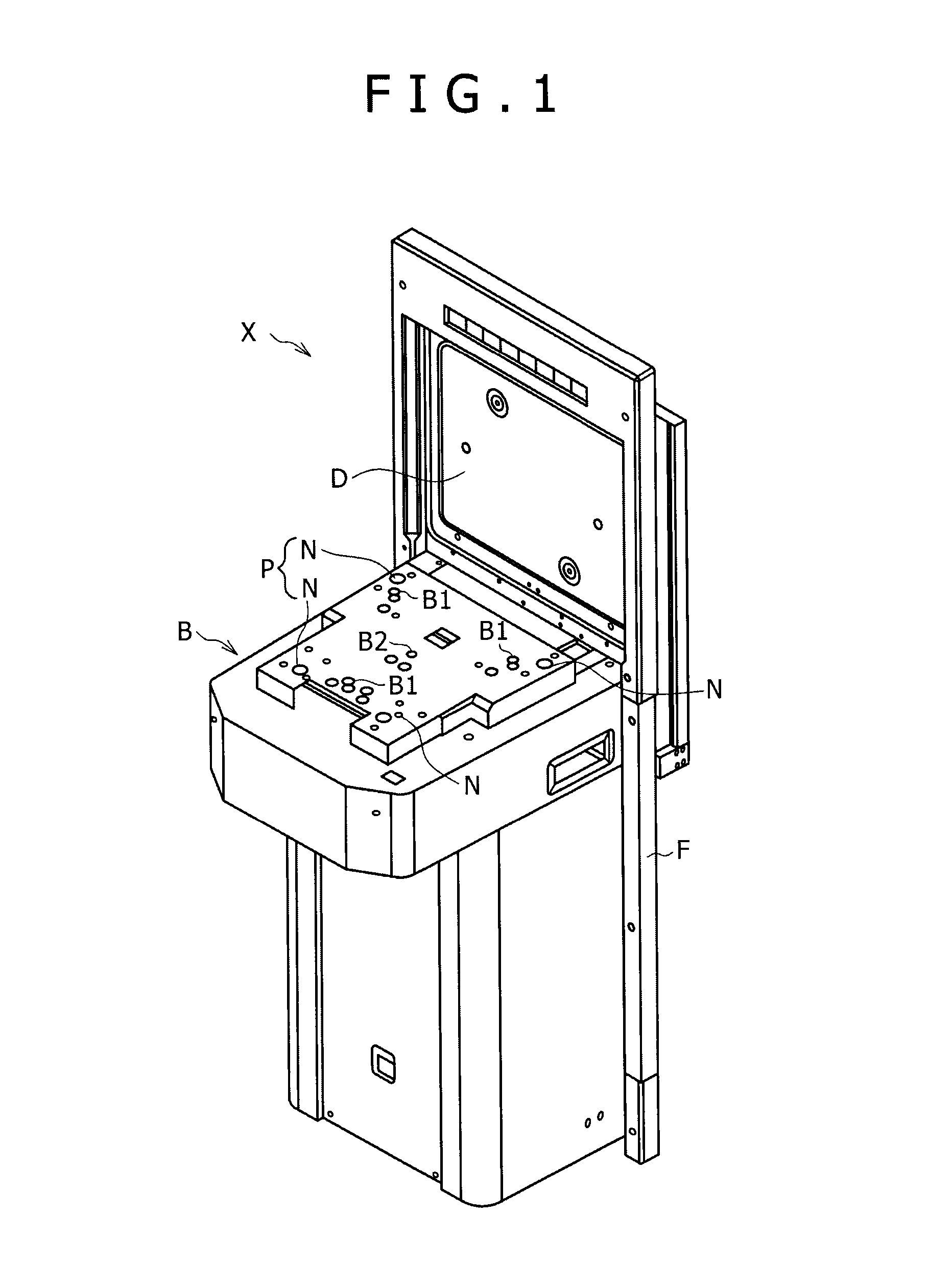

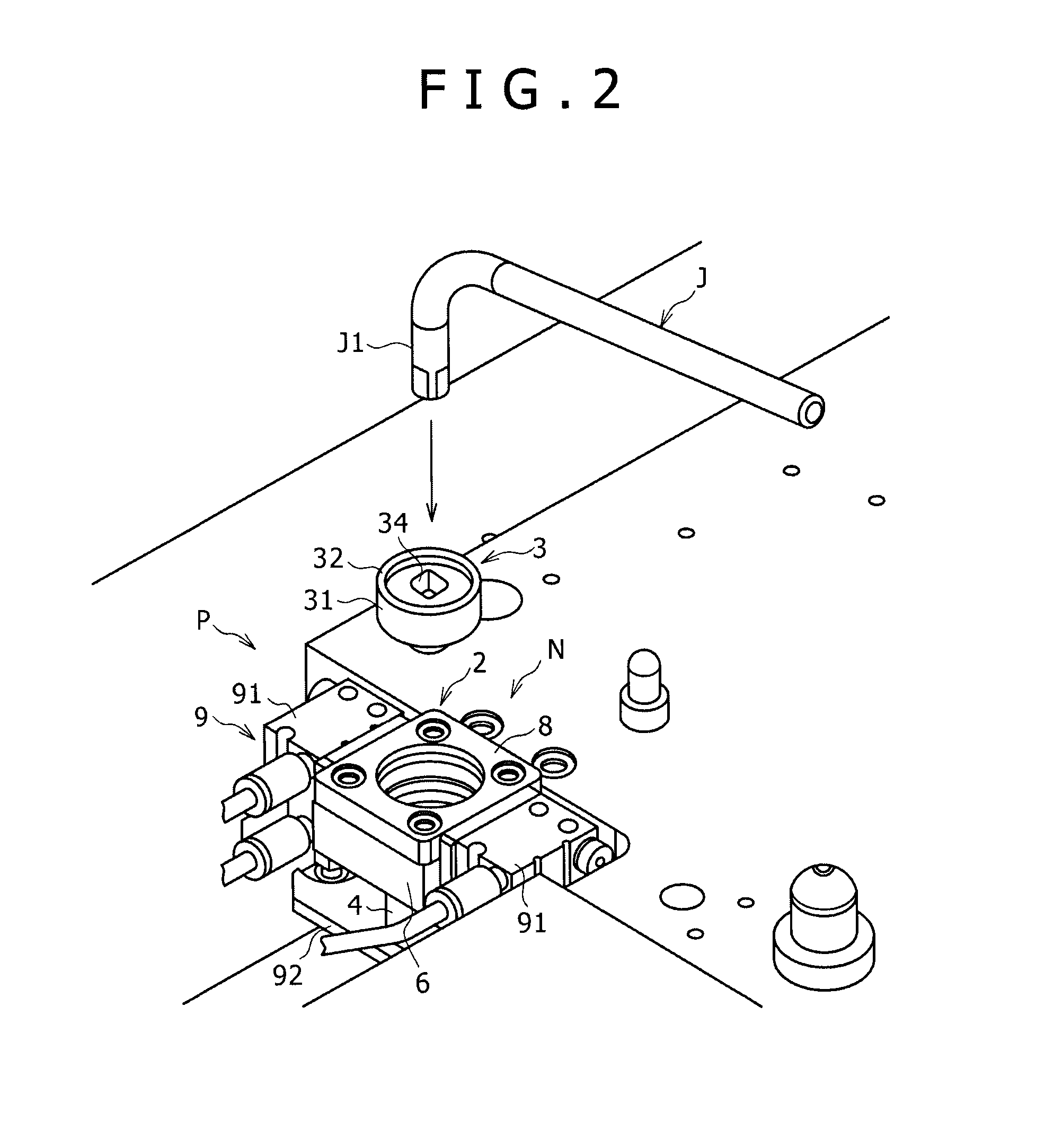

Purge apparatus and load port

ActiveUS20120309286A1Improve air tightnessIncrease concentrationDucting arrangementsLighting and heating apparatusProduct gasAtmosphere

A purge apparatus for replacing a gas atmosphere in a purge object vessel by a purge gas through a port provided on a bottom face of the purge object vessel is disclosed. The purge apparatus includes a purge unit attached to a table that receives the purge object vessel, and a purge nozzle body including a port contacting portion provided on an upper side of the purge nozzle body and an attachment object portion provided on a lower side of the purge nozzle body. The purge unit has an attachment portion and the port contacting portion of the purge nozzle body is configured to contact the port of the purge object vessel. The attachment object portion of the purge nozzle body removably engages with the attachment portion of the purge unit so that the purge nozzle body is removably attached to the purge unit.

Owner:SINFONIA TECHNOLOGY CO LTD

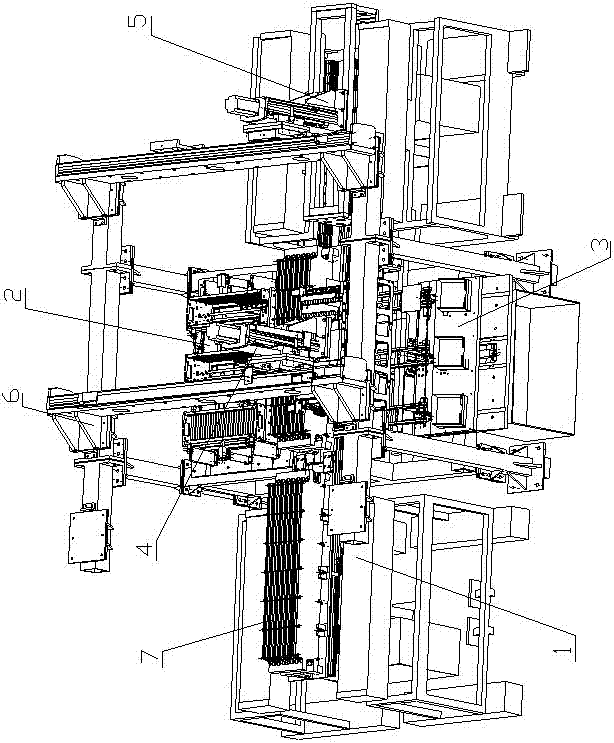

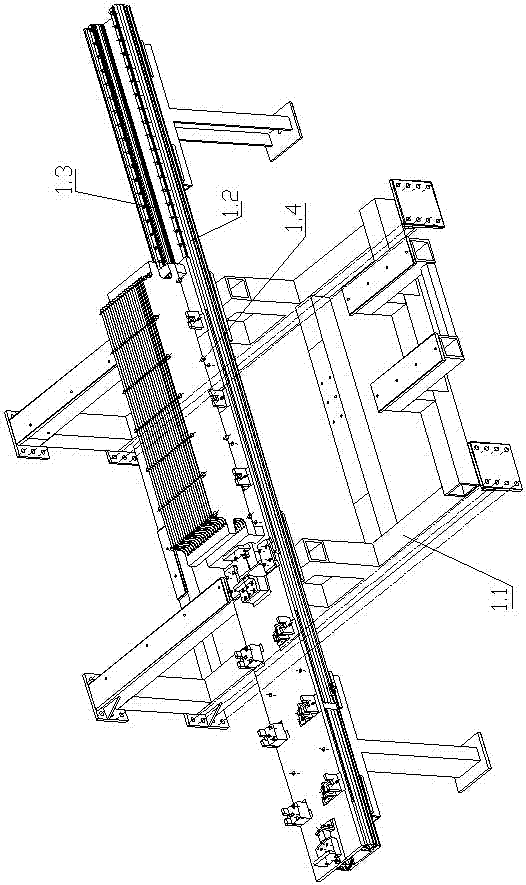

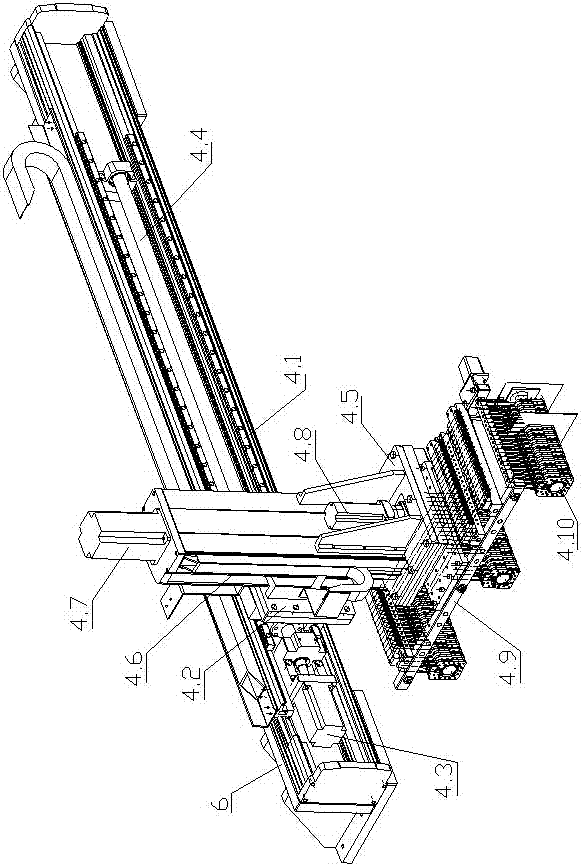

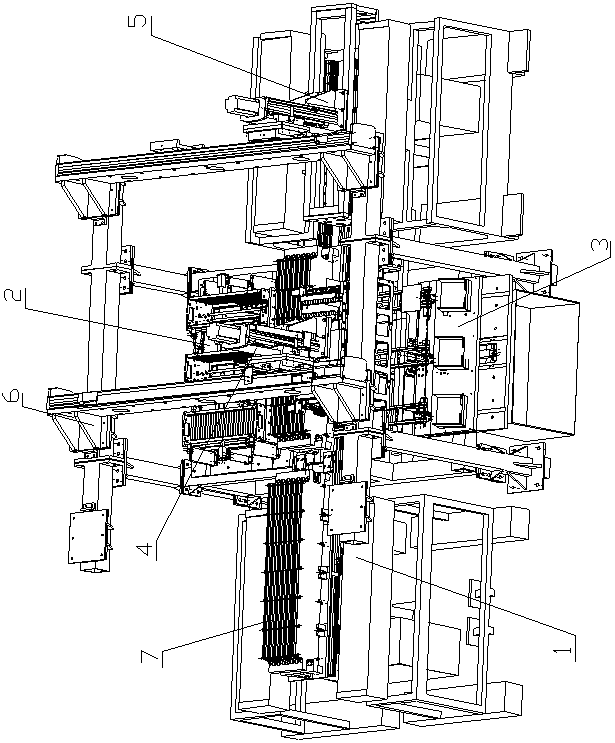

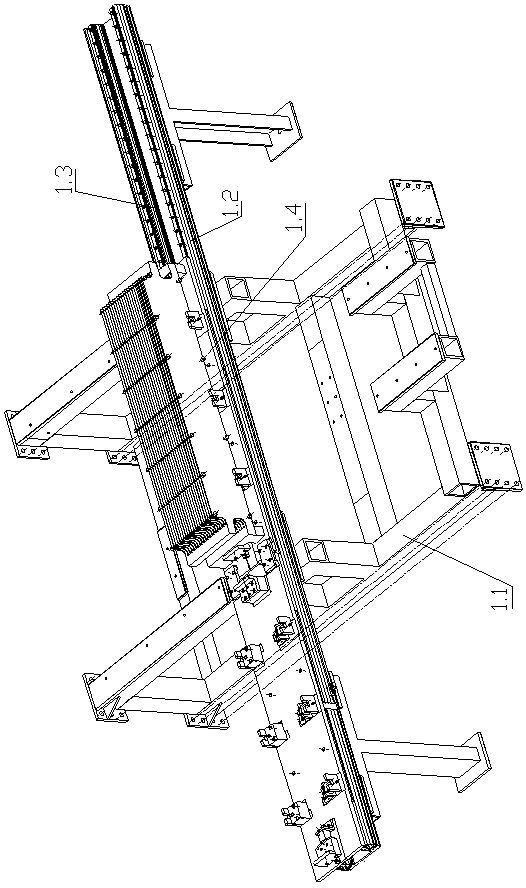

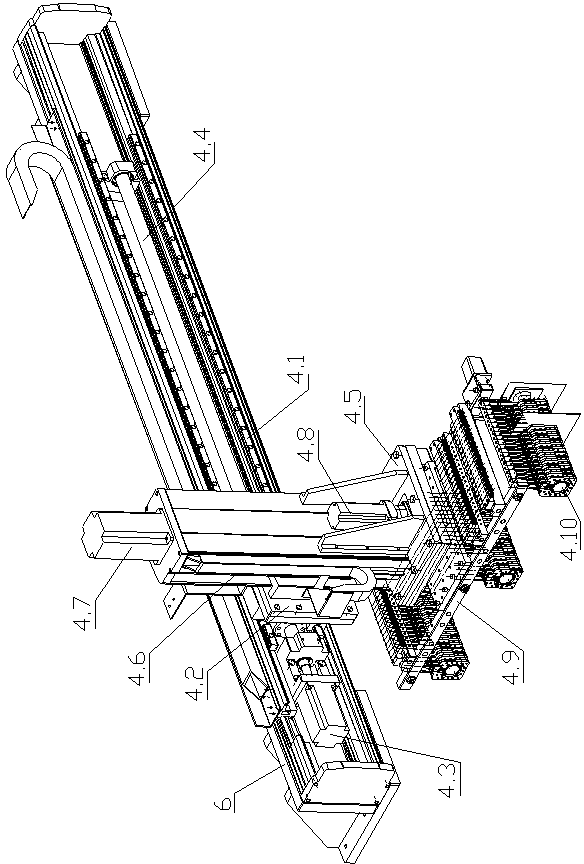

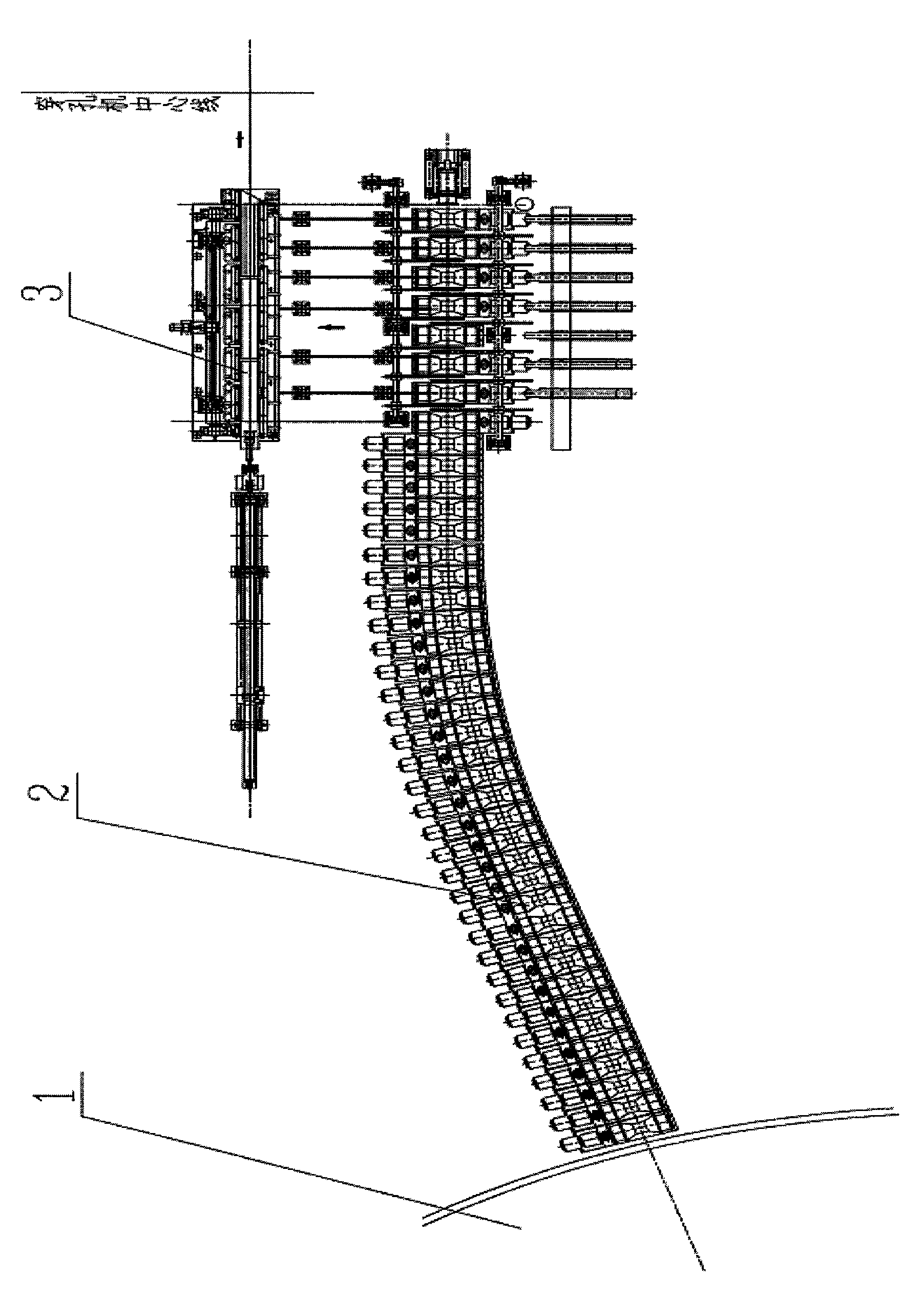

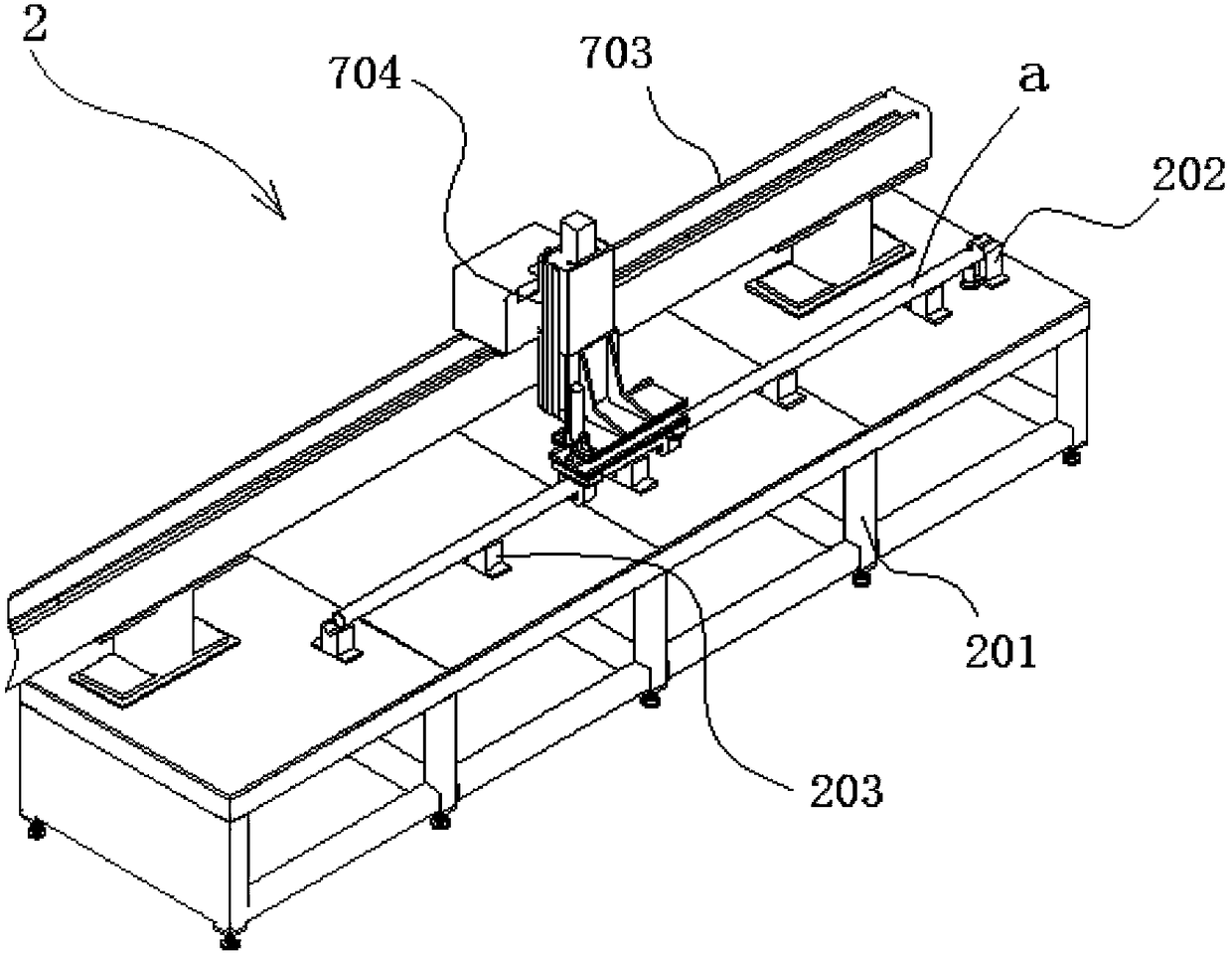

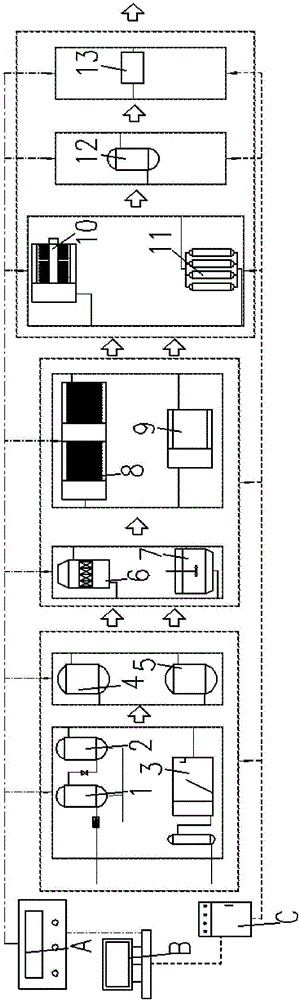

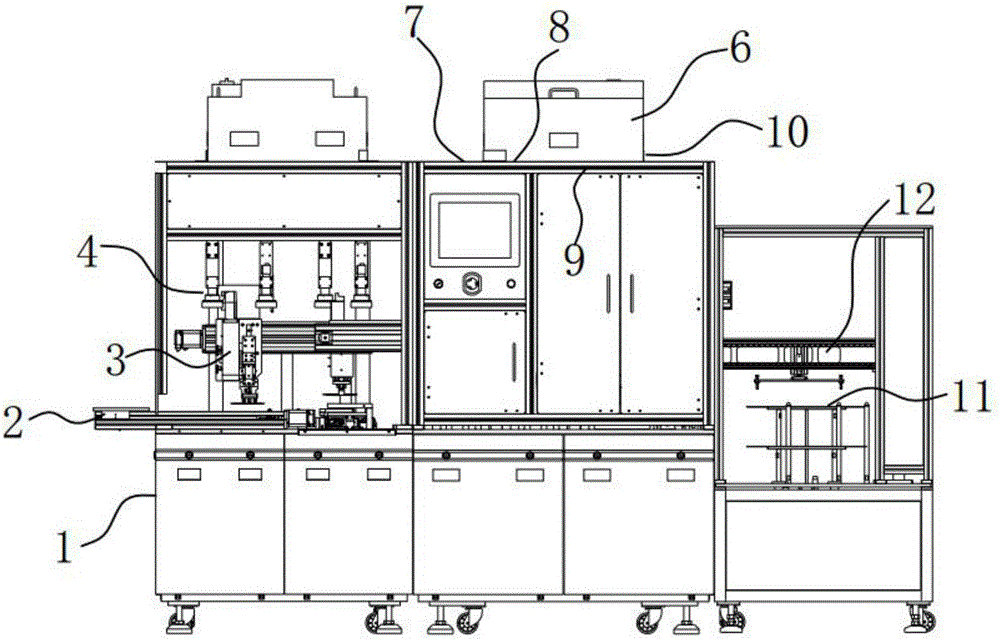

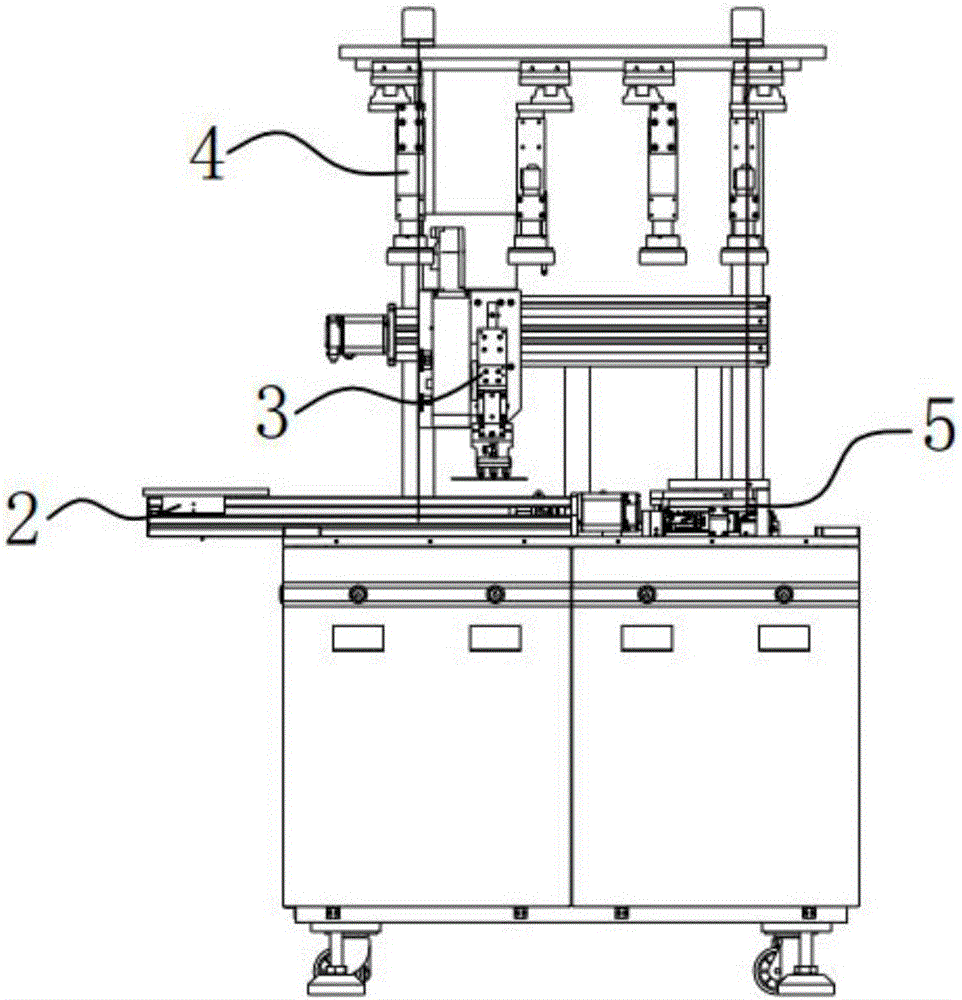

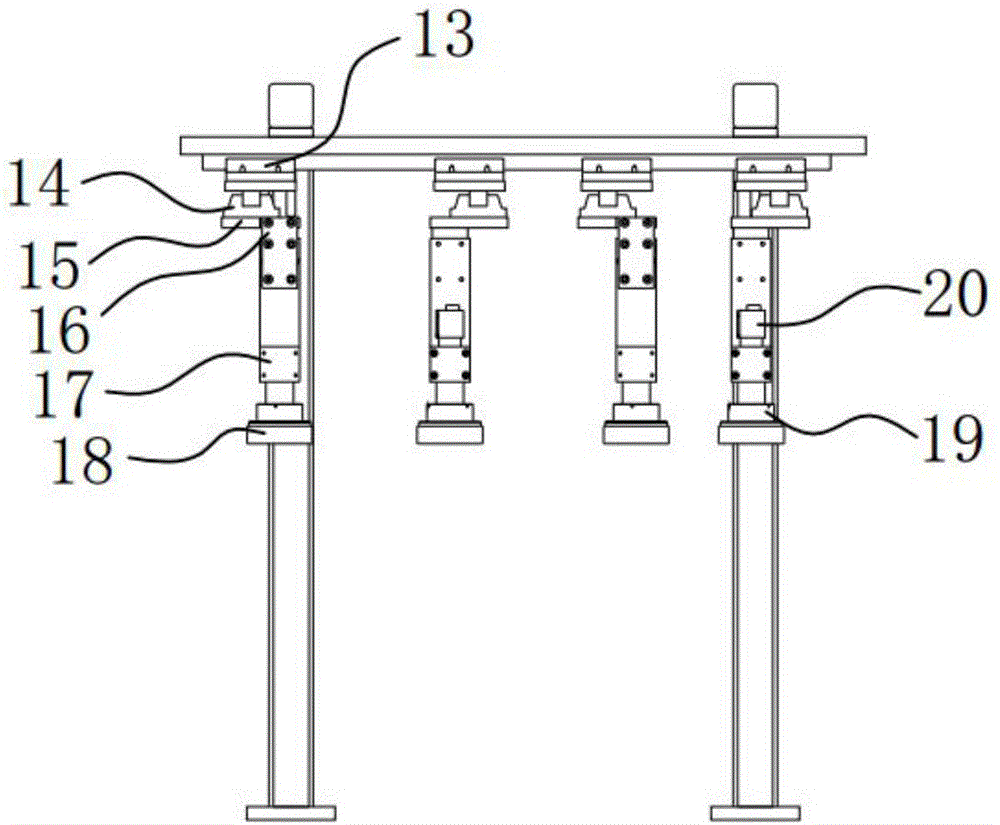

Pipe-type PECVD graphite boat assembling and disassembling piece system and process

ActiveCN104377154AReduce manufacturing costHigh movement accuracyFinal product manufactureSolid-state devicesLinear motionEngineering

The invention relates to a pipe-type PECVD graphite boat assembling and disassembling piece system. The system comprises a graphite boat delivery mechanism (1), a silicon slice feeding mechanism (2), a silicon slice discharging mechanism (3), a silicon slice grabbing and delivery mechanism (4) and a graphite boat assembling and disassembling mechanism (5), wherein the graphite boat delivery mechanism is used for carrying a graphite boat to move horizontally; the silicon slice feeding mechanism is used for taking silicon slices to be processed out of a flower basket; the silicon slice discharging mechanism is used for conducting overturning and discharging on the processed silicon slices; the silicon slice grabbing and delivery mechanism is used for absorbing the silicon slices and delivering the silicon slices in a linear motion mode; the graphite boat assembling and disassembling mechanism is used for assembling and disassembling the graphite boats. The pipe-type PECVD graphite boat assembling and disassembling piece system is precise to position and high in production efficiency.

Owner:江苏方艾机器人有限公司

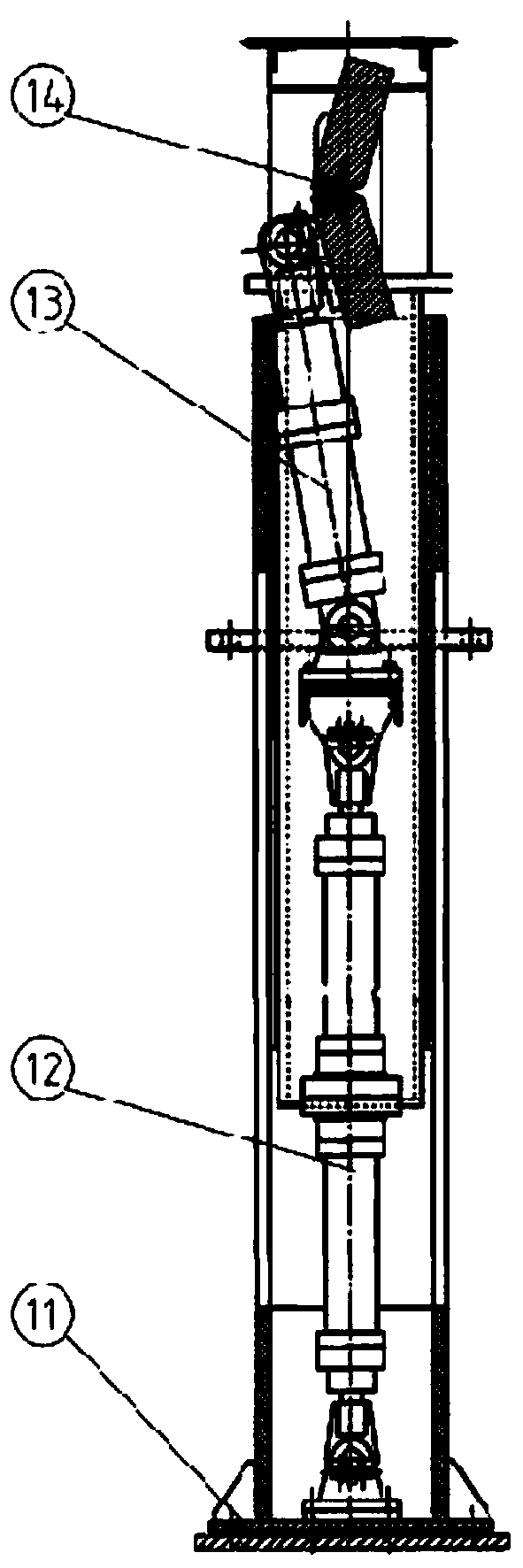

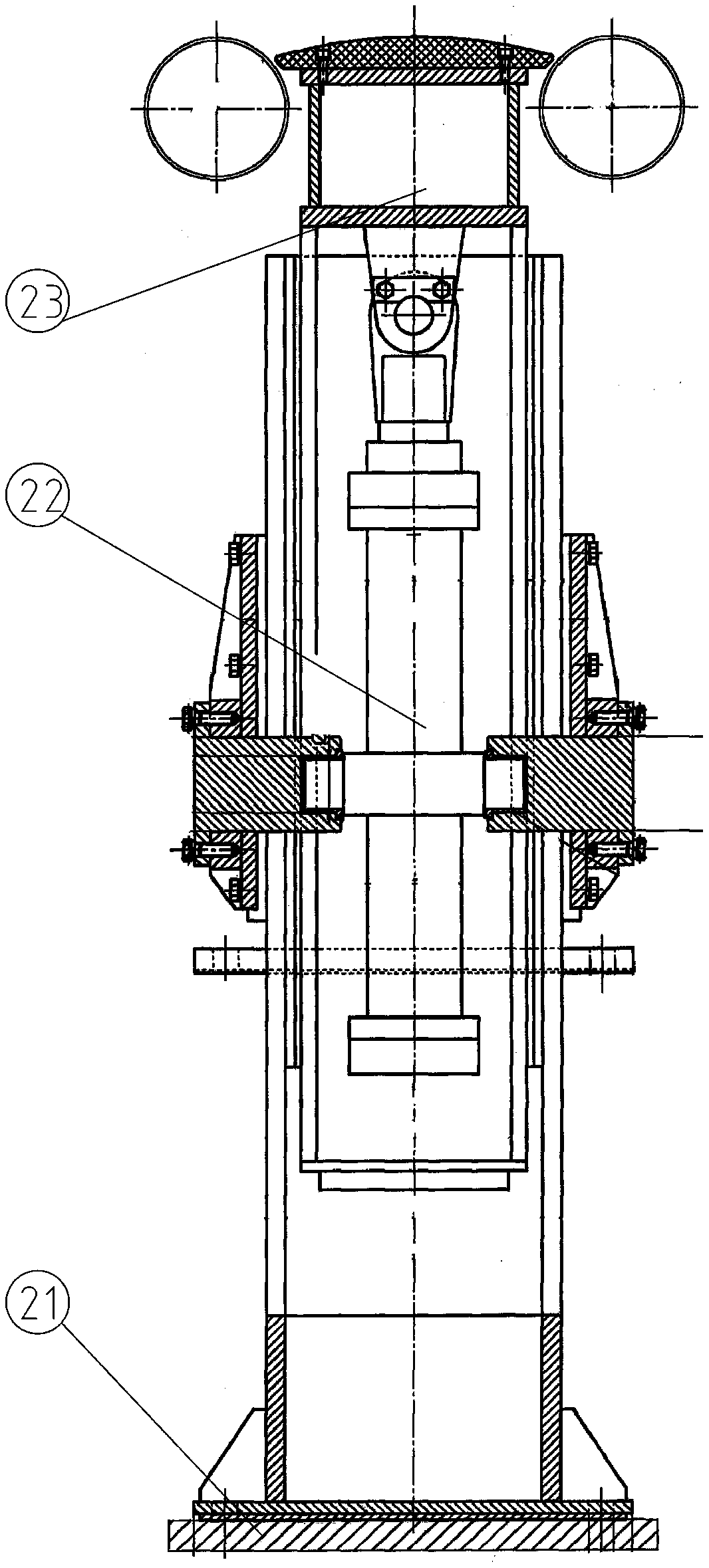

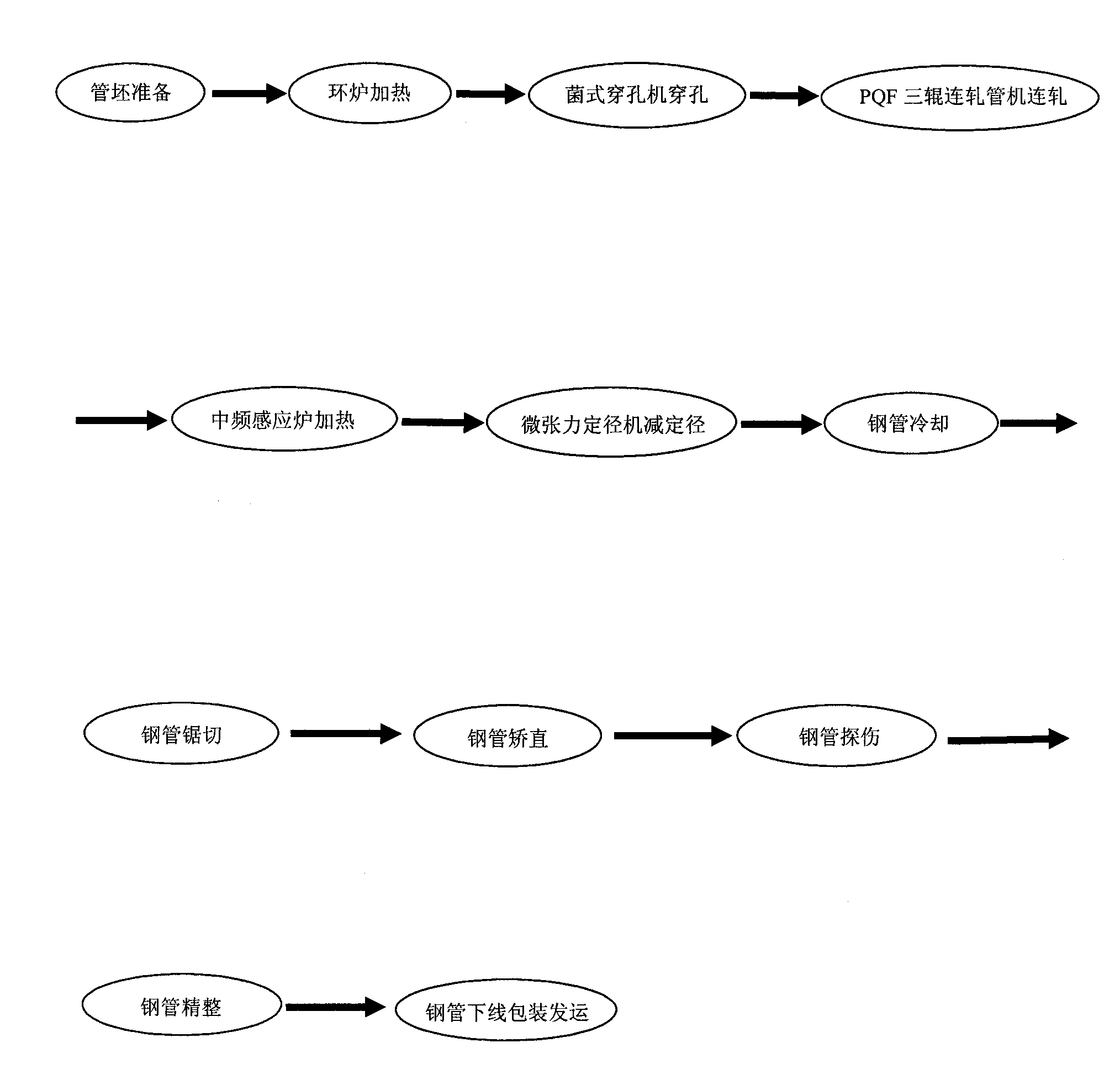

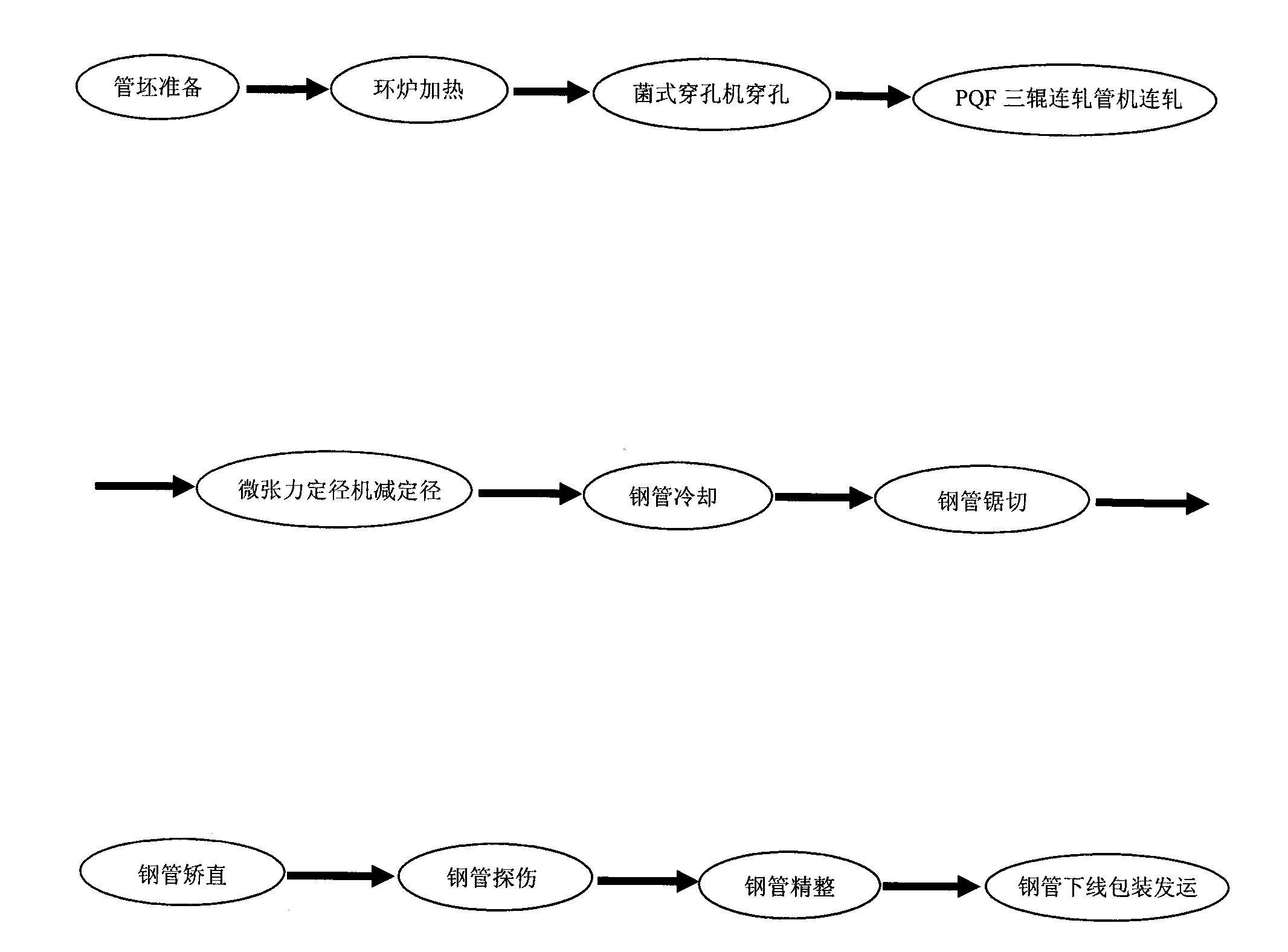

Production process of petroleum pipe

InactiveCN102107213AThe process is simple and smoothSave engineering investmentMetal rolling arrangementsPunchingIntermediate frequency

The invention discloses a production process of a petroleum pipe, and the production process mainly comprises the following steps: preparing a tube blank; heating by virtue of an annular furnace; punching by virtue of a punching machine; continuously rolling by virtue of a continuous roller; carrying out secondary heating on a pierced billet; reducing the sizing; cooling a steel tube; carrying out saw cutting; straightening; performing crack detection; and precisely adjusting. The production process of the petroleum pipe is characterized in that a fungoid type punching machine is adopted in the punching process; PQF (premium quality finishing) is adopted in the continuous rolling process; a middle-frequency inducing furnace is adopted in the secondary heating process of the pierced billet; and a micro tension force sizing machine is adopted in the sizing reduction process. In the invention, based on fungoid type punching and PQF, excellent petroleum pipes also can be produced as well with relatively low production cost by using a 'middle-frequency inducing heating furnace + micro tension force sizing machine' production manner which has the advantages of low investment, small occupied area and relatively lower energy consumption instead of the 'steel tube reheating furnace + tension force sizing reducing machine' production manner which has the defects of high investment, large occupied area and relatively higher energy consumption.

Owner:鞍钢集团工程技术有限公司

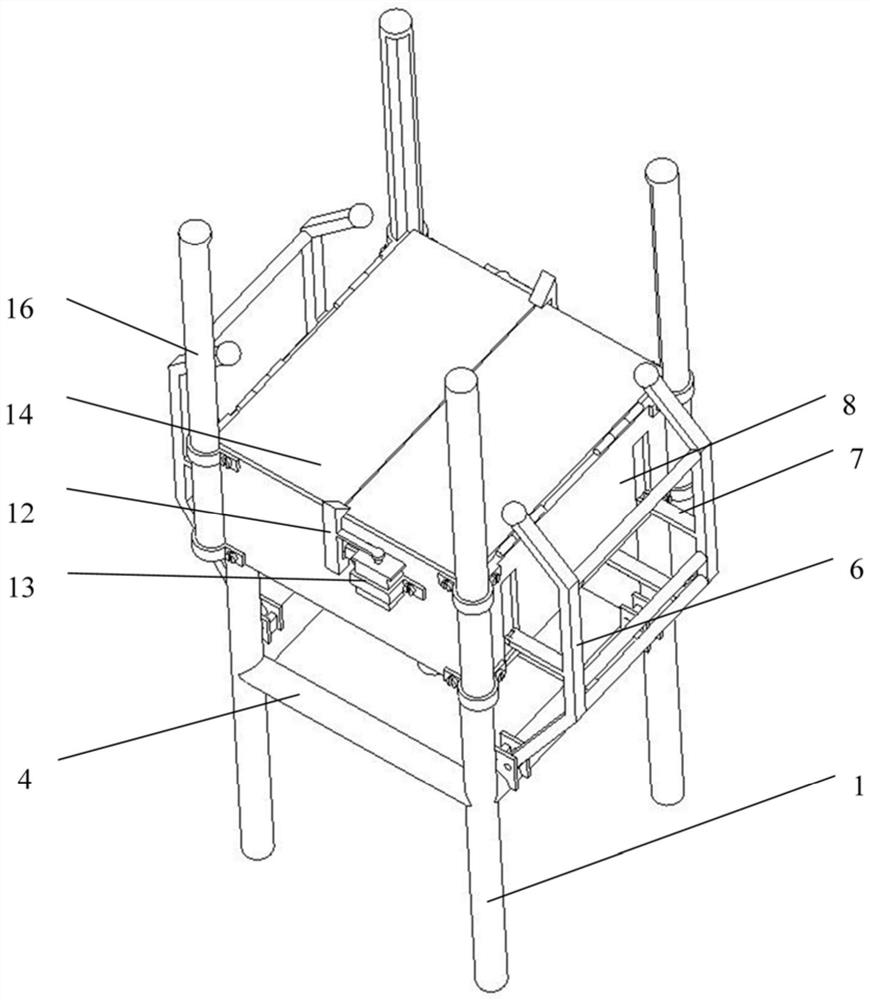

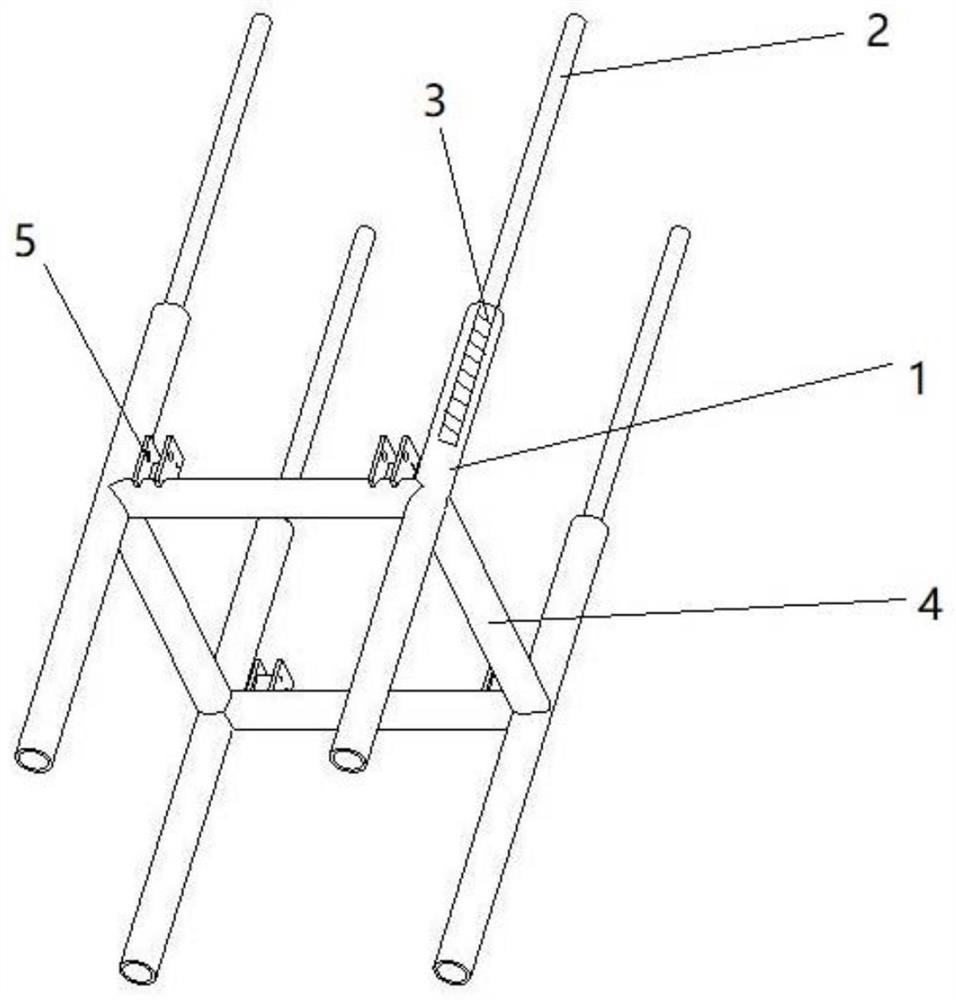

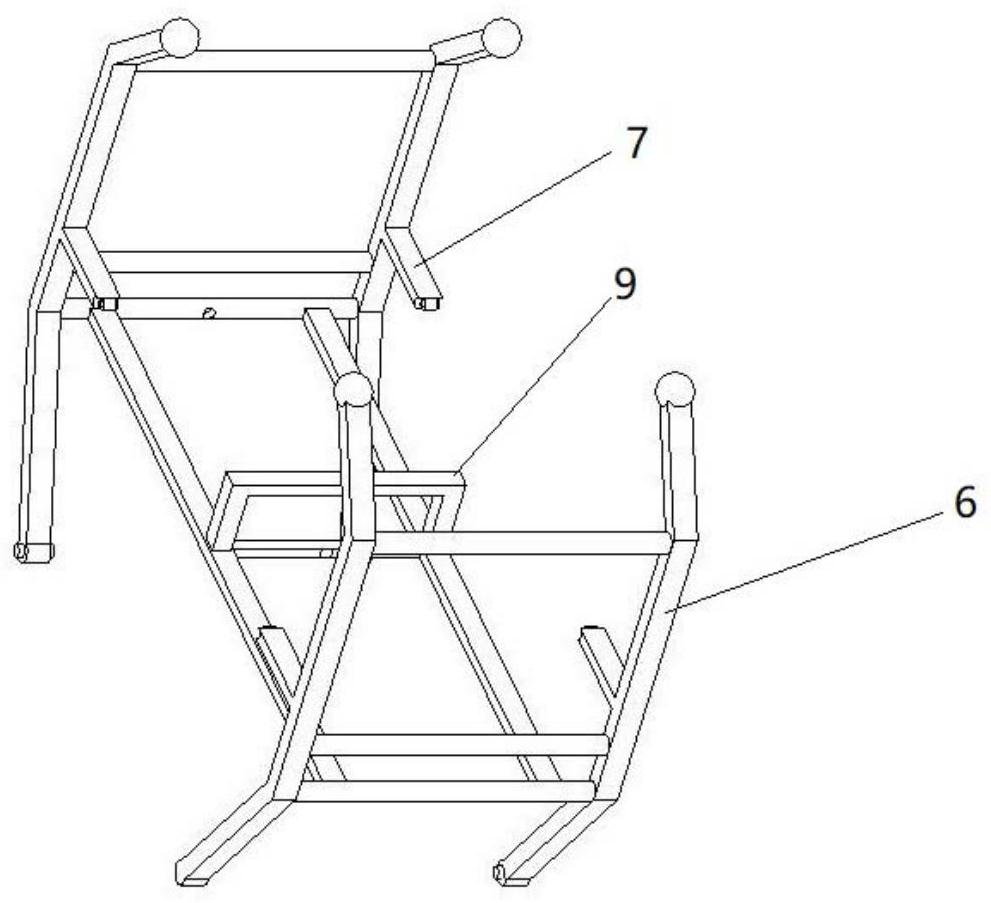

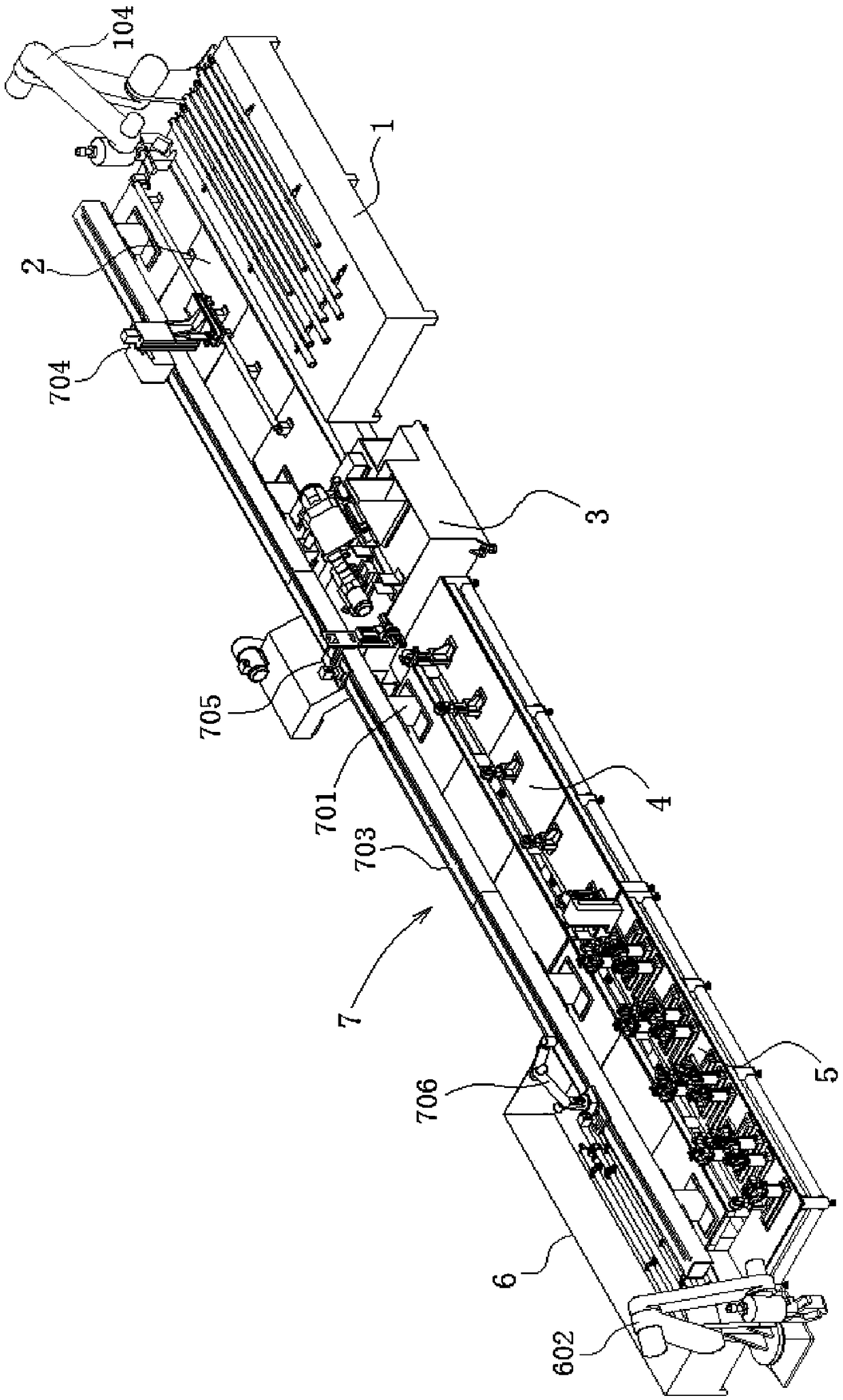

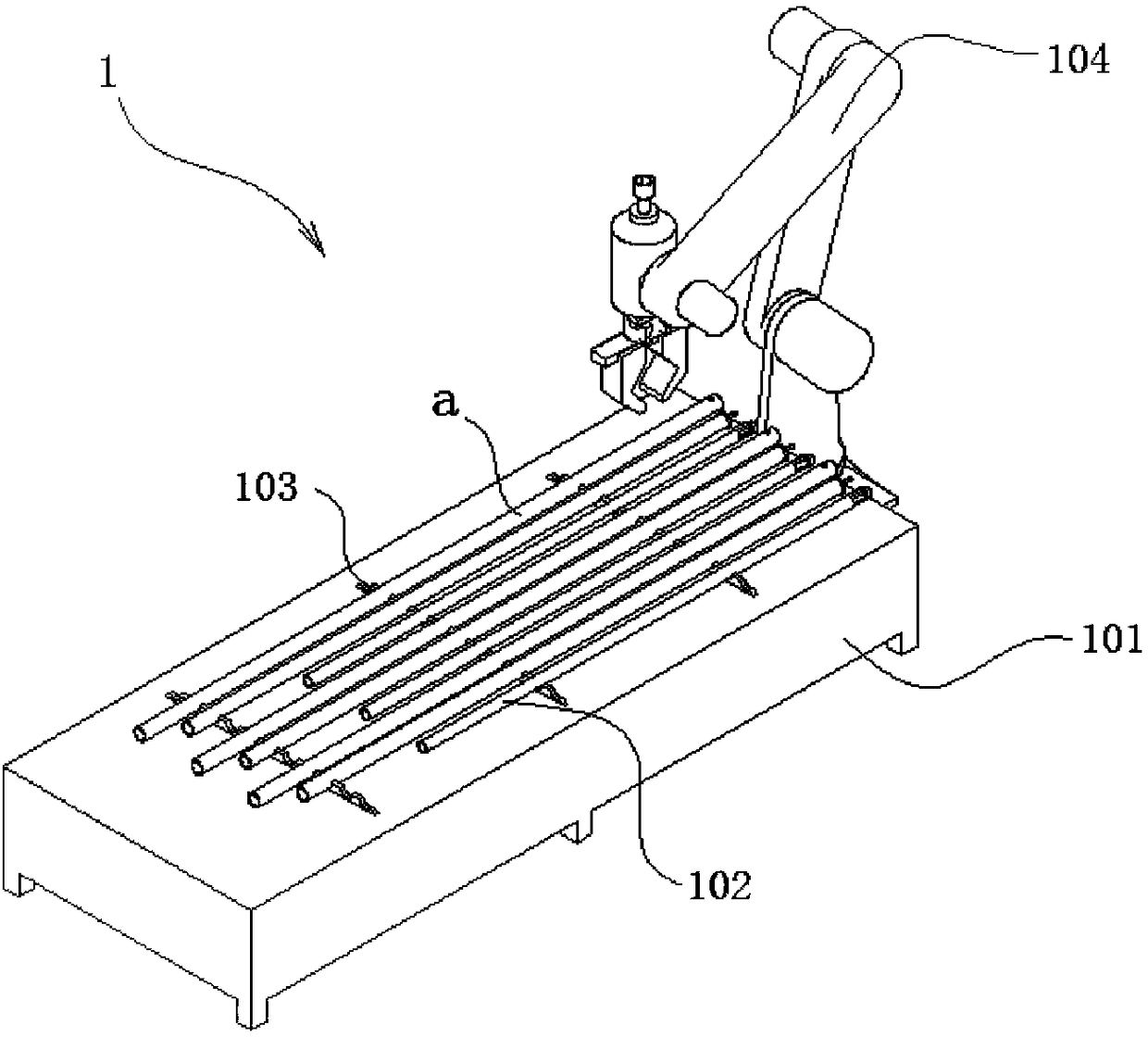

Electric railway overhead contact system cantilever preassembled automatic production line

The invention discloses an electric railway overhead contact system cantilever preassembled automatic production line which comprises a propelling unit, a processing unit, a spraying unit, an assembling unit, a transferring unit, a feeding unit and a discharging unit. The propelling unit, the processing unit, the spraying unit and the assembling unit are sequentially arranged linearly, the transferring unit is arranged on the propelling unit, the processing unit, the spraying unit and the assembling unit, and the feeding unit and the discharging unit are connected with the propelling unit andthe assembling unit respectively; the transferring unit comprises a linear rail arranged on the propelling unit, the processing unit, the spraying unit and the assembling unit and multiple manipulators moving along the linear rail, and the manipulators cooperate with each other to transfer processed materials among the propelling unit, the processing unit, the spraying unit and the assembling unit. The electric railway overhead contact system cantilever preassembled automatic production line can automatically complete all processes of preassembly of various cantilever pipe fittings and has theadvantages of being multifunctional and high in automation and intelligence level.

Owner:CHINA RAILWAY CONSTR ELECTRIFICATION BUREAUGRP +1

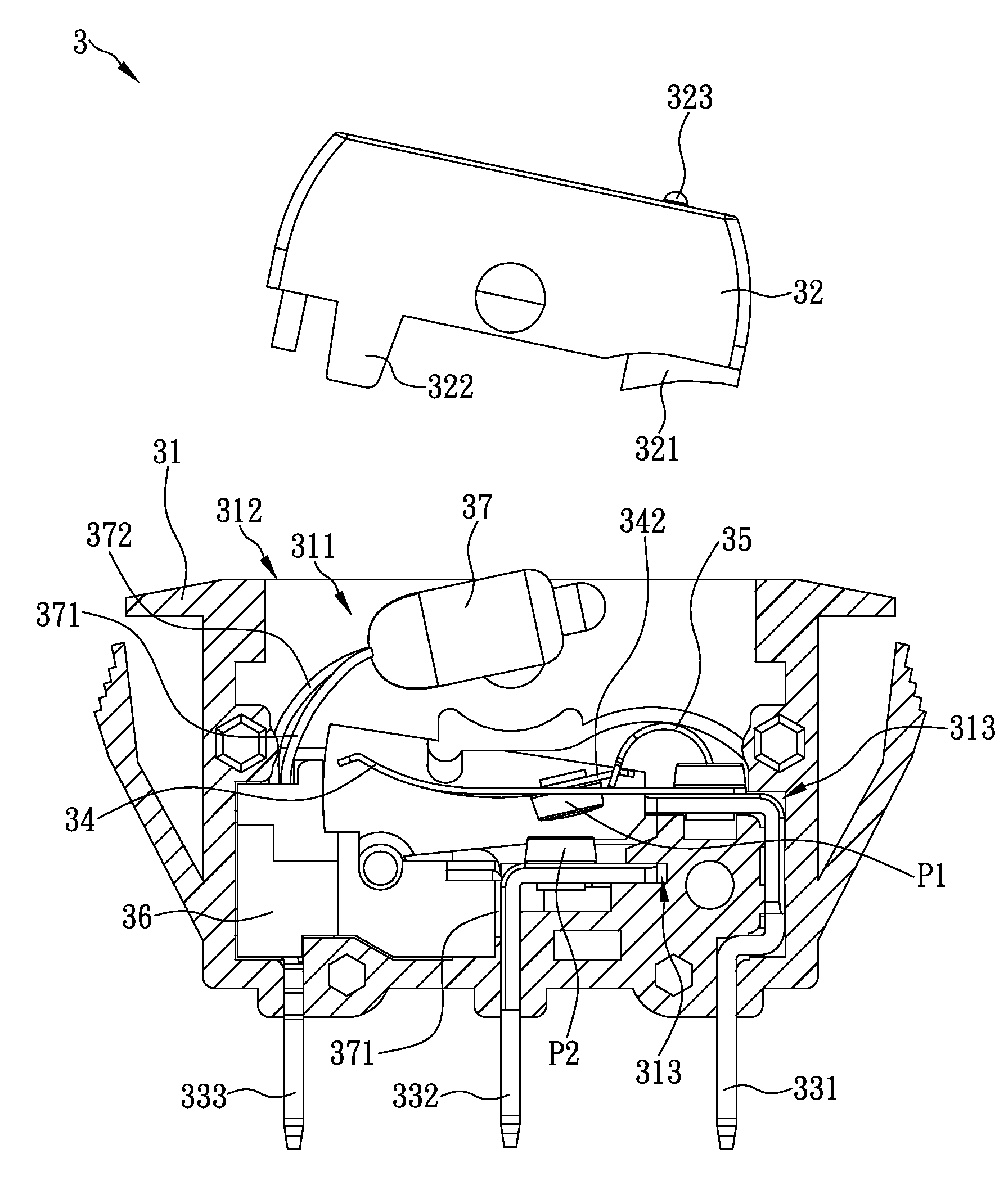

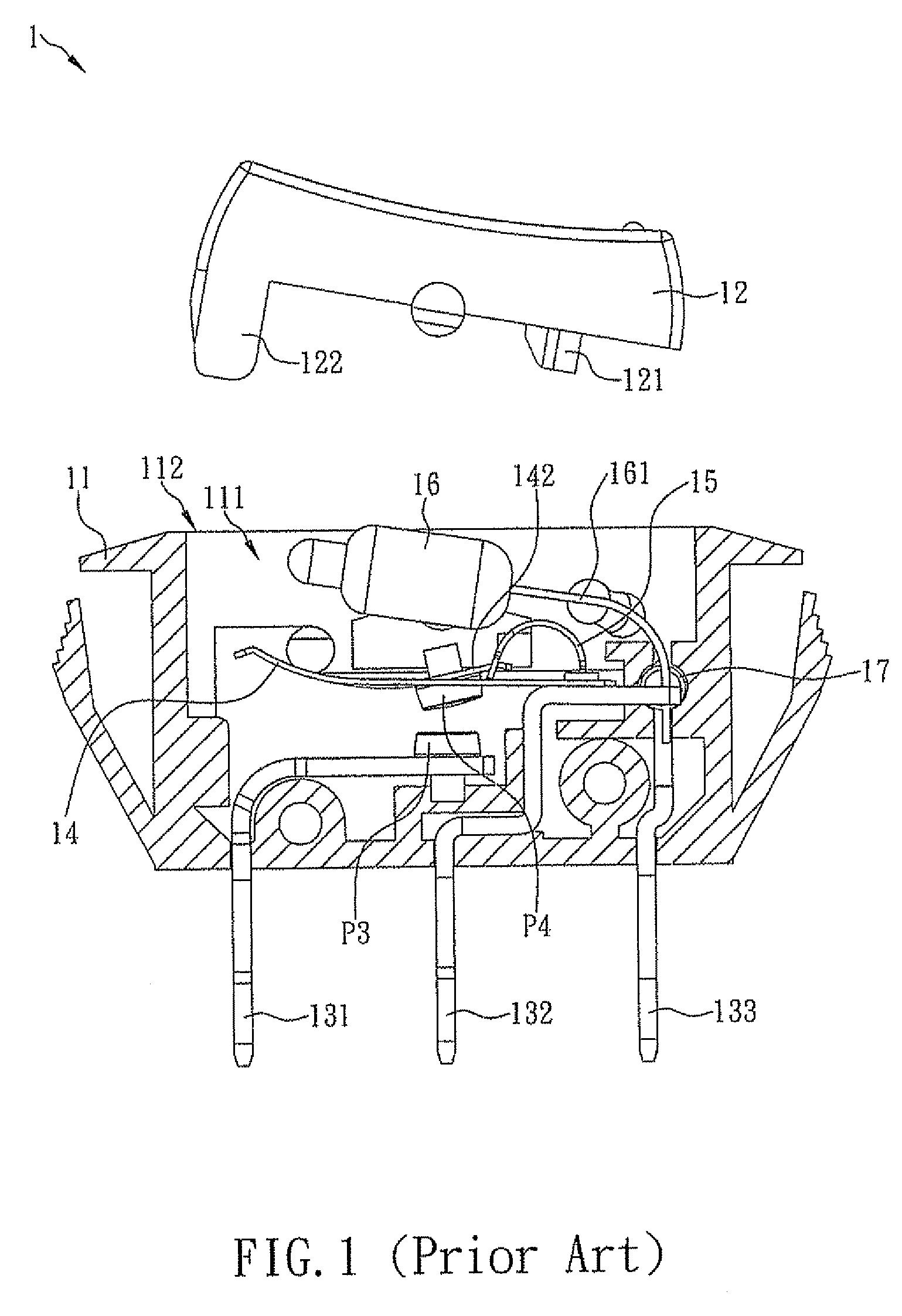

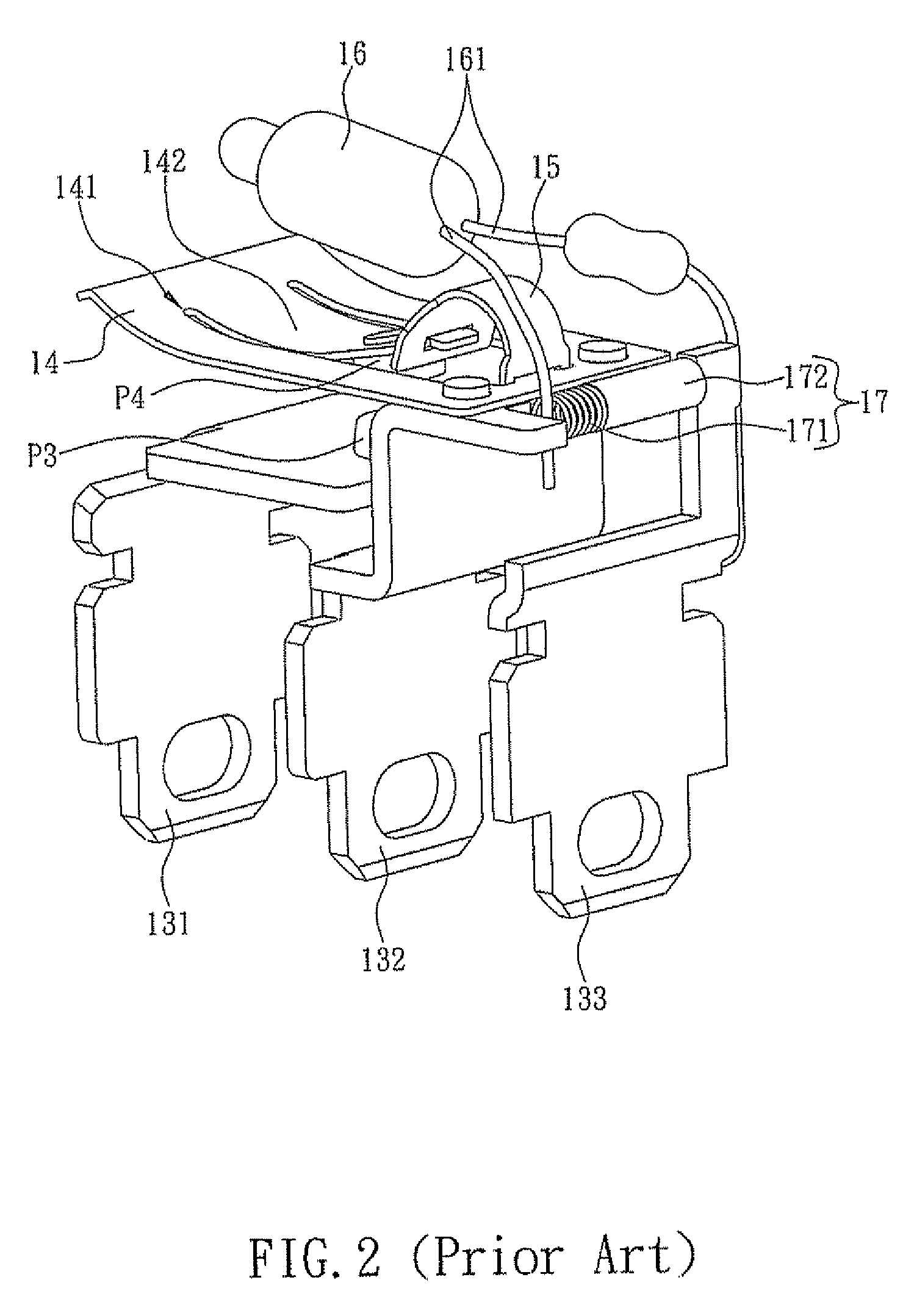

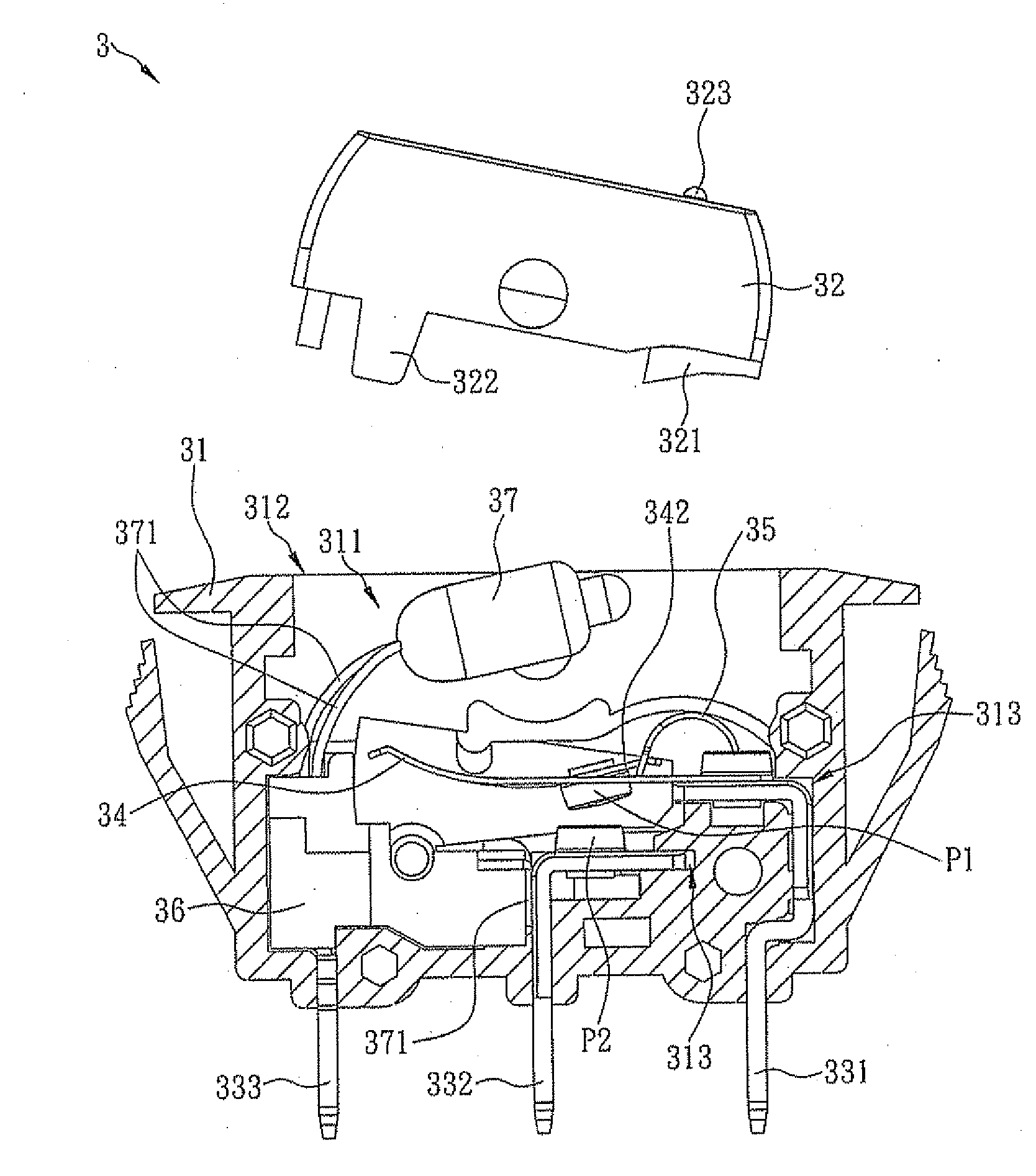

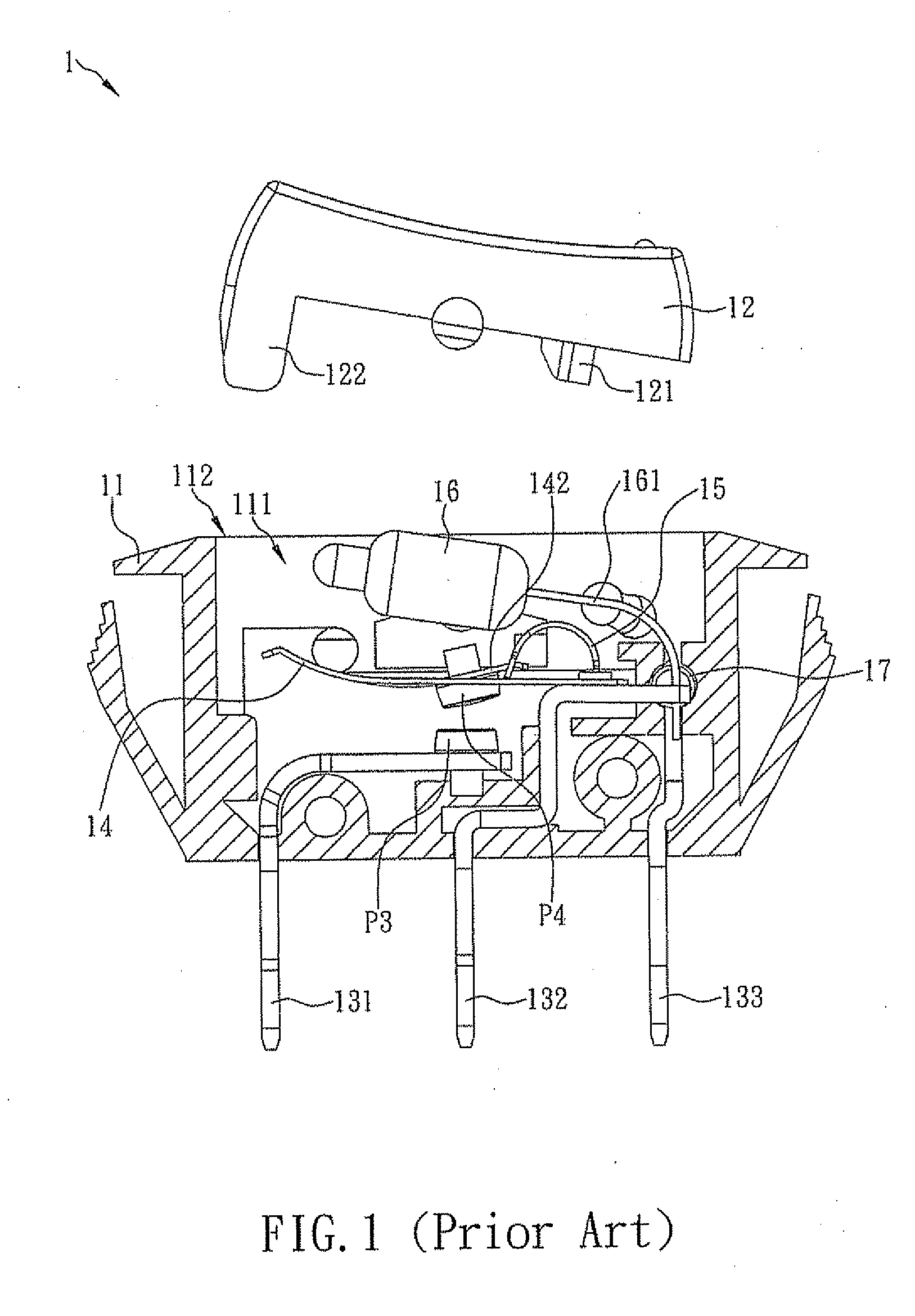

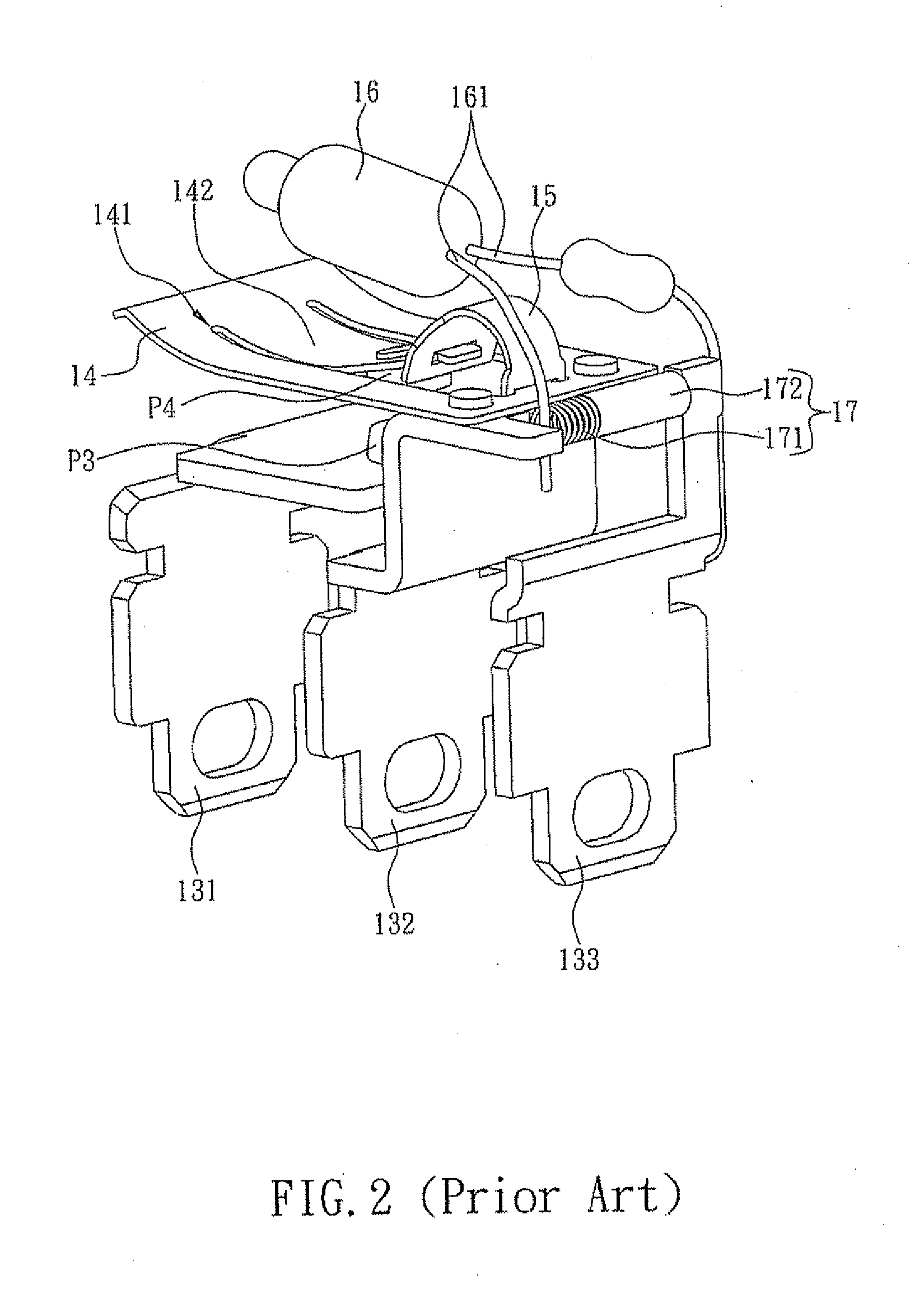

Power switch suitable for automated production

InactiveUS20130112540A1Simplified power switch structureEasy to installSwitches with electrothermal releaseTumbler/rocker switch detailsPower switchingElectrical and Electronics engineering

The present invention relates to a power switch, which includes a housing, a key pivotally connected to the housing, a first conductive plate having one end in the housing, a thermally actuated metal plate having one end fixed to the first conductive plate and a free end extending within the housing, a C-shaped spring having two ends engaged with the thermally actuated metal plate, a second conductive plate having one end in the housing, an insulating seat accommodated in the housing, a light-emitting unit located in the key and having two electrodes connected to the insulating seat, and a third conductive plate having one end in the housing. Thus, the light-emitting unit can be easily installed in the housing along with the insulating seat, and the electrodes can directly connect with the second and third conductive plates respectively, so as to make the power switch suitable for automated production.

Owner:CHEN TSAN CHI

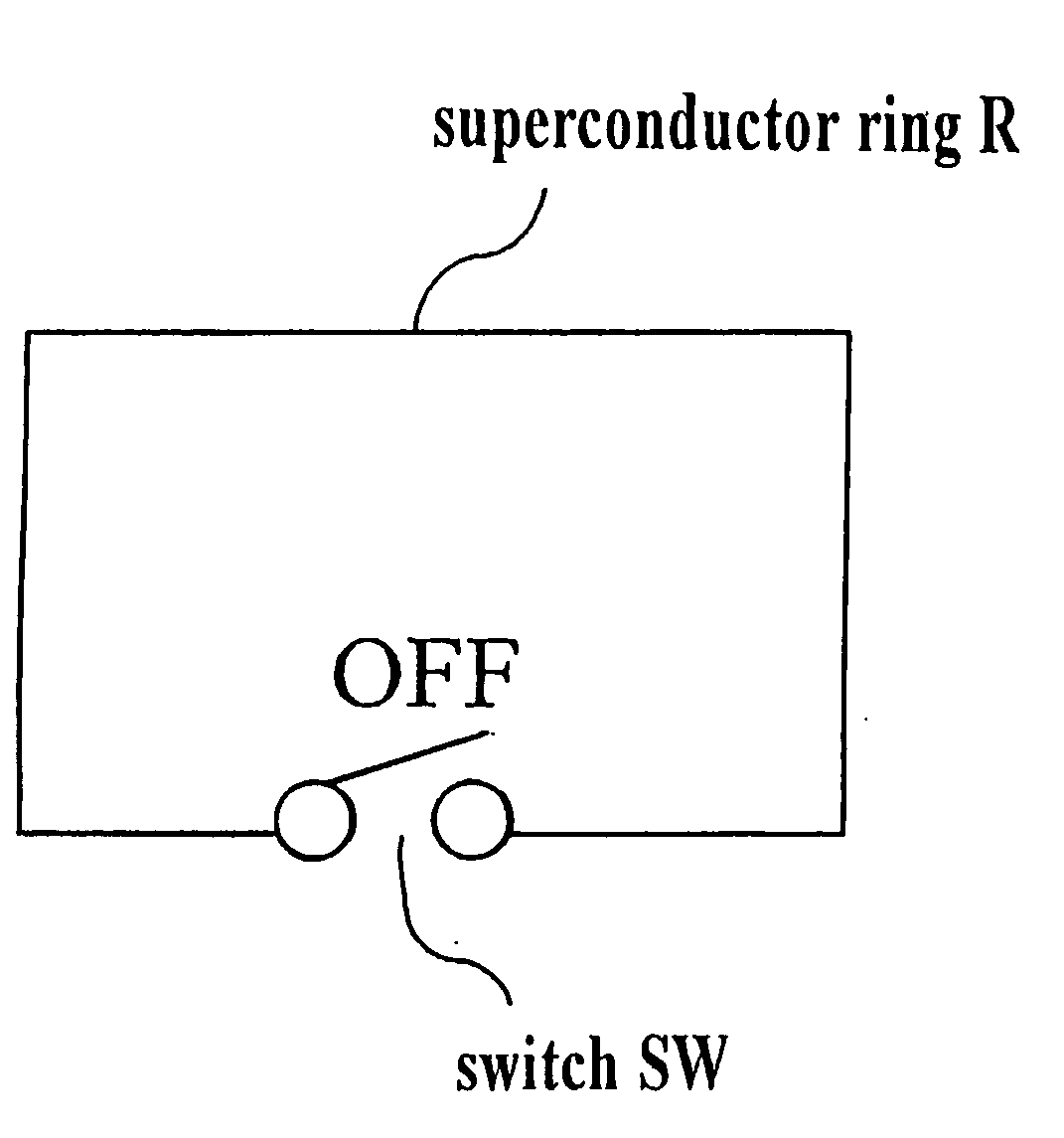

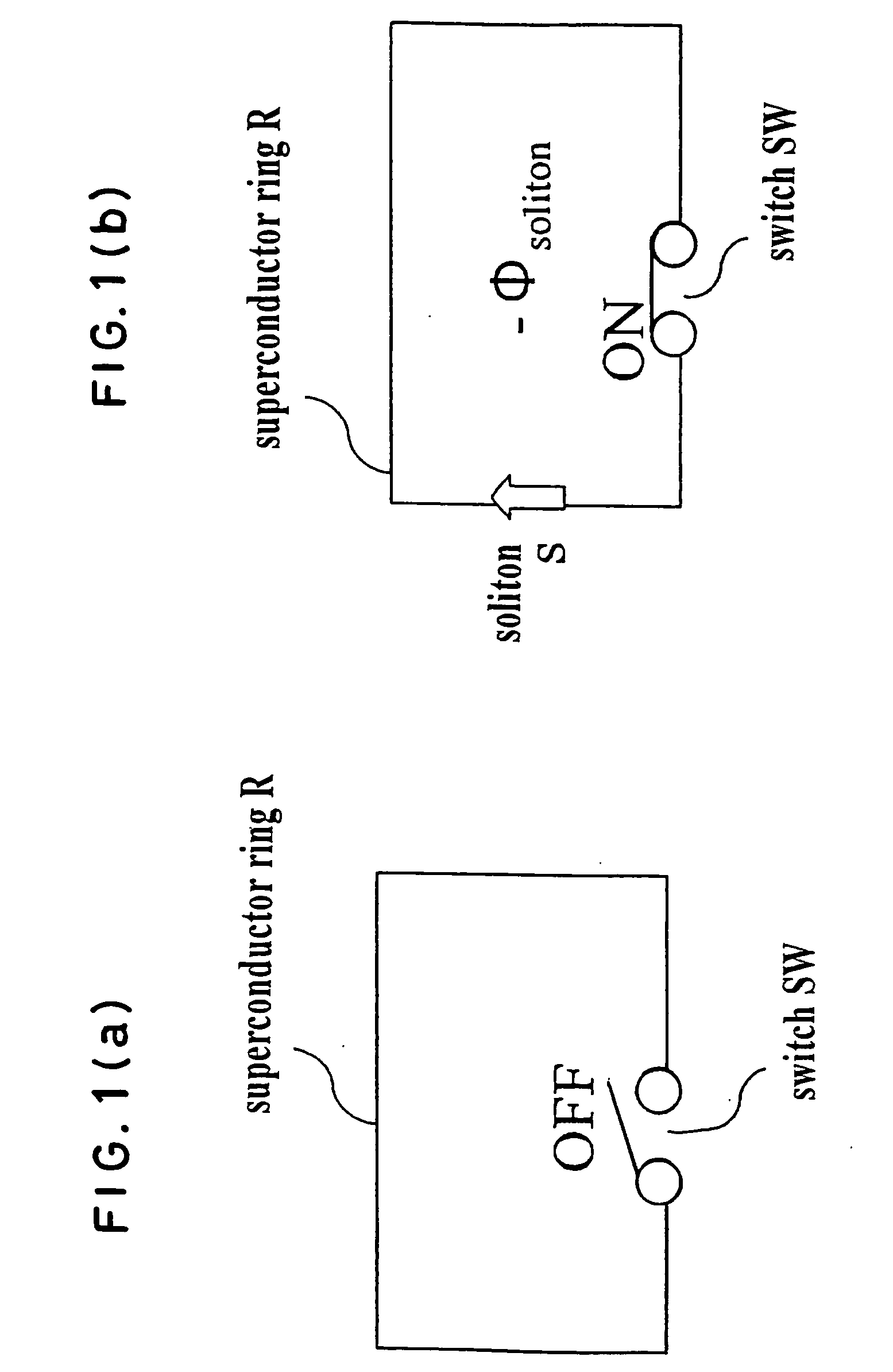

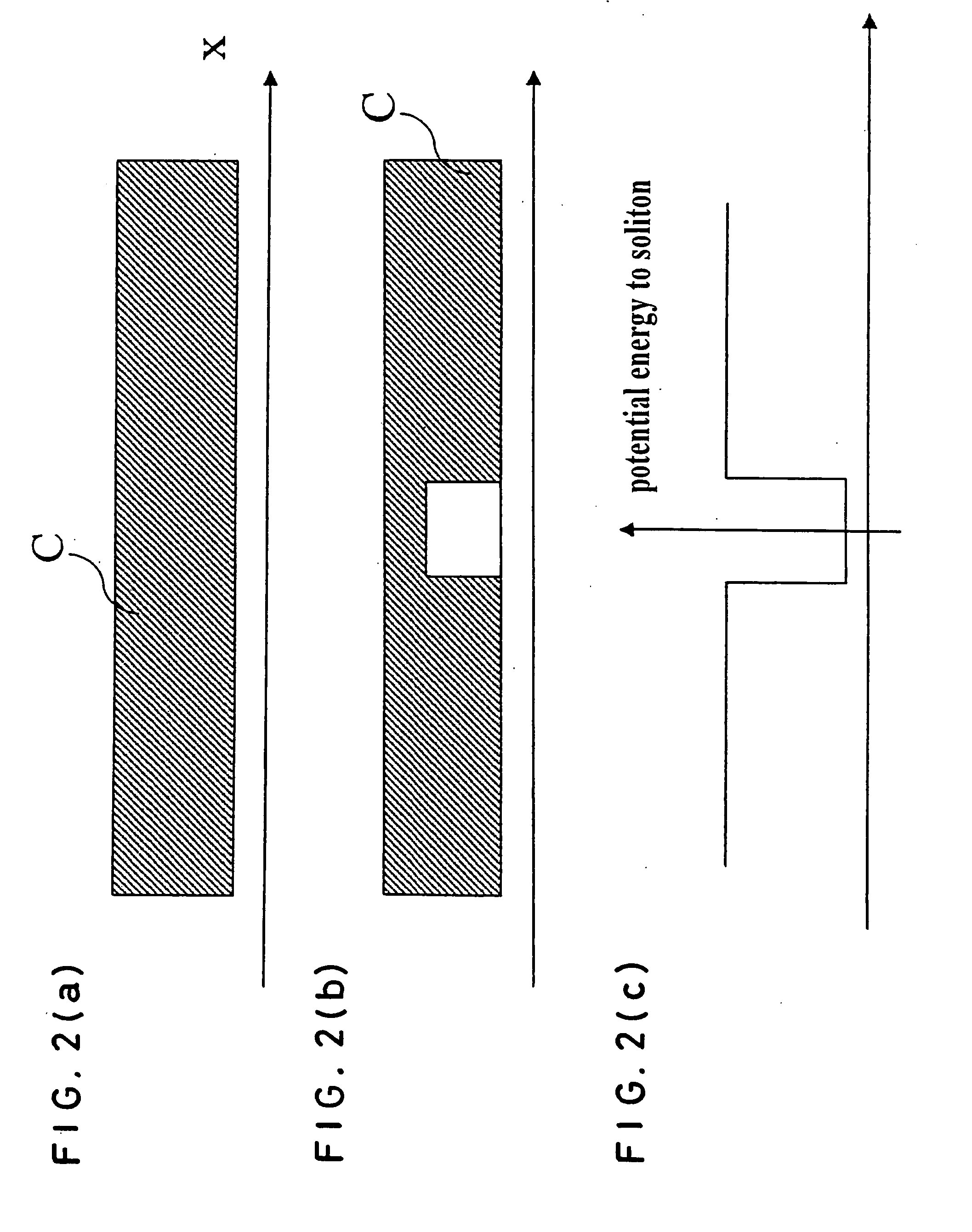

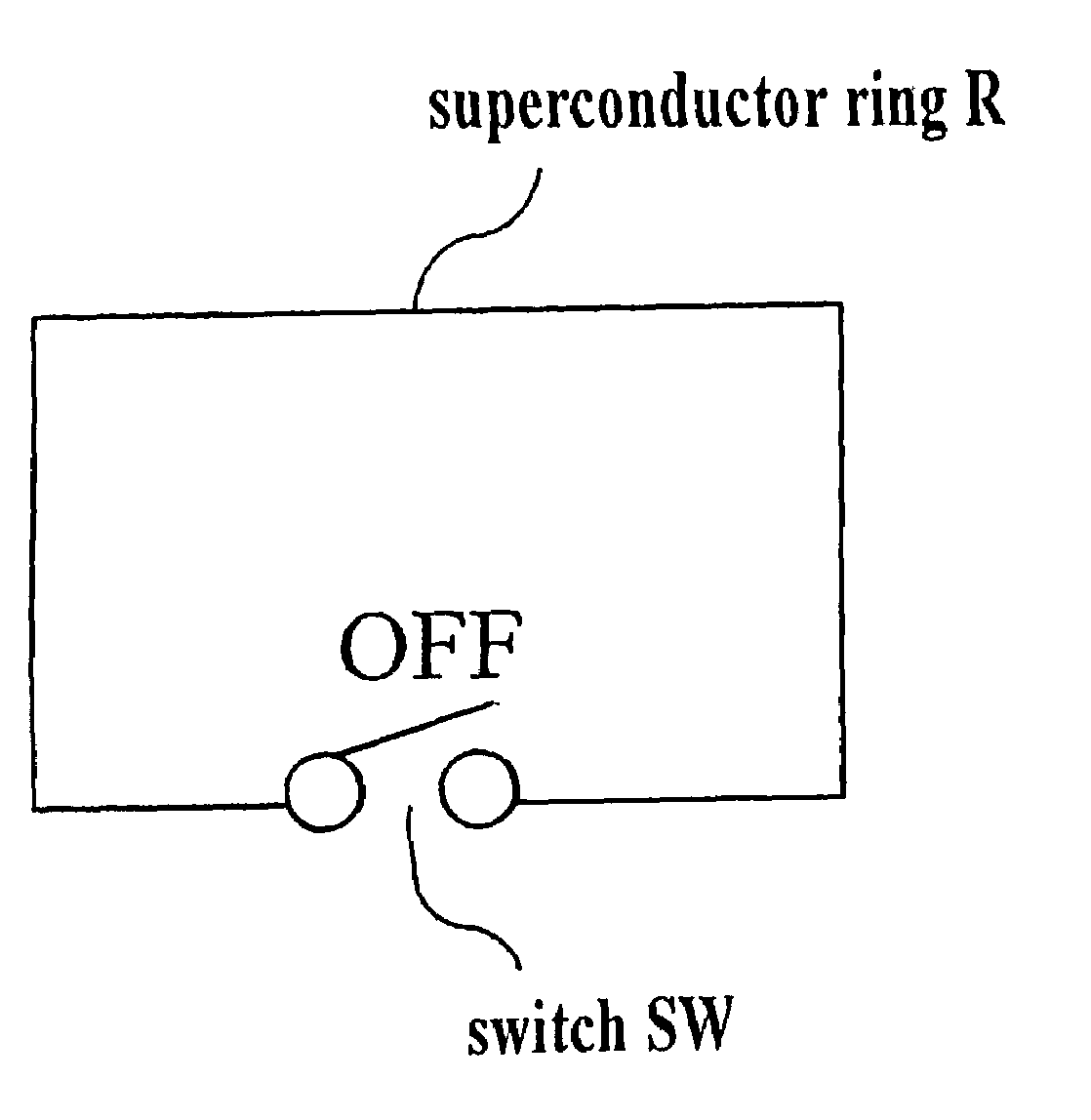

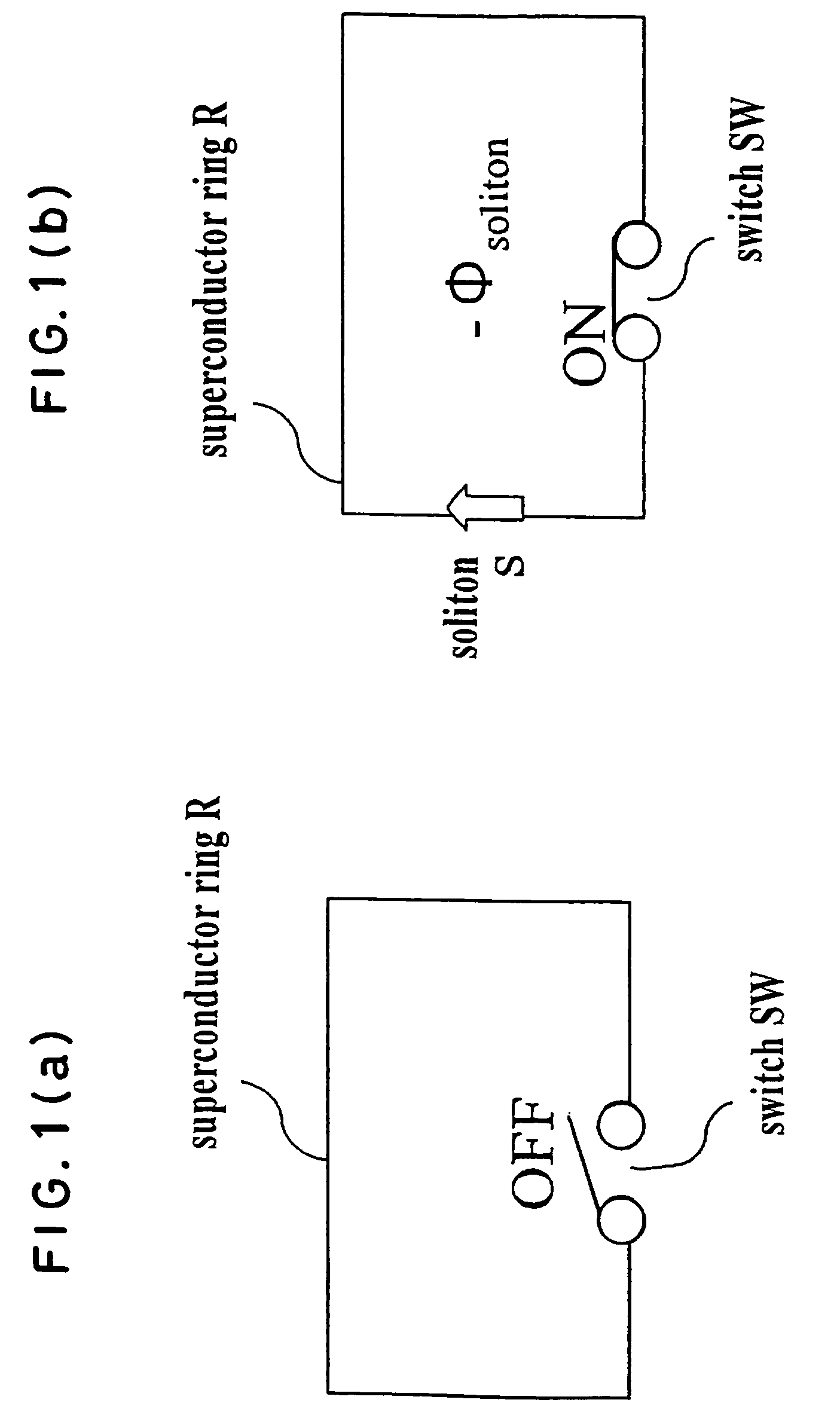

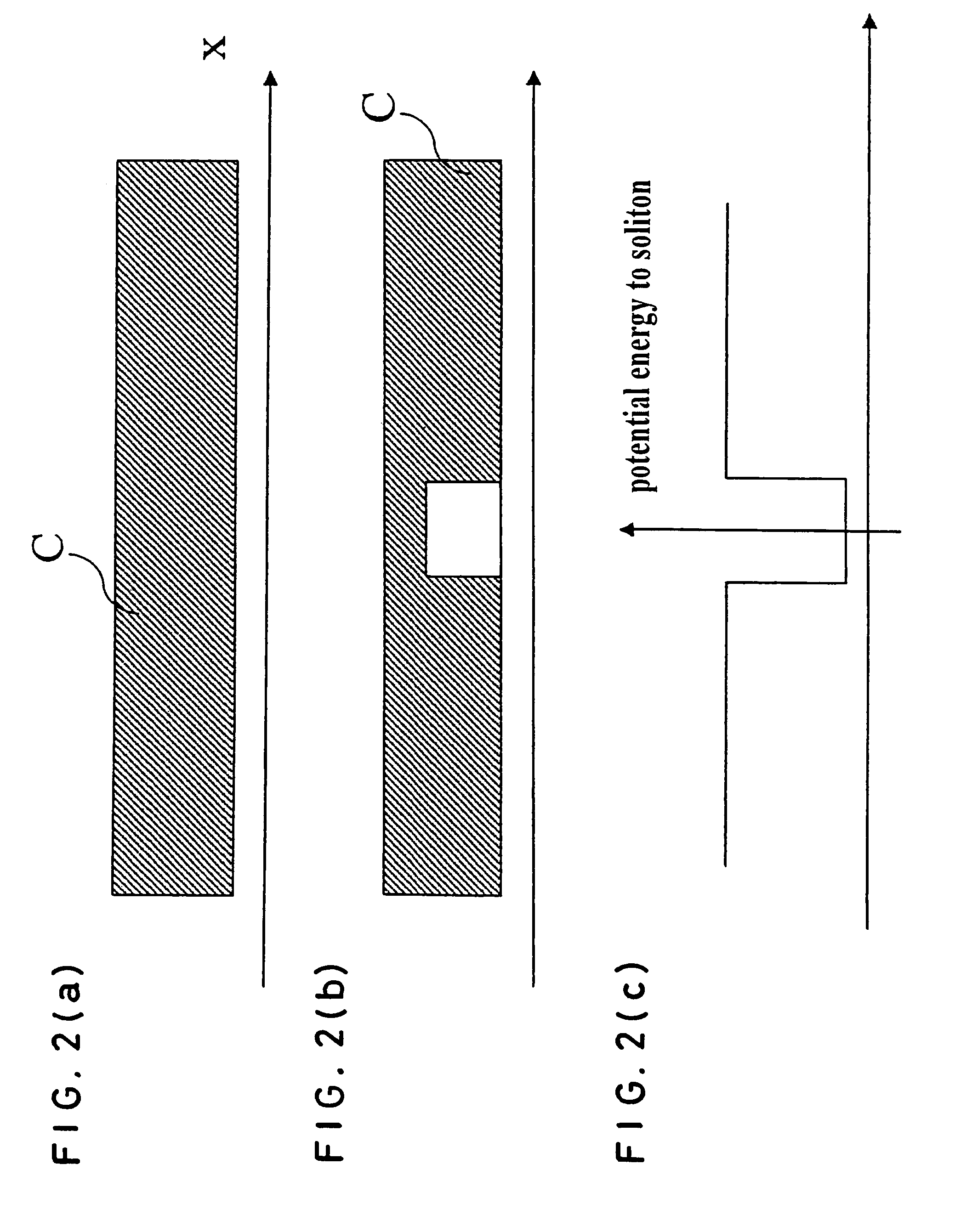

Quantum turing machine

ActiveUS7400282B2Enough timeSimple compositionAnalogue/digital conversionQuantum computersQuantum Turing machineSufficient time

A quantum Turing machine constituted using a quantum bit created by localizing a phase difference soliton S between superconducting electrons existing in each of multiple of bands in a ring R0 that includes a ring main body R1 formed of a superconductor, and well-shaped portions W1, W2 formed with a reduced line-width at at least two positions on the ring main body R1, can easily constitute a quantum bit, can surely execute a basic logical operation, has multiple-bit capability and, moreover, can ensure sufficient time for executing a quantum algorithm.

Owner:NAT INST OF ADVANCED IND SCI & TECH

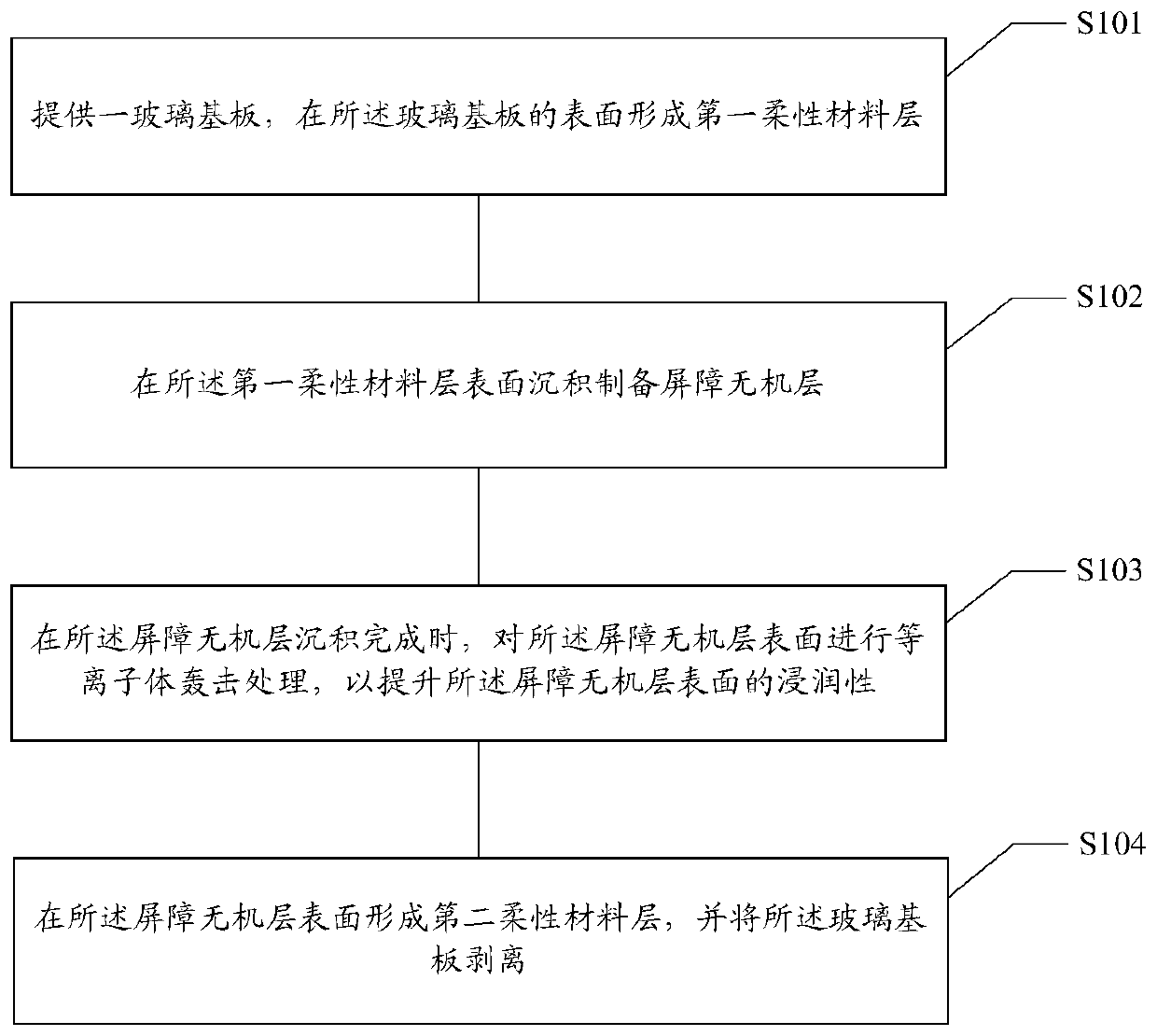

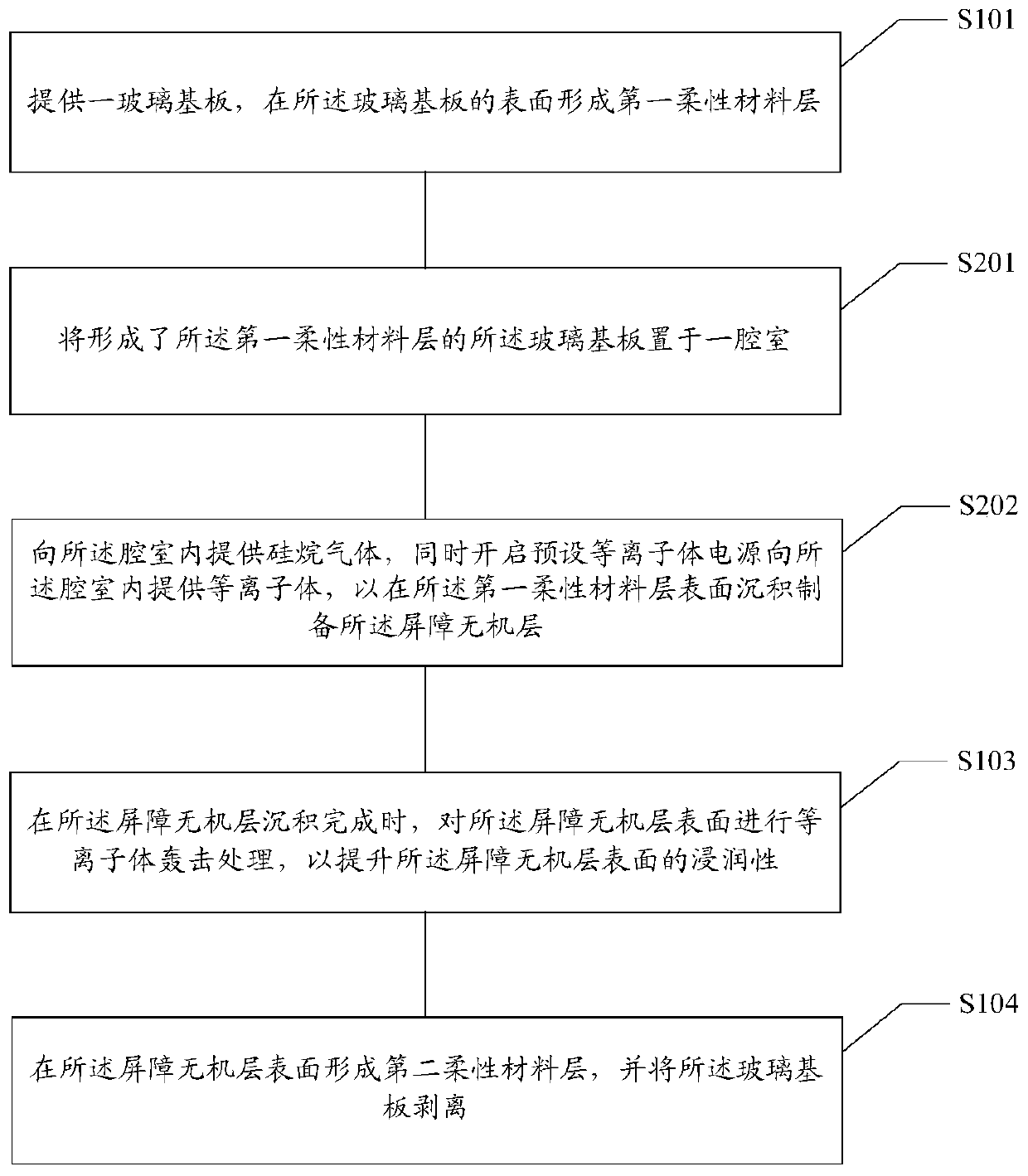

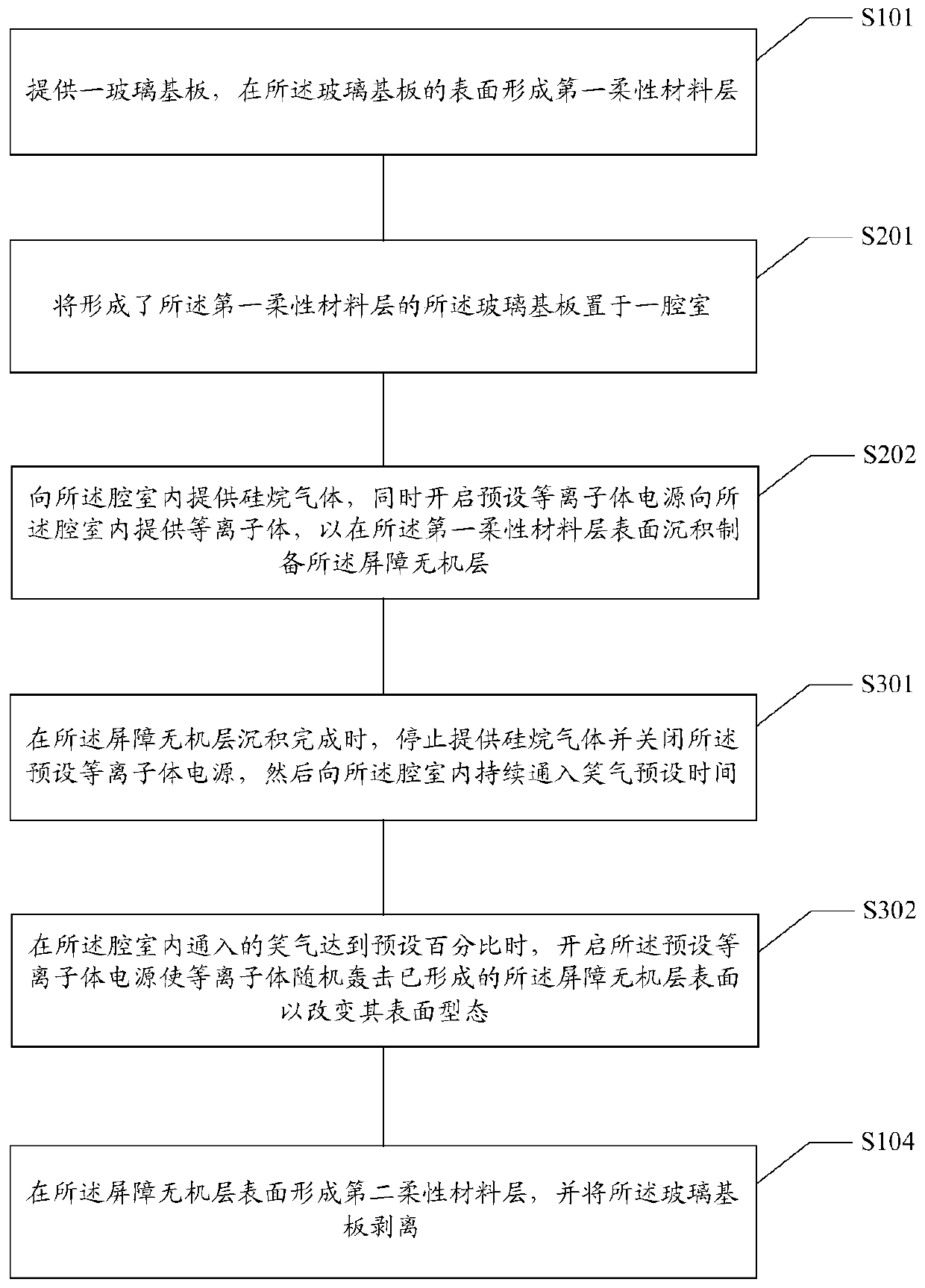

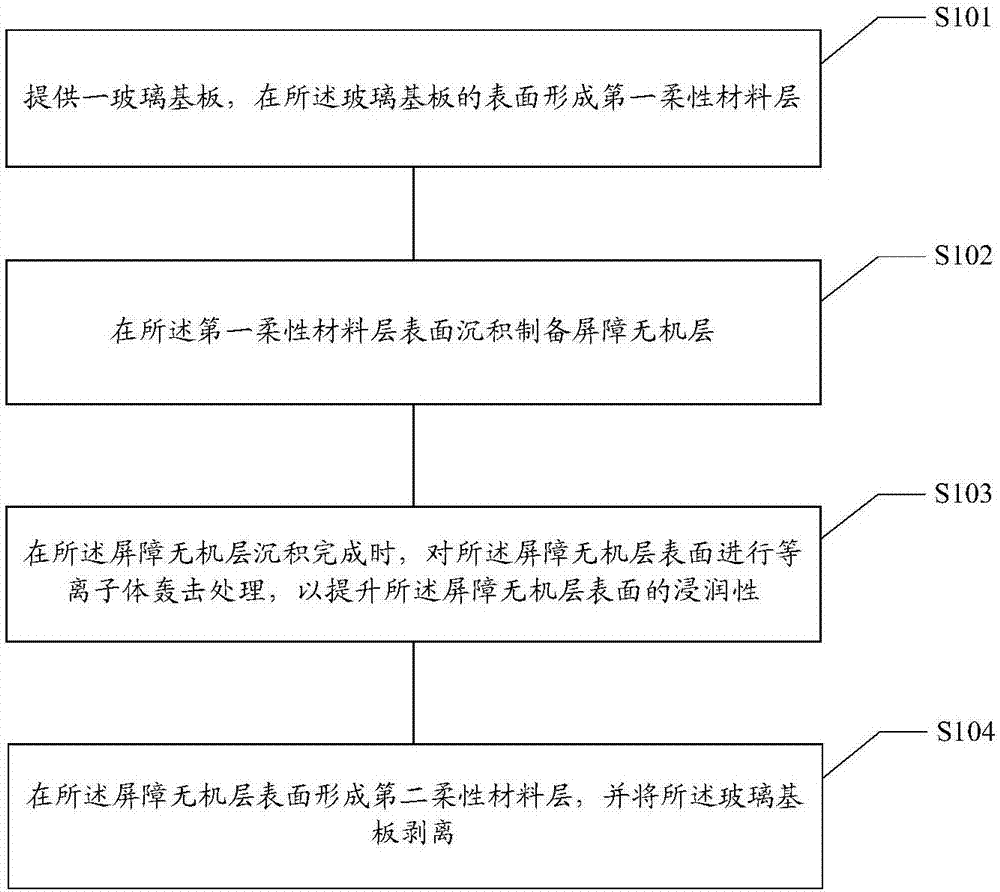

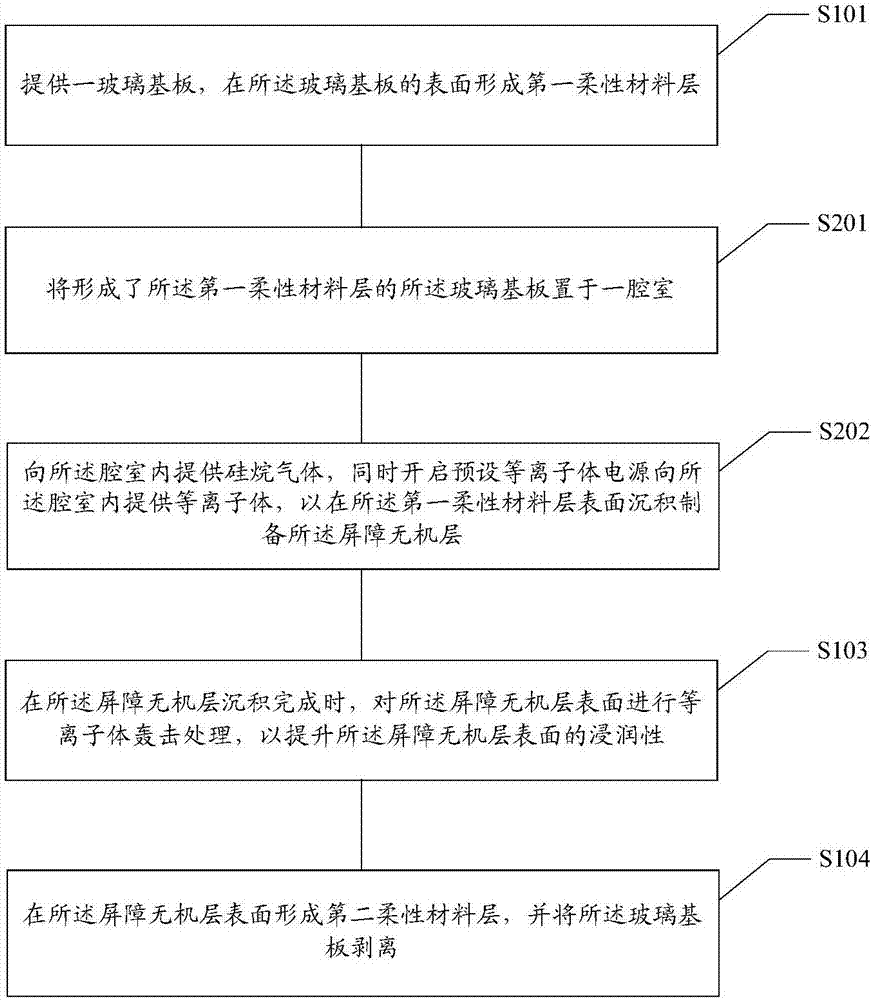

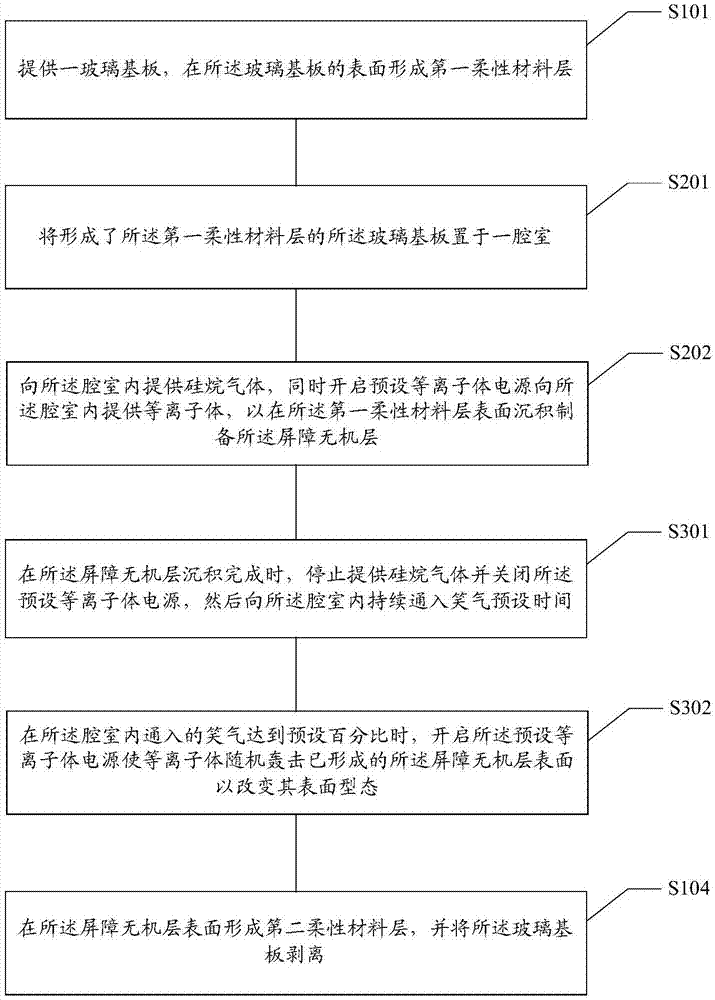

Manufacturing method of flexible substrate, flexible substrate and flexible display panel

ActiveCN107393859ASimple preparation techniqueOptimize the preparation technology to realize the entire flexible substrate processSolid-state devicesSemiconductor/solid-state device manufacturingSilicon oxideFlexible display

The invention belongs to the field of display panels, and specifically relates to a manufacturing method of a flexible substrate, the flexible substrate and a flexible display panel. The manufacturing method comprises: providing a glass substrate, and forming a first flexible material layer on the surface of the glass substrate; depositing a barrier inorganic layer on the surface of the first flexible material layer, wherein the barrier inorganic layer comprises at least one of a silicon oxide material layer and a silicon nitride material layer; when the barrier inorganic layer is deposited, performing plasma bombardment on the surface of the barrier inorganic layer to improve the wettability of the surface of the barrier inorganic layer; forming a second flexible material layer on the surface of the barrier inorganic layer, and peeling the glass substrate. The method can ensure that the second flexible material layer is well attached to the barrier inorganic layer to form a film, does not need to additionally deposit an interface inorganic layer to solve the problems of poor interface attachment and the like, and is simple and low in cost.

Owner:BOE TECH GRP CO LTD

Purge apparatus and load port

ActiveUS9508579B2The process is simple and smoothImprove air tightnessDucting arrangementsLighting and heating apparatusNozzle

A purge apparatus for replacing a gas atmosphere in a purge object vessel by a purge gas through a port provided on a bottom face of the purge object vessel is disclosed. The purge apparatus includes a purge unit attached to a table that receives the purge object vessel, and a purge nozzle body including a port contacting portion provided on an upper side of the purge nozzle body and an attachment object portion provided on a lower side of the purge nozzle body. The purge unit has an attachment portion and the port contacting portion of the purge nozzle body is configured to contact the port of the purge object vessel. The attachment object portion of the purge nozzle body removably engages with the attachment portion of the purge unit so that the purge nozzle body is removably attached to the purge unit.

Owner:SINFONIA TECHNOLOGY CO LTD

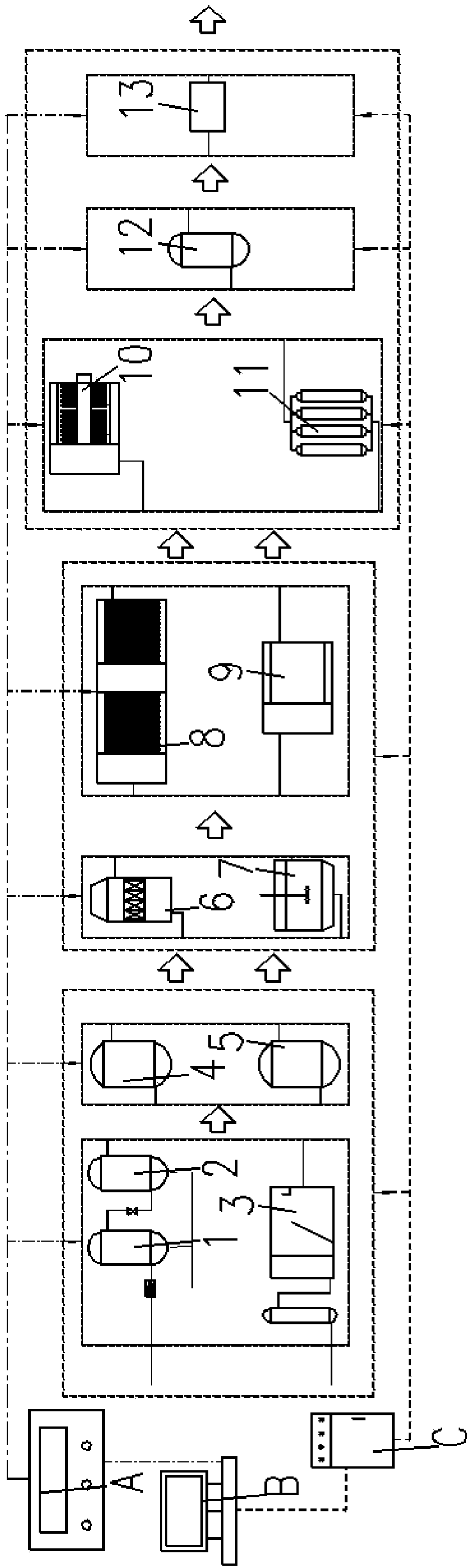

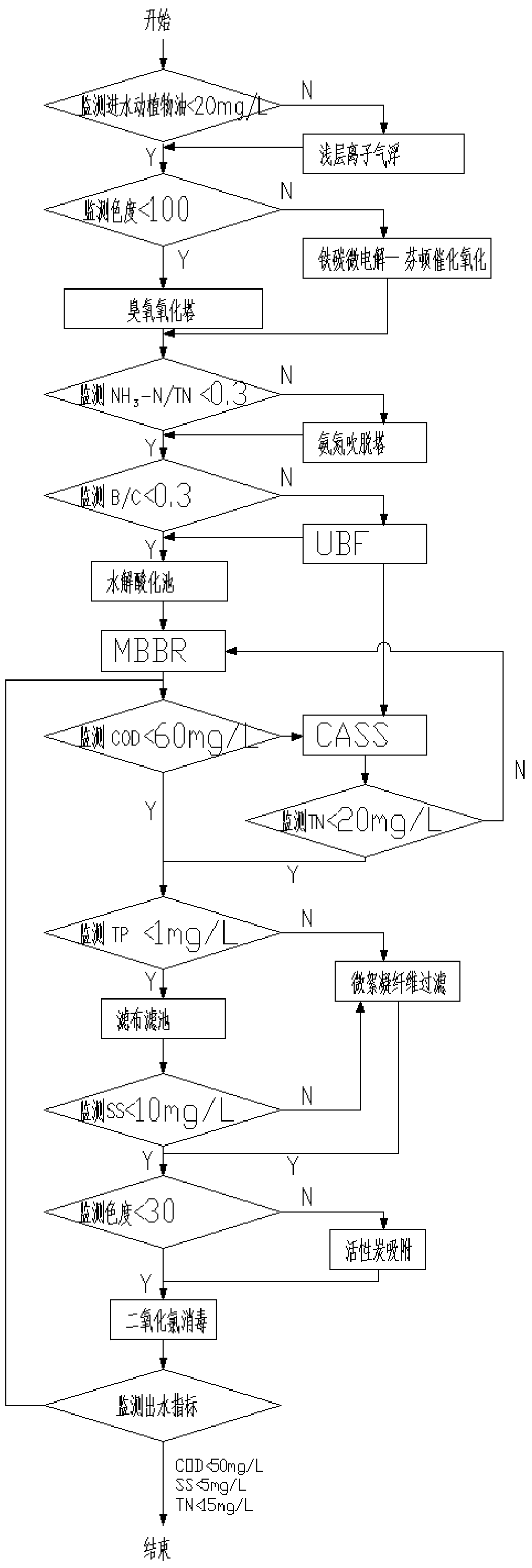

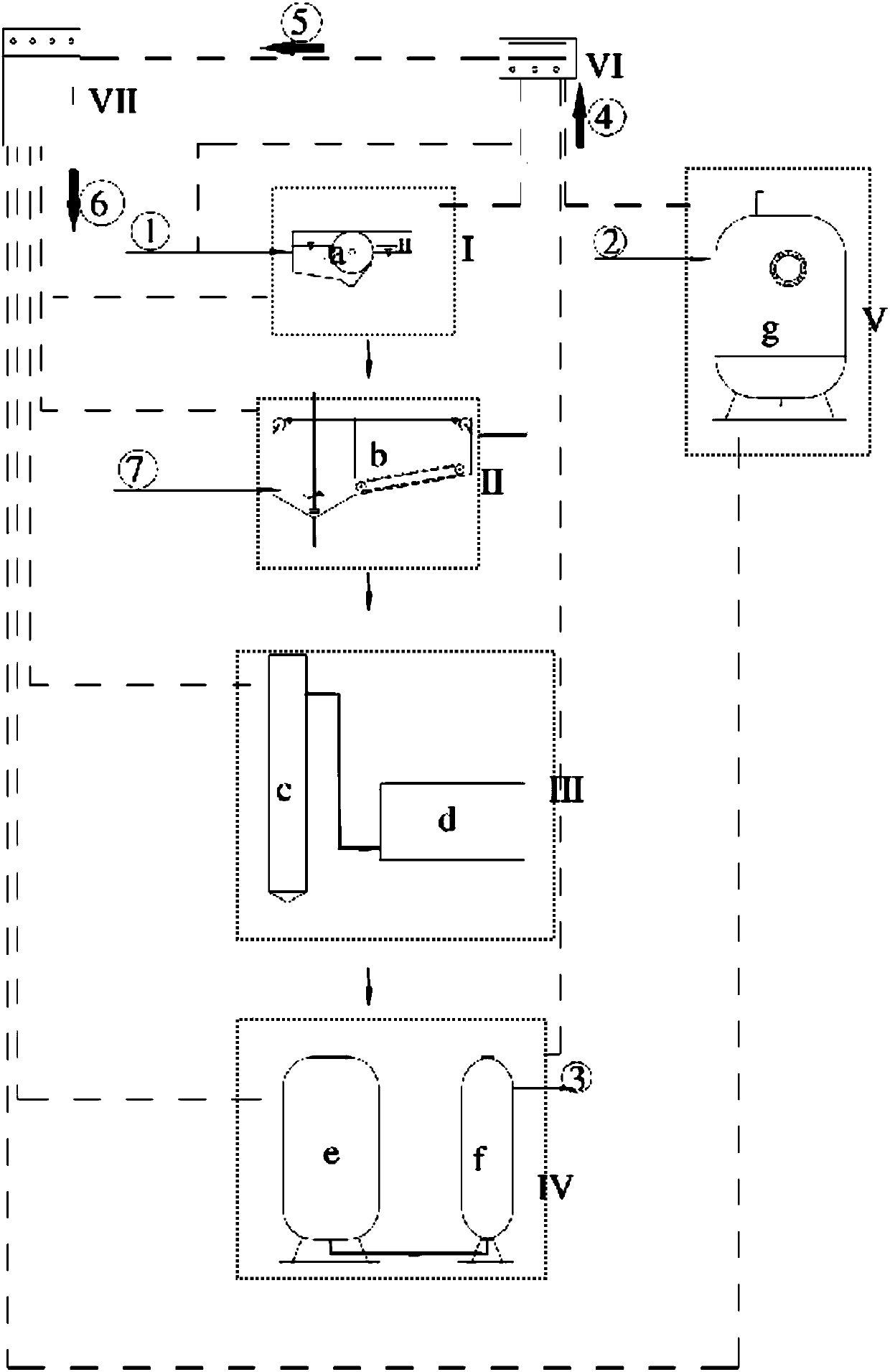

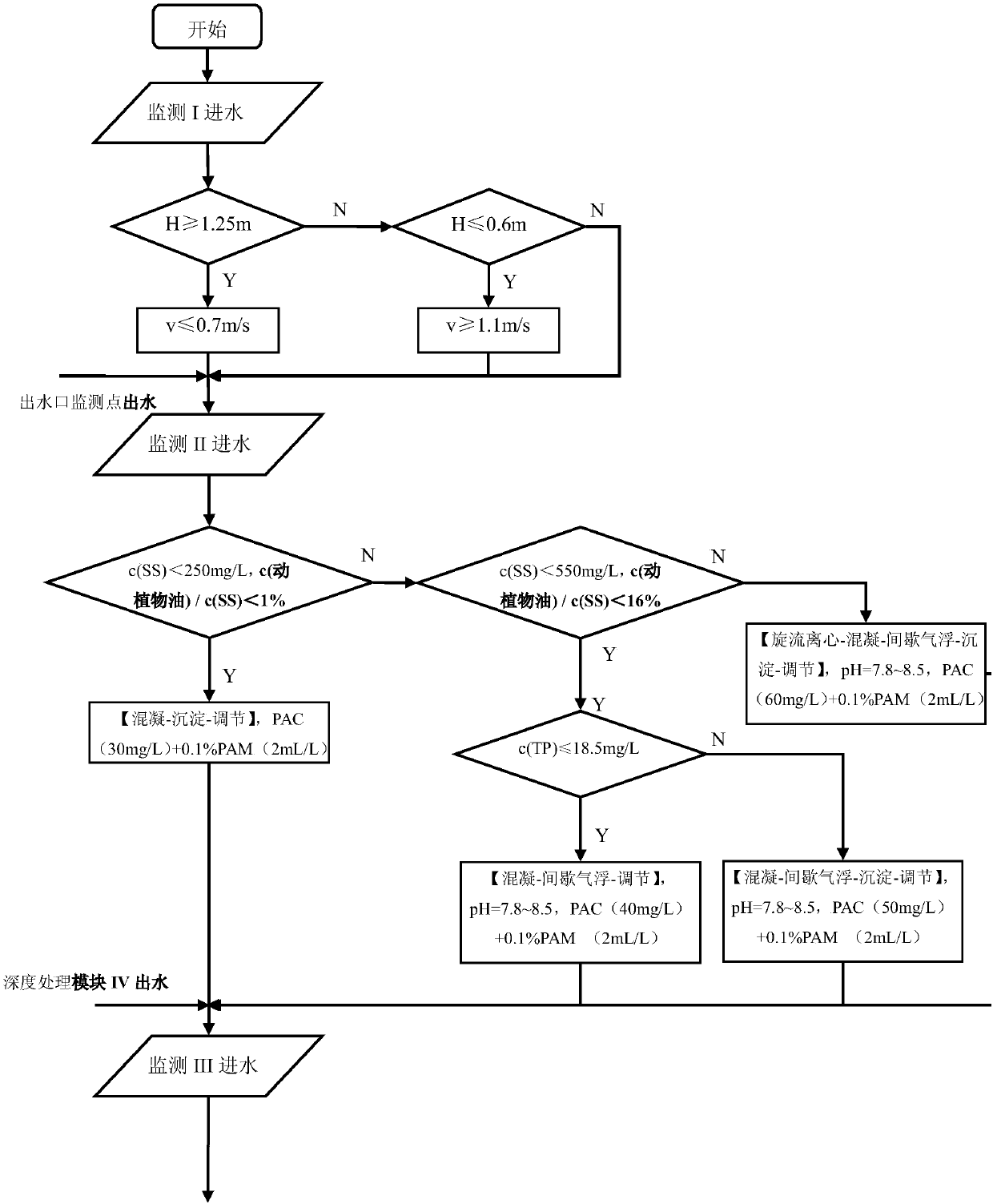

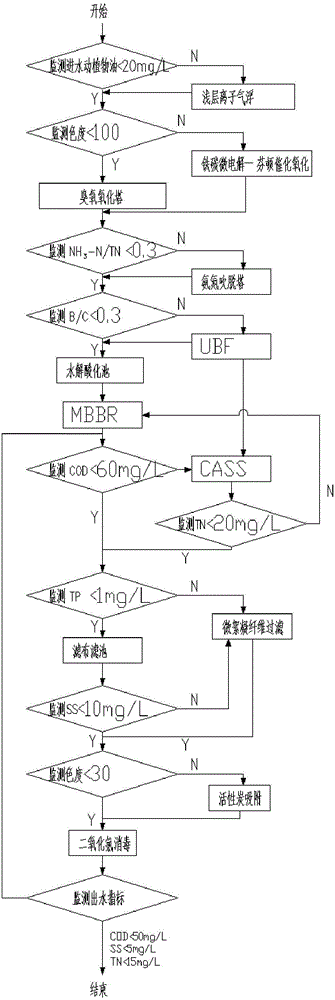

Modular integration process method for kitchen waste filtrate

InactiveCN106430806ALarge fluctuationsHigh degree of modularityWater treatment parameter controlWater treatment compoundsChain scissionFenton reagent

The invention discloses a modular integration process method for kitchen waste filtrate and belongs to the technical field of water treatment. Wastewater is monitored by a water quality monitoring module, a computer controls a PLC self-control system to control the wastewater to enter a primary or secondary physico-chemical module alternatively, and the wastewater is treated by anaerobic and aerobic biochemical modules and a deep treatment module. The modular integration process method is applicable to miniaturized, rapid and dispersed treatment of high-salt, high-COD, high-colority and great-fluctuation kitchen waste filtrate; the process method has high integration, intelligence and modularization degree and facilitates transformation from a technology to integrated equipment and space is saved; the process is manure and reliable and can be used for treating oil, nitrogen and phosphorus simultaneously to stably meet the standard, and effluent can be recycled; the adopted microelectrolysis method and a Fenton reagent strengthening process integrates oxidoreduction, flocculation, adsorption, catalytic oxidation, electrolytic deposition, codeposition and the like, chain scission of macromolecular organic pollutants can be realized, and refractory organic matter can be further removed.

Owner:吉林省零点环境科技有限公司

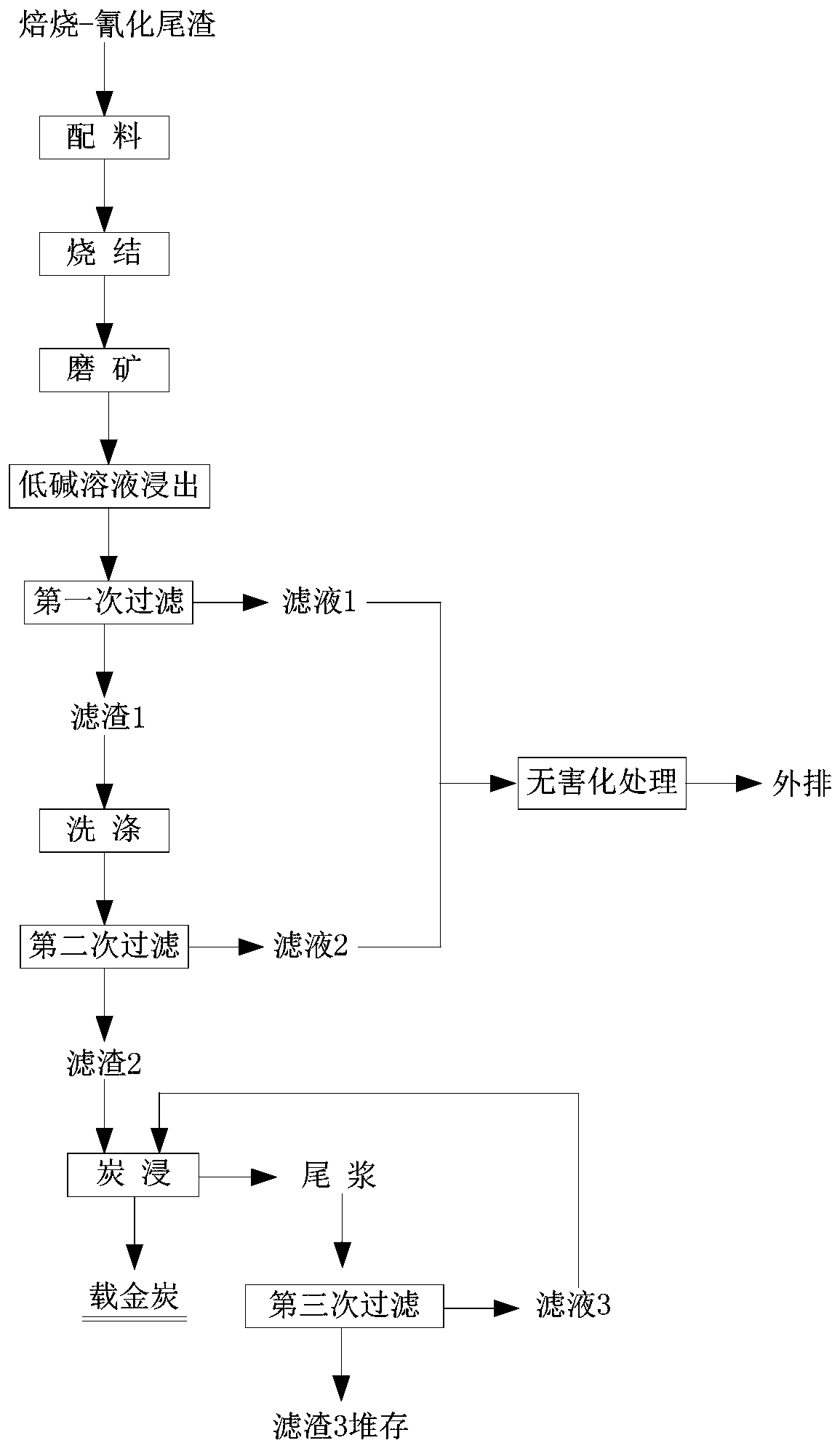

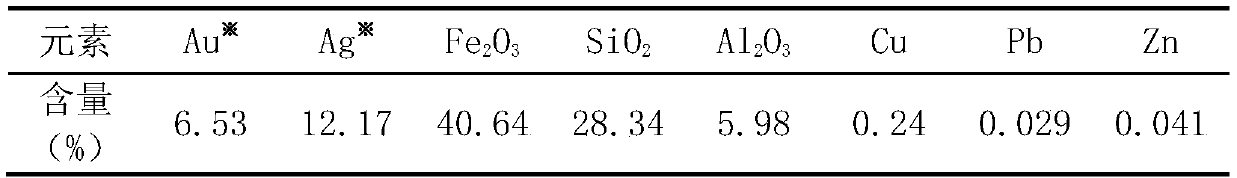

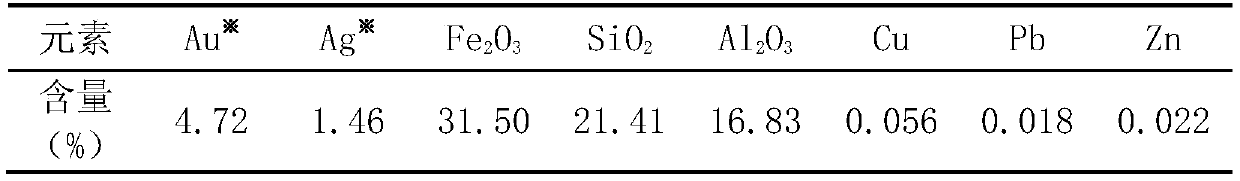

Method for recovering gold from roasting-cyaniding tailings

ActiveCN111100995AEfficient recyclingThe process is simple and smoothProcess efficiency improvementActivated carbonSodium cyanide

The invention relates to a method for recovering gold from roasting-cyaniding tailings. The method comprises the following steps that proportioning is carried out, wherein sodium salt is added into the roasting-cyaniding tailings according to the standard that the ratio of Na2O to (Fe2O3+Al2O3+SiO2) is 1-1.5:1, uniformly mixing is carried out to obtain a mixture, and then water is added to blend the mixture into a mud block material; sintering is carried out, wherein the mud block material is fed into a high-temperature furnace for sintering to obtain sintered clinker; leaching in a low-alkalisolution is carried out, wherein the clinker is finely ground, leaching is carried out under the condition that the mass ratio of the low-alkali solution to the clinker is 4.5-6.5: 1, and primary filtering is carried out after the leaching reaction is finished so as to obtain filtrate 1 and filter residue 1; the filter residue is washed, wherein the filter residue 1 is fed into equipment with a mechanical stirring function, water is added for stirring and washing, and then secondary filtering is carried out to obtain filtrate 2 and filter residue 2; and cyaniding gold leaching is carried out,wherein a solution A is added to blend the filter residue 2 into ore pulp, meanwhile, the pH value is adjusted, activated carbon is added, then a sodium cyanide solution is added for conventional cyaniding gold leaching to obtain gold-loaded carbon, ternary filtering is carried out on cyanided tailing pulp to obtain filtrate 3 and filter residue 3, and the filter residue 3 is piled up. The methodhas the advantages of being simple and smooth in technological process, simple in operation, high in gold recovery rate, short in period, low in investment, environment-friendly, easy to industrialize and the like.

Owner:ZIJIN MINING GROUP

Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one

ActiveCN101417951ARich sourcesReduce manufacturing costOrganic compound preparationAmino compound preparationSodium bicarbonateSulfite salt

The invention discloses a preparation method of 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone, which is an intermediate for the synthesis of antiviral medicine carbonyl ring nucleoside, which is characterized in that, an aqueous solution prepared by anhydrous sodium sulfite and sodium bicarbonate is added to a reactor; the temperature is controlled between 0 to 60 DEG C; a fixed amount of methanesulfonyl chloride is added by dropping, and the temperature is maintained to react for 2 to 4 hours to prepare methyl sulfonate solution; a fixed amount of ether solvent is added to the solution, and under a temperature ranging from 10 to 60 DEG C, cyanogens chloride is added; after 4 to 6 hours reaction, cyclopentadienyl is added by dropping; the pH value of the reaction solution is controlled between 1.5 to 3 to react for 3 to 5 hours; then sodium hydroxide is used for regulating the pH value to 7 to 9; after standing, the ether solvent is separated, and a fixed amount of methyl chloride is used for separated extraction 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone; the methyl chloride is distilled and a crude product is obtained; the crude product is decolorized by activated carbon and recrystallized in ether solvent; 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone with a purity of more than 99.6 percent is obtained after drying. The preparation method has the advantages of rich raw material sources, low cost, simple technological process, small emission of three wastes, benefits for industrial production and other advantages.

Owner:JILIN PURUITE BIOTECH CO LTD

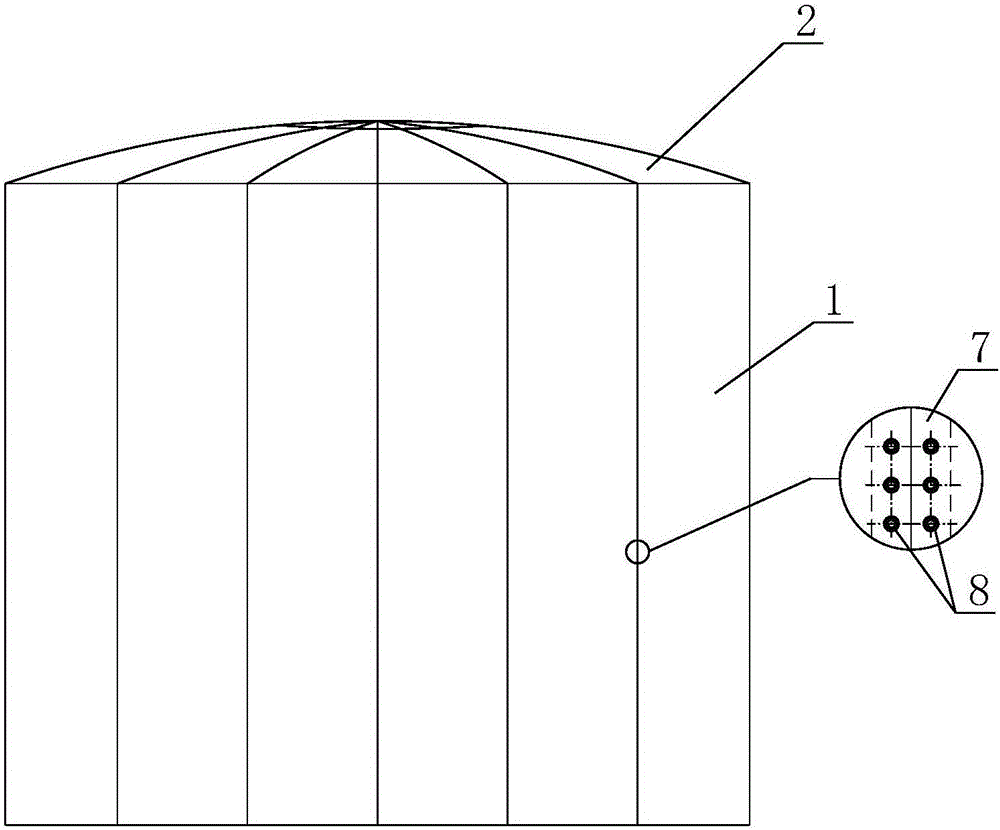

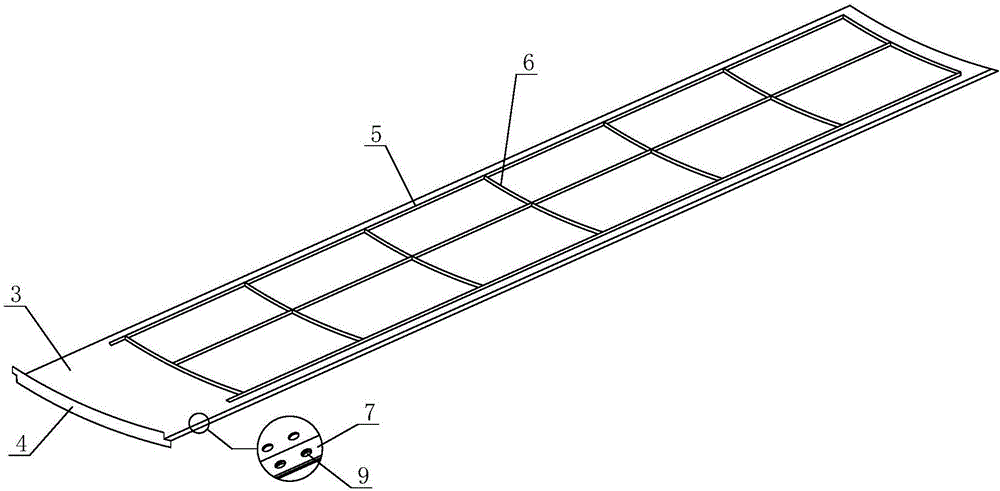

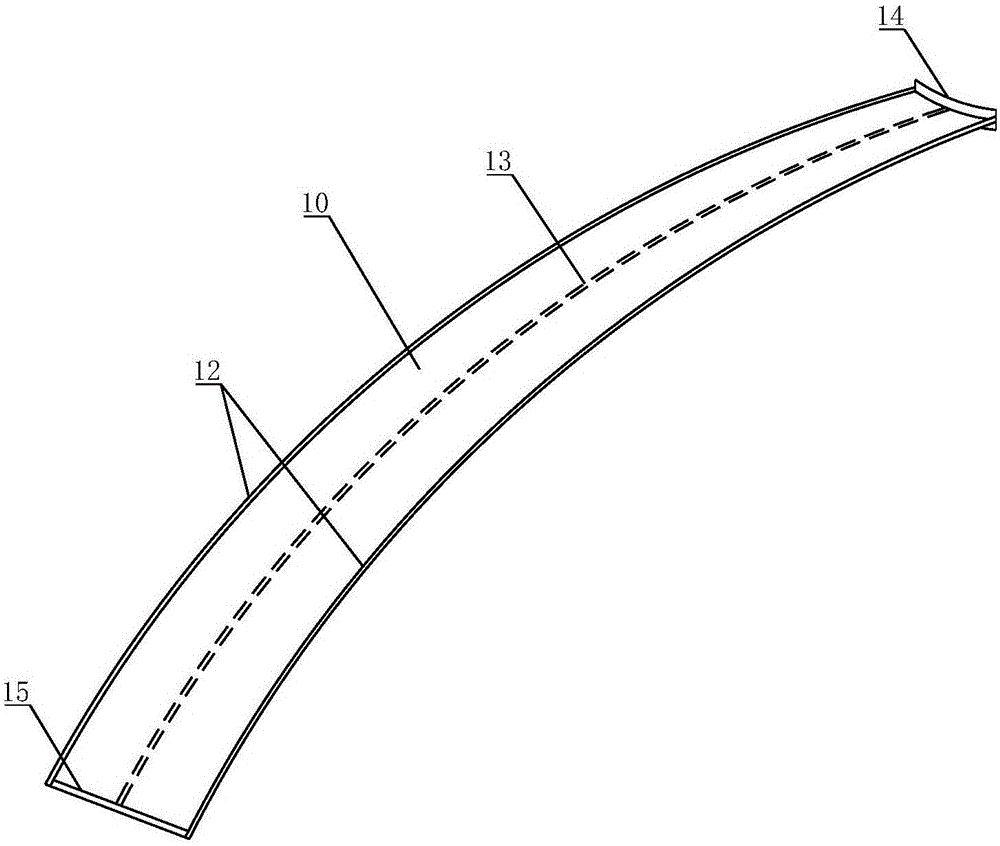

Method for making large-scale vault split mounting type asphalt storage tank

The invention relates to a method for making large-scale vault split mounting type asphalt storage tank, including a tank body making part and a tank backing deal making part, wherein the tank body making process includes: (1) blanking and shaping; (2) groove machining; (3) tank panel assembly; (4) welding; (5) drilling; (6) application; the tank backing deal making process includes: (1) blanking; (2) parts shaping; (3) assemble, preassemble, welding; (4) application. The method for the large-scale vault split mounting type asphalt storage tank, has a strict process control to the production process of the tank body and the tank backing deal, and ensures the production precision and welding quality of each other, and the qualified rate of the field installation is more than 90%.

Owner:CHINA THIRD METALLURGICAL GRP

Intelligentized high-precision visual alignment full attaching equipment

ActiveCN105751662AImprove production efficiencyThe process is simple and smoothLamination ancillary operationsLayered product treatmentManipulatorEngineering

The invention relates to intelligentized high-precision visual alignment full attaching equipment.A rack is provided with a feeding mechanism which is connected with a four-shaft attaching manipulator; the rack is further provided with a camera which is connected with a CCD visual image system, an LCM carrying alignment platform and an attaching cavity, a first X-axis carrying manipulator and a second X-axis carrying manipulator are arranged between the LCM carrying alignment platform and the attaching cavity, and the attaching cavity is fixed to a cavity support frame; the rack is further provided with a precorrection mechanism and a tray assembly, and a discharging four-shaft robot is arranged between the precorrection mechanism and the tray assembly.The intelligentized high-precision visual alignment full attaching equipment has the advantages that the productivity efficiency is improved, the technological processes are simple and smooth, robotic automation operation is completely adopted, manual operation is completely replaced, therefore, the production processes are smooth and stable, the automation degree is high, and the integral design is reasonable.

Owner:SHENZHEN CHONG SHUN TECH CO LTD

Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one

ActiveCN101417951BRich sourcesReduce manufacturing costOrganic chemistrySodium bicarbonateSulfite salt

The invention discloses a preparation method of 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone, which is an intermediate for the synthesis of antiviral medicine carbonyl ring nucleoside, which is characterized in that, an aqueous solution prepared by anhydrous sodium sulfite and sodium bicarbonate is added to a reactor; the temperature is controlled between 0 to 60 DEG C; a fixed amount of methanesulfonyl chloride is added by dropping, and the temperature is maintained to react for 2 to 4 hours to prepare methyl sulfonate solution; a fixed amount of ether solvent is added to the solution, and under a temperature ranging from 10 to 60 DEG C, cyanogens chloride is added; after 4 to 6 hours reaction, cyclopentadienyl is added by dropping; the pH value of the reaction solution is controlled between 1.5 to 3 to react for 3 to 5 hours; then sodium hydroxide is used for regulating the pH value to 7 to 9; after standing, the ether solvent is separated, and a fixed amount of methyl chloride is used for separated extraction 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone; the methyl chloride is distilled and a crude product is obtained; the crude product is decolorized by activated carbon and recrystallized in ether solvent; 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone with a purity of more than 99.6 percent is obtained after drying. The preparation method has the advantages of rich raw material sources, low cost, simple technological process, small emission of three wastes, benefits for industrial production and other advantages.

Owner:JILIN PURUITE BIOTECH CO LTD

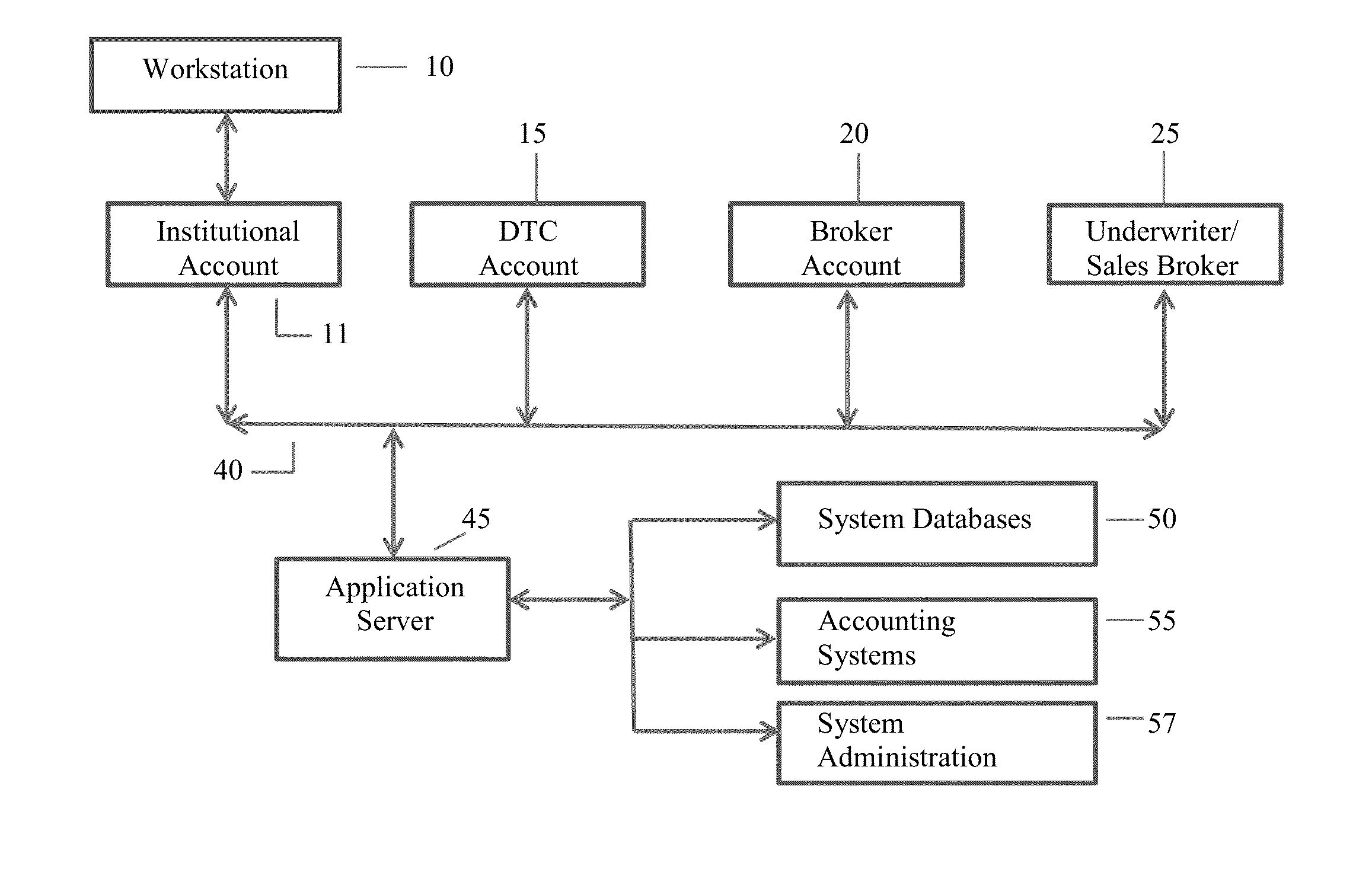

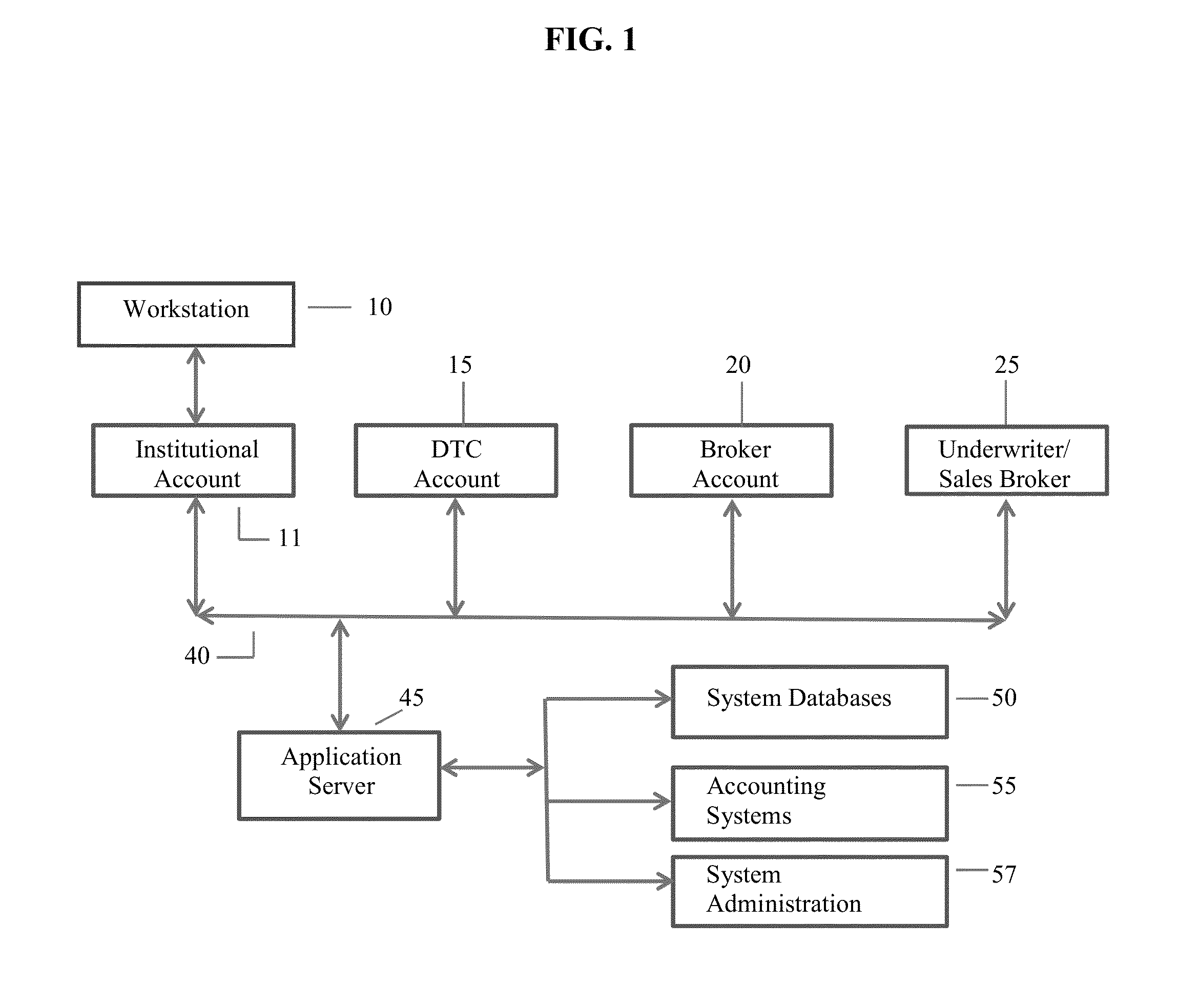

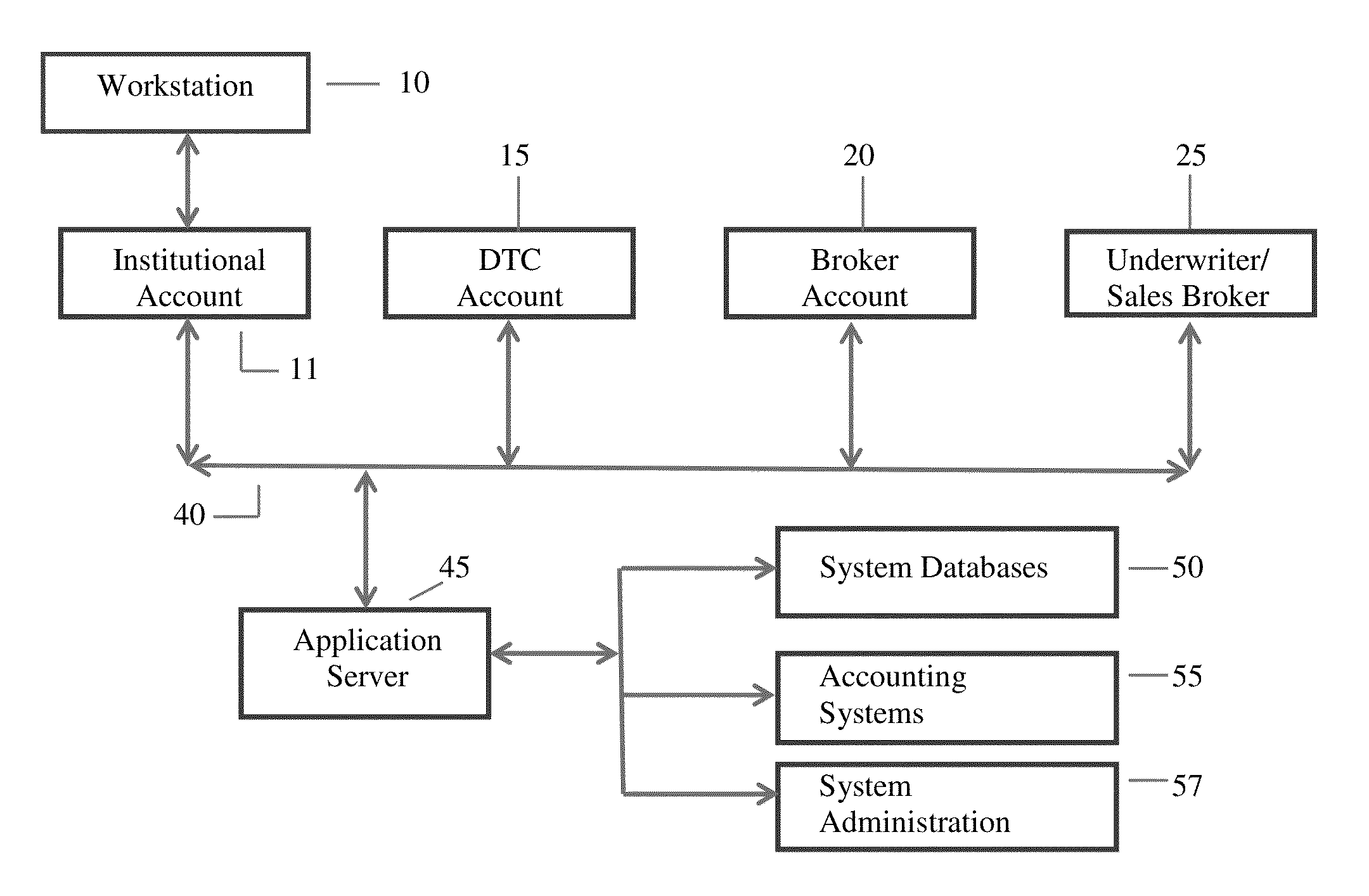

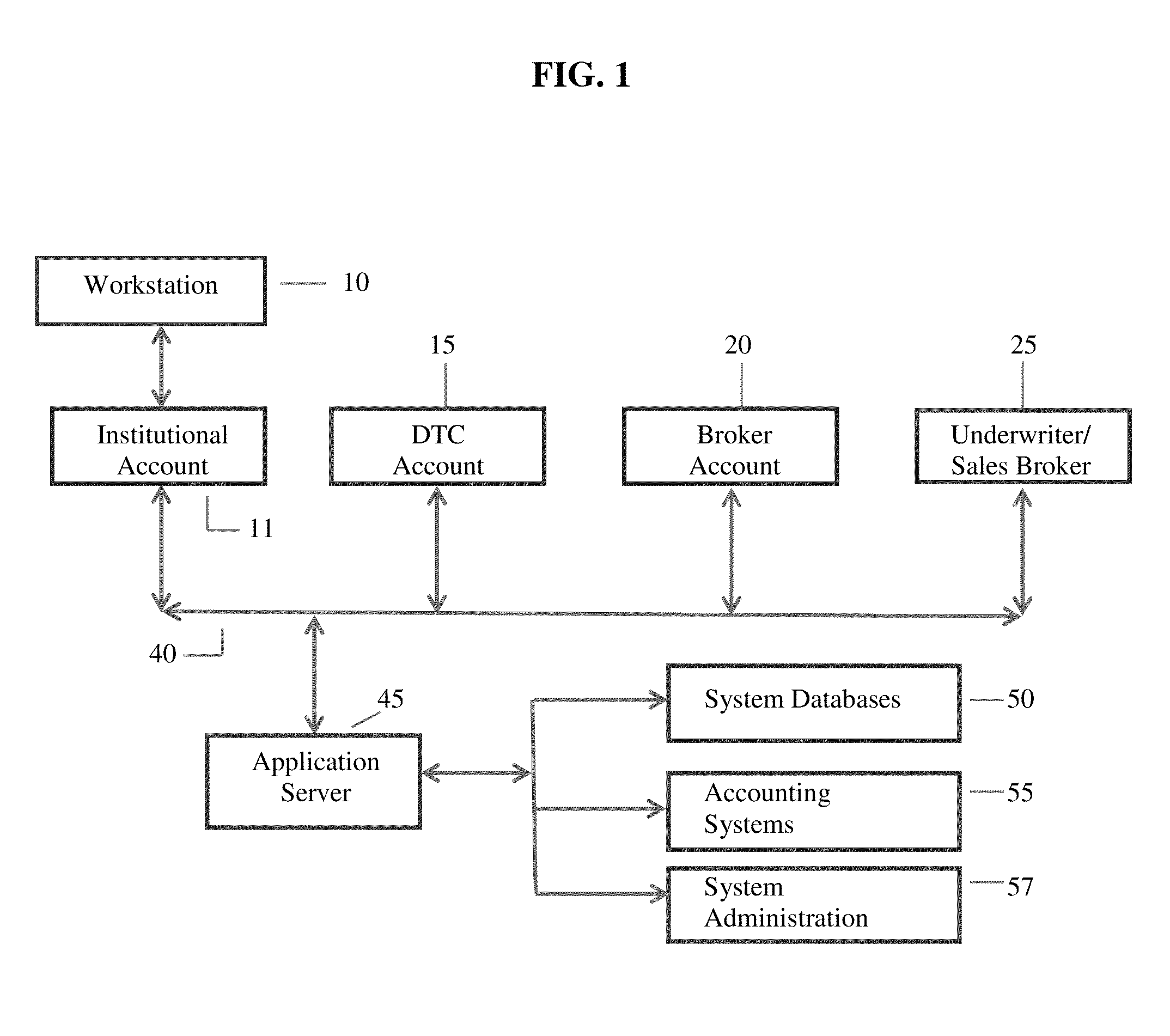

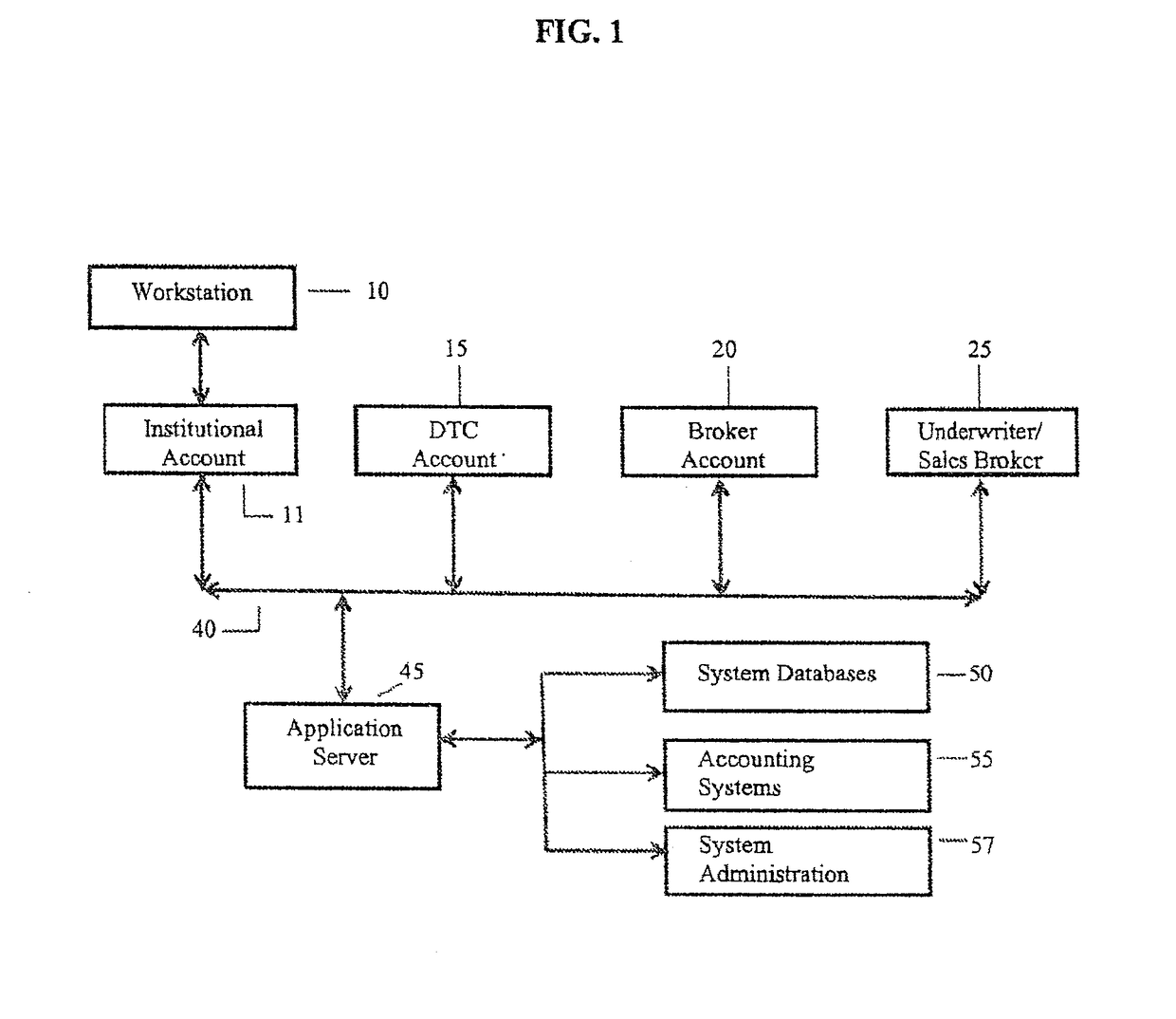

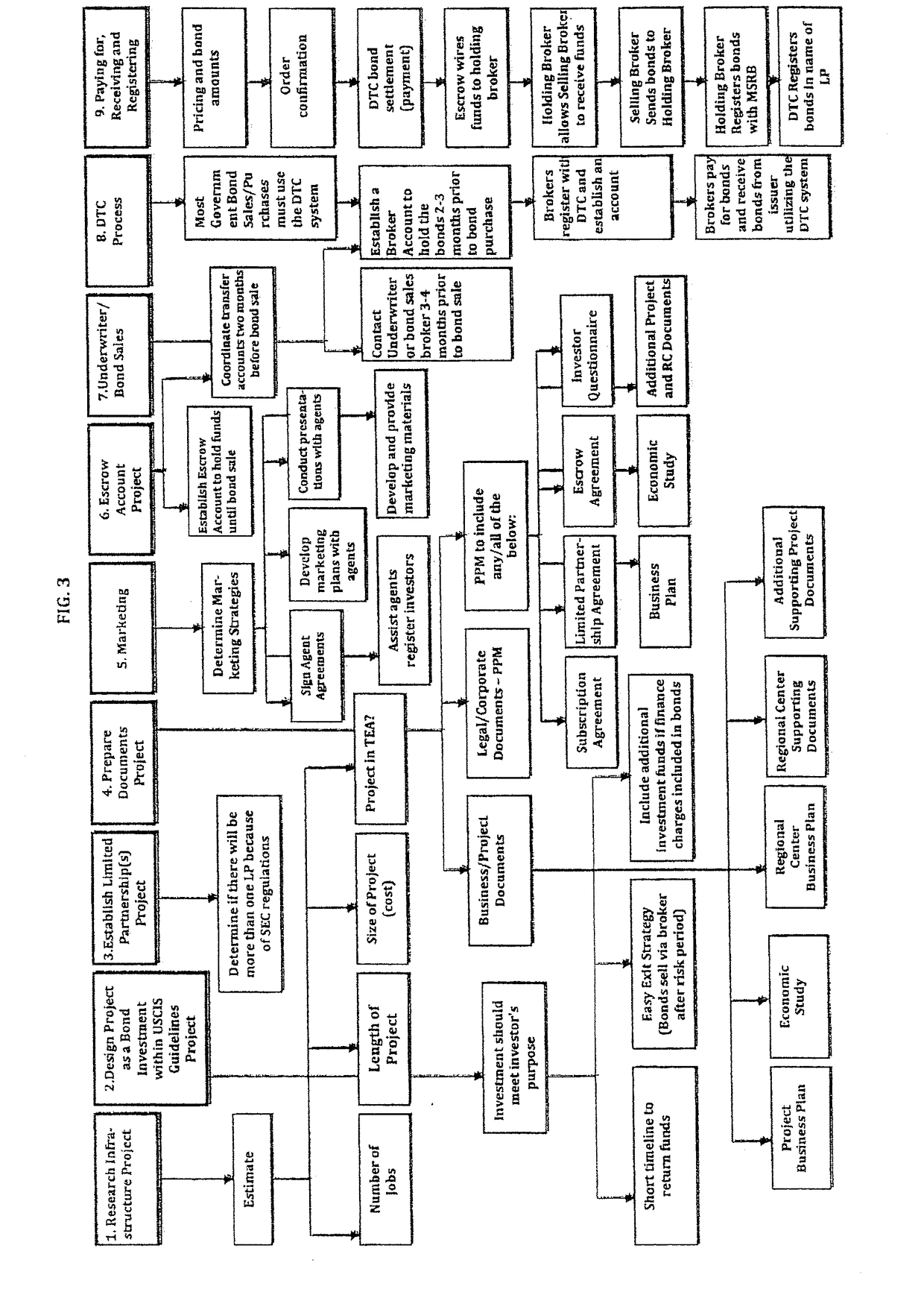

Computerized Method And System For Financing By EB-5 Investor Visa Regional Center

InactiveUS20130282613A1Facilitates taskThe process is simple and smoothFinanceProgram planningKnowledge management

A computer-implemented financed commercial economic system and method for EB-5 immigrant investor visa programs through a regional center directed to promotion of economic growth, improved economic regional productivity, job creation and increased capital investment, in which EB-5 investors by a capital investment for economic commercialization of projects and an electronic database accessible through a communications network to maintain regional center and EB-5 investor information, with an escrow account of funds from sales of products produced in by the projects, and returning of capital investments to the EB-5 investors after a pre-determined period of time with the proceeds of the escrow account.

Owner:GILLIARD WILLIAM M +7

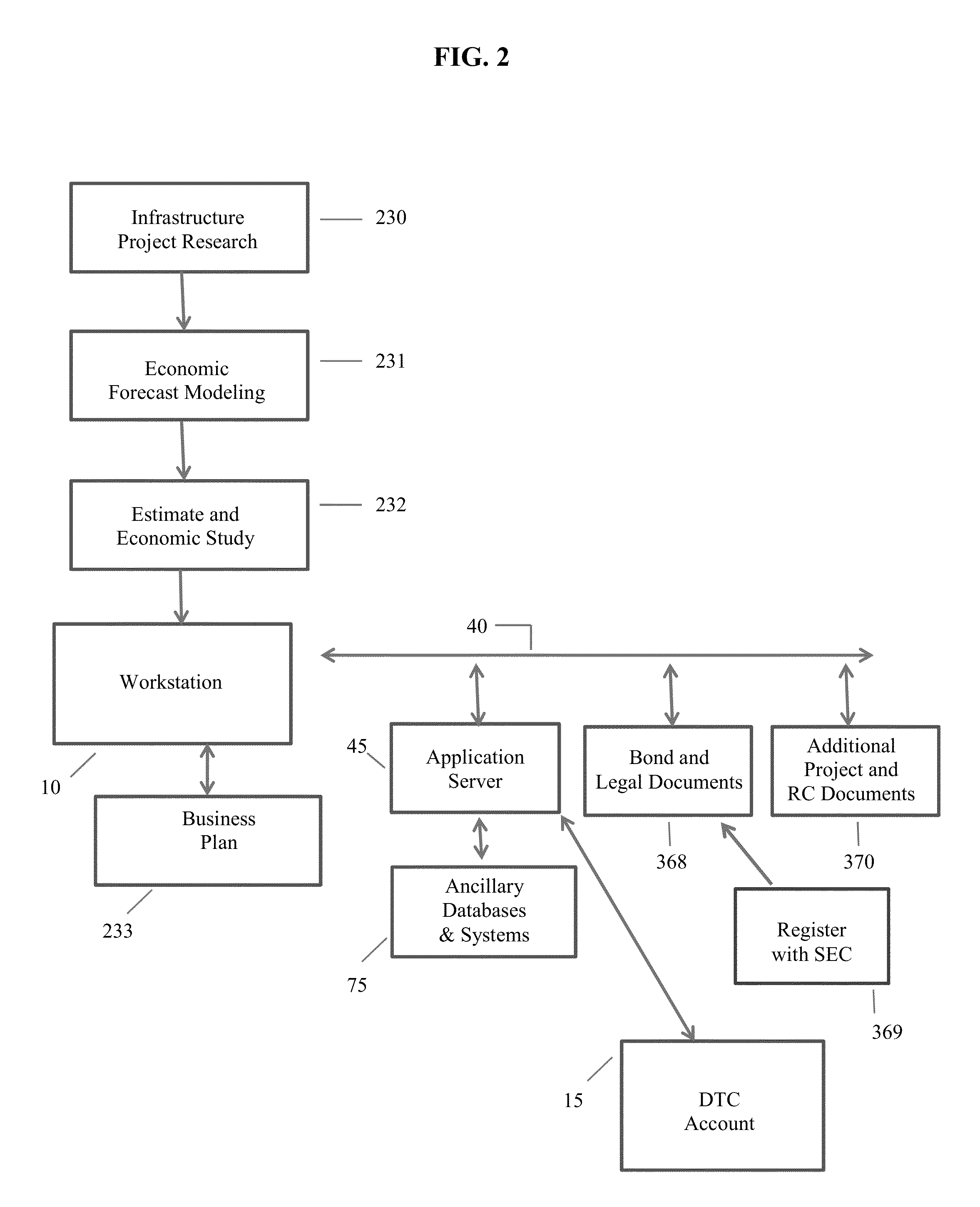

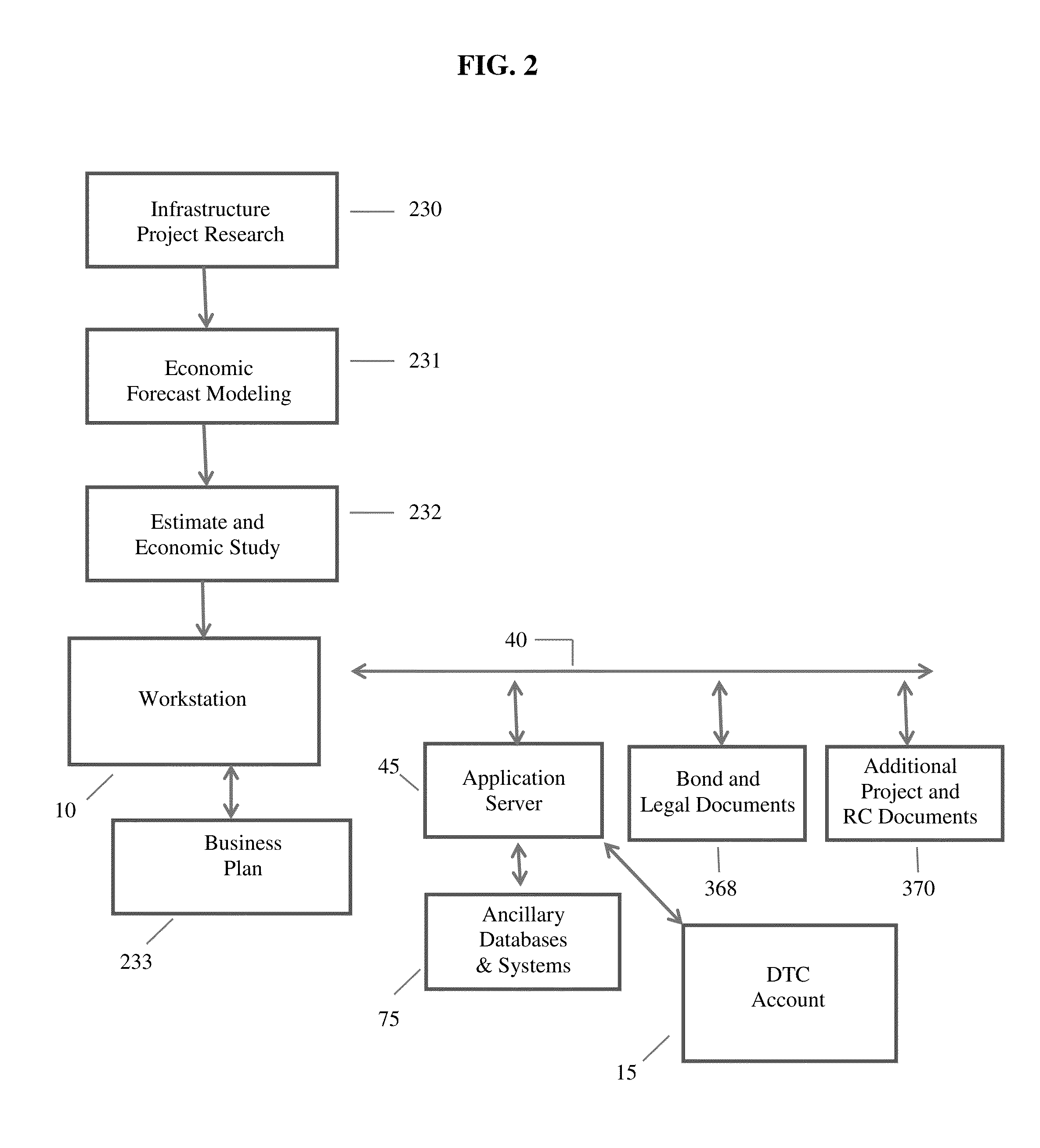

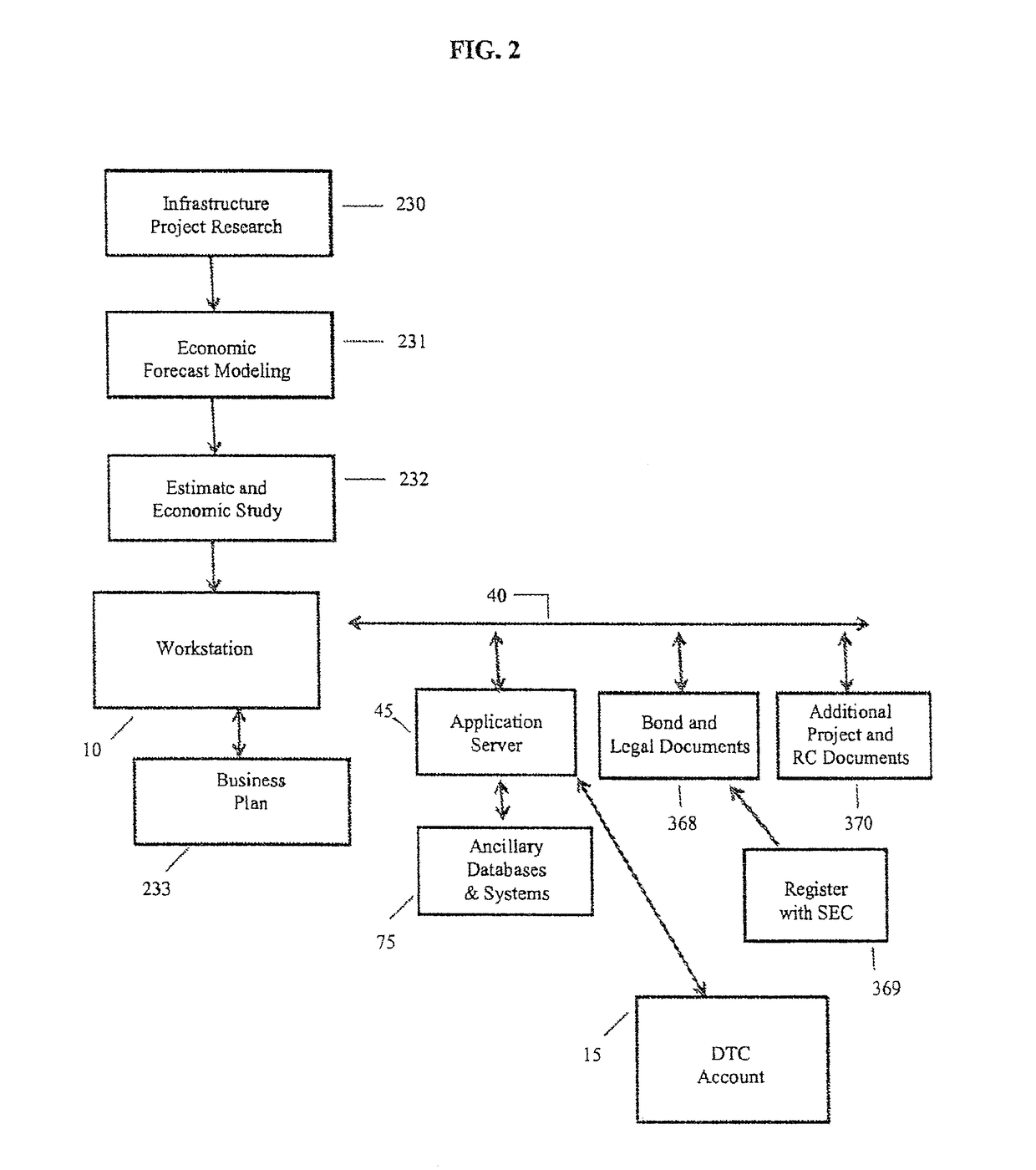

Computerized Method for Platinum Bond Financing By EB-5 Investor Visa Regional Center

In some embodiments, a comprehensive computer system and method (See FIGS. 2, 3) for automating and facilitating the performing and processing of tasks, information transfer, and information storage associated with the financing through platinum bonds of EB-5 Investor Visa Regional Centers (or performing other business processes) over a distributed computing network are disclosed.

Owner:GILLIARD WILLIAM M +7

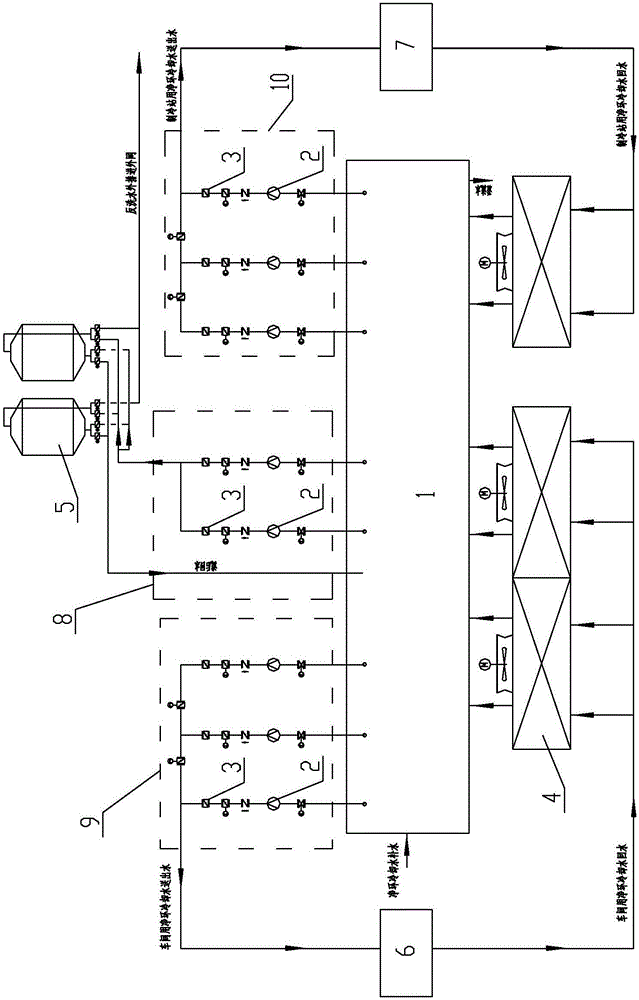

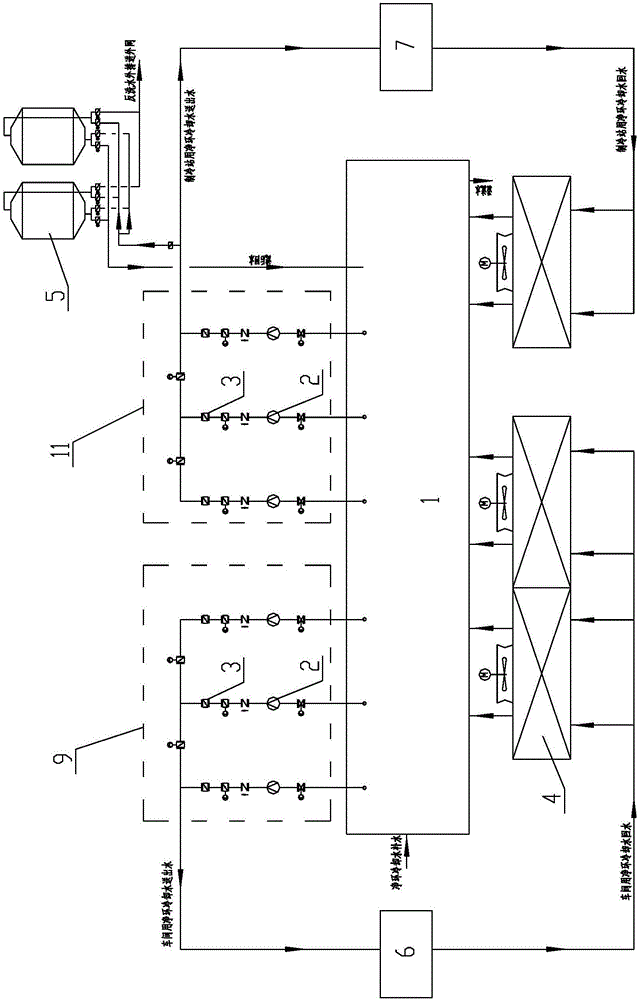

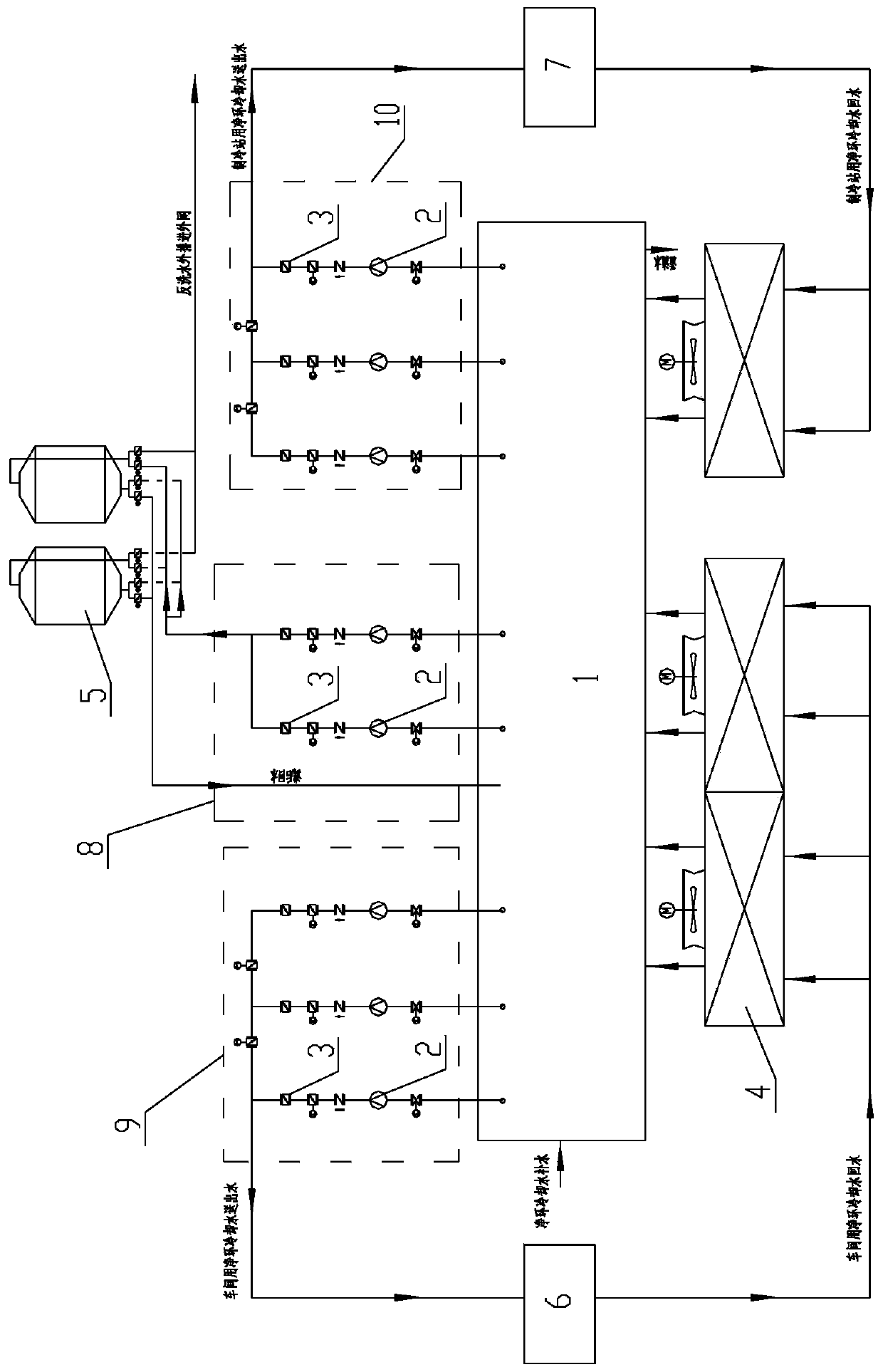

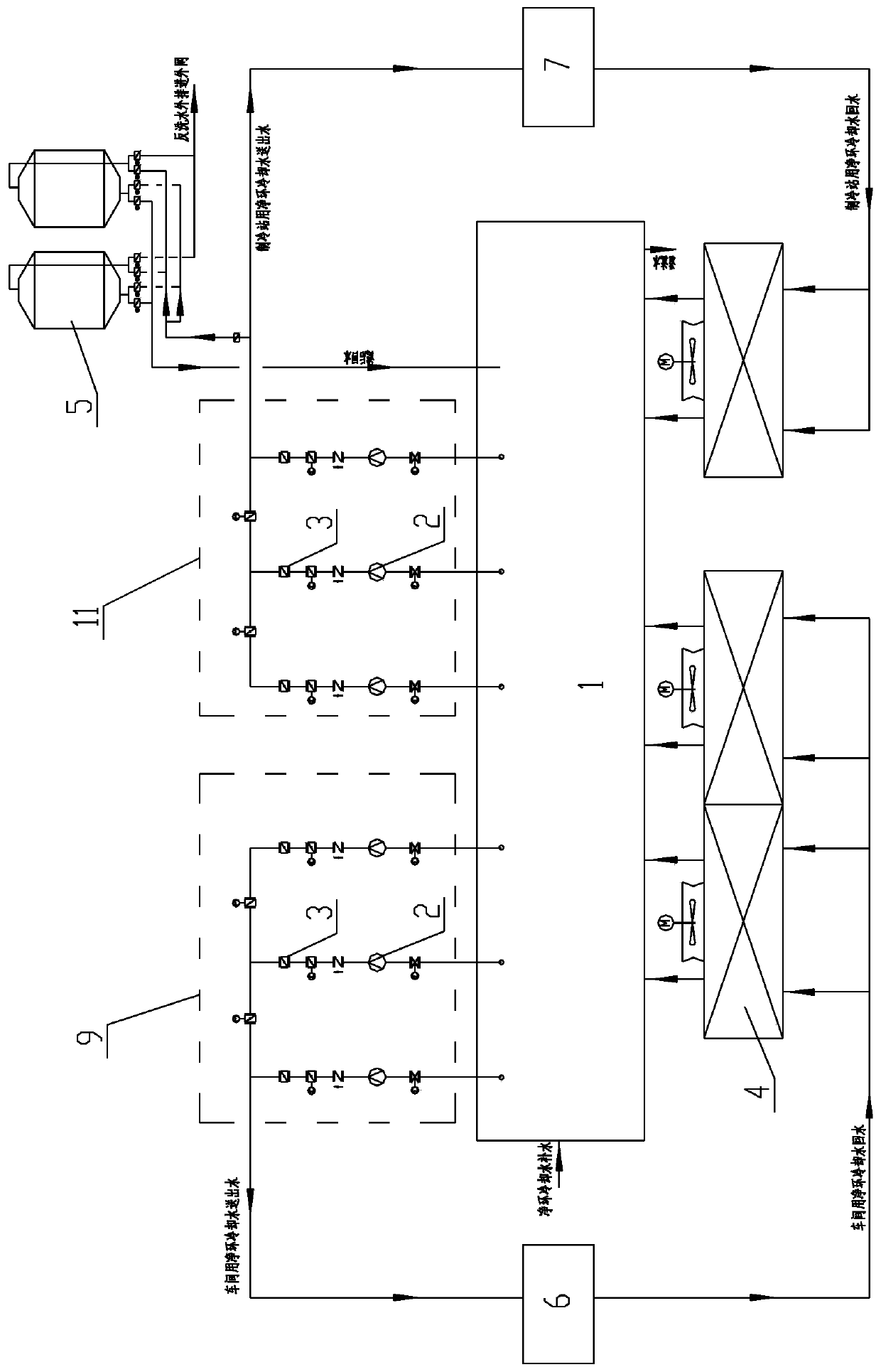

Method for integrating clean circulating side-filtration water supply pump set and clean circulating water supply pump set

ActiveCN107524192AThe process is simple and smoothLow investment costService pipe systemsWater mainsCooling towerWater filter

The invention relates to a method for integrating a clean circulating side-filtration water supply pump set and a clean circulating water supply pump set. A clean circulating cooling water system comprises a clean circulating cooling water suction well, a plurality of clean circulating water supply pump sets, a bypass filter and a clean circulating cooling tower. In order to remove impurities brought into the system in the circulation cooling process, the bypass filter is arranged; one pump set with the pressure grade the same as or close to that of the clean circulating side-filtration water supply pump set is selected from the clean circulating water supply pump sets, the two pump sets are integrated, and then the integrated pump set is used so that the clean circulating water supply function and the bypass filtration function can be achieved at the same time. A branch pipe is branched from a clean circulating cooling water supply pipe of the integrated pump set for the bypass filter, and water filtered by the bypass filter flows back to the clean circulating cooling water suction well through a filtered water return pipe. By means of the method, the clean circulating side-filtration water supply pump set and the clean circulating water supply pump set are integrated, the technological process is simple and smooth, operations are stable, investment is small, the occupied area is saved, the production and maintenance cost is greatly reduced, the maintenance period is shortened, and the production efficiency is improved.

Owner:鞍钢集团工程技术有限公司

Quantum turing machine

ActiveUS20070120727A1Easy to maintain coherenceEnough timeAnalogue/digital conversionQuantum computersQuantum Turing machineSufficient time

A quantum Turing machine constituted using a quantum bit created by localizing a phase difference soliton S between superconducting electrons existing in each of multiple of bands in a ring R0 that includes a ring main body R1 formed of a superconductor, and well-shaped portions W1, W2 formed with a reduced line-width at at least two positions on the ring main body R1, can easily constitute a quantum bit, can surely execute a basic logical operation, has multiple-bit capability and, moreover, can ensure sufficient time for executing a quantum algorithm.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Power switch suitable for automated production

InactiveUS8729415B2Easy to installLess materialContact mechanismsTumbler/rocker switchesPower switchingEngineering

The present invention relates to a power switch, which includes a housing, a key pivotally connected to the housing, a first conductive plate having one end in the housing, a thermally actuated metal plate having one end fixed to the first conductive plate and a free end extending within the housing, a C-shaped spring having two ends engaged with the thermally actuated metal plate, a second conductive plate having one end in the housing, an insulating seat accommodated in the housing, a light-emitting unit located in the key and having two electrodes connected to the insulating seat, and a third conductive plate having one end in the housing. Thus, the light-emitting unit can be easily installed in the housing along with the insulating seat, and the electrodes can directly connect with the second and third conductive plates respectively, so as to make the power switch suitable for automated production.

Owner:CHEN TSAN CHI

Technique for preparing gardenia yellow pigment

Owner:DAMIN FOODSTUFF ZHANGZHOU CO LTD

Tubular pecvd graphite boat loading and unloading system and its technology

ActiveCN104377154BReduce manufacturing costHigh movement accuracyFinal product manufactureSolid-state devicesLinear motionEngineering

The invention relates to a pipe-type PECVD graphite boat assembling and disassembling piece system. The system comprises a graphite boat delivery mechanism (1), a silicon slice feeding mechanism (2), a silicon slice discharging mechanism (3), a silicon slice grabbing and delivery mechanism (4) and a graphite boat assembling and disassembling mechanism (5), wherein the graphite boat delivery mechanism is used for carrying a graphite boat to move horizontally; the silicon slice feeding mechanism is used for taking silicon slices to be processed out of a flower basket; the silicon slice discharging mechanism is used for conducting overturning and discharging on the processed silicon slices; the silicon slice grabbing and delivery mechanism is used for absorbing the silicon slices and delivering the silicon slices in a linear motion mode; the graphite boat assembling and disassembling mechanism is used for assembling and disassembling the graphite boats. The pipe-type PECVD graphite boat assembling and disassembling piece system is precise to position and high in production efficiency.

Owner:江苏方艾机器人有限公司

Parachute ejection device

PendingCN111731486AAchieve releaseSimple structureParachutesStructural engineeringMechanical engineering

The invention provides a parachute ejection device which comprises a starting support assembly, a rotating support assembly, a box containing device and a parachute device, whereinthe starting supportassembly can be connected with flight equipment. The starting support assembly and the rotating support assembly are connected with the box containing device, the rotating support assembly is rotationally connected with the starting support assembly, and the parachute device is arranged in the box containing device. The box containing device comprises a locking mechanism; the parachute ejection device has a locking state and an opening state, and when the parachute ejection device is in the locking state, the locking mechanism can lock the box containing device to lock the parachute device inthe box containing device; when the parachute ejection device is in an opening state, the locking mechanism can open the box containing device, the starting support assemblyand the rotating support assembly can release the parachute deviceout of the box containing device. The parachute ejection device is simple in structure and convenient to operate, releasing of the parachute device can be rapidly achieved, and high-altitude safety accidents are reduced.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

A modular integrated process method for kitchen waste filtrate

InactiveCN106430806BLarge fluctuationsHigh degree of modularityWater treatment parameter controlWater treatment compoundsChain scissionFenton reagent

The invention discloses a modular integration process method for kitchen waste filtrate and belongs to the technical field of water treatment. Wastewater is monitored by a water quality monitoring module, a computer controls a PLC self-control system to control the wastewater to enter a primary or secondary physico-chemical module alternatively, and the wastewater is treated by anaerobic and aerobic biochemical modules and a deep treatment module. The modular integration process method is applicable to miniaturized, rapid and dispersed treatment of high-salt, high-COD, high-colority and great-fluctuation kitchen waste filtrate; the process method has high integration, intelligence and modularization degree and facilitates transformation from a technology to integrated equipment and space is saved; the process is manure and reliable and can be used for treating oil, nitrogen and phosphorus simultaneously to stably meet the standard, and effluent can be recycled; the adopted microelectrolysis method and a Fenton reagent strengthening process integrates oxidoreduction, flocculation, adsorption, catalytic oxidation, electrolytic deposition, codeposition and the like, chain scission of macromolecular organic pollutants can be realized, and refractory organic matter can be further removed.

Owner:吉林省零点环境科技有限公司

Computerized Method And System For Financing By EB-5 Investor Visa Regional Center

InactiveUS20190043133A1The process is simple and smoothWork lessFinanceProgram planningKnowledge management

A computer-implemented financed commercial economic system and method for EB-5 immigrant investor visa programs through a regional center directed to promotion of economic growth, improved economic regional productivity, job creation and increased capital investment, in which EB-5 investors by a capital investment for economic commercialization of projects and an electronic database accessible through a communications network to maintain regional center and EB-5 investor information, with an escrow account of funds from sales of products produced by the projects, and returning of capital investments to the EB-5 investors after a pre-determined period of time with the proceeds of the escrow account, with an agreement providing management compensation from asset rights of the EB-5 investors.

Owner:GILLIARD WILLIAM M +7

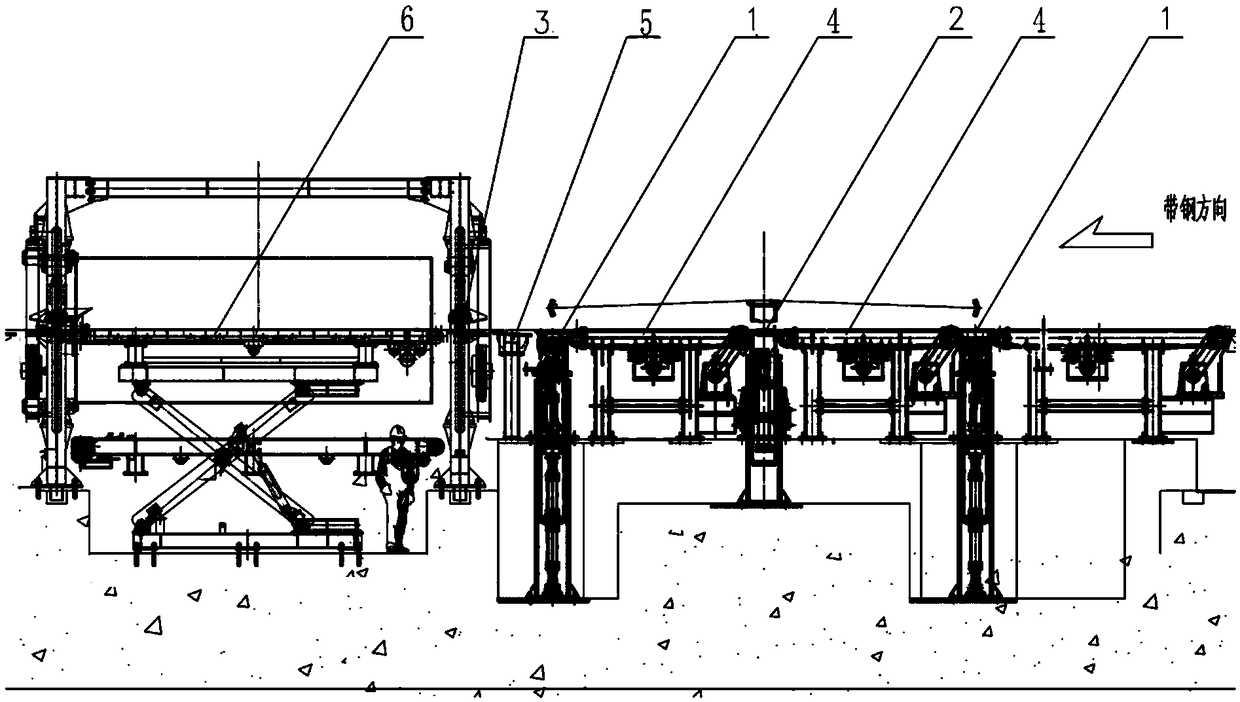

Inspection device and inspection method for composite multi-station steel plate

ActiveCN108994089AImprove pass rateThe process is simple and smoothMeasuring devicesMetal rolling arrangementsStrip steelMaterials science

The invention provides an inspection device and an inspection method for a composite multi-station steel plate. The inspection method comprises a strip steel double-sided inspection device, a strip steel single-sided inspection device and a threading guide plate, wherein the strip steel double-sided inspection device and the strip steel single-sided inspection device are sequentially arranged, thethreading guide plate is arranged between the strip steel double-sided inspection device and the strip steel single-sided inspection device, the distance between the strip steel double-sided inspection device and the strip steel single-sided inspection device is 6500 mm-7500 mm. and the upper surface of the threading guide plate is obliquely arranged. Compared with the prior art, the inspection device has the beneficial effects that the process is simple and smooth, the defect inspection rate is improved, the yield of the products is improved, and equipment and reasons which are generated bythe defect are clearly judged. The inspection device has good effects for improving the qualified rate of the rolled finished products, replacing the defects in time is achieved, and reducing production operation and equipment maintenance cost.

Owner:鞍钢集团工程技术有限公司

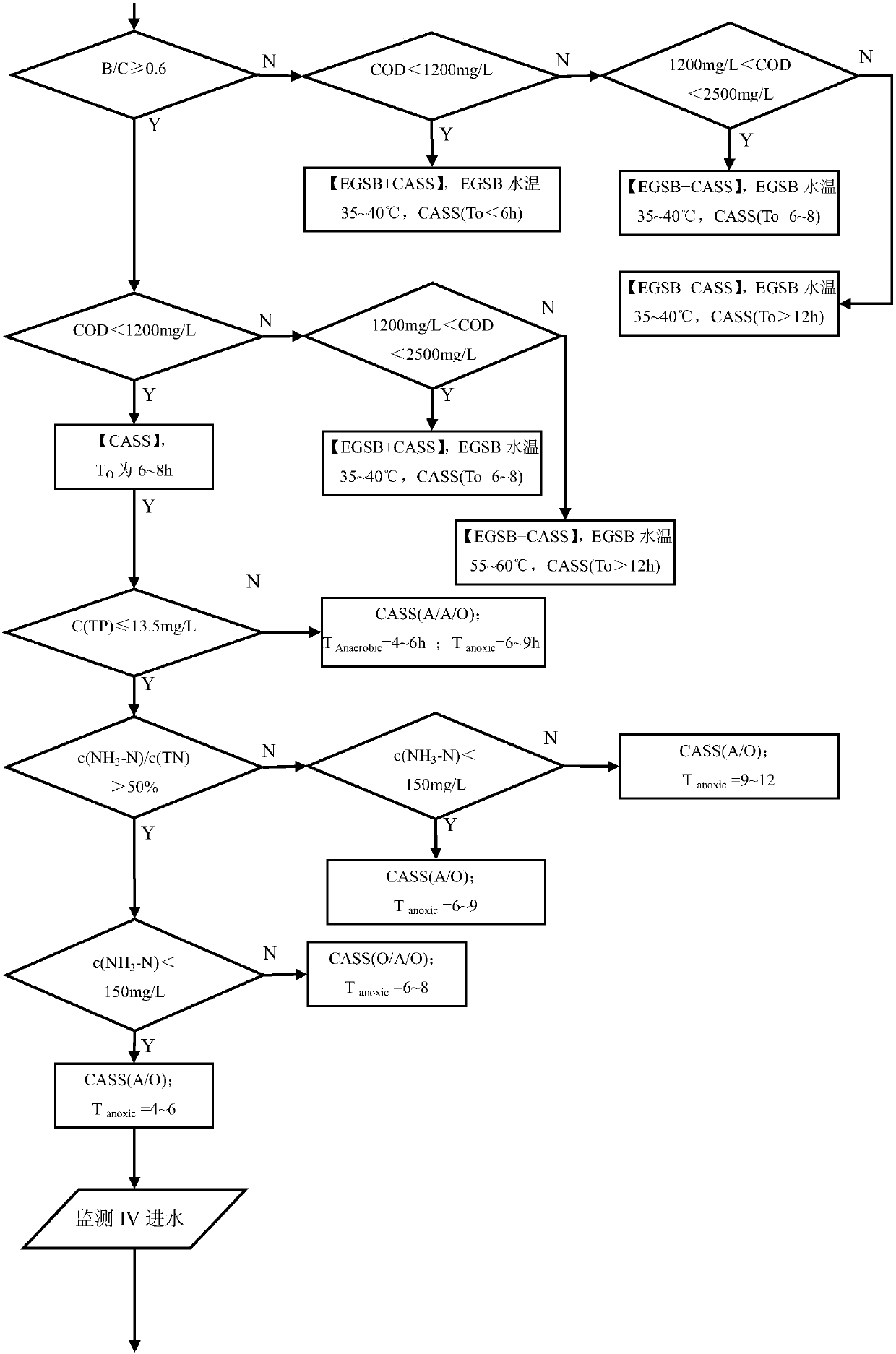

A Modular Integrated Process Method Suitable for Treating Slaughterhouse Wastewater

InactiveCN105601027BHigh degree of modularityPromote conversionWaste water treatment from animal processingMultistage water/sewage treatmentActivated carbonCyclone

The invention relates to a modular integration method suitable for treating slaughter workshop wastewater. A system adopted in the method is composed of a pretreatment module, a primary physicochemical module, a secondary biochemical module, a tertiary deep treatment module and a solid residue anaerobic fermentation module. The pretreatment module is a grating; the primary physicochemical module main has adjustment, coagulation, precipitation, air floatation and cyclone centrifuge functions, above functions are integrated in a same reactor, and an air floatation unit adopts an intermittence dissolved air floatation technology; the secondary biochemical module is mainly provided with an EGSB unit and a CASS unit, and the EGSB unit and the CASS unit are serially arranged; the tertiary deep treatment module is mainly provided with an O3 oxidation unit and an active carbon adsorption unit, and the O3 oxidation unit and the active carbon adsorption unit are serially arranged; and the solid residue anaerobic fermentation module is mainly used to collect grating and air floatation discharge residues and residual sludge of the biochemical module. The method adapts to the small, fast and scattered characteristics of slaughterhouses in China, can effectively solve the problem of treatment of distributed slaughter wastewater, and is intelligent, modular and integral.

Owner:SHENYANG JIANZHU UNIVERSITY

Gastrodia elata extract and preparation method thereof

PendingCN113754706AThe process is simple and smoothReduce manufacturing costNervous disorderSugar derivativesUltrafiltrationMedicinal herbs

The invention discloses a gastrodia elata extract and a preparation method thereof, and the preparation method comprises the following steps: (1) taking a gastrodia elata medicinal material, and coarsely crushing; (2) adding water, boiling, refluxing, extracting and filtering, continuously adding water into filter residues, boiling, refluxing, extracting and filtering, and combining filtrates; (3) clarifying the filtrate through a ceramic membrane; (4) transferring part of the feed liquid penetrating through the ceramic membrane into ultrafiltration membrane equipment, respectively collecting ultrafiltration membrane trapped fluid and permeated fluid, and performing spray drying on the trapped fluid to obtain a gastrodia elata polysaccharide extract; and (5) transferring the permeate into a nanofiltration membrane for concentration, collecting trapped fluid, and performing spray drying to obtain the gastrodin extract. The gastrodia elata extract prepared by the invention is clear and transparent, is high in gastrodin content, and has a remarkable effect in the aspects of tranquilizing and allaying excitement and the like; and the ultrafiltration interception part contains more gastrodia elata polysaccharide extracts, so that the comprehensive utilization of gastrodia elata can be improved.

Owner:广东青云山药业有限公司

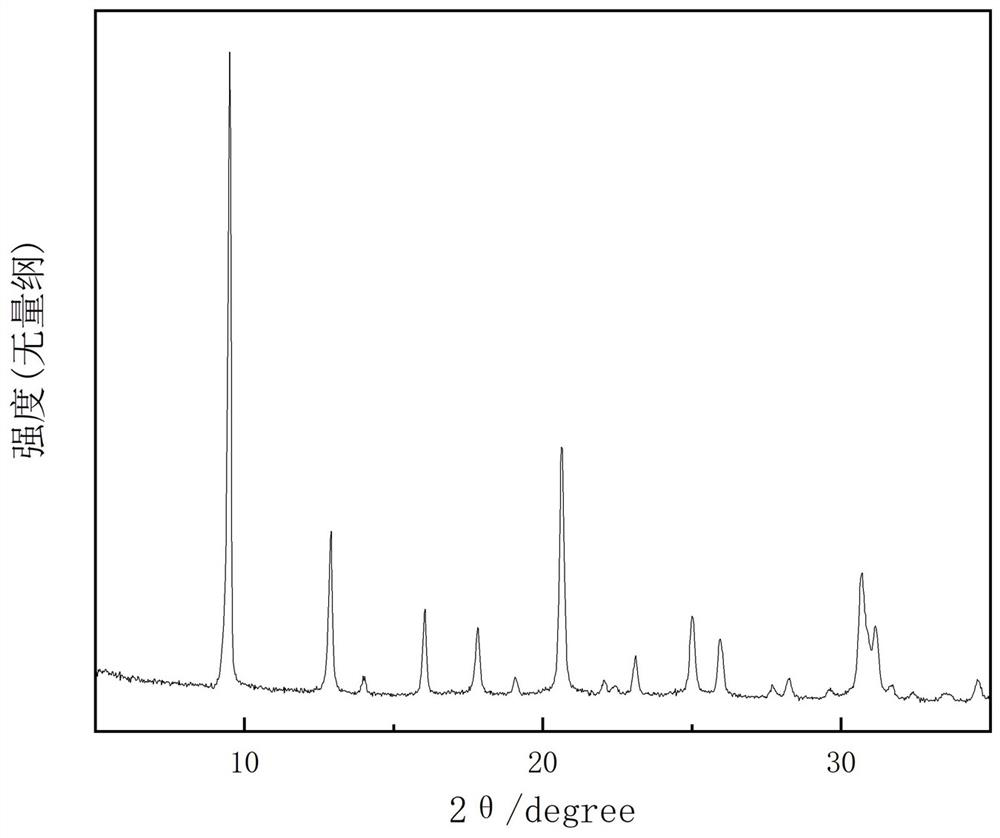

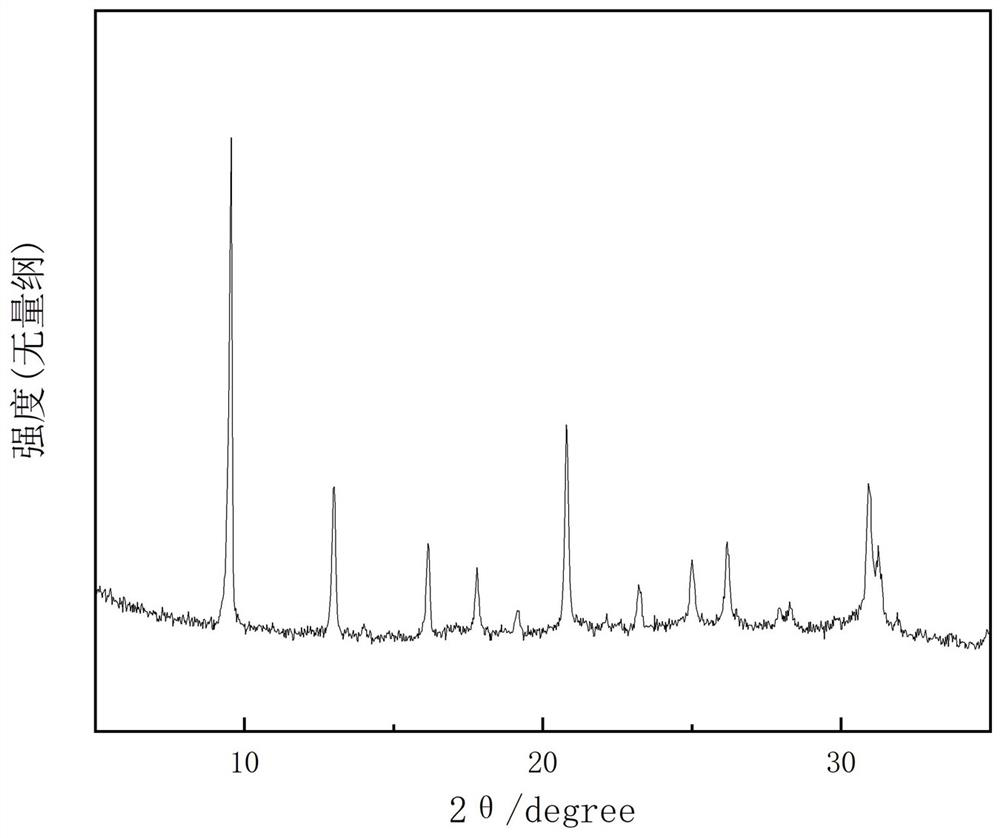

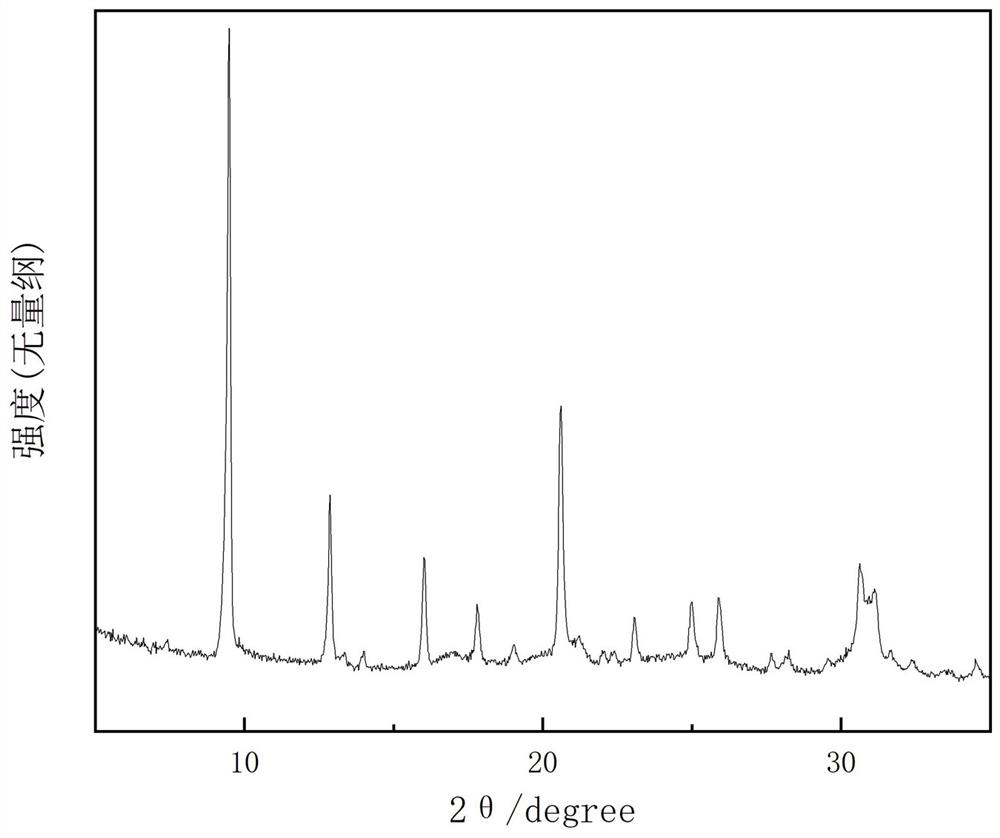

A method for synthesizing sapo-34 molecular sieves by utilizing industrial phosphate fertilizer by-product fluosilicic acid and its application

ActiveCN113428872BLarge grainHigh crystallinityIon-exchange process apparatusOther chemical processesMolecular sieveO-Phosphoric Acid

The invention provides a method for synthesizing SAPO‑34 molecular sieves by using fluosilicic acid, a by-product of industrial phosphate fertilizers, and its application, belonging to the technical field of comprehensive utilization of resources. The method includes the following steps: 1) adding phosphorus source and aluminum source to water, stirring and adding triethylamine to obtain solution I; 2) mixing industrial fluosilicic acid and triethylamine to obtain solution II, and adding solution II to the The precursor solution is obtained in the solution I, and the molar ratio of the substance in the precursor solution is Al2O3: SiO2: P2O5: H2O: TEA=1:0.3-0.6:1-1.1:70-90:3.2-9.5; 3) the precursor 4) Roasting the SAPO-34 molecular sieve precursor to obtain microporous SAPO-34 molecular sieve. An application based on the SAPO-34 molecular sieve described above, the SAPO-34 molecular sieve is loaded into a chromatography column, crude phosphoric acid is added, and vacuum filtration is performed to defluorinate the crude phosphoric acid. The SAPO-34 molecular sieve prepared by the present invention has large crystal grains, high crystallinity, good purity, and less impurity phases, can defluorinate more than 65% of fluorine-containing 6g / L crude phosphoric acid, and the fluorine adsorption capacity of the molecular sieve can reach 350mg / g .

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Manufacturing method of flexible substrate, flexible substrate and flexible display panel

ActiveCN107393859BSimple preparation techniqueSimple processSolid-state devicesSemiconductor/solid-state device manufacturingIn planeSilicon oxide

The disclosure belongs to the field of display panels, and in particular relates to a manufacturing method of a flexible substrate, a flexible substrate and a flexible display panel. The manufacturing method includes: providing a glass substrate, forming a first flexible material layer on the surface of the glass substrate; depositing and preparing a barrier inorganic layer on the surface of the first flexible material layer; wherein the barrier inorganic layer includes a silicon oxide material layer and at least one of the silicon nitride material layers; when the deposition of the barrier inorganic layer is completed, the surface of the barrier inorganic layer is subjected to plasma bombardment treatment to improve the wettability of the surface of the barrier inorganic layer; A second flexible material layer is formed on the surface of the inorganic layer, and the glass substrate is peeled off. The present disclosure can ensure good adhesion and film formation of the second flexible material layer on the barrier inorganic layer, without additionally depositing an interface inorganic layer to improve problems such as poor interface adhesion, and the process is simple and cost-effective.

Owner:BOE TECH GRP CO LTD

A method for integrating the net ring side filter water supply pump group and the net ring water supply pump group

ActiveCN107524192BThe process is simple and smoothLow investment costService pipe systemsWater mainsCooling towerWater filter

The invention relates to a method for integrating a clean circulating side-filtration water supply pump set and a clean circulating water supply pump set. A clean circulating cooling water system comprises a clean circulating cooling water suction well, a plurality of clean circulating water supply pump sets, a bypass filter and a clean circulating cooling tower. In order to remove impurities brought into the system in the circulation cooling process, the bypass filter is arranged; one pump set with the pressure grade the same as or close to that of the clean circulating side-filtration water supply pump set is selected from the clean circulating water supply pump sets, the two pump sets are integrated, and then the integrated pump set is used so that the clean circulating water supply function and the bypass filtration function can be achieved at the same time. A branch pipe is branched from a clean circulating cooling water supply pipe of the integrated pump set for the bypass filter, and water filtered by the bypass filter flows back to the clean circulating cooling water suction well through a filtered water return pipe. By means of the method, the clean circulating side-filtration water supply pump set and the clean circulating water supply pump set are integrated, the technological process is simple and smooth, operations are stable, investment is small, the occupied area is saved, the production and maintenance cost is greatly reduced, the maintenance period is shortened, and the production efficiency is improved.

Owner:鞍钢集团工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/112b2583-6a73-484f-a31c-39a0c3939d47/a200710056212c00021.PNG)

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/112b2583-6a73-484f-a31c-39a0c3939d47/a200710056212c00031.PNG)

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/112b2583-6a73-484f-a31c-39a0c3939d47/a200710056212d00061.PNG)

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/760f75f2-2d75-4f94-a716-ef866d0cbcfd/S2007100562121C00011.PNG)

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/760f75f2-2d75-4f94-a716-ef866d0cbcfd/S2007100562121C00021.PNG)

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/760f75f2-2d75-4f94-a716-ef866d0cbcfd/S2007100562121D00031.PNG)